Graphene-exfoliation hydrotalcite-like compound composite material immobilized protein modified electrode, production method and application thereof

A composite material and protein modification technology, which is applied in the field of graphene-exfoliated hydrotalcite-like sheet composite immobilized protein modified electrodes, achieves the effects of simple operation, inhibition of re-stacking, and improvement of electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (a) Preparation of ELDH

[0036] divalent metal salt CoCl 2 ·6H 2 O, trivalent metal salt AlCl 3 ·6H 2 Add O and urea into a round bottom flask with a certain volume of deionized water at a molar ratio of 2:1:7, the total metal ion concentration is 0.15mol / L, stir and reflux at 85°C for 18 hours, and suction filter after the reaction is completed , the filter cake was washed with distilled water for 3 to 5 times, and dried at room temperature for 48 hours to obtain carbonate-intercalated LDH; weigh 100 mg of carbonate-intercalated LDH, and disperse it in NaCl and 3.3 mmol / L concentrations of 1 mol / L and 3.3 mmol / L respectively. mixed aqueous solution of HCl, N 2 Stir under the atmosphere for 12 hours, and dry at room temperature for 12 hours after suction filtration to obtain LDH intercalated with chloride ions; weigh 60 mg of LDH intercalated with chloride ions, and disperse it in 60 mL of NaNO with a concentration of 0.1 mol / L 3 in aqueous solution, N 2 Stir und...

Embodiment 2

[0044] (a) Preparation of ELDH

[0045] divalent metal salt CoCl 2 ·6H 2 O, trivalent metal salt AlCl 3 ·6H 2 O and urea were added into a round-bottomed flask with a certain volume of deionized water in a molar ratio of 2:1:7, the total metal ion concentration was 0.15mol / L, stirred and refluxed at 90°C for 24 hours, and pumped out after the reaction was completed. filter, the filter cake was washed with distilled water for 3 to 5 times, and dried at room temperature for 48 hours to obtain carbonate-intercalated LDH; weigh 100 mg of carbonate-intercalated LDH, and disperse it in NaCl and 3.3 mmol / L concentrations of 1 mol / L and 3.3 mmol / L respectively. L mixed aqueous solution of HCl, N 2 Stir under the atmosphere for 12 hours, and dry at room temperature for 12 hours after suction filtration to obtain LDH intercalated with chloride ions; weigh 60 mg of LDH intercalated with chloride ions, and disperse it in 60 mL of NaNO with a concentration of 0.1 mol / L 3 in aqueous so...

Embodiment 3

[0053] (a) Preparation of ELDH

[0054] divalent metal salt CoCl 2 ·6H 2 O, trivalent metal salt AlCl 3 ·6H 2 O and urea were added into a round-bottomed flask with a certain volume of deionized water at a molar ratio of 2:1:7, the total metal ion concentration was 0.15mol / L, stirred and refluxed at 95°C for 32 hours, and pumped out after the reaction was completed. filter, the filter cake was washed with distilled water for 3 to 5 times, and dried at room temperature for 48 hours to obtain carbonate-intercalated LDH; weigh 100 mg of carbonate-intercalated LDH, and disperse it in NaCl and 3.3 mmol / L concentrations of 1 mol / L and 3.3 mmol / L respectively. L mixed aqueous solution of HCl, N 2 Stir under the atmosphere for 12 hours, and dry at room temperature for 12 hours after suction filtration to obtain LDH intercalated with chloride ions; weigh 60 mg of LDH intercalated with chloride ions, and disperse it in 60 mL of NaNO with a concentration of 0.1 mol / L 3 in aqueous so...

PUM

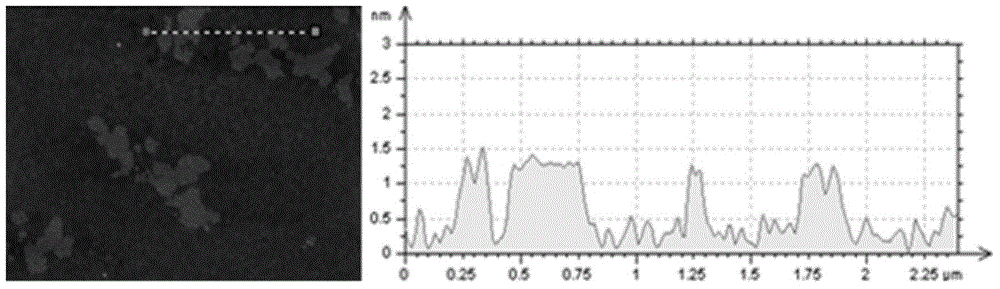

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com