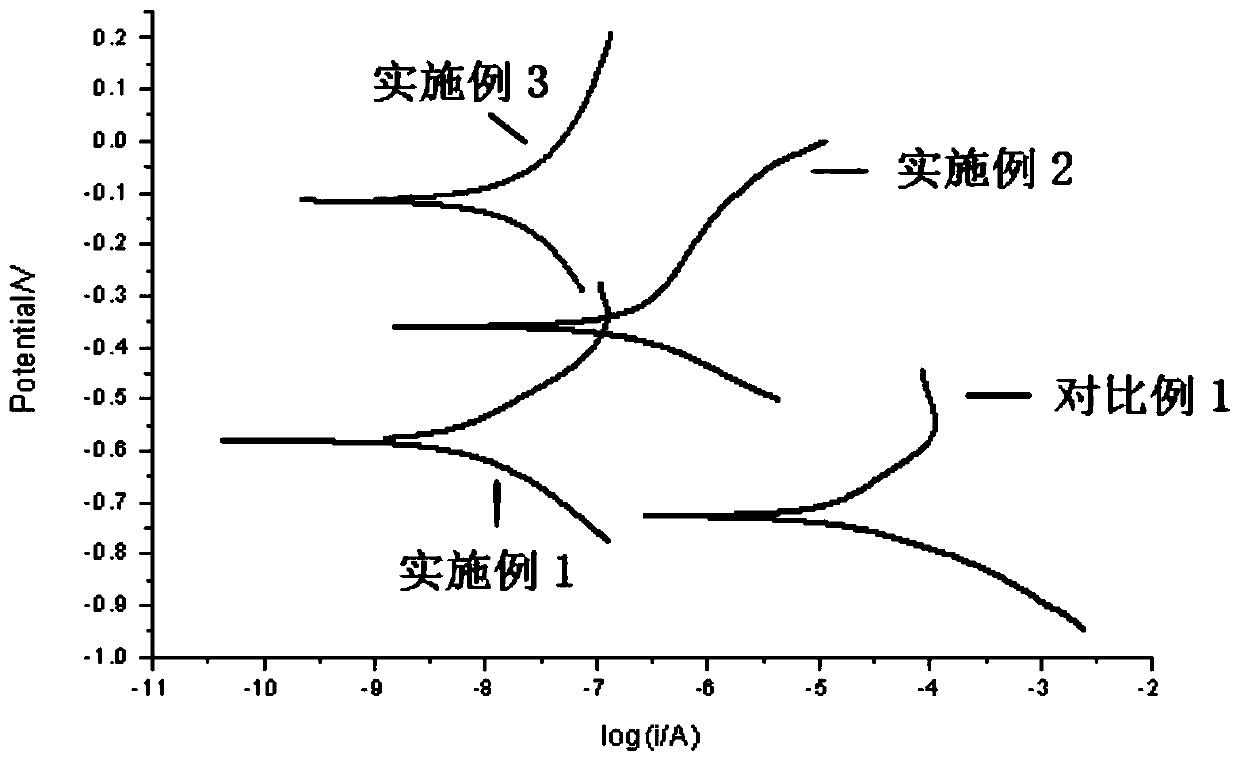

Graphene conductive anticorrosive coating for grounding grid and preparation method thereof

A conductive anti-corrosion and graphene technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of poor dispersion of nano-fillers, easy to agglomerate, etc., to achieve improved electrical conductivity and corrosion resistance, good electrical conductivity, The effect of improving corrosion resistance and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preferably, the preparation method of the acidified multi-walled carbon nanotubes comprises: adding the multi-walled carbon nanotubes into a mixture of concentrated sulfuric acid and concentrated nitric acid, and heating to reflux to obtain the acidified multi-walled carbon nanotubes. More preferably, the volume ratio of concentrated sulfuric acid to concentrated nitric acid in the mixture of concentrated sulfuric acid and concentrated nitric acid is (2-4):1, more preferably (2.5-3.5):1. Wherein, the heating to reflux is reflux reaction at 90-98° C. for 7-9 hours. Under the above conditions, the carbon nanotubes are sheared by the strong oxidative properties of the mixed acid, and the length of the tubes becomes shorter, and then groups such as hydroxyl groups and carboxyl groups appear in these destroyed places. This increases its own activity and removes impurities. At the same time, it also makes the surface of carbon nanotubes have hydroxyl, carboxyl and other group...

Embodiment 1

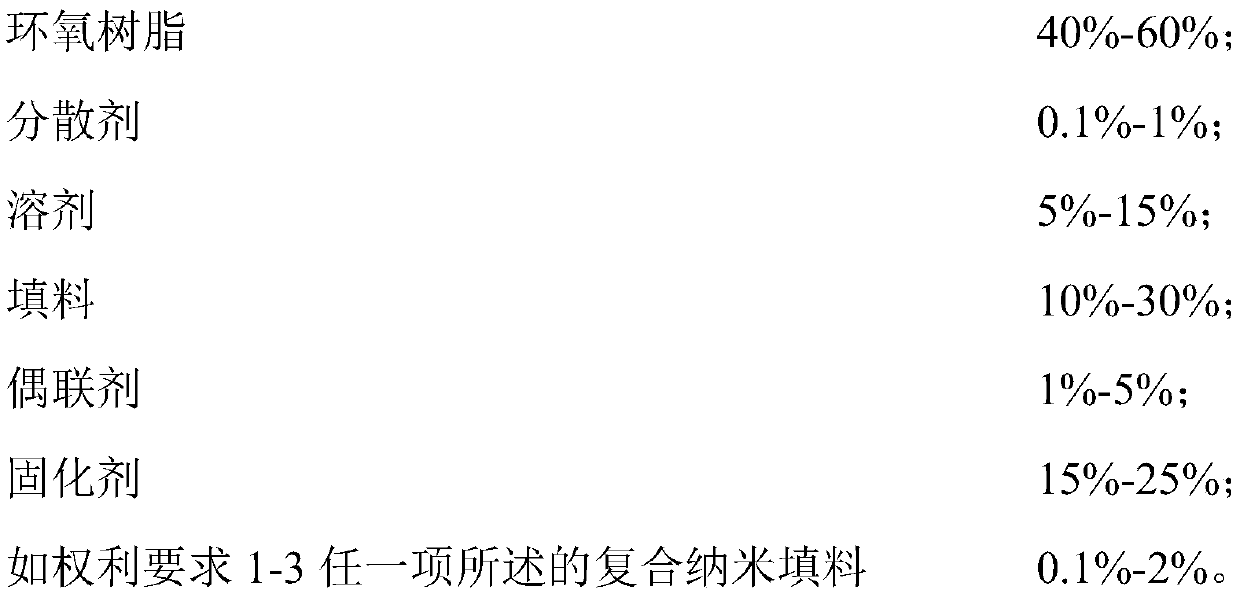

[0057] The ground grid described in the present embodiment uses the graphene conductive anticorrosion paint, comprises the following components with mass percentage:

[0058]

[0059] In the present embodiment, the preparation method of composite nanofiller graphene-p-phenylenediamine-carbon nanotube composite includes the following parts:

[0060] (1) First add 1.25g of sodium nitrate to the round bottom flask, then add 120mL of concentrated sulfuric acid to it, and stir in an ice bath; add 3g of graphite powder at a temperature lower than 5°C, and stir for 2.5 hours; slowly add 15g of high Potassium manganate, the temperature is controlled below 20°C; continue to stir for 2 hours. Adjust the temperature of the water bath to 95°C, slowly add deionized water, and continue stirring; finally add hydrogen peroxide, suction filter while it is hot, centrifugally wash, and vacuum dry to obtain graphene oxide.

[0061] (2) 5 g of multi-walled carbon nanotubes were added to a mixt...

Embodiment 2

[0068] The ground grid described in the present embodiment uses the graphene conductive anticorrosion paint, comprises the following components with mass percentage:

[0069]

[0070] Wherein, the composite nanofiller is the graphene-p-phenylenediamine-carbon nanotube composite described in Example 1.

[0071] According to the proportioning of each component of the graphene conductive anticorrosion coating for the above-mentioned grounding grid, the preparation method is as follows:

[0072] Take deionized water, dispersant, and solvent, add them to the reactor in turn, and mix them evenly with mechanical stirring, then add epoxy resin, filler, coupling agent, curing agent, and stir to make them evenly dispersed.

[0073] The stirring speed in each step in the above preparation process is 800 rpm, and the stirring is carried out at 20°C-35°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com