Tobacco paving, flattening and monolayer-conveying method and device

A tobacco leaf, single-layer technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as inability to spread and single-layer tobacco leaves cannot be accurately removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: as Figure 4 , Figure 5 Shown, a kind of tobacco leaf spreading that the present invention relates to, flattening, the method for single-layering, operation process is as follows:

[0038] Tobacco leaves enter the material dispersion chamber 2 at a speed of 2m / s from the belt surface of the feeding belt conveyor 1, which can be 1-3m / s, and enter the material dispersion chamber 2 in a direction at an angle of 20° with the material dispersion chamber 2 horizontal direction;

[0039] Tobacco leaf passes through the speed of speed 5m / s in material dispersion cavity 2, and this speed can be in

[0040] The updraft between 3m / s-6m / s removes the heavy impurities 14 through the outlet of the impurities below, and at the same time loosely conveys the remaining tobacco leaves into the material-gas separation air duct 4 .

[0041] Due to the narrowing of the cross-section of the tobacco leaves in the material-gas separation duct 4, the material-gas mixture is accel...

Embodiment 2

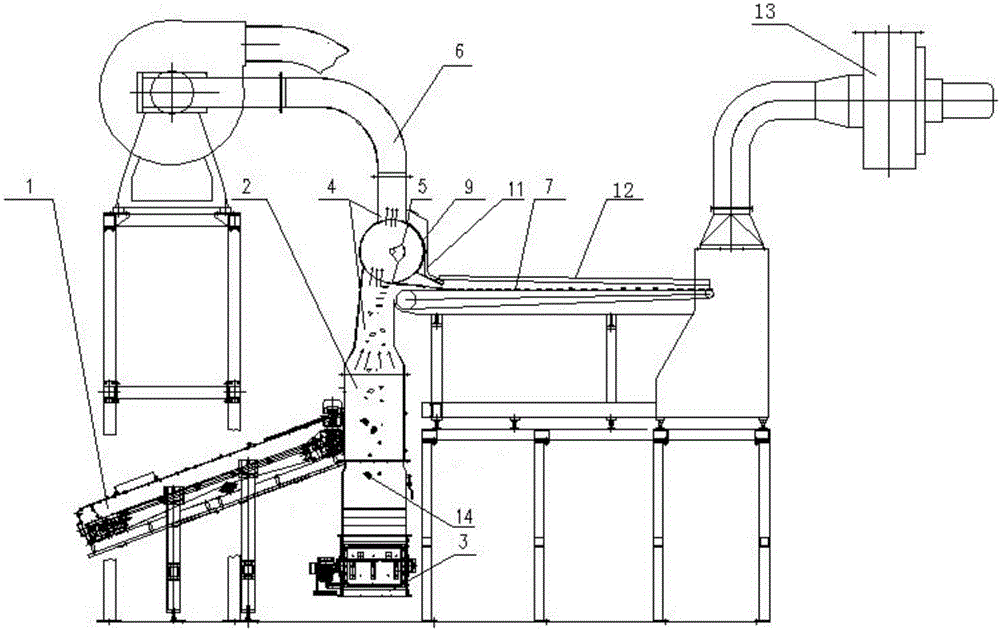

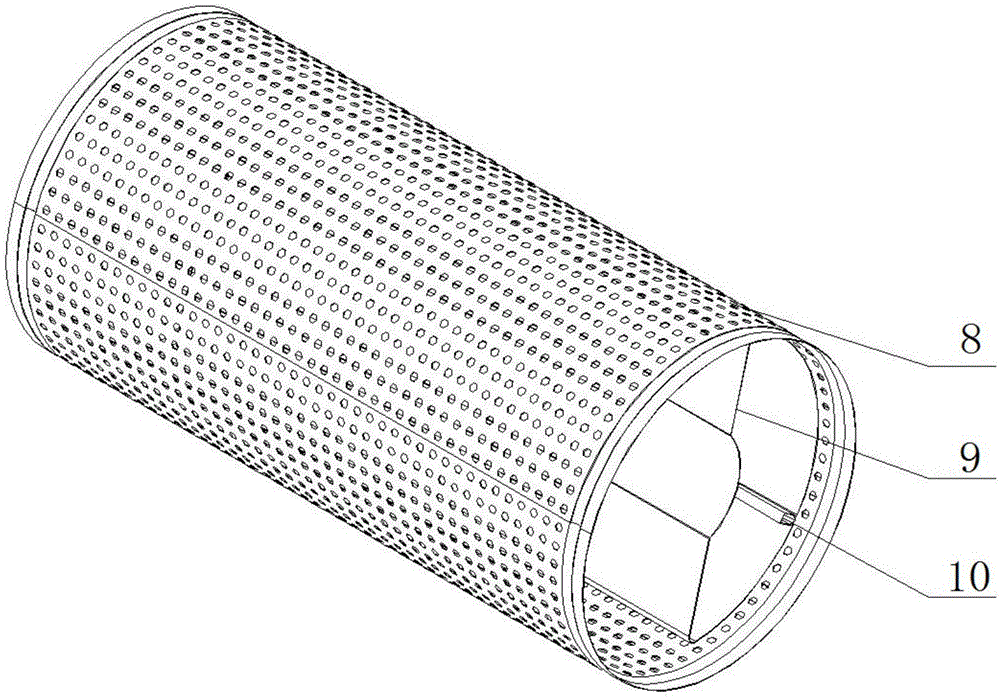

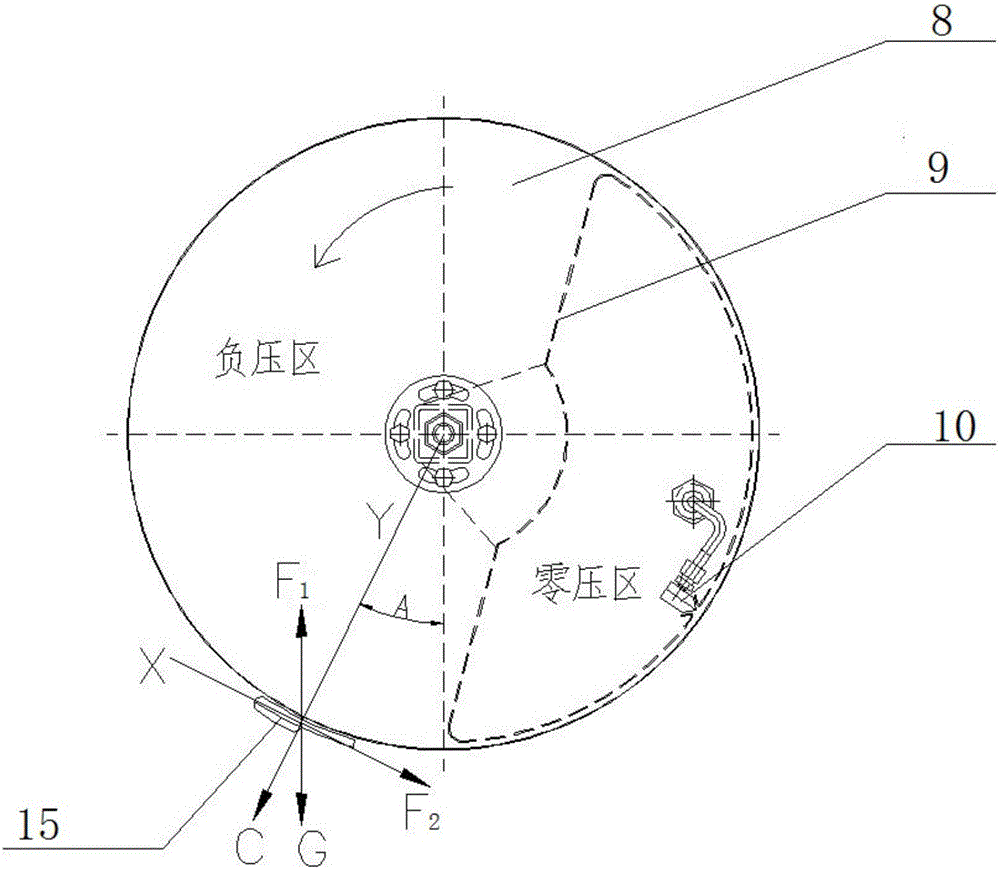

[0043] Embodiment 2: as Figure 1 to Figure 5 As shown, a device for paving, flattening and single-layering of tobacco leaves includes a frame, a feeding belt conveyor 1, a discharging belt conveyor 7, and an air flow system, and is characterized in that the end of the feeding belt conveyor 1 is connected to Material dispersion chamber 2, the bottom of the material dispersion chamber 2 is equipped with an air distributor 3 connected to the air flow system, the upper part of the material dispersion chamber 2 is connected to the material-air separation air duct 4, and the middle part of the material-air separation air duct 4 is equipped with a negative pressure monolayer The sieve cylinder 5 and the upper part of the material-gas separation air duct 4 are connected to the negative pressure suction duct 6, and the side of the negative-pressure single-layer sieve cylinder 5 is provided with a discharge port on the side wall of the material-gas separation air duct 4, and the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com