Preparation method for modified graphite anode material

A graphite negative electrode and modification technology, which is applied in the direction of battery electrodes, electrochemical generators, electrical components, etc., can solve the problems that the first irreversible capacity cannot be eliminated, the charge-discharge efficiency reduces the capacity, and the charge-discharge cycle cannot be achieved. Good cycle stability performance, improved cycle stability, and improved co-embedded performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

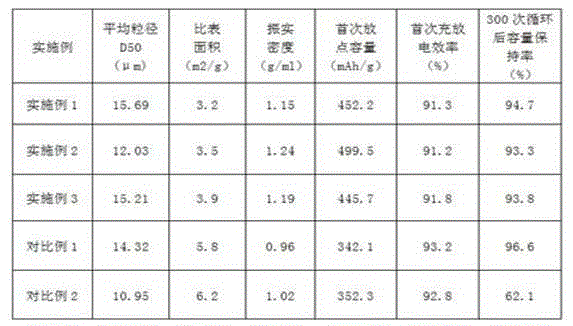

Embodiment 1

[0024] According to the ratio of graphite:resin:nickel powder:silicon powder=100:10:3:3, weigh 1000g artificial graphite, 100g phenolic resin, 30g nickel powder, 30g silicon powder, according to the ratio of solid content of 30%, weigh In 2706g of ethanol solvent, use zirconia grinding balls, and ball mill for 12 hours to obtain a uniform slurry; then dry the slurry at -0.1Mpa and 30°C for 10 hours to obtain a powder; then put the powder in an inert gas Under protection, the temperature was raised to 1000°C at a rate of 10°C / min, then kept at a temperature of 3 hours, the temperature was naturally lowered, and the graphite negative electrode material of the present invention was obtained by sieving after cooling.

Embodiment 2

[0026] According to the ratio of graphite:resin:nickel powder:silicon powder=100:5:5:1, weigh 1000g of natural graphite, 50g of epoxy resin, 50g of nickel powder, and 10g of silicon powder. Take 1665g of ethanol solvent, use zirconia grinding balls, and ball mill for 12 hours to obtain a uniform slurry; then dry the slurry at -0.1Mpa and 40°C for 80 hours to obtain a powder; then put the powder in an inert gas Under the protection of 20°C / min, the temperature was raised to 800°C, and then kept for 10 hours, the temperature was naturally lowered, and the graphite negative electrode material of the present invention was obtained by sieving after cooling.

Embodiment 3

[0028] According to the ratio of graphite:resin:nickel powder:silicon powder=100:8:4:3, weigh 1000g artificial graphite, 80g phenolic resin, 40g nickel powder, 30g silicon powder, according to the proportion of solid content of 30%, weigh In 2683g of ethanol solvent, ceramic grinding balls were used to mill for 12 hours to obtain a uniform slurry; then the slurry was dried at -0.1Mpa and 35°C for 9 hours to obtain a powder; then the powder was placed under the protection of an inert gas The temperature was raised to 850°C at a rate of 10°C / min, and then kept at a temperature of 14 hours, the temperature was naturally lowered, and the graphite negative electrode material of the present invention was obtained by sieving after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com