Method for preparing porous silicon/graphene composite lithium ion battery anode material using diatomite as raw material

A graphene composite, lithium-ion battery technology, applied in the field of materials, can solve problems such as high cost and pollute the environment, and achieve the effects of low price, good electronic conduction, and buffer volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

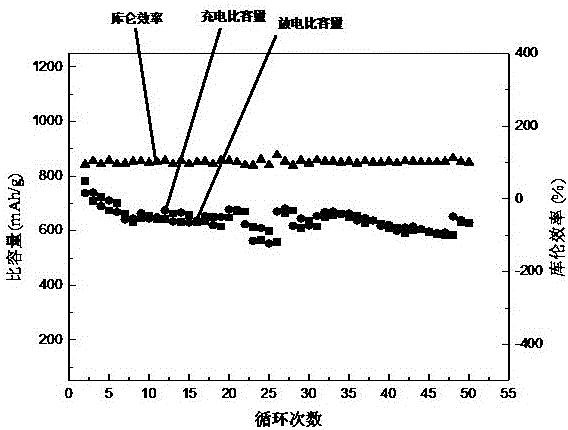

Embodiment 1

[0027] Take 2.0g of natural diatomite, heat it to 900°C at a heating rate of 5°C / min under air (atmospheric pressure), keep it warm for 4h, remove organic matter, and then wash it with 0.01mol / L sodium hydroxide alkali for 2.5h , washed to neutral, then pickled with 6.0mol / L sulfuric acid solution at 95°C for 6h, finally washed with deionized water and dried at 80°C to obtain purified diatomite; the purified diatomite and magnesium powder Mix according to the mass ratio of 1:2, under the protection of argon, keep warm at 700°C for 3h, cool naturally to room temperature, pickle the solid powder in 0.1mol / L hydrochloric acid solution for 12h, then wash and dry to obtain porous silicon; Take 0.35g of porous silicon as the substrate, under the action of nickel foam, heat to 950°C in a tube furnace with a helium flow rate of 200 sccm, and then naturally cool down and anneal for 5 minutes under a hydrogen flow rate of 20 sccm, and then control the ethanol by argon flow rate. Quantit...

Embodiment 2

[0029] Take 2.5g of natural diatomite, heat it to 800°C at a heating rate of 8°C / min under air (atmospheric pressure), keep it warm for 4h, remove organic matter, then wash it with 0.02M sodium hydroxide alkali for 5h, and wash until Neutral, then pickled with 6.0mol / L sulfuric acid solution at 95°C for 6h, finally washed with deionized water and dried at 80°C to obtain purified diatomite; the purified diatomite and magnesium powder Mix at a ratio of 1:1, under the protection of helium, keep warm at 850°C for 3h, cool naturally to room temperature, pickle the solid powder in 0.5mol / L hydrochloric acid solution for 18h, then wash with deionized water and dry at 80°C to obtain Porous silicon: take 0.35g of porous silicon as the substrate, under the action of nickel foam, heat to 1000°C in a tube furnace with an argon flow rate of 300 sccm, anneal for 10 minutes at a hydrogen flow rate of 30 sccm, and then pass through the acetylene carbon source , flow rate is 12sccm, pyrolytic ...

Embodiment 3

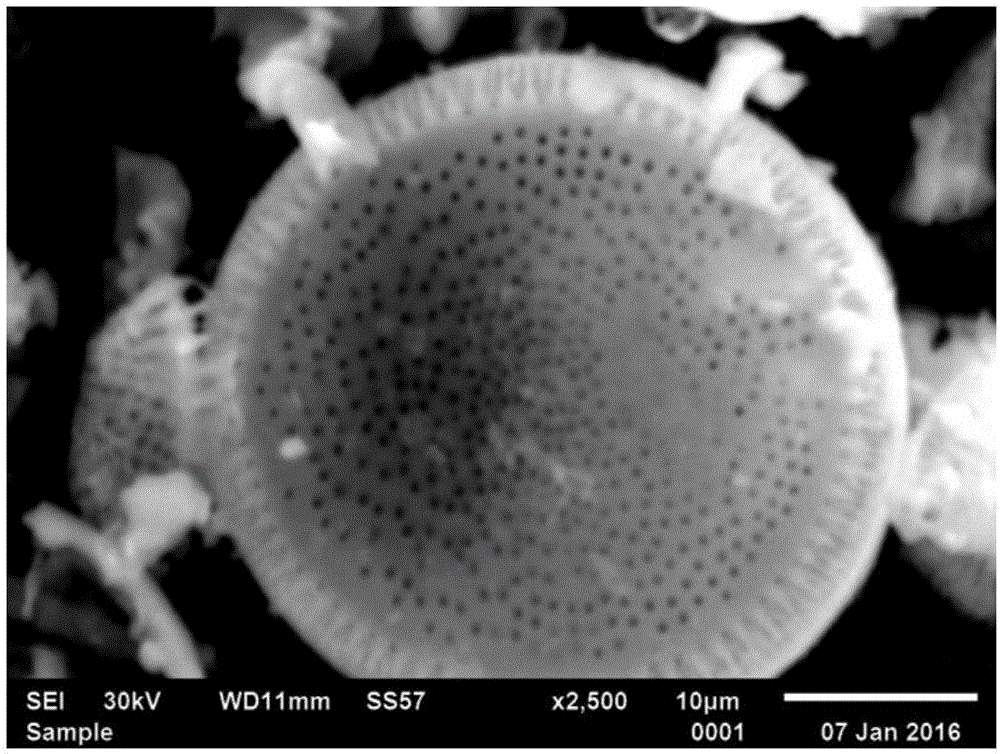

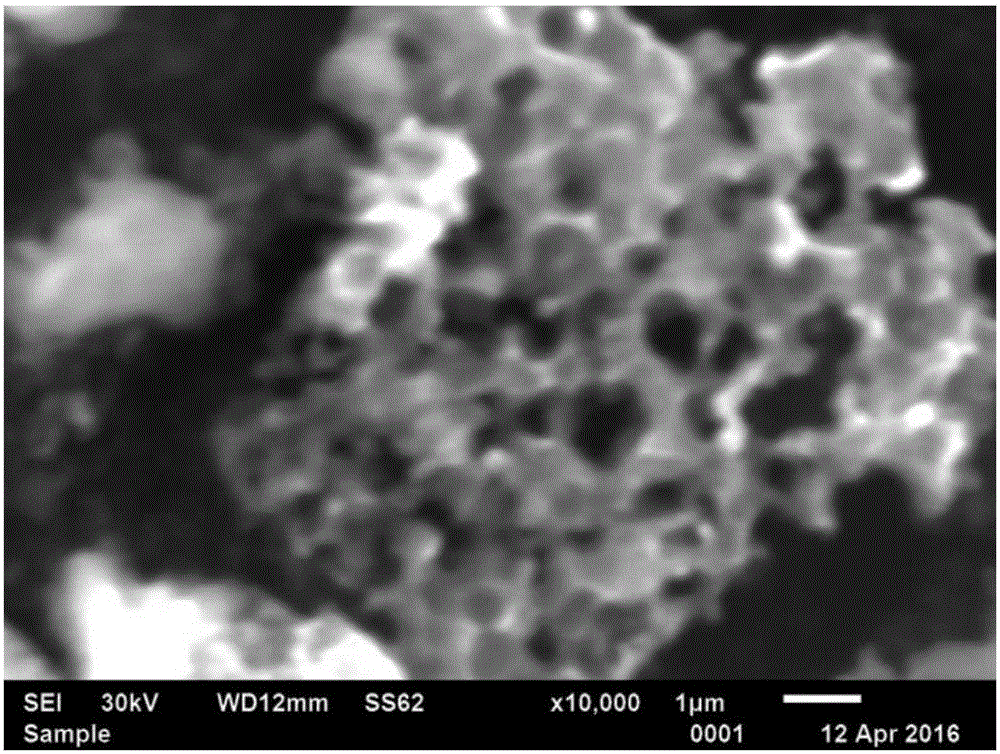

[0031] Take 5.0g of natural diatomite, heat it up to 650°C at a heating rate of 10°C / min under air (atmospheric pressure), keep it warm for 2h, remove organic matter, then wash with 0.05M sodium hydroxide alkali for 3h, and wash until Neutral, then pickled with 6.0M sulfuric acid solution at 95°C for 5h, finally washed with deionized water, and dried at 80°C to obtain purified diatomite; the purified diatomite and magnesium powder are in a mass ratio of 1: 1 mixed, under the protection of argon, keep warm at 850°C for 3h, naturally cool to room temperature, pickle the solid powder in 2.0mol / L hydrochloric acid solution for 15h, then wash with deionized water and dry at 80°C to obtain porous silicon See figure 2Get 0.35g of porous silicon as the substrate, under the action of copper powder and nickel, heat to 1000° C. under the argon flow rate of 200 sccm in the tube furnace, anneal treatment for 10 min under the hydrogen flow rate of 20 sccm, and then feed the acetylene carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com