Preparation of Self-Supported Three-Dimensional Graphene/Tin Composite Anode Material for Lithium Ion Battery

A technology for ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as voltage hysteresis, particle agglomeration, and electrode pulverization, and achieve the effects of inhibiting shedding, good rate performance, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

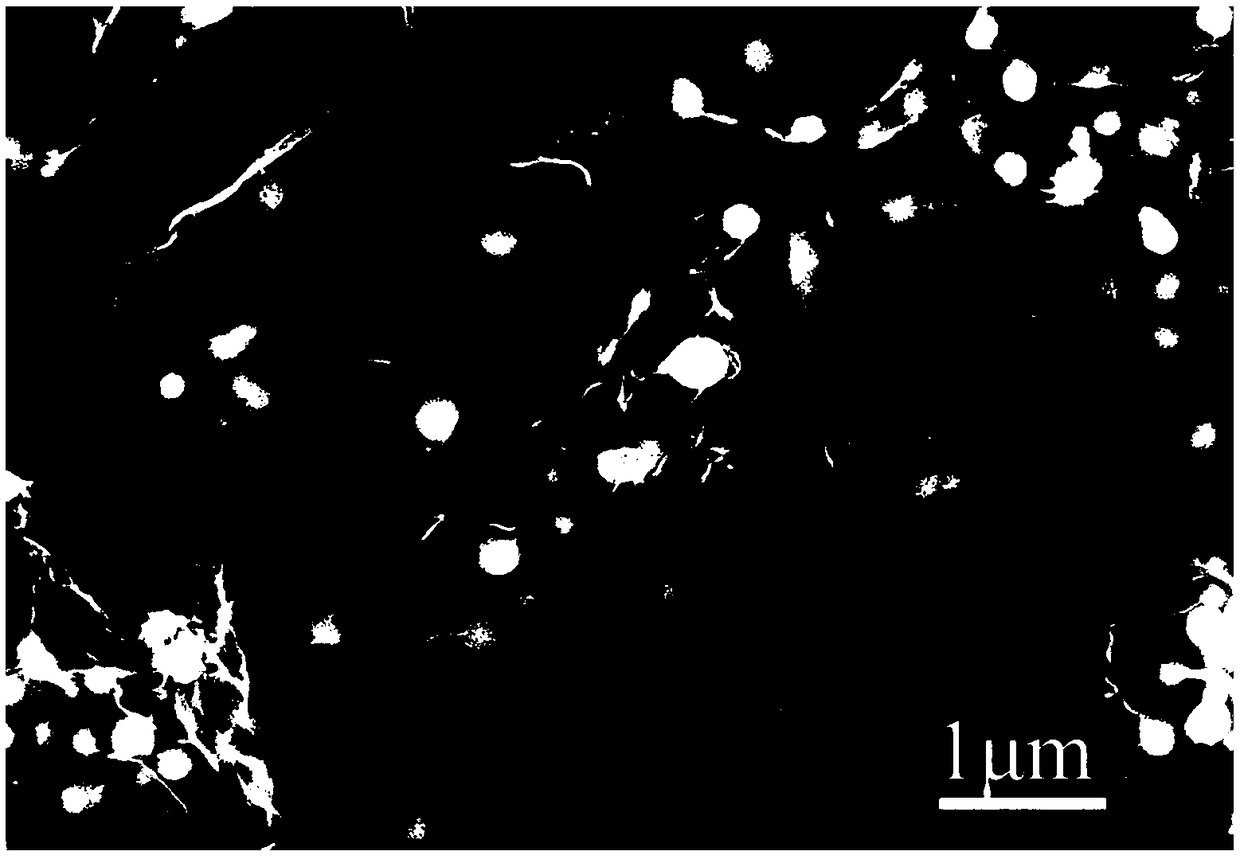

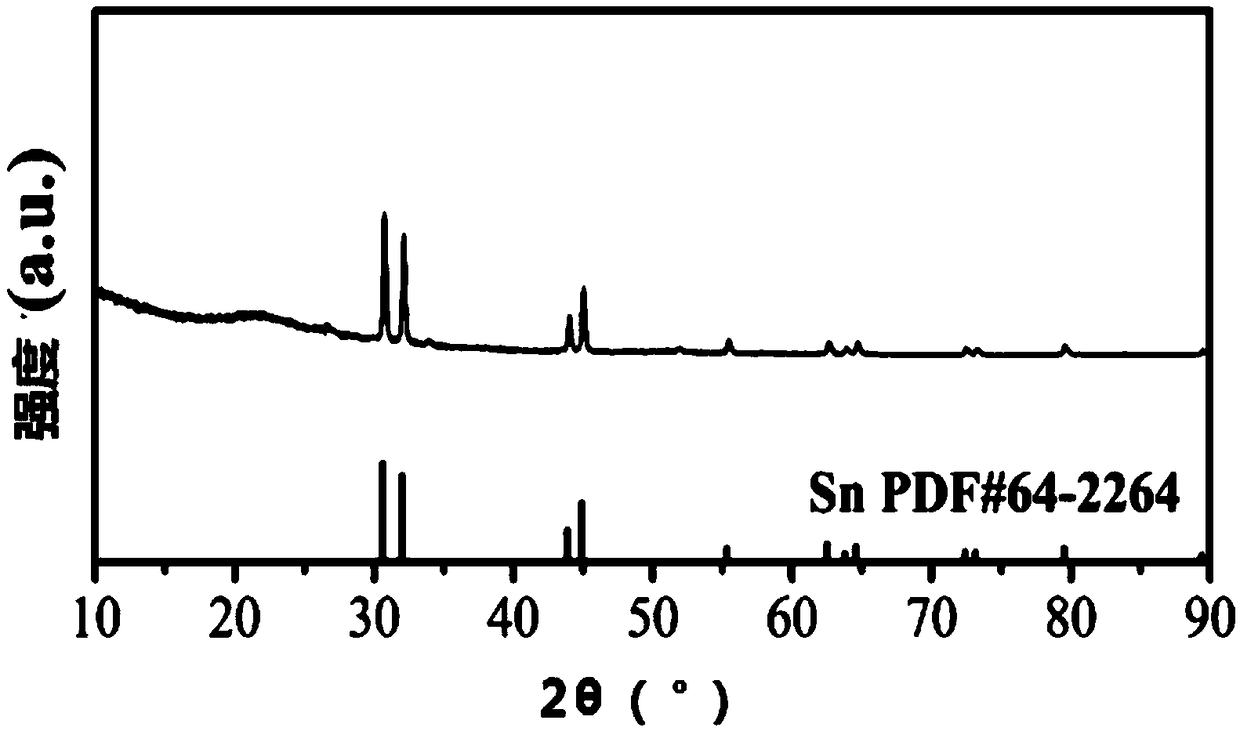

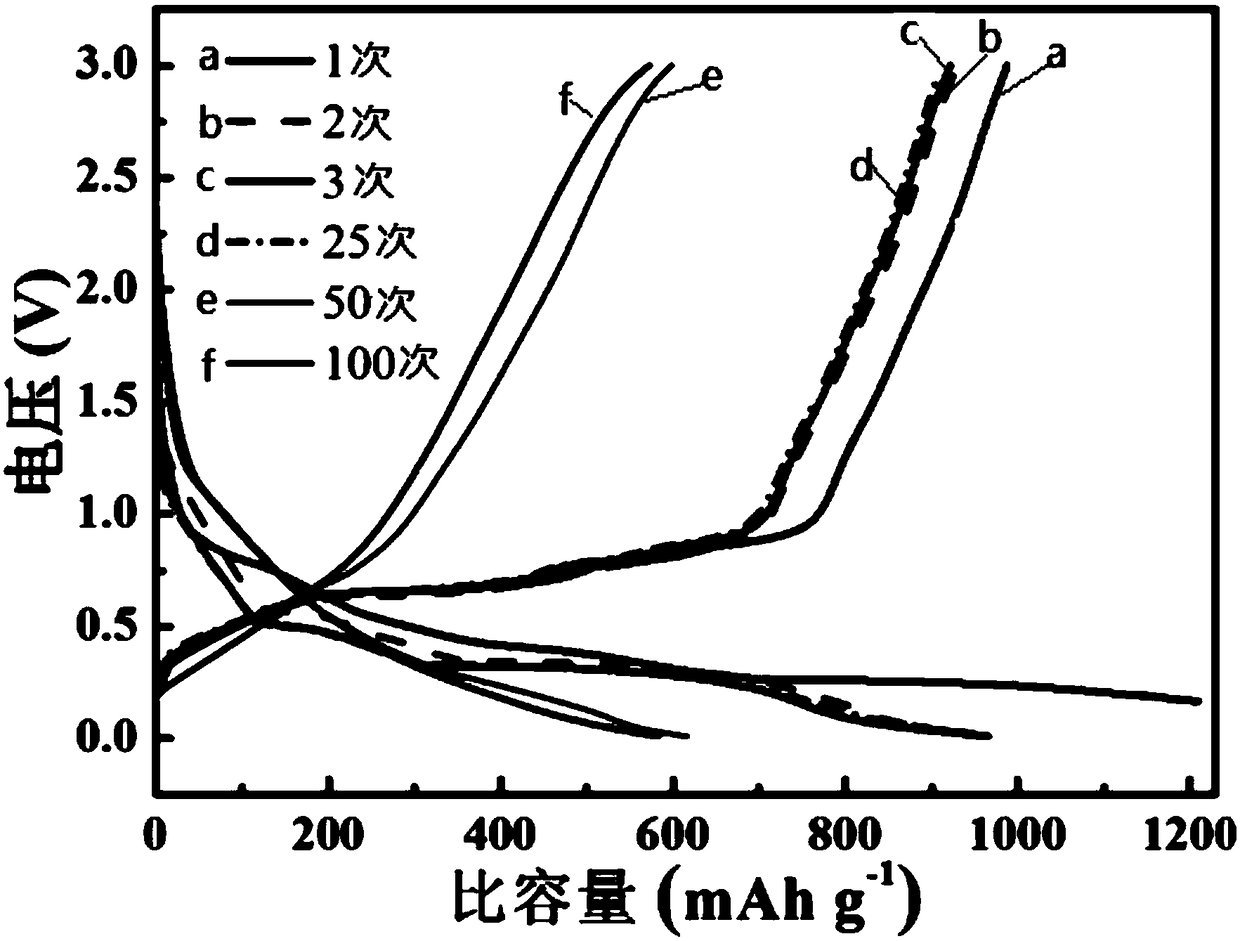

[0024] Specific embodiment one: the preparation method of the self-supporting three-dimensional graphene / tin composite lithium-ion battery negative electrode material of the present embodiment, carry out according to the following steps:

[0025] 1. Material preparation:

[0026] Take graphene oxide dispersion liquid, nano tin dioxide and mix homogeneously, obtain mixed solution; The total mass of graphene oxide in nano tin dioxide and graphene oxide dispersion liquid is counted as M, and the quality of nano tin dioxide is ( 60%~70%)M;

[0027] Or take by weighing graphene oxide dispersion liquid, nano tin dioxide and acidified carbon nanotube and mix uniformly, obtain mixed solution; is N, the quality of nano tin dioxide is (60%-70%) N; the quality of acidified carbon nanotubes is (15%-25%) N;

[0028] 2. Add the mixed solution obtained in step 1 into a hydrothermal kettle, then place the hydrothermal kettle in an oven for hydrothermal reaction at 180-200°C for 12-16 hours,...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of the graphene oxide dispersion liquid described in step one is as follows:

[0031] a. Add 2.0g of natural flake graphite, 2.0g of sodium nitrate and 96mL of concentrated sulfuric acid with a mass percent concentration of 98% in the there-necked flask, stir for 1 hour under ice bath conditions, then slowly add 12.0g of potassium permanganate, continue Stir for 1.5h; then heat to 35°C, react in a water bath at 35°C for 3h; then slowly add 80mL of distilled water, continue stirring, then add 200ml of distilled water to dilute to obtain a suspension;

[0032] b. Pour 20mL of 30% hydrogen peroxide solution into the suspension, stir and dilute to 1000ml with water, let stand at room temperature for 12 hours, remove supernatant scum, then dilute with water and centrifuge for several times To remove nitrate and sulfate ions and incomplete graphite particles ...

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the preparation method of acidified carbon nanotubes described in step one is as follows:

[0035] a. First mix the concentrated nitric acid with a mass concentration of 68% and the concentrated sulfuric acid with a mass concentration of 98% in a volume ratio of 1:3 to obtain a mixed acid; then weigh 0.3g of multi-walled carbon nanotubes (MWCNTs) and place them in a single-necked flask Add mixed acid, disperse in a 100W ultrasonic cleaner at room temperature for 30 minutes, move the one-necked flask to a water bath and heat it to 80°C for a warm water bath reaction for 3 hours, keep stirring and condense and reflux during the reaction; after the reaction is completed, Natural cooling to room temperature;

[0036] b. Add 40mL 10M HCl solution to the single-necked flask, mix well, and filter the mixed solution with polytetrafluoroethylene filter membrane, and repeatedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com