Alkaline polymer electrolyte membrane and preparation method thereof

An electrolyte membrane, polymer technology, applied in circuits, fuel cells, electrical components, etc., can solve problems such as poor water swelling resistance and decreased mechanical properties of wet membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

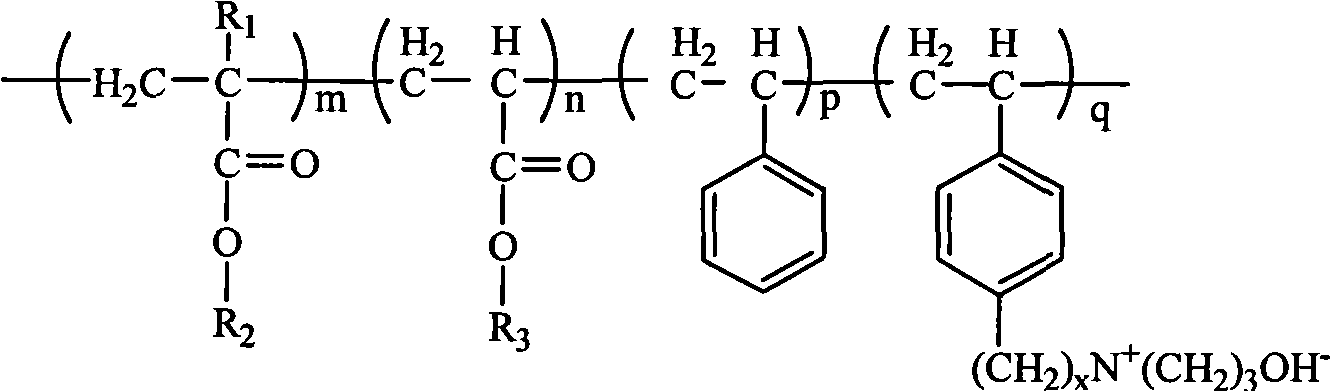

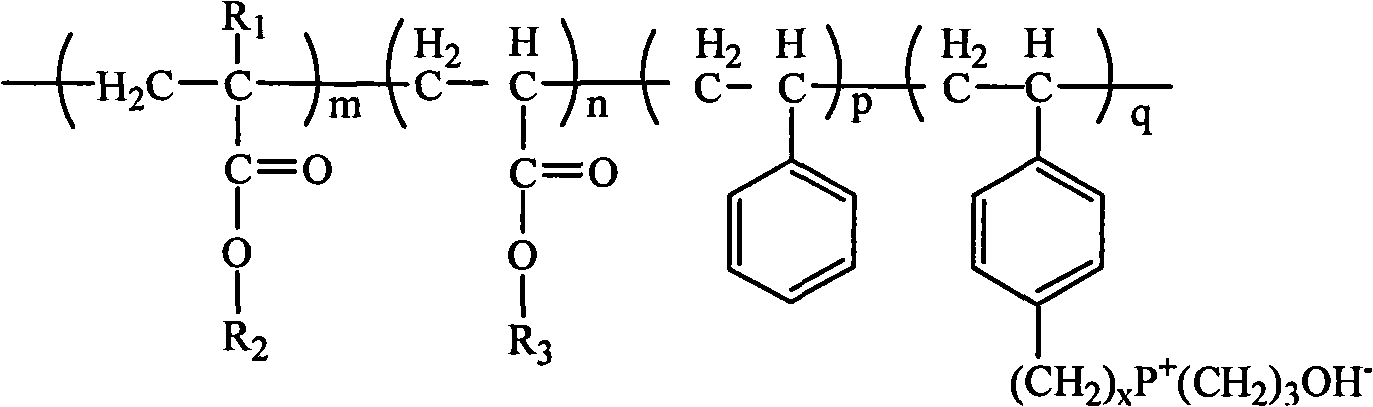

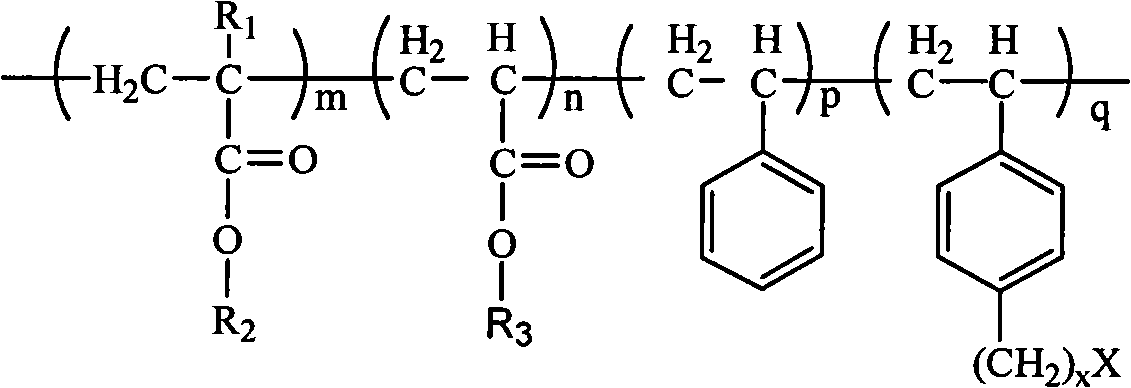

Method used

Image

Examples

Embodiment 1

[0086] A preparation method for an alkaline polymer electrolyte membrane, comprising the following steps:

[0087] a. Polymer synthesis: In a container equipped with a reflux condenser, add styrene, p-chloromethylstyrene, methyl methacrylate and butyl acrylate, wherein styrene accounts for the moles of the total amount of the four monomers The content is 10%, p-chloromethyl styrene accounts for 10% of the total amount of the four monomers, the molar content of methyl methacrylate accounts for the total amount of the four monomers is 40%, and butyl acrylate accounts for the four The molar content of the total amount of monomer is 40%, and it is poured into toluene equal to the volume of the total monomer, and the 2 gas while stirring, while passing N 2 After gas ten minutes, add azobisisobutyronitrile, its add-on accounts for the mole fraction of total monomer and is 1%, reacts in N 2 Heat in an oil bath at 50°C for 34 hours in an air atmosphere. After the reaction is complet...

Embodiment 2

[0112] A preparation method for an alkaline polymer electrolyte membrane, comprising the following steps:

[0113] a. Polymer synthesis: In a container equipped with a reflux condenser, add styrene, p-chloromethylstyrene, ethyl ethacrylate and methyl acrylate, wherein styrene accounts for the moles of the total amount of the four monomers The content is 20%, p-chloromethyl styrene accounts for 20% of the total amount of the four monomers, ethyl ethacrylate accounts for 30% of the total amount of the four monomers, and methyl acrylate accounts for the four The molar content of the total amount of monomers is 30%, and it is poured into tetrahydrofuran equal to the volume of the total monomers, and the 2 gas while stirring, while passing N 2 After gas ten minutes, add azobisisoheptanonitrile, its add-on accounts for the mole fraction of total monomer and is 1.5%, reacts in N 2 Heat in an oil bath at 60°C for 35 hours in an air atmosphere. After the reaction is completed, the so...

Embodiment 3

[0138] A preparation method for an alkaline polymer electrolyte membrane, comprising the following steps:

[0139] a. Polymer synthesis: In a container equipped with a reflux condenser, add styrene, p-chloromethylstyrene, propyl acrylate and ethyl acrylate, wherein styrene accounts for the moles of the total amount of the four monomers The content is 25%, p-chloromethyl styrene accounts for 25% of the total amount of the four monomers, the molar content of propyl acrylate accounts for 25% of the total amount of the four monomers, and ethyl acrylate accounts for the four The molar content of the total amount of monomers is 25%, and it is poured into chloroform equal to the volume of the total monomers and passed through N 2 gas while stirring, while passing N 2 After gas ten minutes, add dibenzoyl peroxide, its add-on accounts for the molfraction of total monomer and is 2%, reacts in N 2 Heated in an oil bath at 70°C for 36 hours in an air atmosphere. After the reaction was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com