Carbon coated nanosilicon composite material as well as preparation method and application thereof

A composite material, carbon-silicon composite technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process and high cost, achieve simple process, recycle resources, and improve circulation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

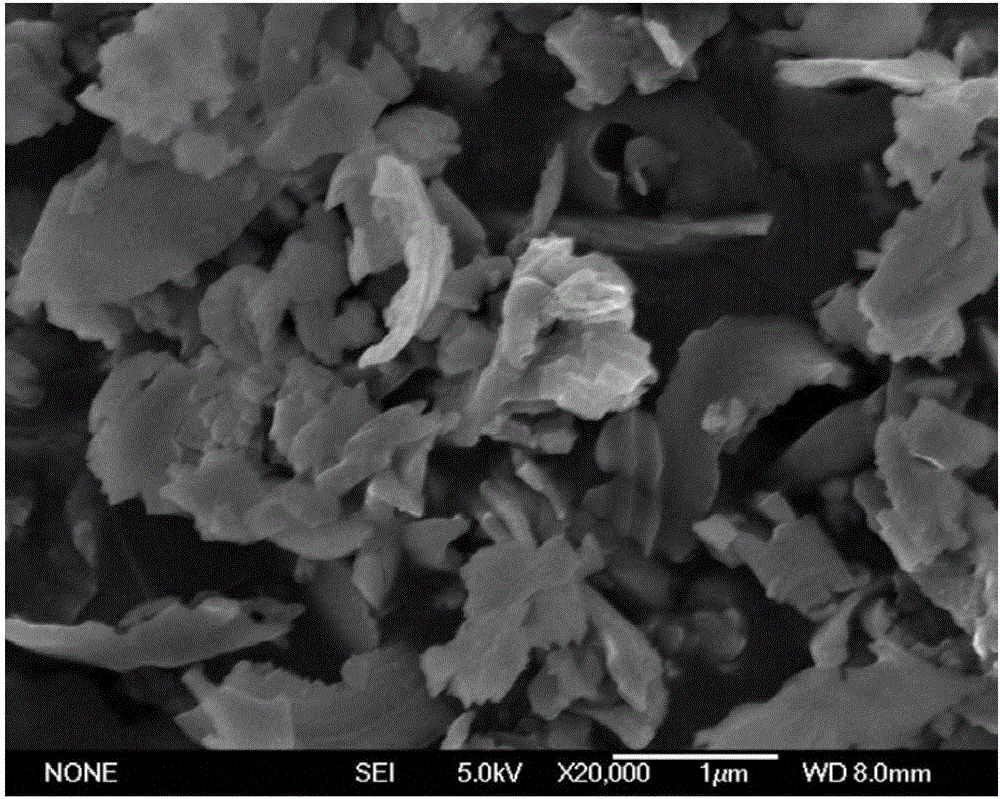

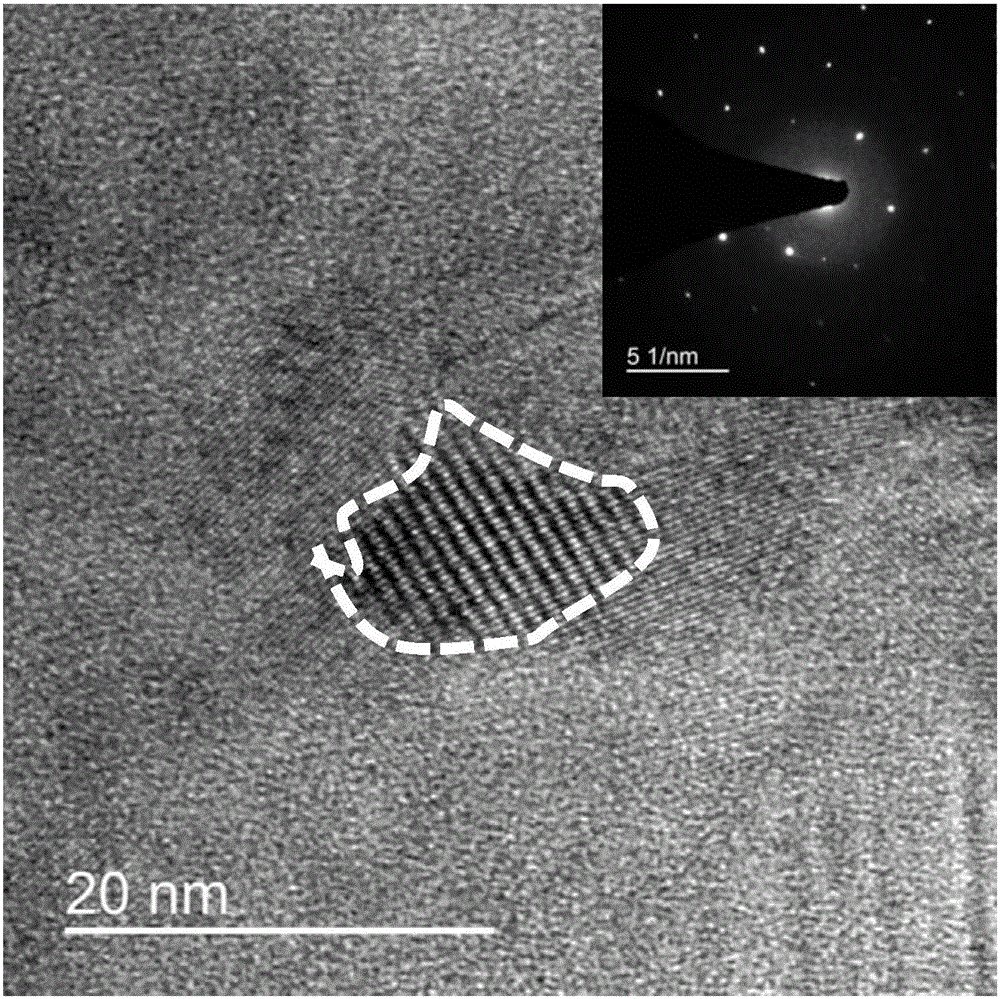

[0020] Embodiment 1: The carbon-coated nano-silicon composite material in this embodiment is a powder of a core-shell structure with nano-silicon particles as the content and carbon as the outer shell.

specific Embodiment approach 2

[0021] Specific embodiment two: the preparation method of the carbon-coated nano-silicon composite material described in specific embodiment one is carried out according to the following steps:

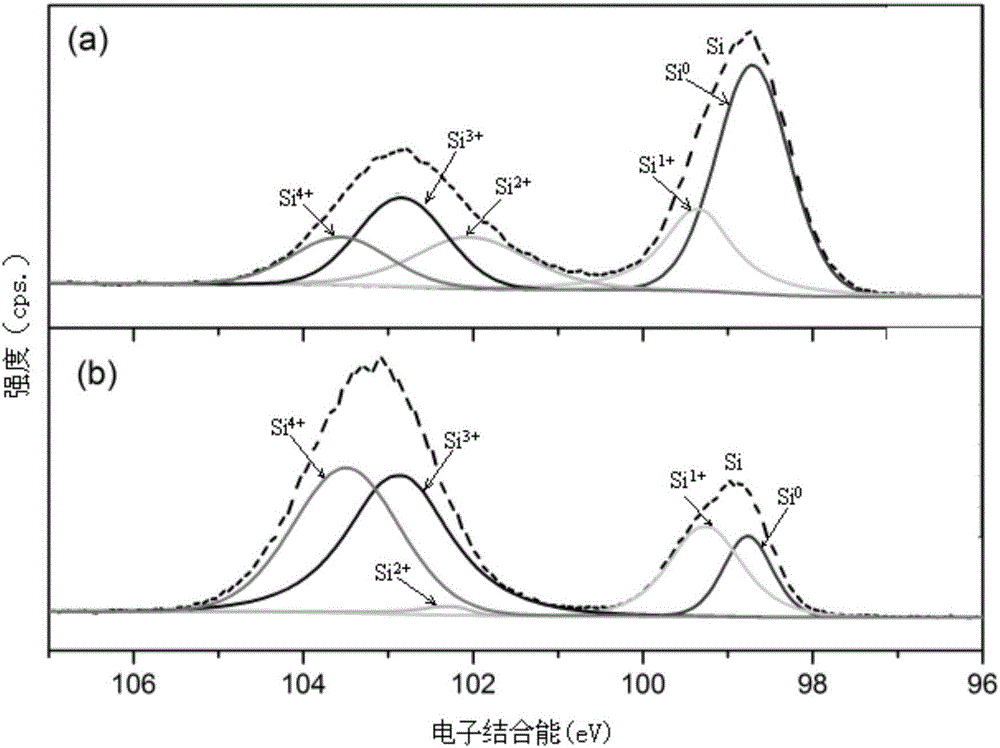

[0022] 1. Put the micron-sized silicon powder with an oxide layer on the surface into an oxygen diffusion furnace, and carry out oxygen diffusion treatment at a temperature of 500-1300°C and a pressure of less than 1 atmosphere until the color of the silicon powder changes from black to earth. Yellow or tan, get silicon micropowder with nano-silicon embedded in silicon oxide;

[0023] 2. Carry out carbon-coating treatment to the silicon micropowder embedded in silicon oxide with the nano-silicon obtained in step 1 to form a carbon-silicon composite powder;

[0024] 3. Soak the carbon-silicon composite powder obtained in step 2 with a hydrofluoric acid solution to remove silicon oxide components, and wash and dry to obtain a carbon-coated nano-silicon composite material.

[0025] In t...

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 2 in that the ratio of silicon atoms to oxygen atoms in the micron-sized silicon powder with an oxide layer on the surface in step 1 is 1: (0.8-1.2). Others are the same as in the second embodiment.

[0027] In the micron-sized silicon micropowder with an oxidized layer on the surface of this embodiment, the degree of oxidation is relatively high, which is a precondition for the smooth progress of subsequent oxygen diffusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com