SnS/Ti02/rGO composite material for a potassium-ion battery negative electrode, preparation method thereof and matching electrolyte

A composite material and battery negative electrode technology, applied in the field of electrochemistry, can solve problems such as the inability to guarantee the kinetic properties of the modified material, the uniformity of the thickness, and the uncontrollable thickness of the coating layer, so as to improve the cycle stability, The effect of enhancing electrical conductivity and maintaining structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

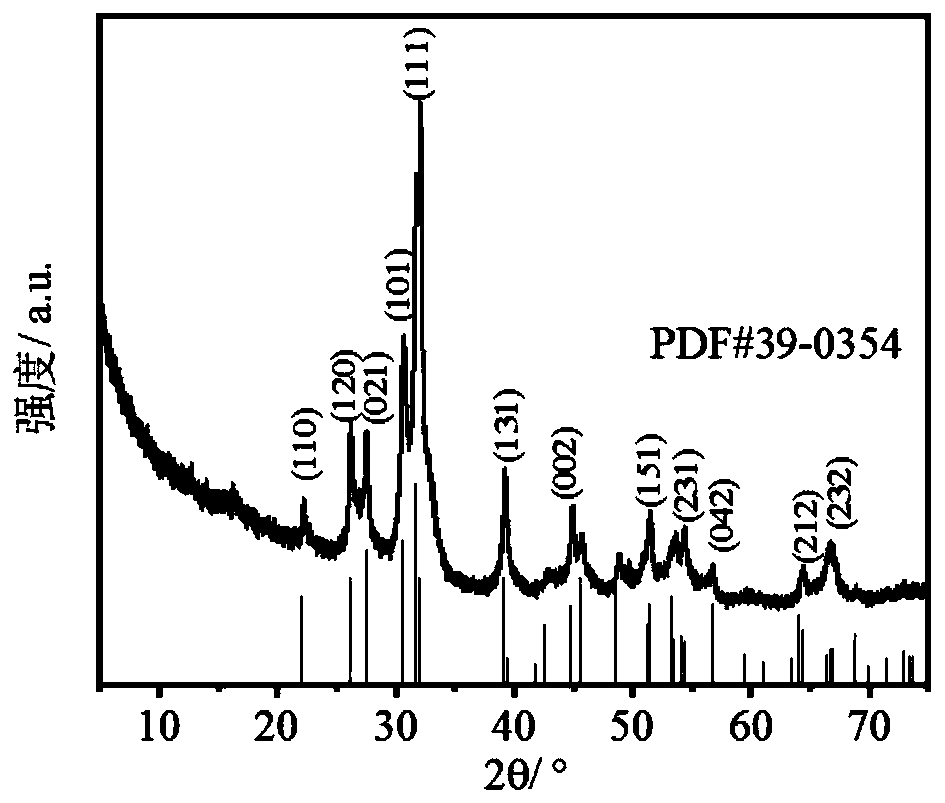

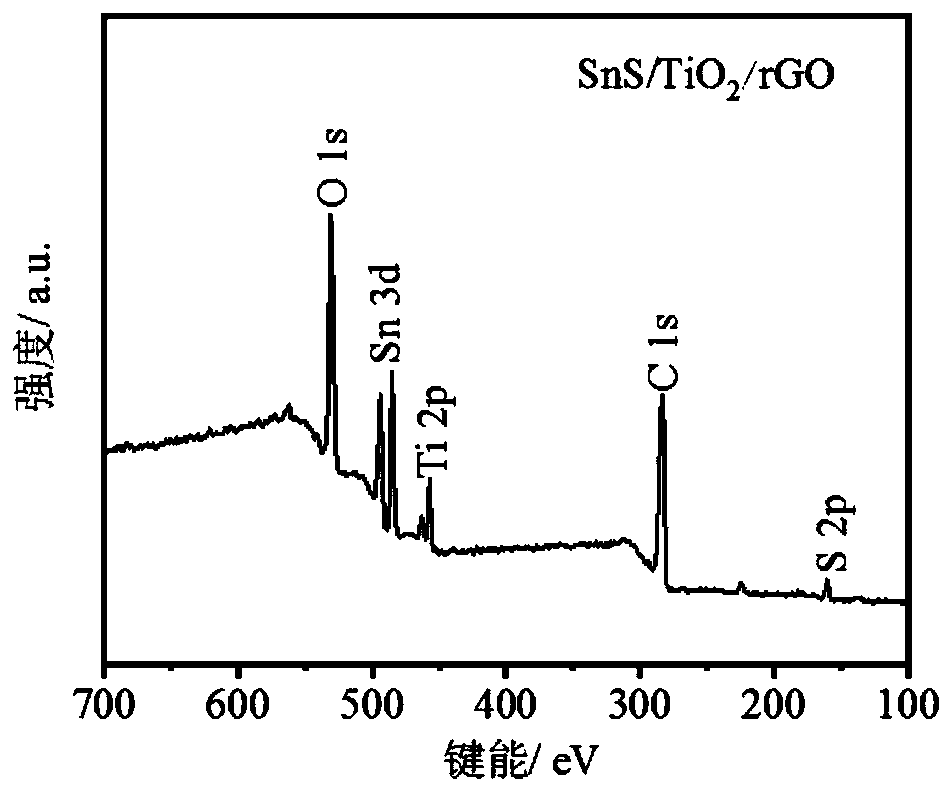

[0046] A kind of SnS / TiO for negative electrode of potassium ion battery 2 The preparation method of / rGO composite material comprises steps as follows:

[0047] (1) Disperse 60mg graphene oxide in 50ml deionized water, add 0.8765g SnCl 4 ·5H 2 O and 0.56g thioacetamide were mixed evenly to obtain a reaction solution, which was hydrothermally reacted at 95°C for 6 hours, washed with deionized water, centrifuged three times, and then freeze-dried for 48 hours to obtain SnS 2 / rGO composites.

[0048] (2) SnS prepared in step (1) 2 / rGO composites in H 2 / Ar(H 2 SnS / rGO composites were obtained by calcining at 500 °C for 2 hours in an atmosphere with a volume ratio of 0.1:1 to Ar.

[0049] (3) Put the SnS / rGO composite material prepared in step (2) into the reaction chamber of the atomic layer deposition equipment filled with argon gas in advance, raise it to the reaction temperature, and keep the temperature of the reaction chamber at 220 ° C, and send to the above reactio...

Embodiment 2

[0054] A kind of SnS / TiO for negative electrode of potassium ion battery 2 The preparation method of / rGO composite material comprises steps as follows:

[0055] (1) Disperse 60mg graphene oxide in 50ml deionized water, add 0.8765g SnCl 4 ·5H 2 O and 0.56g thioacetamide were mixed evenly to obtain a reaction solution, and the resulting reaction solution was hydrothermally reacted at 110°C for 6 hours, washed with deionized water, centrifuged three times, and then freeze-dried for 48 hours to obtain SnS 2 / rGO composites.

[0056] (2) SnS prepared in step (1) 2 / rGO composites in H 2 / Ar(H 2 SnS / rGO composites were obtained by calcining at 600 °C for 3 hours in an atmosphere with a volume ratio of 0.1:1 to Ar.

[0057] (3) Put the SnS / rGO composite material prepared in step (2) into the reaction chamber of the atomic layer deposition equipment filled with argon in advance, raise it to the reaction temperature, and keep the temperature of the reaction chamber at 250 ° C; F...

Embodiment 3

[0059] A kind of SnS / TiO for negative electrode of potassium ion battery 2 The preparation method of / rGO composite material comprises steps as follows:

[0060] (1) Disperse 60mg graphene oxide in 50ml deionized water, add 0.8765g SnCl 4 ·5H 2 O and 0.56 g of thioacetamide were mixed evenly to obtain a reaction solution, and the resulting reaction solution was hydrothermally reacted at 150 ° C for 6 hours, washed with deionized water, centrifuged three times, and then freeze-dried for 48 hours to obtain SnS2 / rGO composites.

[0061] (2) SnS prepared in step (1) 2 / rGO composites in H 2 / Ar(H 2 SnS / rGO composites were obtained by calcining at 700 °C for 3 hours in an atmosphere with a volume ratio of 0.1:1 to Ar.

[0062] (3) Put the SnS / rGO composite material prepared in step (2) into the reaction chamber of the atomic layer deposition equipment filled with argon in advance, raise it to the reaction temperature, and keep the temperature of the reaction chamber at 250 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com