Method for preparing porous silicon/graphene composite lithium ion battery anode material by using diatomite as raw material

A graphene composite and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not being able to fully adapt to silicon volume shrinkage and expansion, high cost of synthesis process, and difficulty in commercialization, etc., to achieve protection of electrodes The effect of complete structure, low price and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 2.0g of natural diatomite, heat it to 900°C at a heating rate of 5°C / min under air conditions, keep it warm for 4h, remove organic matter, and then wash it with 0.01mol / L sodium hydroxide alkali for 2.5h, and wash until medium properties, and then pickled with 6.0mol / L nitric acid solution at 95°C for 6h, and finally washed and dried at 80°C to obtain purified diatomite.

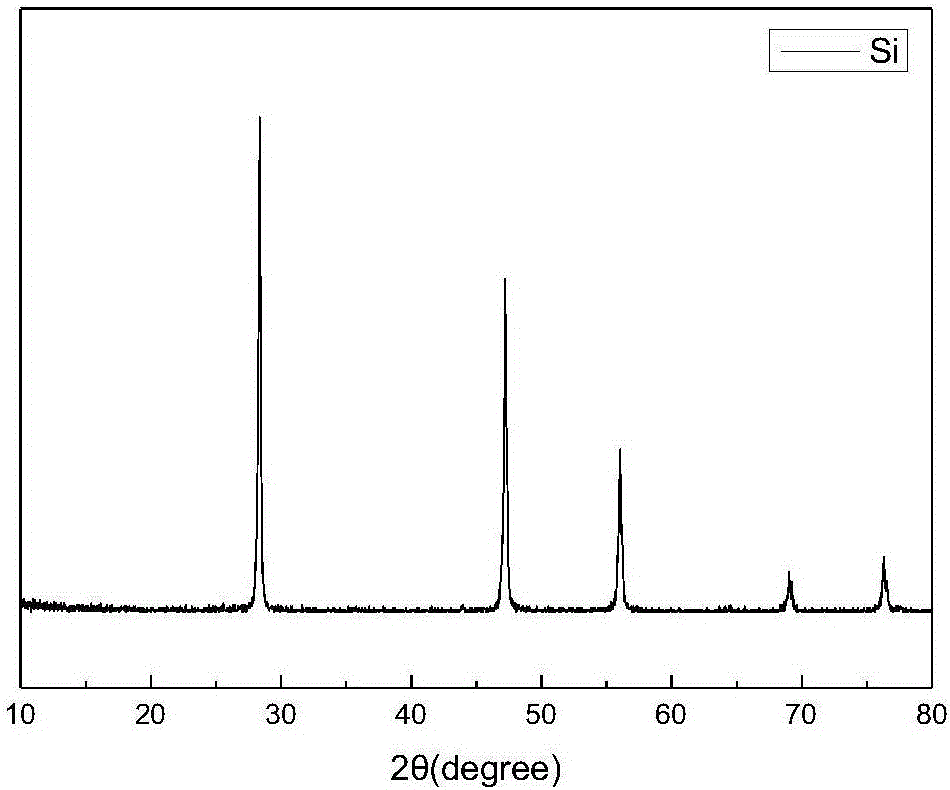

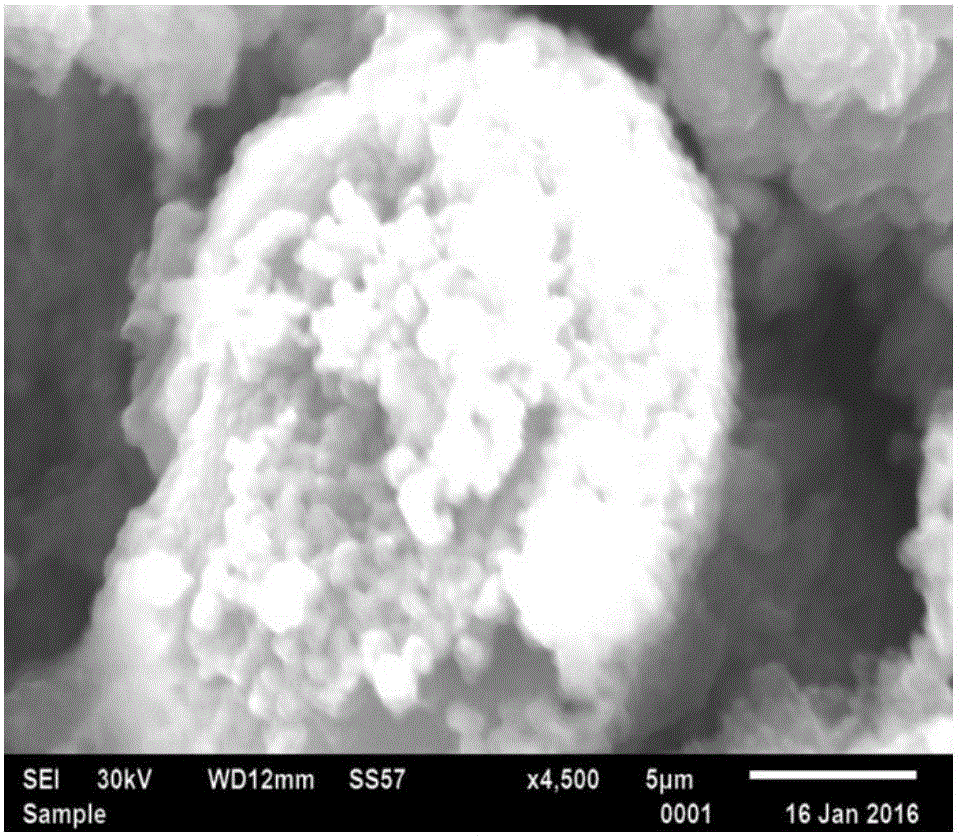

[0032] Mix the purified diatomite and magnesium powder at a mass ratio of 1:2.0, under the protection of argon, keep warm at 700°C for 3h, cool naturally to room temperature, and pickle the solid powder in 0.1mol / L hydrochloric acid solution for 12h, Then it is washed and dried to obtain silicon with a porous structure.

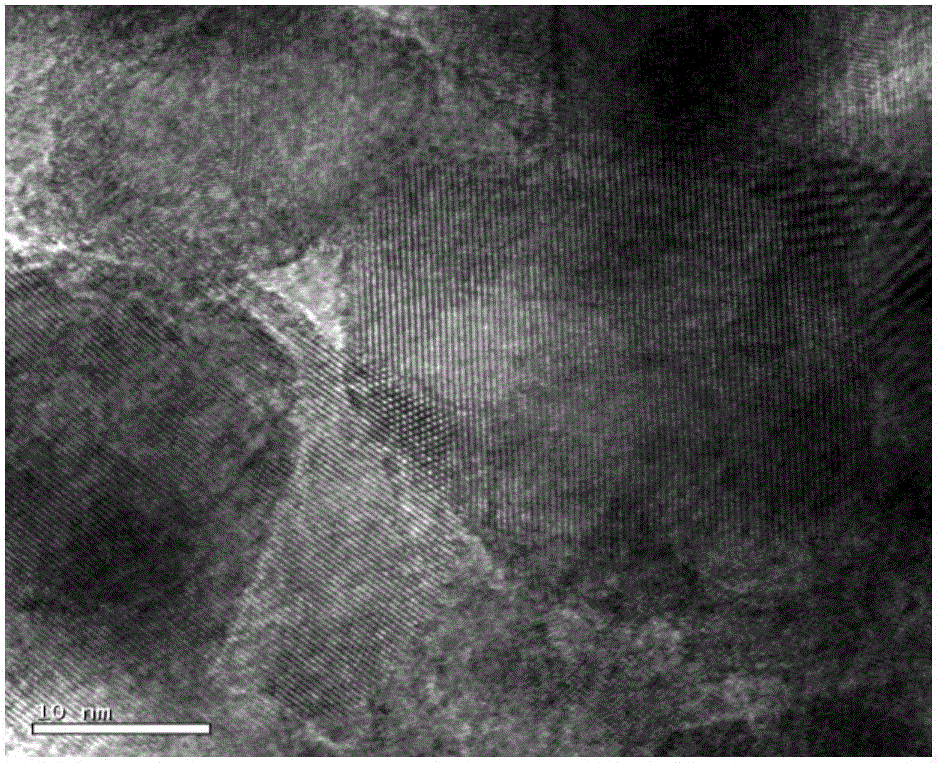

[0033] Weigh 0.35g of porous silicon and 0.15g of edible sugar, mix and dissolve in the aqueous solution, load it on the nickel foam by evaporation, place it in a tube furnace and heat it to 1050 under the conditions of a helium flow rate of 200sccm and a heating rate of 5°C / min...

Embodiment 2

[0036] Take 2.5g of natural diatomite, heat it to 850°C at a heating rate of 8°C / min under air conditions, keep it warm for 5h, remove organic matter, and then wash it with calcium hydroxide alkali with a concentration of 0.01mol / L for 3h until neutral , and then pickled with 5.0mol / L sulfuric acid solution at 95°C for 4h, and finally washed and dried at 80°C to obtain purified diatomite.

[0037] Mix the purified diatomaceous earth and magnesium powder at a mass ratio of 1:1.5, under the protection of helium, keep warm at 750°C for 3h, cool down to room temperature naturally, pickle the solid powder in 0.5mol / L hydrochloric acid solution for 15h, Then it is washed and dried to obtain silicon with a porous structure.

[0038] Weigh 0.35g of porous silicon and 0.20g of edible sugar, mix and dissolve in the aqueous solution, load it on the nickel foam by evaporation, place it in a tube furnace and heat it to 1000 under the conditions of a helium flow rate of 250sccm and a heatin...

Embodiment 3

[0041] Take 2.5g of natural diatomite, heat it up to 800°C at a heating rate of 10°C / min under air conditions, keep it warm for 2h, remove organic matter, and then wash it with sodium hydroxide with a concentration of 0.01mol / L for 3h until neutral , and then pickled with 6.0mol / L hydrochloric acid solution at 95°C for 6h, and finally washed and dried at 80°C to obtain purified diatomite.

[0042] Mix the purified diatomite and magnesium powder at a mass ratio of 1:2.0, under the protection of argon, keep warm at 750°C for 4h, cool down to room temperature naturally, pickle the solid powder in 0.1mol / L hydrochloric acid solution for 15h, Then it is washed and dried to obtain silicon with a porous structure.

[0043] Weigh 0.35g of porous silicon and 0.25g of glucose, mix and dissolve in aqueous solution, load it on foamed nickel by evaporation, and heat it to 1000°C in a tube furnace with a helium flow rate of 200 sccm and a heating rate of 20°C / min. , annealed at a hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com