Lithium-ion battery germanium/carbon composite negative electrode material and preparation method and application thereof

A lithium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of limited development, electrode pulverization failure, capacity attenuation, etc., to achieve the suppression of collapse failure, prevention of agglomeration, high quality Effect of capacity and volume ratio capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A preparation method of a germanium / carbon composite negative electrode material for a lithium ion battery of the present invention, comprising the following steps:

[0052] (1) GeO 2 Dissolve in alkaline solution to form uniform and transparent solution A;

[0053] (2) Add nanocrystalline cellulose to solution A, stir until a uniform first suspension is formed, then adjust the pH value of the first suspension to 6.0-8.0, then add mesophase carbon microspheres, and continue stirring until A uniform second suspension is formed, and then transferred to a water bath at 50°C to 60°C to obtain a second suspension at 50°C to 60°C;

[0054] (3) NaBH 4 The powder is completely dissolved in water at 1°C to 4°C to obtain NaBH 4 solution, then NaBH 4 The solution is added to the second suspension at 50°C to 60°C, stirred and reacted in a water bath at 50°C to 60°C, vacuum filtered after the reaction is completed, and the precipitate obtained is washed until the washed solution...

Embodiment 1

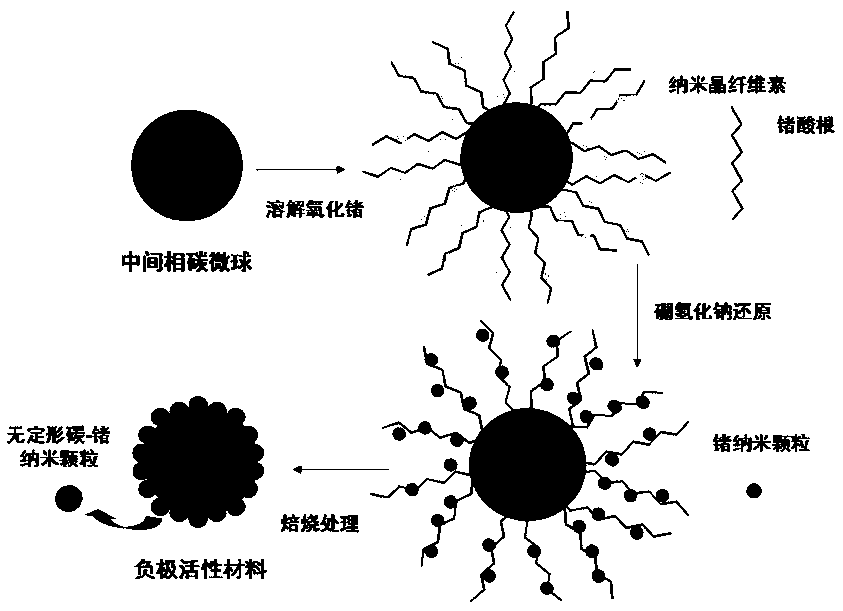

[0061] A germanium / carbon composite negative electrode material for a lithium ion battery of the present invention, which is mainly composed of germanium nanoparticles, mesocarbon microspheres and amorphous carbon, wherein the amorphous carbon layer is coated with nano-scale germanium particles and coated with amorphous carbon The nano-germanium particles in the layer evenly cover the surface of the mesocarbon microspheres, and the amorphous carbon layer acts as a "bridge" connecting the nano-germanium particles and the mesocarbon microspheres. figure 1 shown. Among them, in terms of mass fraction, the content of germanium nanoparticles is 9.7%, the content of mesocarbon microspheres is 88%, and the content of amorphous carbon is 2.3%.

[0062] A kind of preparation method of the lithium ion battery germanium / carbon composite negative electrode material of this embodiment, its preparation process schematic diagram is as follows figure 1 shown, including the following steps: ...

Embodiment 2

[0078] A germanium / carbon composite negative electrode material for a lithium ion battery of the present invention, mainly composed of germanium nanoparticles, mesocarbon microspheres and amorphous carbon, wherein the amorphous carbon layer is coated with nano-scale germanium particles, and the amorphous carbon layer is coated The nano-germanium particles uniformly cover the surface of mesocarbon microspheres, and the amorphous carbon layer acts as a "bridge" connecting germanium and mesocarbon microspheres. Among them, by mass fraction, germanium nanoparticles account for 24.2%, and the mesophase Carbon microspheres are 72.6%, and amorphous carbon is 3.2%.

[0079] A kind of preparation method of the lithium ion battery germanium / carbon composite negative electrode material of this embodiment, its preparation process schematic diagram is as follows figure 1 shown, including the following steps:

[0080] (1) Add 200mL of 0.5M ammonia solution to a 1000mL beaker, add 4.8g of G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com