Hollow porous cuprous oxide-copper oxide-ferric oxide cubic lithium ion battery anode and one-step preparation method thereof

A technology of ferric oxide and lithium-ion batteries, which is applied to battery electrodes, secondary batteries, negative electrodes, etc., can solve problems such as increasing electrode polarization and impedance, hindering electron transmission, and active component shedding and failure, achieving increased capacity, alleviate volume change, improve cycle stability and specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

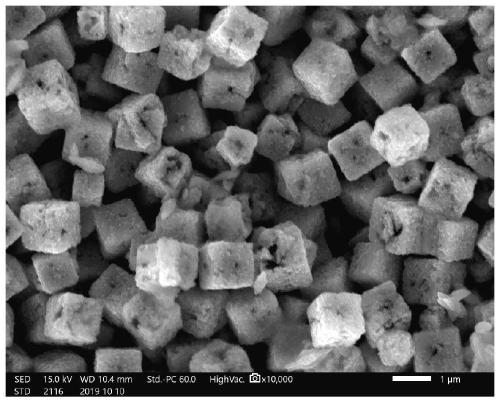

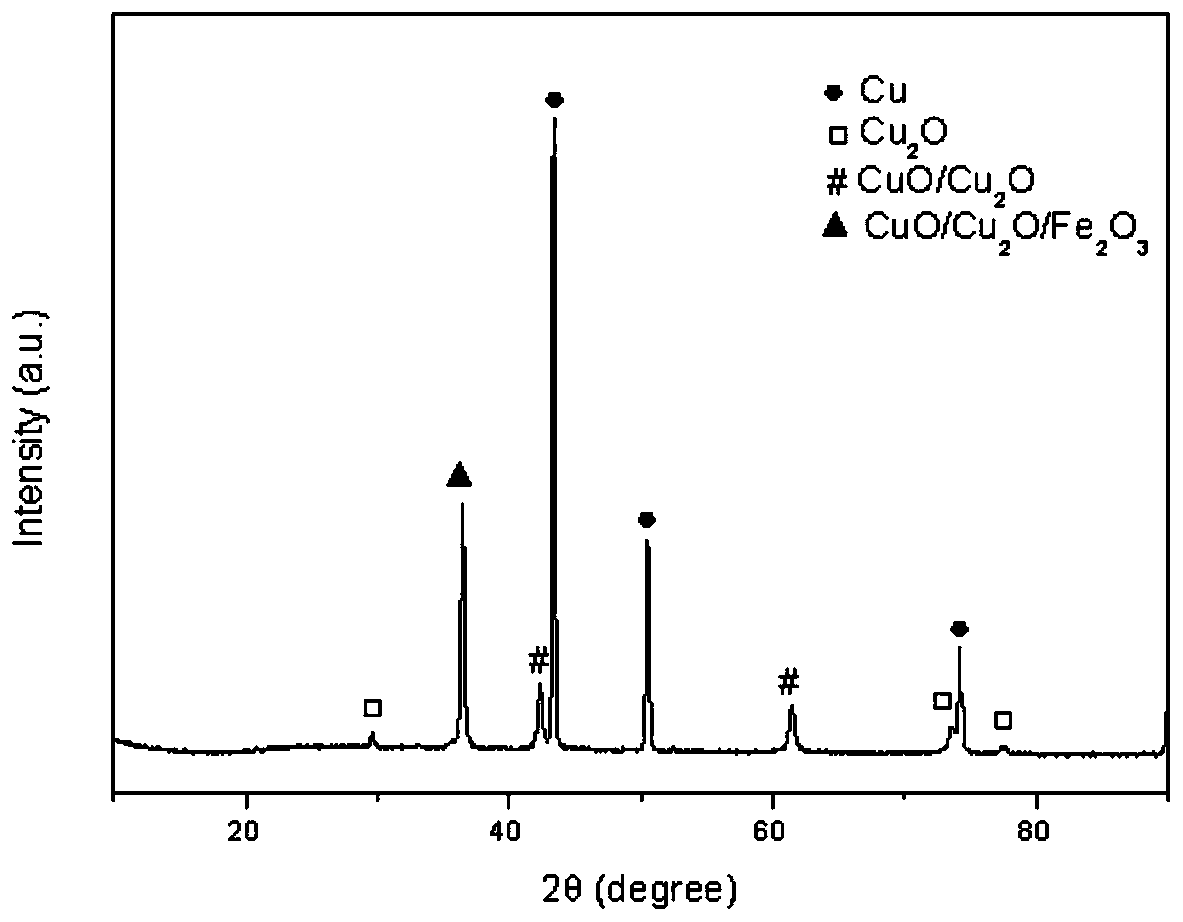

[0039] In this embodiment, a one-step preparation method for the negative electrode of a hollow porous cuprous oxide-copper oxide-iron trioxide cubic lithium ion battery based on the in-situ growth of a three-dimensional porous copper skeleton is provided, and the specific steps are as follows:

[0040] (1) Pretreatment: Cut the three-dimensional porous copper with micron-sized pores into square pieces with a side length of 8 mm, put them in a tablet press to be thinned, and then immerse them in dilute hydrochloric acid with a concentration of 2 mol / L for ultrasonic cleaning for 10 min. To remove the oxide layer on the surface, then washed with deionized water and ethanol successively, and vacuum dried to obtain a three-dimensional porous copper framework with a thickness of about 400 μm.

[0041] (2) Dissolve ferric nitrate nonahydrate and urea in deionized water to form a mixed aqueous solution of ferric nitrate nonahydrate and urea. In the mixed aqueous solution of ferric ni...

Embodiment 2

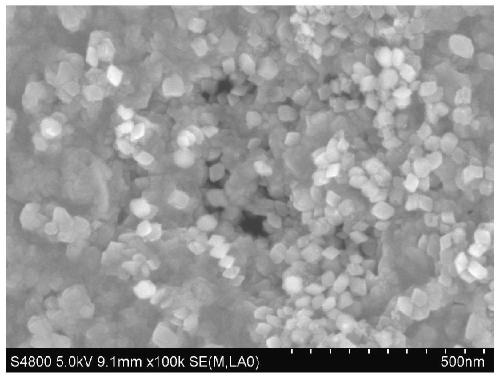

[0056] In this embodiment, a one-step preparation method for the negative electrode of a hollow porous cuprous oxide-copper oxide-iron trioxide cubic lithium ion battery based on the in-situ growth of a three-dimensional porous copper skeleton is provided, and the specific steps are as follows:

[0057] (1) Pretreatment: Cut the three-dimensional porous copper with micron-sized pores into square pieces with a side length of 8 mm, put them in a tablet press to be thinned, and then immerse them in dilute hydrochloric acid with a concentration of 2 mol / L for ultrasonic cleaning for 10 min. To remove the oxide layer on the surface, then washed with deionized water and ethanol successively, and vacuum dried to obtain a three-dimensional porous copper framework with a thickness of about 400 μm.

[0058] (2) Dissolve ferric nitrate nonahydrate and urea in deionized water to form a mixed aqueous solution of ferric nitrate nonahydrate and urea. In the mixed aqueous solution of ferric ni...

Embodiment 3

[0064] In this embodiment, a one-step preparation method for the negative electrode of a hollow porous cuprous oxide-copper oxide-iron trioxide cubic lithium ion battery based on the in-situ growth of a three-dimensional porous copper skeleton is provided, and the specific steps are as follows:

[0065] (1) Pretreatment: Cut the three-dimensional porous copper with micron-sized pores into square pieces with a side length of 8 mm, put them in a tablet press to be thinned, and then immerse them in dilute hydrochloric acid with a concentration of 1 mol / L for ultrasonic cleaning for 20 min To remove the oxide layer on the surface, then washed with deionized water and ethanol successively, and vacuum dried to obtain a three-dimensional porous copper framework with a thickness of about 150 μm.

[0066] (2) Dissolve ferric nitrate nonahydrate and urea in deionized water to form a mixed aqueous solution of ferric nitrate nonahydrate and urea. The concentration of 0.6 mol / L. The three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com