Si-TiO2-C nano fiber composite thin film, preparation method and application thereof

A nanofiber membrane, si-tio2-c technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as lattice distortion, lack of channels, affecting battery performance, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

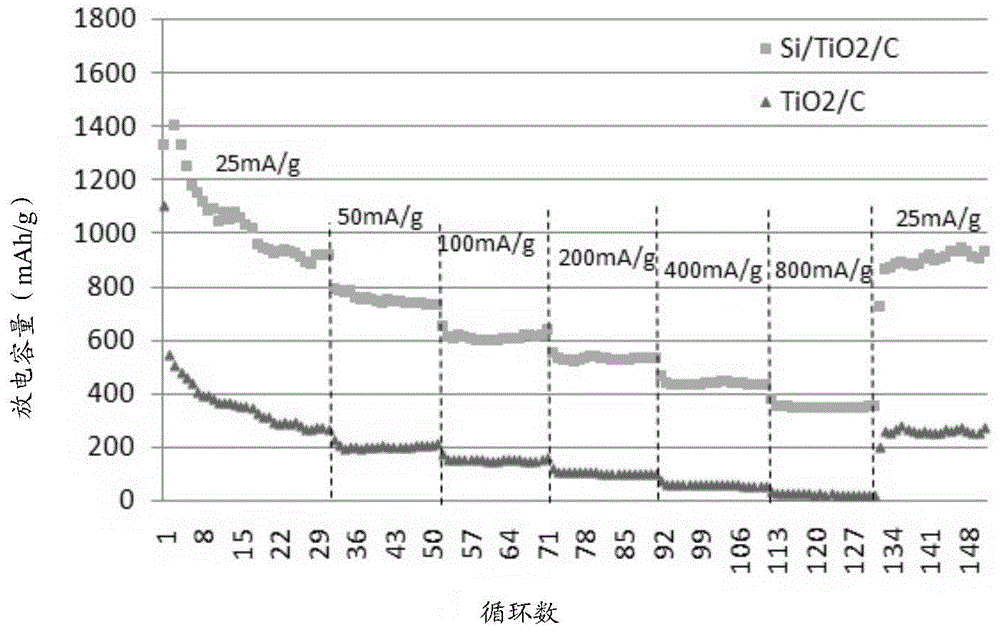

Examples

Embodiment 1

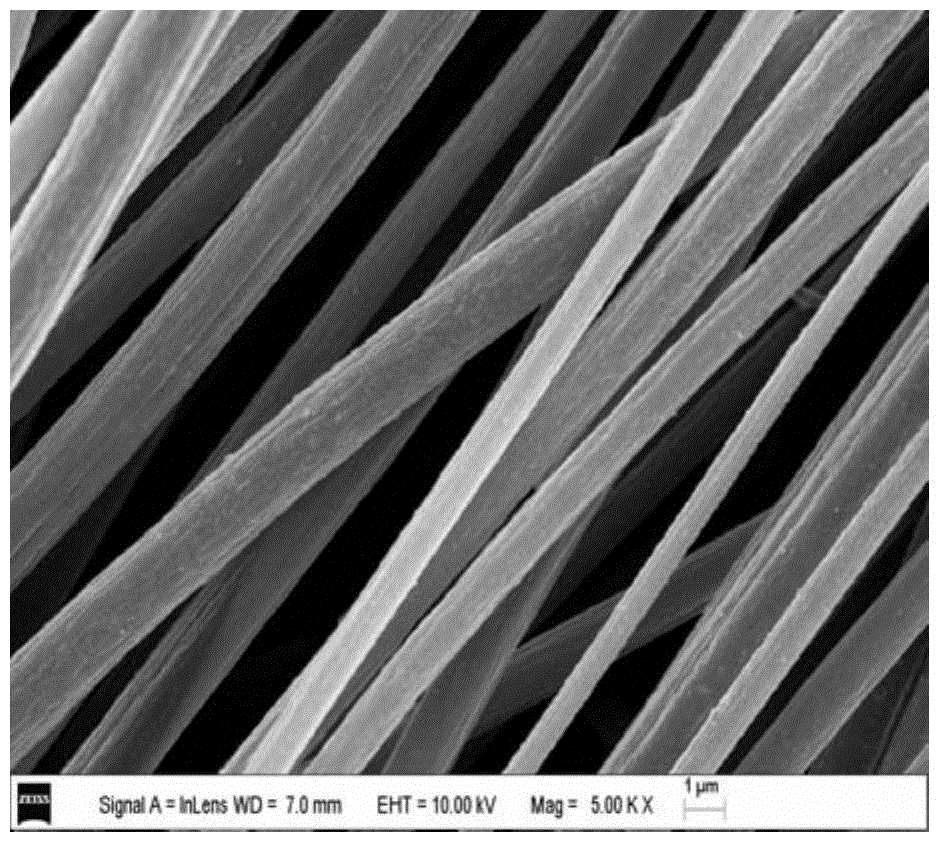

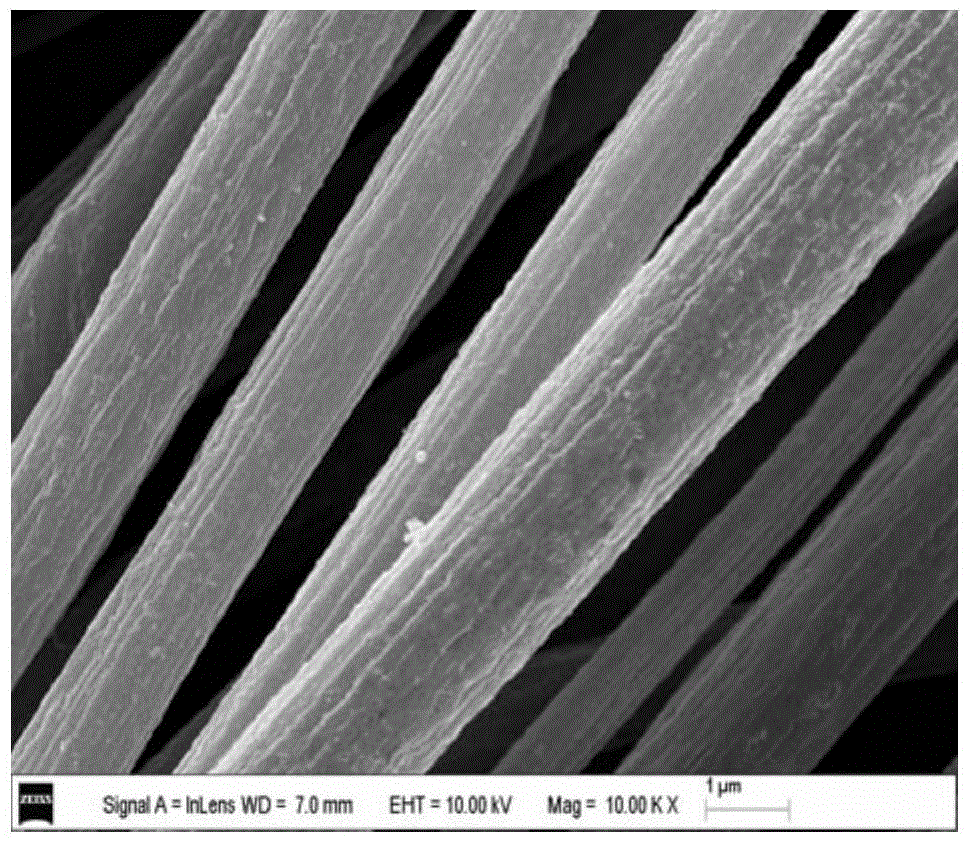

[0050] Si-TiO 2 Preparation of -C nanofiber composite film:

[0051] Prepare a spinning solution using N,N-dimethylformamide (DMF) as a solvent, wherein the ratio of various raw materials in the spinning solution is: polyacrylonitrile concentration 10wt%, tetrabutyl titanate concentration 1.0mol / L, the concentration of nano silicon powder is 0.3mol / L.

[0052] Next, carry out electrospinning on the above-mentioned spinning solution. The conditions of electrospinning are: the inner diameter of the needle is 1mm, the spinning voltage is 12kV, the receiving method is drum receiving, the flow rate of the spinning solution is 0.5mL / h, and the receiving distance is 20cm. After 3 hours, the electrospun nanofiber precursor film was obtained.

[0053] Then, the obtained electrospun nanofiber precursor film was subjected to pre-oxidation treatment, and the process was firstly kept at 120° C. for 1 h, and then kept at 250° C. for 2 h at a constant temperature.

[0054] Finally, the p...

Embodiment 2

[0063] Si-TiO 2 Preparation of -C nanofiber composite film:

[0064] Prepare a spinning solution using DMSO as a solvent, wherein the ratio of various raw materials in the spinning solution is: polyvinyl alcohol concentration 7wt%, titanic acid concentration 0.1mol / L, nano silicon powder concentration 0.1mol / L.

[0065] Next, carry out electrospinning on the above-mentioned spinning solution, the condition of electrospinning is: inner diameter of the needle head is 0.6mm, spinning voltage is 20kV, receiving mode is drum receiving, flow rate of spinning solution is 0.3mL / h, receiving distance is 30cm, spinning The silk time is 2h, and the electrospun nanofiber precursor film is obtained.

[0066] Then, the obtained electrospun nanofiber precursor film was subjected to pre-oxidation treatment. The process was firstly kept at 100° C. for 2 hours, and then kept at 250° C. for 4 hours.

[0067] Finally, the pre-oxidized electrospun nanofiber precursor film was carbonized in an ar...

Embodiment 3

[0070] Si-TiO 2 Preparation of -C nanofiber composite film:

[0071] Prepare the spinning solution with chloroform as solvent, wherein, the proportioning of various raw materials in the spinning solution is: polyvinylpyrrolidone concentration 15wt%, isopropyl titanate concentration 0.5mol / L, the concentration of nano silicon powder is 0.5mol / L.

[0072] Next, carry out electrospinning on the above-mentioned spinning liquid, the conditions of electrospinning are: the inner diameter of the needle head is 2.0mm, the spinning voltage is 8kV, the receiving mode is drum receiving, the flow rate of spinning liquid is 1.5mL / h, the receiving distance is 10cm, the spinning The silk time is 6 hours, and the electrospun nanofiber precursor film is obtained.

[0073] Then, the obtained electrospun nanofiber precursor film was subjected to pre-oxidation treatment. The process was firstly kept at 100°C for 2h, and then kept at 250°C for 2h.

[0074] Finally, the pre-oxidized electrospun n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com