Single-layer/double-layer coated silicon oxide composite anode material and preparation method thereof

A negative electrode material, silicon oxide technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low material compaction density and difficult control of silicon source agglomeration, and achieve reduced volume expansion effect, high stability, and improved cyclic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

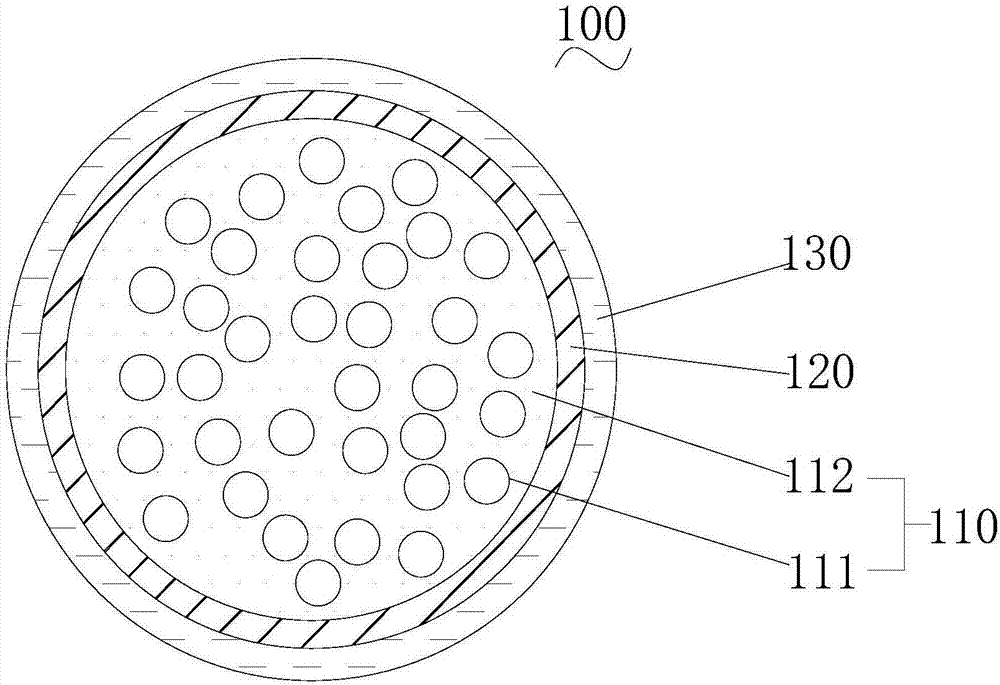

[0046] see figure 1 , a double-layer coated silicon oxide composite negative electrode material, the double-layer coated silicon oxide composite negative electrode material 100 is a three-layer composite material with a core-shell structure, wherein the inner core is a silicon-oxygen precursor 110, and the middle layer is titanium The lithium oxide layer 120 has a carbon layer 130 coated on the outer surface of the lithium titanate layer 120 as the outermost layer, and the silicon-oxygen precursor 110 is a material formed by uniformly dispersing nano-silicon 111 in silicon dioxide 112 . Preferably, the silicon-oxygen precursor is SiO x , where 0.5<x<1.5. The thickness of the lithium titanate layer is 5-500 nm, and the thickness of the carbon layer is 0.05-10 μm.

[0047] A method for preparing a double-layer coated silicon oxide composite negative electrode material, comprising the following steps:

[0048] 1) Mix 10g of nano-silicon and 21.4g of nano-silicon dioxide (molar...

Embodiment 2

[0053] A method for preparing a double-layer coated silicon oxide composite negative electrode material, comprising the following steps:

[0054] 1) Mix 7.5g of nano-silicon and 21.4g of nano-silicon dioxide and ball mill, ball mill at a speed of 300rpm for 3 hours, mix the materials evenly to obtain a mixture, and roast the mixture at 1500°C for 6 hours under vacuum conditions, cool it, and crush it with a crusher until the particle size is 10-50 μm; and ball milling for 6 hours to obtain the silicon-oxygen precursor, wherein the particle size of the silicon-oxygen precursor is 2-10 μm.

[0055] 2) Put 5g of silicon-oxygen precursor into 50ml of absolute ethanol solution containing 0.5g of tetrabutyl titanate, stir for 6h, then add 5ml of water and stir for 60min; then add 50mL of acetone solution containing 0.11g of lithium oxalate, and finally Add 1g of glacial acetic acid and stir evenly, stop stirring when the sol turns into a gel, then age the resulting gel for 12 hours,...

Embodiment 3

[0059] A method for preparing a double-layer coated silicon oxide composite negative electrode material, comprising the following steps:

[0060] 1) Mix 10g of nano-silicon and 21.4g of nano-silicon dioxide (molar ratio is 1:1) and ball mill, and ball mill at a speed of 300rpm for 3h to mix the materials evenly to obtain a mixture. Under vacuum conditions, bake the mixture at 2000°C for 8h , cooled, and crushed with a crusher to a particle size of 10-50 μm; and then ball milled for 6 hours to obtain a silicon-oxygen precursor, wherein the particle size of the silicon-oxygen precursor is 2-10 μm.

[0061] 2) Put 5g of silicon-oxygen precursor into 50ml of absolute ethanol solution containing 0.25g of tetrabutyl titanate, stir for 6h, then add 5ml of water and stir for 60min; then add 50mL of absolute ethanol containing 0.1g of lithium chloride solution, finally add 1g of glacial acetic acid and stir evenly, stop stirring when the sol turns into a gel, then age the resulting gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com