Preparation method of dopamine stabilized Pickering emulsion and application thereof on immobilized enzymes

A Pickering emulsion, dopamine technology, applied in biochemical equipment and methods, immobilized on/in organic carriers, enzymes, etc., can solve the problem of large resistance to enzyme catalysis mass transfer, complicated operation and production steps, and high preparation costs problems, to achieve good economic feasibility and practicability, good reusability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

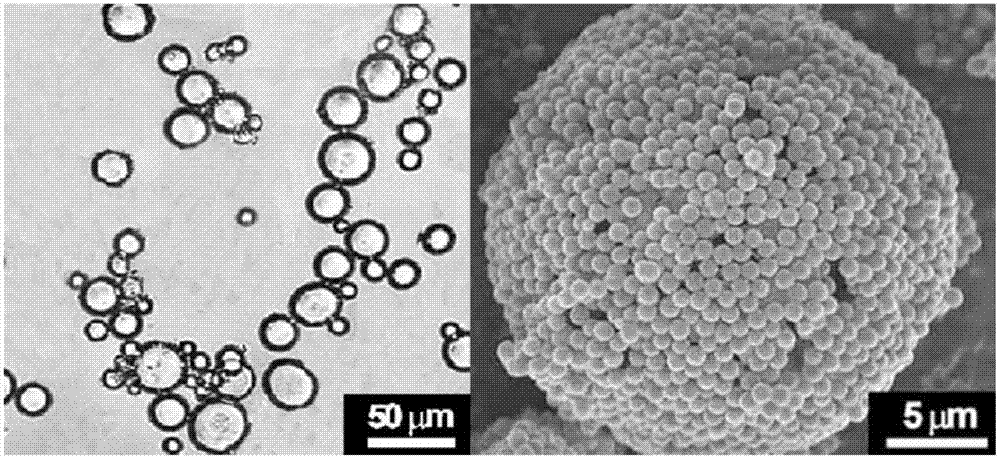

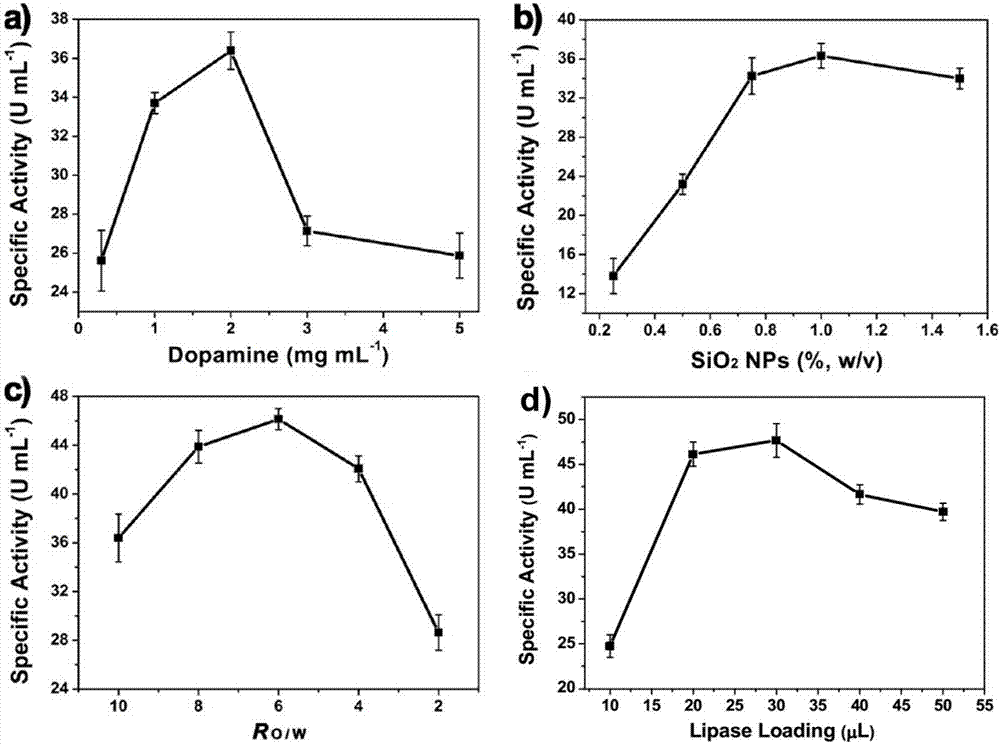

[0034] Take 20 μL free enzyme solution and add 180 μL Tris buffer (10 mM, pH 8.5), mix well and add to the solution dispersed with 20 mg hydrophobically modified SiO 2 In 2mL of n-heptane containing nanoparticles, homogenize at high speed (15000rpm, 2min), then add 0.25mg / mL dopamine into the emulsion, stir homogeneously for 1min, and incubate in a shaker for 24h (180rpm, 28°C) to obtain A dopamine-stabilized Pickering emulsion-immobilized enzyme system.

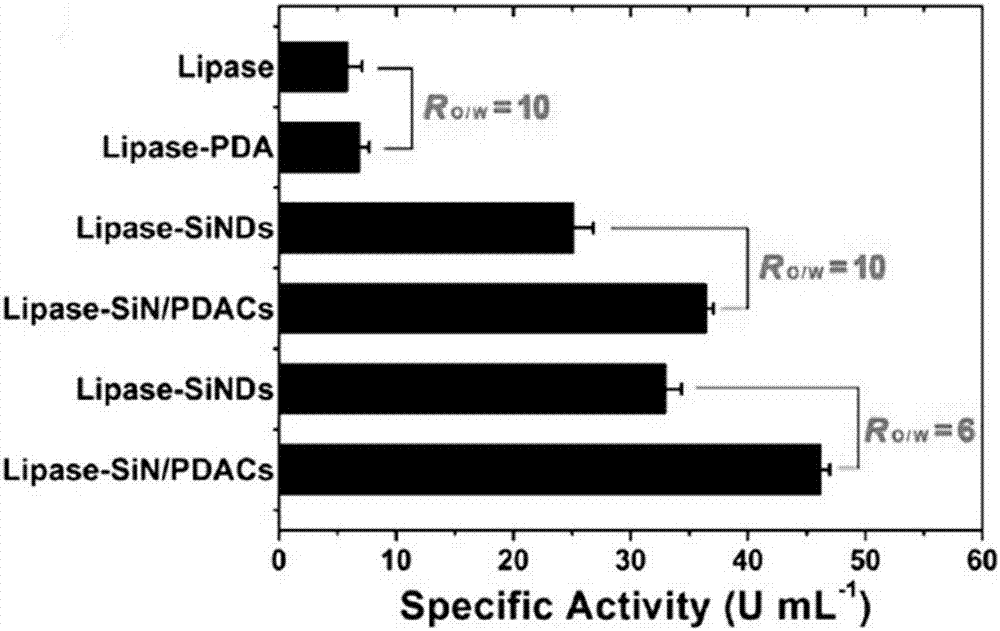

[0035] The catalytic effects of free and immobilized enzymes were measured by the esterification of n-hexanol and n-hexanoic acid in water / n-heptane system. Will contain 400mmol L -1 N-hexanoic acid and 400mmol L -1 A solution of n-hexanol in 2 mL of n-heptane was added to the enzyme-coated Pickering emulsion. The enzyme-catalyzed reaction was carried out at 37°C in a water-bath shaker at 200 rpm for 1 hour, and 1 μL of the product was taken to analyze the results by gas chromatography, as shown in image 3 shown. The r...

Embodiment 2

[0037] Take 20 μL free enzyme solution and add 180 μL Tris buffer (10 mM, pH 8.5), mix well and add to the solution dispersed with 20 mg hydrophobically modified SiO 2 In 2mL of n-heptane containing nanoparticles, homogenize at high speed (20000rpm, 2min). Then 2mg / mL dopamine was added to the emulsion, stirred homogeneously for 1min, and incubated in a shaker for 24h (180rpm, 28°C) to obtain a dopamine-stabilized Pickering emulsion-immobilized enzyme system.

[0038] The catalytic effects of free and immobilized enzymes were measured by the esterification of n-hexanol and n-hexanoic acid in water / n-heptane system. Will contain 400mmol L -1 N-hexanoic acid and 400mmol L -1 A solution of n-hexanol in 2 mL of n-heptane was added to the enzyme-coated Pickering emulsion. The enzyme-catalyzed reaction was carried out at 37°C in a water-bath shaker at 200 rpm for 1 hour, and 1 μL of the product was taken to analyze the results by gas chromatography, as shown in image 3 shown. ...

Embodiment 3

[0040] Take 20 μL free enzyme solution and add 180 μL Tris buffer (10 mM, pH 8.5), mix well and add to the solution dispersed with 20 mg hydrophobically modified SiO 2 In 2mL of n-heptane containing nanoparticles, homogenize at high speed (20000rpm, 2min). Afterwards, 5 mg / mL dopamine was added to the emulsion, stirred homogeneously for 1 min, and incubated in a shaker for 24 h (180 rpm, 28°C) to obtain a dopamine-stabilized Pickering emulsion-immobilized enzyme system.

[0041] The catalytic effects of free and immobilized enzymes were measured by the esterification of n-hexanol and n-hexanoic acid in water / n-heptane system. Will contain 400mmol L -1 N-hexanoic acid and 400mmol L -1 A solution of n-hexanol in 2 mL of n-heptane was added to the enzyme-coated Pickering emulsion. The enzyme-catalyzed reaction was carried out at 37°C in a water-bath shaker at 200 rpm for 1 hour, and 1 μL of the product was taken to analyze the results by gas chromatography, as shown in image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com