Environment-friendly ink-jet printing dye ink for artificial cotton and preparation method of environment-friendly ink-jet printing dye ink

An inkjet printing and dye ink technology, applied in the field of textiles, can solve the problem of less rayon fabric, and achieve the effects of improving binding force, improving performance and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

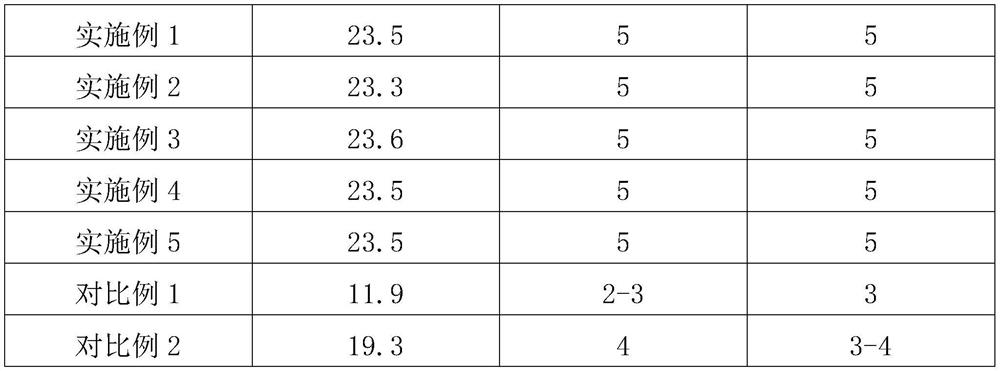

Examples

Embodiment 1

[0023] (1) 90ml water and 5ml concentration are 0.35mol / L benzyltrimethylammonium chloride solution and join in the reactor, then add 9.2g styrene and 0.7g butyl acrylate under stirring state, heat up to 70 ℃, then add 4ml of 2,2'-azobis[2-methylpropionamidine]-dihydrochloride solution with a concentration of 20g / L, and stir the reaction at 500rpm for 3h. After the reaction, filter the reaction solution, The filtered precipitate was washed and dispersed in ethanol to obtain a polymer microsphere dispersion with a concentration of 10wt%; 5mmol of caffeic acid, 2.5mmol of copper chloride and 7.5mmol of sodium perborate were added to 500ml of polymer microsphere dispersion , heat up to 60°C, stir and react for 1 h at a speed of 1000 rpm, filter the reaction solution after the reaction, and disperse the filtered precipitate in water to obtain a modified dispersion with a concentration of 20 g / L;

[0024] (2) 4ml of C.I. reactive red 218 solution and 150ml of water with a concentra...

Embodiment 2

[0027] (1) 100ml of water and 5ml of concentration are added to the reactor as 0.45mol / L benzylvinyltrimethylammonium chloride solution, then add 9.2g of styrene and 0.8g of butyl acrylate under agitation, and heat up to 80 ℃, then add 5ml of 2,2'-azobis[2-methylpropionamidine]-dihydrochloride solution with a concentration of 20g / L, and stir the reaction at 800rpm for 3h. After the reaction, filter the reaction solution, The filtered precipitate was washed and dispersed in ethanol to obtain a polymer microsphere dispersion with a concentration of 10wt%; 5mmol of caffeic acid, 2.5mmol of copper chloride and 7.5mmol of sodium perborate were added to 500ml of polymer microsphere dispersion , heated to 60°C, stirred and reacted at a speed of 1500 rpm for 2 hours, after the reaction, the reaction solution was filtered, and the filtered precipitate was dispersed in water to obtain a modified dispersion with a concentration of 20 g / L;

[0028] (2) 5ml concentration is that the C.I. r...

Embodiment 3

[0031] (1) 95ml water and 5ml concentration are 0.4mol / L benzyl vinyl trimethyl ammonium chloride solution and join in the reactor, then add 9.2g styrene and 0.75g butyl acrylate under stirring state, heat up to 75 ℃, then add 4ml of 2,2'-azobis[2-methylpropionamidine]-dihydrochloride solution with a concentration of 20g / L, stir and react for 3h at a rotating speed of 600rpm, and filter the reaction solution after the reaction is completed. The filtered precipitate was washed and dispersed in ethanol to obtain a polymer microsphere dispersion with a concentration of 10wt%; 5mmol of caffeic acid, 2.5mmol of copper chloride and 7.5mmol of sodium perborate were added to 500ml of polymer microsphere dispersion , heated to 60°C, stirred and reacted at 1200 rpm for 1 h, after the reaction, the reaction solution was filtered, and the filtered precipitate was dispersed in water to obtain a modified dispersion with a concentration of 20 g / L;

[0032] (2) 5ml concentration is that the C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com