Patents

Literature

62 results about "Benzyltrimethylammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

BENZYLTRIMETHYLAMMONIUM CHLORIDE is a light yellow liquid with a mild almond odor. May float or sink in water. (USCG, 1999)

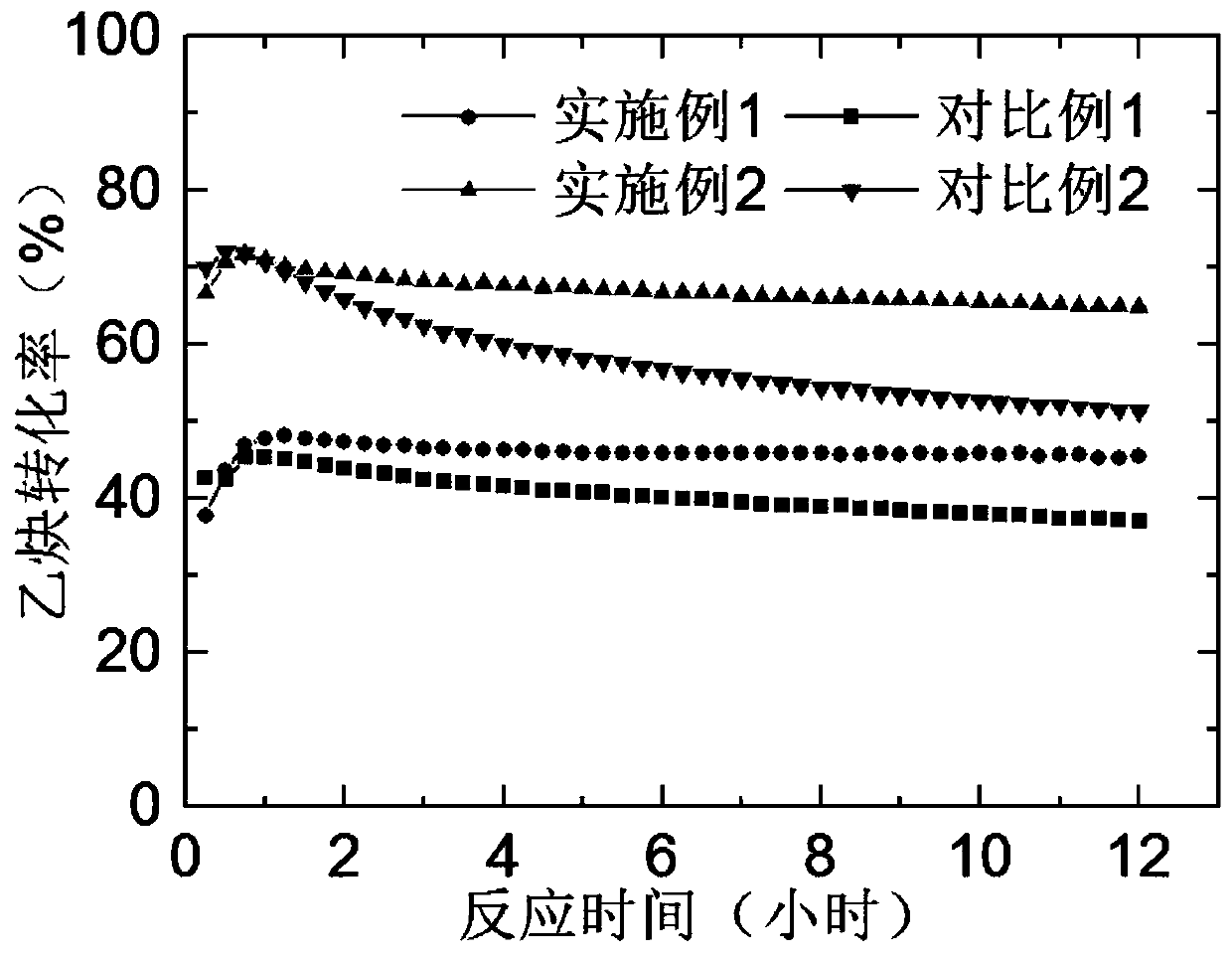

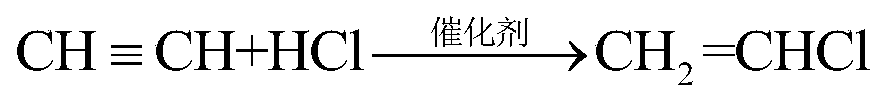

Copper-based catalyst with high activity and stability for acetylene hydrochlorination

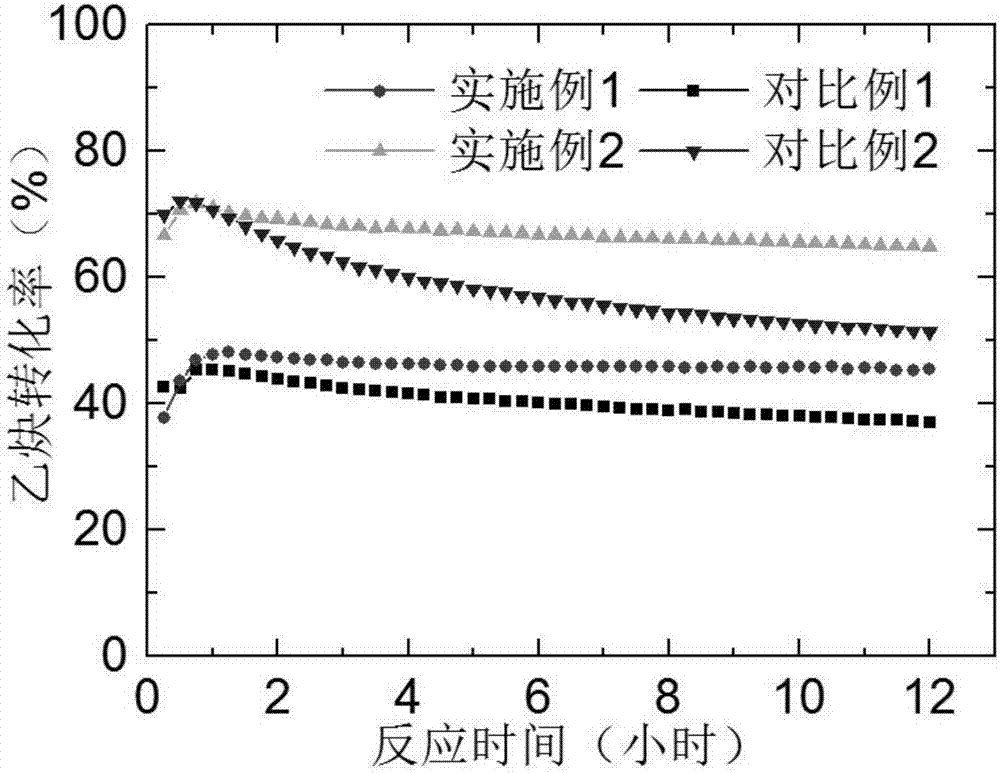

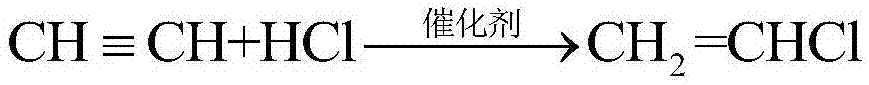

ActiveCN107008465ALow costIncrease costPhysical/chemical process catalystsPreparation by halogen halide additionSteam pressurePhosphate

The invention relates to a copper-based catalyst with high activity and stability for acetylene hydrochlorination. According to the copper-based catalyst, a copper salt is taken as an active component, wherein the copper salt is selected from one or more of copper chloride, copper nitrate, copper sulfate and copper phosphate. The copper-based catalyst is characterized in that a stabilizer is introduced into the copper-based catalyst; and the stabilizer is selected from one or more of guanidine hydrochloride, tetramethylethylenediamine hydrochloride, tetramethylammonium chloride, tetraethylammonium chloride, benzyltrimethylammonium chloride, benzyl triethyl ammonium chloride, tetramethyl phosphorus chloride, tetrabutyl phosphorus chloride, methyl triphenyl phosphorus chloride and 1-butyl triphenylphosphonium. Through introducing the stabilizer has the advantages of being low in cost, low in toxicity, good in heat stability and small steam pressure into the catalyst, and the stability of the copper-based catalyst for acetylene hydrochlorination is significantly improved.

Owner:TSINGHUA UNIV

Antibacterial finishing method of wool fabric

InactiveCN105568678AGood antibacterial effectHigh antibacterial rateBiochemical fibre treatmentAnimal fibresSodium lactateKetone

The invention discloses an antibacterial finishing method of a wool fabric. The method comprises the following steps of first adding water into a finishing agent to prepare into a dipping solution, and then putting the fabric into the dipping solution for padding, wherein the pickup rate is 70 percent to 80 percent, and finally washing the padded fabric by water for 2 to 3 times, dehydrating the washed fabric, and drying the dehydrated fabric. The finishing agent is prepared from the following components in parts by weight: 10 to 16 parts of phenyl salicytate, 3 to 6 parts of chitosan, 5 to 9 parts of benzyltrimethylammonium chloride, 3 to 5 parts of sodium lactate, 15 to 20 parts of 2-methyl-4-isothiazolin-3-one, 4 to 5 parts of phenyltriethoxysilane, 5 to 8 parts of soap powder, 5 to 9 parts of vinyltrimethoxysilane, 3 to 7 parts of didecyl dimethyl ammonium chloride, 5 to 7 parts of fatty acid diethanol amide, 2 to 4 parts of sodium citrate, 2 to 7 parts of sodium borate, 6 to 8 parts of polyoxyethylene oleate and 100 to 110 parts of water. The wood fabric finished by using the antibacterial finishing method of the wool fabric has a great bacteriostatic effect on various bacteria.

Owner:HUZHOU HONGXIN SILK FACTORY

Production method of environmentally friendly antifouling synthetic leather

ActiveCN105155291AImprove adsorption capacityIncrease cation exchange capacityFibre treatmentHazardous substanceBenzyltrimethylammonium chloride

The invention discloses a production method of environmentally friendly antifouling synthetic leather in order to solve the problems of residual toxic and harmful substances in present synthetic leather products, and harmfulness for environmental protection and the health of human bodies. The production method of the environmentally friendly antifouling synthetic leather comprises the steps of wet base production, dry dosing, dry surface lamination and antifouling treatment, bentonite is modified by benzyltrimethylammonium chloride, the obtained modified bentonite is used as a filler for producing a wet base, and the modified bentonite can effectively adsorb harmful substances in the synthetic leather products, so the synthetic leather produced through adopting the method is safe and environmentally-friendly. The surface of the synthetic leather produced in the invention is processed by an antifouling agent, and the surface of the processed synthetic leather has the characteristics of difficult dirt contamination and superior fouling resistance.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

High-strength water-resistant and mildew-proof glass cement

InactiveCN104910850AImprove mechanical propertiesImprove water resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCarbamateSodium Bentonite

The invention discloses high-strength water-resistant and mildew-proof glass cement, which is prepared from the following components in parts by weight: 60-64 parts of a silicane terminated polyurethane prepolymer, 7-9 parts of a plasticizer, 18-20 parts of talcum powder, 15-25 parts of kieselguhr powder, 4-8 parts of lithium-based bentonite, 8-10 parts of bamboo charcoal granule powder, 2-4 parts of -200-mesh cerium oxide powder, 1.2-1.4 parts of an antioxidant, 0.8-1.2 parts of an ultraviolet absorbent, 0.2-0.4 part of a thixotropic agent, 1-2 parts of benzimidazole carbamate, 1-2 parts of benzyltrimethylammonium chloride, 2.5-3.5 parts of an adhesion promoter and 0.2-0.4 part of a catalyst.

Owner:饶玉明

Decontamination solution and method

A chemical warfare agent decontamination solution made up of about 20% of a quaternary ammonium complex containing benzyltrimethylammoniumchloride and benzyltriethylammonium chloride and about 20% by weight of an oxidizer, dissolved in a solvent, such as water or glycol, is provided. This solution is a noncorrosive, nontoxic, nonflammable decontaminant, which may also be used to neutralize organophosphorus agricultural chemicals.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Production method of environmentally friendly leather imitation synthetic leather

ActiveCN105155292AImprove adsorption capacityIncrease cation exchange capacityFibre typesSodium BentoniteBenzyltrimethylammonium chloride

The invention discloses a production method of environmentally friendly leather imitation synthetic leather in order to solve the problems of residual toxic and harmful substances in present synthetic leather products, and harmfulness for environmental protection and the health of human bodies. The production method of the environmentally friendly leather imitation synthetic leather synthetic leather comprises the steps of wet base production, dry dosing, dry surface lamination and post-treatment, bentonite is modified by benzyltrimethylammonium chloride, the obtained modified bentonite is used as a filler for producing a wet base, and the modified bentonite can effectively adsorb harmful substances in the synthetic leather products, so the synthetic leather produced through adopting the method is safe and environmentally-friendly. The produced synthetic leather is post-treated by adopting a delustering agent, so the appearance and the hand feeling of the synthetic leather are improved, and the soft luster and the natural leather-like hand feeling are given to the synthetic leather.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

Anti-static finishing method for wool fabric

InactiveCN105696343AImprove antistatic performanceImprove antibacterial propertiesGrip property fibresAnimal fibresPolyvinyl alcoholPolyethylene glycol

The invention discloses an anti-static finishing method for wool fabric. The method comprises steps as follows: firstly, water is added to a finishing agent, an impregnation solution is prepared, then the fabric is placed into the impregnation solution for impregnation, the pick-up is 70%-80%, and finally, the fabric is washed with water 2-3 times, dehydrated and dried, wherein the finishing agent is prepared from components in parts by weight as follows: 20-25 parts of polyethylene glycol diamine, 12-15 parts of N-(phosphonomethyl)glycine isopropylamine salt, 6-9 parts of benzyltrimethylammonium chloride, 2-4 parts of sodium carboxymethyl starch, 10-14 parts of linolenic acid, 2-5 parts of acetone, 1-6 parts of acrylamide, 4-9 parts of common fibraurea stem powder, 3-6 parts of polyvinyl alcohol, 15-17 parts of styrene, 5-8 parts of sodium aliphatate, 3-6 parts of sodium citrate and 1-8 parts of aluminum sulfate. The finishing method is convenient to operate and environment-friendly, and the finished wool fabric has excellent ant-static and anti-bacterial performance, is high in washability and touches soft.

Owner:HUZHOU HONGXIN SILK FACTORY

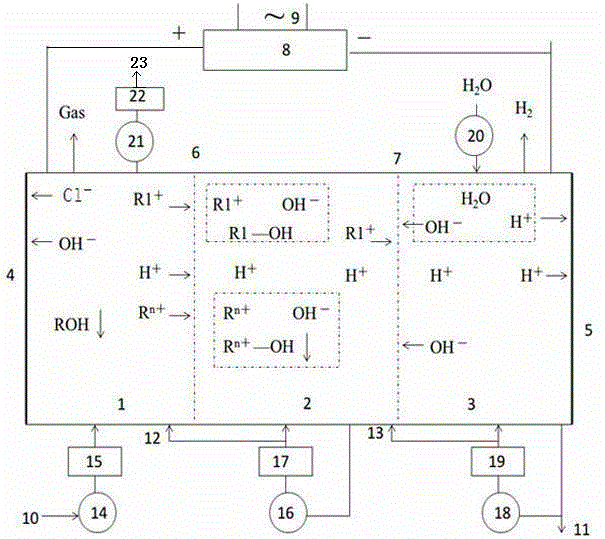

Method for preparing high-purity benzyltrimethylammonium hydroxide by carrying out continuous electrolysis by virtue of three chambers and two membranes

ActiveCN104630818ANot prone to lifeNot prone to performance drawbacksCellsChemical industryElectrolysisBenzyltrimethylammonium chloride

The invention discloses a method for preparing high-purity benzyltrimethylammonium hydroxide by carrying out continuous electrolysis by virtue of three chambers and two membranes. The method for preparing the high-purity benzyltrimethylammonium hydroxide by carrying out continuous electrolysis by virtue of the three chambers and two membranes comprises the following steps: enabling a 30-50% benzyltrimethylammonium hydroxide aqueous solution to enter an anode chamber from a raw material feeding hole, adding a 5-30% benzyltrimethylammonium hydroxide aqueous solution into an intermediate chamber, adding a 5-30% benzyltrimethylammonium hydroxide aqueous solution into a cathode chamber, opening all the circulating pumps, and turning on a power supply to switch on an anode plate and a cathode plate and carry out continuous electrolysis; and selecting by virtue of an anion membrane and continuously circulating and filtering to remove impurities, so that benzyltrimethylammonium hydroxide with high purity of 5-30% can be obtained. Concentration of each metal ion in the benzyltrimethylammonium hydroxide is less than 20ppb, concentration of each anion is less than 1ppm, product purity is high, current efficiency is 61-72%, utilization rate of electrical energy is high, energy is saved, and product conversion ratio is more than 98%.

Owner:赵文洲

Preparation of vinyl benzyl trimethyl ammonium chloride-modified carbon fibre adsorbent

InactiveCN105749868AGood physical and chemical stabilityHigh mechanical strengthFatty/oily/floating substances removal devicesOther chemical processesFiberCarbon fibers

The invention discloses a preparation method for a vinyl benzyl trimethyl ammonium chloride-modified carbon fibre adsorbent. The preparation method comprises the following steps: first, performing an oxidation treatment on carbon fibres by adopting a mixed solution of concentrated hydrochloric acid and hydrogen peroxide; then, performing acylchlorination modification on the oxidized carbon fibres by adopting thionyl chloride; later on, adding 50 to 58 mass percent of water, 20 to 28 mass percent of vinyl benzyl trimethyl ammonium chloride, 18 to 24 mass percent of acylchlorinated carbon fibres and 1.0 to 2.0 mass percent of potassium permanganate into a reactor, wherein the sum of the percentage of various components is 100 percent; finally, keeping a constant temperature of 75+ / -2 DEG C, stirring, refluxing and reacting for 6 to 8 hours, cooling, washing with water until the filtrate is neutral, performing solid-liquid separation, and drying to obtain the vinyl benzyl trimethyl ammonium chloride-modified carbon fibre adsorbent. The absorbent has high stability, high adsorption capacity and high reuse frequency, and is low in cost and environment-friendly.

Owner:UNIV OF JINAN

Preparation method of high-strength water-resistant mildewproof glass cement

InactiveCN104893646AImprove mechanical propertiesImprove water resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCarbamateAntioxidant

The invention discloses a preparation method of high-strength water-resistant mildewproof glass cement, which comprises the following steps: preparing a silane-terminated polyurethane prepolymer, proportionally mixing with talcum powder, diatomite powder, lithium bentonite, bamboo charcoal granular powder, -200-mesh cerium oxide, an antioxidant, an ultraviolet absorbent, a plasticizer, a thixotropic agent, benzimidazole carbamate and benzyltrimethylammonium chloridem and adding a binding accelerator and a catalyst. The glass cement is formed by mixing the following components in parts by mass: 60-64 parts of silane-terminated polyurethane prepolymer, 7-9 parts of plasticizer, 18-20 parts of talcum powder, 15-25 parts of diatomite powder, 4-8 parts of lithium bentonite, 8-10 parts of bamboo charcoal granular powder, 2-4 parts of -200-mesh cerium oxide powder, 1.2-1.4 parts of antioxidant, 0.8-1.2 parts of ultraviolet absorbent, 0.2-0.4 part of thixotropic agent, 1-2 parts of benzimidazole carbamate, 1-2 parts of benzyltrimethylammonium chloride, 2.5-3.5 parts of binding accelerator and 0.2-0.4 part of catalyst.

Owner:饶玉明

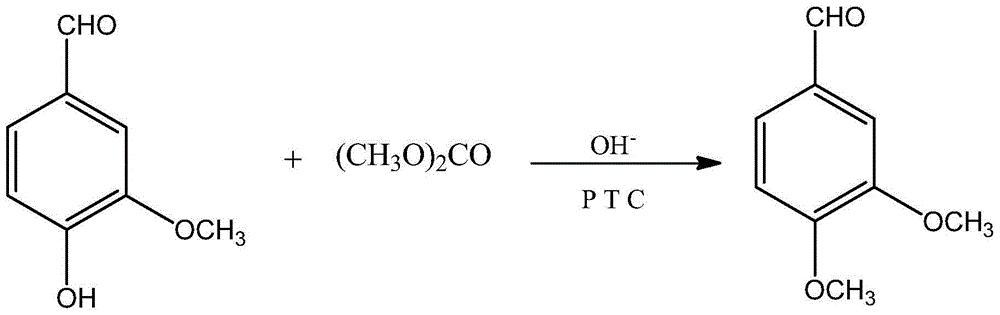

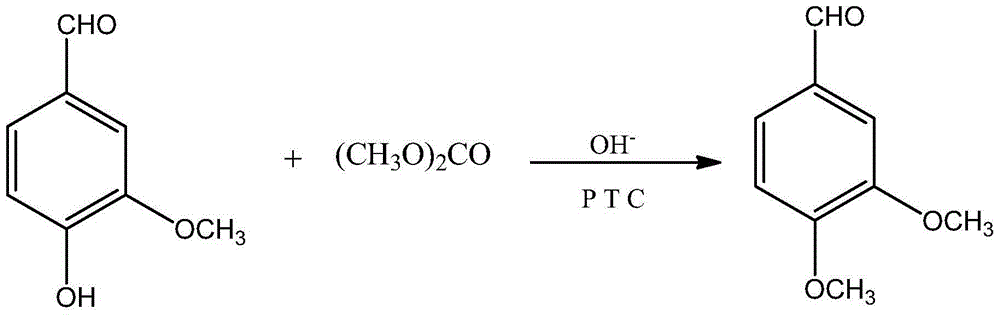

Veratraldehyde preparation method

InactiveCN105622377AYield flatEasy to operateOrganic compound preparationCarbonyl compound preparationSodium acetatePolyethylene glycol

The invention relates to a veratraldehyde preparation method. The method is characterized in that under alkaline condition, vanillin and dimethyl carbonate are subjected to a phase-transfer catalytic reaction, a reaction equation is shown in a specification, wherein, a weight ratio of a phase-transfer catalyst to vanillin is 0.85:1 to 1.27:1, a weight ratio of dimethyl carbonate to vanillin is 2.96:1 to 8.89:1, content of the obtained veratraldehyde is 97-99%, the phase-transfer catalyst can be tetrabutylammonium chloride, tetrabutylammonium bromide, polyethylene glycol, and benzyltrimethylammonium chloride, alkali selects potash, sodium carbonate or sodium acetate, the reaction temperature is 20-120 DEG C, and reaction time is 10-100 hours. Compared with a traditional method, the method has the advantages of no toxicity and environmental protection, and is suitable for industrial production.

Owner:SHANGHAI AIPU VEGETABLE TECH +1

Scouring resistant alloy steel anticorrosive paint and preparation method thereof

InactiveCN106189815AUniform particlesFine grainAnti-corrosive paintsMetallic material coating processesEpoxyALUMINUM STEARATES

The invention discloses scouring resistant alloy steel anticorrosive paint. The scouring resistant alloy steel anticorrosive paint is prepared from the following raw materials in parts by weight: 0.5-1 part of sodium borate, 2-3 parts of polyisobutylene, 1-2 parts of butylmercaptooxo-stannane, 0.1-0.4 part of 2-mercaptobenziMidazole, 50-60 parts of aniline, 30-40 parts of pyrrole, 7-9 parts of sulphosalicylic acid, 3-4 parts of epoxy resin E51, 1.3-2 parts of ammonium persulfate, 4-6 parts of molybdic acid, 3-5 parts of polyamide resin, 160-170 parts of n-butanol, 20-30 parts of ethylene glycol monobutyl ether, 2-3 parts of ammonium metaboragte, 0.7-1 part of alkenyl succinic anhydride, 1-2 parts of hydroxyethyl acrylate, 0.8-2 parts of benzyltrimethylammonium chloride and 0.6-1 part of aluminum stearate. The paint disclosed by the invention can form a hard paint film on a base material, and has good scouring resistance.

Owner:TIANCHANG YINHU PAINT

Preparation method of environment-protective skin-feel synthetic leather

InactiveCN105133365AImprove adsorption capacityIncrease cation exchange capacityTextiles and paperAfter treatmentSodium Bentonite

The invention discloses a preparation method of environment-protective skin-feel synthetic leather and aims to overcome the problems that synthetic leather in the prior art has residual toxic and harmful substances and has adverse effect on environment protection and human body health. The preparation method of the environment-protective skin-feel synthetic leather includes four steps of wet-method base preparation, dry-method material blending, dry-method surface pasting and after treatment. In the invention, benzyltrimethyl ammonium chloride modified bentonite is employed as a filling material for preparing the wet-method base. The modified bentonite can effectively adsorb harmful substances in the synthetic leather, so that the synthetic leather is more environment-protective. Meanwhile, the surface of the synthetic leather is treated through a skin-feel treatment agent, so that the surface of the synthetic leather has a unique skin-like hand feel.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

Sewage flocculating agent and preparation method thereof

InactiveCN107963700AStrong decontaminationGood removal effectWater/sewage treatment by flocculation/precipitationSewageBenzyltrimethylammonium chloride

The invention relates to a sewage flocculating agent and a preparation method thereof. The flocculating agent comprises the following components: acrylamide, diatom, titanium tetrachloride, mercaptosuccinic acid-modified starch, sodium hydroxide, chitosan, polymerized iron oxide, walnut shell powder, and benzyltrimethylammonium chloride. The decontamination capability of the flocculating agent isobviously better than the flocculating agents in the prior art, compared with the prior art, the flocculating agent provided by the invention has the advantages of good COD and BOD removal effect as well as low cost, and the product is environmentally friendly and degradable.

Owner:侯英

Crease-resistant finishing method for wool fabric

InactiveCN105568666AImprove wrinklesGuaranteed wrinkle resistanceWrinkle resistant fibresGrip property fibresEthylenediamineSilanes

The invention discloses a crease-resistant finishing method for wool fabric. The method comprises the following steps: firstly adding water to a finishing agent to prepare an impregnating solution, then putting the fabric in the impregnating solution for padding, wherein pick up ratio is 7o to 80 percent; finally, washing for 2 to 3 times, and dewatering and drying; the finishing agent is prepared from the following components in parts by weight: 48 to 58 parts of water, 20 to 30 parts of ethylene glycol monobutyl ether acetate, 3 to 6 parts of sodium fluorosilicate, 3 to 6 parts of chitosan, 3 to 6 parts of N-phenyl-2-naphthylamine, 4 to 7 parts of sodium ethylenediamine tetracetate, 4 to 6 parts of barium sulfate, 3 to 7 parts of methyl cyclosiloxane, 4 to 8 parts of vinyl trimethoxy silane, 3 to 7 parts of benzyltrimethylammonium chloride, 4 to 8 parts of N,N-nickel dibutyldithiocarbamate, 1 to 6 parts of acrylamide and 13 to 20 parts of ammonium polyphosphate. The finishing method disclosed by the invention is used for crease-resistant finishing processing of the wool fabric, and while a crease-resistant effect is ensured, a problem that wool fabric is easy to crease in the past is improved; moreover, the wool fabric is high in washability and soft in handfeel.

Owner:HUZHOU HONGXIN SILK FACTORY

Preparation method of environmentally-friendly powder wax synthetic leather

InactiveCN105178046AImprove adsorption capacityIncrease cation exchange capacityPolyurea/polyurethane coatingsTextiles and paperWaxHazardous substance

The invention discloses a preparation method of environmentally-friendly powder wax synthetic leather and aims to overcome the problem that existing synthetic leather products contain residual toxic and hazardous compounds and are not beneficial to environmental protection and human health. The preparation method of the environmentally-friendly powder wax synthetic leather comprises four steps, namely wet-process base preparation, dry-process batching, dry-process overlaying and postprocessing. According to the invention, benzyltrimethyl ammonium chloride is used to modify bentonite, and the modified bentonite is used as a filler for the wet-process base preparation. The modified bentonite can effectively adsorb harmful substances in a synthetic leather product. The synthetic leather prepared by the above method is safer and more environmentally-friendly. Meanwhile, micronized polyethylene waxes are also used in postprocessing the prepared synthetic leather, thus endowing the surface of the synthetic leather with properties such as smoothness, abrasion resistance, scratch resistance and the like.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

Bactericidal agent for water injection well and preparation method and application of bactericidal agent

InactiveCN107751230ANot volatileNot easy to decomposeWaste water treatment from quariesBiocidePolyhexamethylene guanidineBenzyltrimethylammonium chloride

The invention discloses a bactericidal agent for a water injection well and a preparation method and application of the bactericidal agent, and belongs to the field of oilfield reinjection water. Thebactericidal agent for the water injection well is prepared from, by mass, 14.6-26.3% of quaternary ammonium salt bactericide, 4.9-13.2% of aldehyde bactericide, 0.9-3.4% of guanidine bactericide, 0.5-3% of isothiazolinone and the balance water. The quaternary ammonium salt bactericide refers to dodecyl dimethyl benzyl ammonium chloride and / or dodecyl benzyl trimethyl ammonium chloride; the aldehyde bactericide refers to glutaraldehyde; the guanidine bactericide refers to guanidine sulfate and / or polyhexamethylene guanidine. The provided bactericidal agent for the water injection well is smallin toxicity, not easy to volatilize and difficult to decompose and has the advantages of being good in chemical stability, long in sterilization time, free of secondary pollution and the like.

Owner:PETROCHINA CO LTD

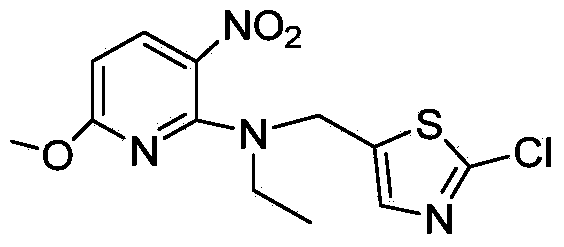

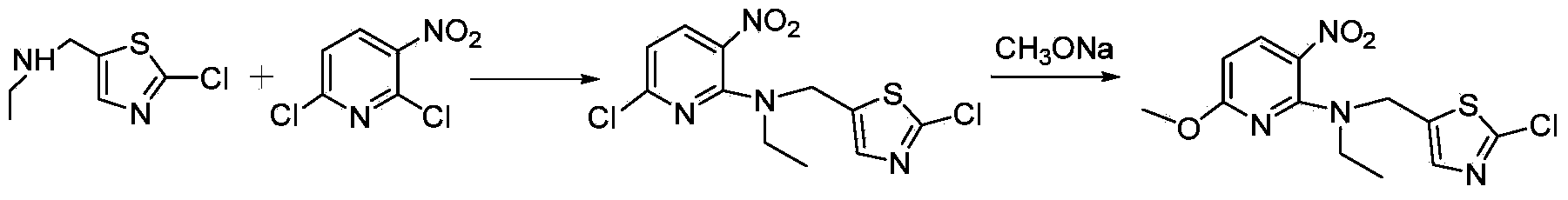

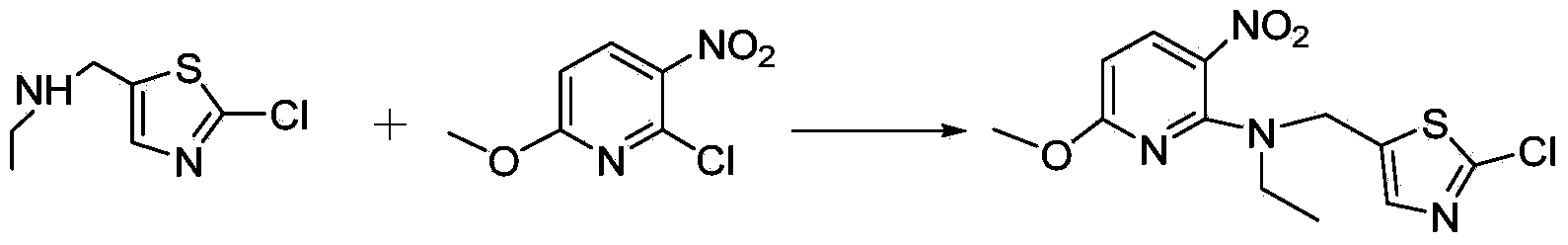

Preparation method of thiazole methylamino pyridine compound

The invention discloses a method for synthesizing a thiazole methylamino pyridine compound 6-methoxy-N-((2-chlorothiazol-5-yl)methyl)-N-ethyl-3-nitropyridin-2-amine. According to the method, 2-chloro-5-ethylaminemethylthiazol and 2-chloro-6-methoxy-3-nitropyridine are used as raw materials; toluene is adopted as a solvent; a sodium hydroxide water solution is used as an acid-binding agent; and the synthesis is carried out under the effect of a catalyst tetrabutyl ammonium bromide, or benzyltrimethyl ammonium chloride, or benzyltriethyl ammonium chloride, or tetraethyl ammonium bromide, or tetrabutyl ammonium iodide. A chemical reaction formula is shown below. According to the invention, the acid-binding agent and the reaction solvent are changed, and the catalyst is added, such that reaction is full and complete, reaction speed is greatly improved, reaction time is shortened, reaction yield is improved, and product purity is improved. The process is simple to operate. Post-treatments of the novel solvent toluene and the acid-binding agent sodium hydroxide water solution are simple, and the solvent and the acid-binding agent are easy to recycle. With the method, three-waste amount is low, production cost is reduced, and industrialized application value is high.

Owner:湖南海利常德农药化工有限公司

High-yield synthesis method of n-ethyl-p-menthane-3-carboxamide

InactiveCN103694130AStrong cool tasteCool and deliciousOrganic compound preparationCarboxylic acid amides preparationPtru catalystPhosphoric acid

The invention discloses a high-yield synthesis method of n-ethyl-p-menthane-3-carboxamide. The method comprises the following steps: (1) adding a tetrahydrofuran solvent, phosphorus pentachloride and a composite catalyst into a container, fully stirring, dissolving L-menthol by the tetrahydrofuran solvent, and preparing L-chlorinated menthol; (2) heating and washing methylbenzene, L-chlorinated menthol, NaCN and a phase transfer catalyst-benzyltrimethylammonium chloride, distilling to obtain methylbenzene at first and then performing reduced pressure distillation to obtain L-menthyl nitrile; (3) performing heating reflux by polyphosphoric acid, triethyl phosphate and menthyl nitrile at 140 DEG C for 5 hours, cooling, adding distilled water, neutralizing to be neutral by a sodium hydroxide solution, extracting by ethyl ether, drying an organic phase by anhydrous magnesium sulfate, rotationally evaporating to remove the solvent, and re-crystallizing by acetone-water to obtain a finished product. According to the method, the menthyl nitrile intermediate yield is relatively high, a synthetic process is more reasonable, the comprehensive yield of the finished product can reach 75%, and the obtained finished product is relatively high in cool degree.

Owner:丁铁梅

Preparing method for veratrole

ActiveCN106518631ASimple processEther preparation by ester reactionsOil phaseBenzyltrimethylammonium chloride

The invention discloses a preparing method for veratrole. In the method, catechol and dimethyl carbonate are taken as raw materials and are subjected to reaction under a catalyst condition to produce veratrole. The method comprises the following specific progress: under the temperature condition of 0-5 DEG C, adding catechol and diethyl carbonate into a water solution, starting stirring and adding a catalyst, gradually heating to 100 DEG C, controlling the reaction system at a pH of 8-9 during reaction and then continuing to heat to reflux; after reflux is finished, performing standing and layering, adding liquid caustic soda into the oil phase, and performing washing, so as to obtain crude oil; and at last performing reduced-pressure distilling on the crude oil, so as to obtain a pure product veratrole. The catalyst is benzyltrimethylammonium chloride. The yield of veratrole prepared by the method is as high as 99% or more and the purity is as high as 99.5% or more. Furthermore, the whole manufacturing technique has the characteristics of low cost, environment friendliness and cleanness and safety.

Owner:ZHANG JIA GANG VINSCE BIO PHARM

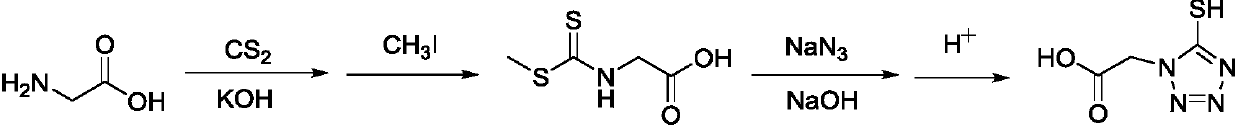

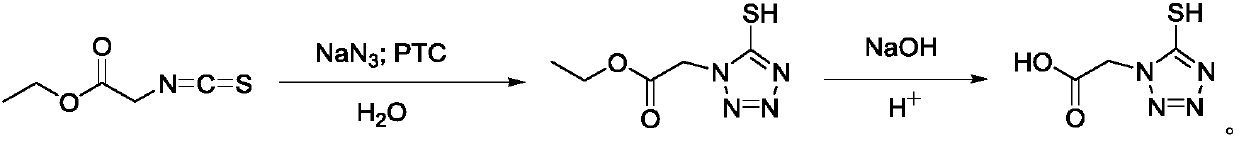

5-tetrazole-thione acetic acid and preparation method of sodium salt thereof

The invention discloses a preparation method of 5-tetrazole-thione acetic acid. Sodium azide, benzyl trimethyl ammonium chloride and water are added into a three-mouth flask of 500mL, and ethyl acetate for an ethyl isothiocyanatoacetate reaction system is dropwise for extraction; organic phases are mixed, and a solvent is spin-dried to obtain a crude 5-tetrazole-thione acetic acid product; the obtained crude 5-tetrazole-thione acetic acid product is heated, dissolved and clarified, and activated carbon is added and stirred; a filter cake is subjected to vacuum drying to obtain the product 5-tetrazole-thione acetic acid. The preparation method has the advantages that a poisonous reagent methyl iodide is omitted in the synthesis of the 5-tetrazole-thione acetic acid and sodium salt thereof according to the above steps, the yield of the whole 5-tetrazole-thione acetic acid synthesis method is as high as 80%, and the single-step yield of the mono-sodium salt and disodium salt of the 5-tetrazole-thione acetic acid is as high as 90%. By adopting the method, the process cost is greatly reduced, and a feasible way is provided for industrialized production of the5-tetrazole-thione acetic acid.

Owner:九江中星医药化工有限公司

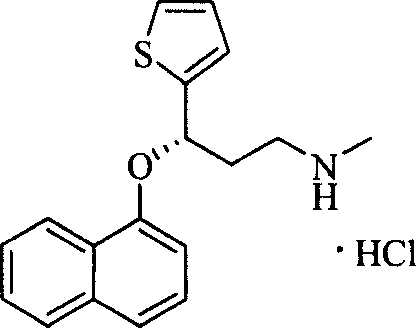

Method of preparing dulouxetine

InactiveCN101012219AShort reaction stepsEasy to operateOrganic chemistryPotassium hydroxide1-Propanol

The invention discloses a making method of donosidine and isomer in the preparing technique of drug composition to treat depression, which comprises the following steps: adding (S)-3-methylamino-1-(2-thiophene)-1-propanol or (R)-3-methylamino-1-(2-thiophene)-1-propanol or racemic 3-methylamino-1-(2-thiophene)-1-propanol in the solvent of N, N-dimethyl formamide or dimethyl sulfoxide; adding sodium hydroxide or potassium hydroxide; adding 1-flutenal or adding benzyl trimethyl amchlor or benzyl triethyl amchlor as phase transfer catalyst in the reacting system; reacting 0.5-24h under 30-150 deg.c; adjusting pH value to 3.0; cooling reacting material; adding water and dichloromethane to do phase separation; evaporating partial organic solvent; adjusting pH value to 3.0; obtaining (S)-(+)-N-methyl-3-(1-naphthoxy)-3-(2-thiophene)-1-propanamine hydrochlorate, (R)-N-methyl-3-(1-naphthoxy)-3-(2-thiophene)-1-propanamine and N-methyl-3-(1-naphthoxy)-3-(2-thiophene)-1-propanamine.

Owner:TIANJIN UNIV

Method for synthesizing methyl cinnamate based on eutectic solvent catalyst

PendingCN112552172AEasy to prepareLess corrosiveOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystP-Toluenesulfonic acid

The invention discloses a method for catalytically synthesizing methyl cinnamate by adopting a benzyltrimethylammonium chloride eutectic solvent, which comprises the following steps of: performing esterification reaction by taking an acidic eutectic solvent benzyltrimethylammonium chloride p-toluenesulfonic acid (BTAC-PTSA) as a catalyst and cinnamic acid and methanol as raw materials; and carrying out phase separation, neutralization, crystallization purification and other processes to obtain methyl cinnamate. The eutectic solvent used in the invention has an atom utilization rate of 100% inthe preparation process, and has the advantages of mild reaction conditions, small corrosivity to equipment, easy recovery, reusability and the like compared with traditional catalysts such as sulfuric acid and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Water-resistant silicon sealant

InactiveCN106047260AImprove water resistanceGood anti-mildew effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesBenzoyl peroxideCarbamate

The invention discloses water-resistant silicon sealant. The water-resistant silicon sealant comprises, by weight, 15-20 parts of silane-terminated polyurethane prepolymers, 7-9 parts of talc powder, 12-14 parts of diatomaceous earth powder, 5-7 parts of lithium base bentonite, 4-6 parts of bamboo charcoal particle powder, 5-7 parts of benzimidazole carbamate, 3-5 parts of benzyltrimethylammonium chloride, 32-36 parts of water glass, 8-11 parts of organic silicon resin, 9-11 parts of acrylic resin, 9-10 parts of titanium dioxide powder and 6-8 parts of benzoyl peroxide. The water-resistant silicon sealant has the advantages of good water resistance and mildew resistance, difficulty in falling, high adhesion and zero cracking.

Owner:青岛燕园海洋生物科技有限公司

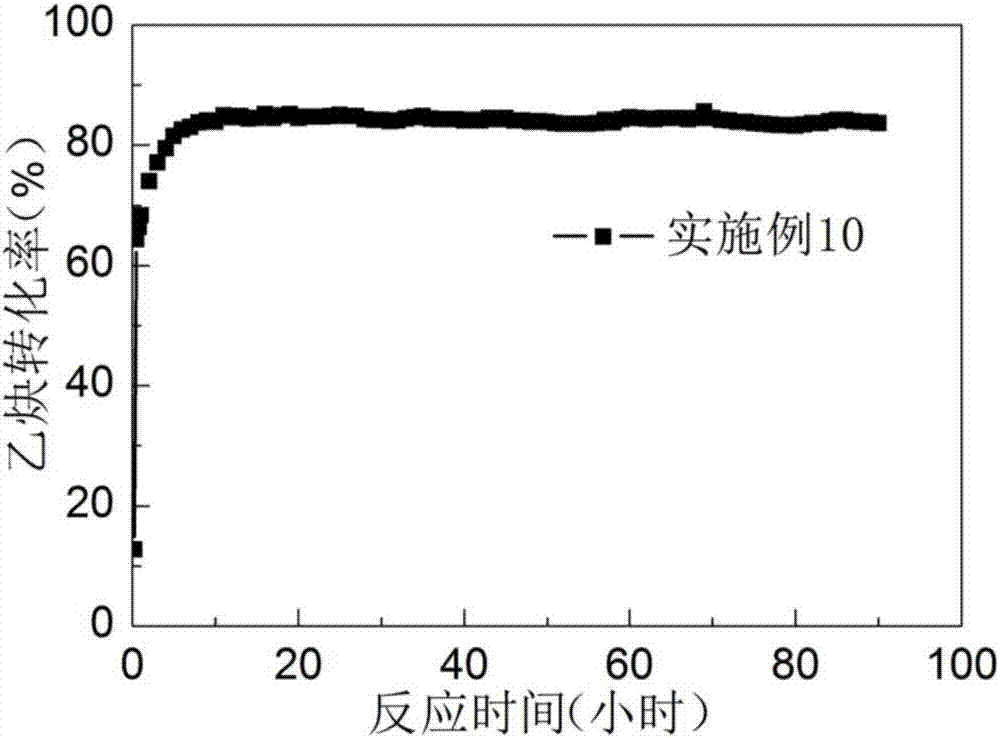

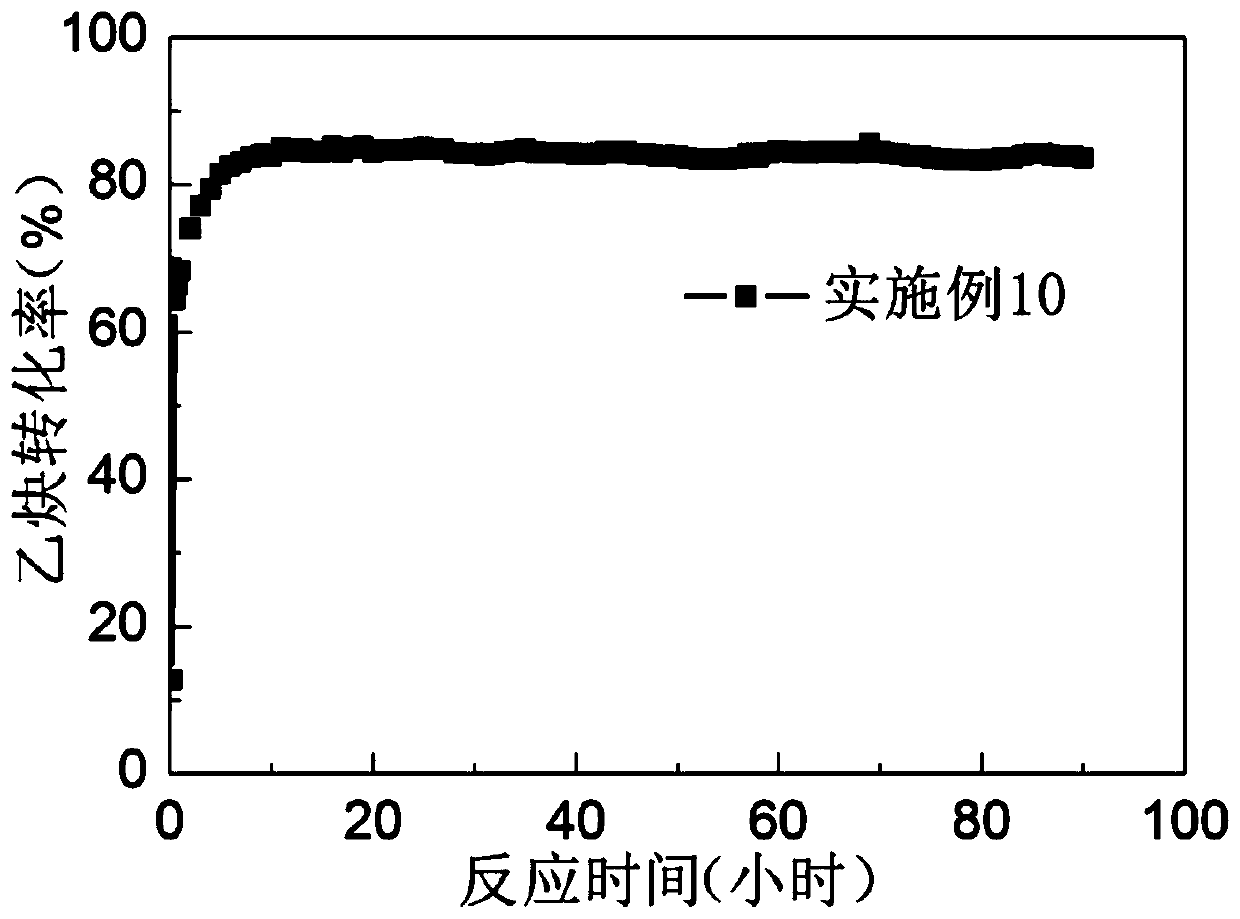

A copper-based catalyst for acetylene hydrochlorination with high activity and stability

ActiveCN107008465BLow costLow toxicityPhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystPhosphate

The invention relates to a copper-based catalyst with high activity and stability for acetylene hydrochlorination. According to the copper-based catalyst, a copper salt is taken as an active component, wherein the copper salt is selected from one or more of copper chloride, copper nitrate, copper sulfate and copper phosphate. The copper-based catalyst is characterized in that a stabilizer is introduced into the copper-based catalyst; and the stabilizer is selected from one or more of guanidine hydrochloride, tetramethylethylenediamine hydrochloride, tetramethylammonium chloride, tetraethylammonium chloride, benzyltrimethylammonium chloride, benzyl triethyl ammonium chloride, tetramethyl phosphorus chloride, tetrabutyl phosphorus chloride, methyl triphenyl phosphorus chloride and 1-butyl triphenylphosphonium. Through introducing the stabilizer has the advantages of being low in cost, low in toxicity, good in heat stability and small steam pressure into the catalyst, and the stability of the copper-based catalyst for acetylene hydrochlorination is significantly improved.

Owner:TSINGHUA UNIV

Antibacterial finishing method of silk fabric

InactiveCN105696344AImprove antibacterial propertiesHigh inhibition rateAnimal fibresPalmitatesStaphylococcus aureus

The invention discloses an antibacterial finishing method for silk fabrics. The method comprises the following steps: first adding water to the finishing agent to prepare an impregnating solution, then putting the fabric into the impregnating solution for padding, with a residual rate of 70-80%, and finally washing with water for 2 -3 times, it can be dehydrated and dried; the finishing agent is composed of the following components in parts by weight: 10-15 parts of polyoxyethylene ether, 3-8 parts of sodium polystyrene sulfonate, 2-methyl-4 - 15-20 parts of isothiazolin-3-one, 1-3 parts of oleoyl amino acid sodium, 3-6 parts of benzyltrimethylammonium chloride, 2-6 parts of sodium xylenesulfonate, 2-6 parts of starch ether 10-20 parts of propylene glycol, 3-6 parts of chitosan, 5-8 parts of isooctyl palmitate, 1-6 parts of acrylamide, 5-8 parts of vinyltrimethoxysilane, 2-7 parts of borax and 55-65 parts of deionized water. The silk fabric finished by the invention has good antibacterial performance, especially high inhibition rate to Escherichia coli and Staphylococcus aureus, can reduce the probability of people getting sick due to microorganisms attached to the fabric, and meet people's living needs.

Owner:HUZHOU HONGXIN SILK FACTORY

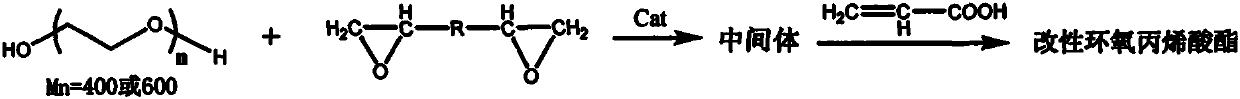

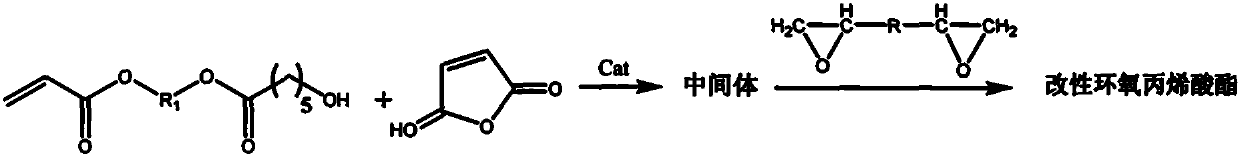

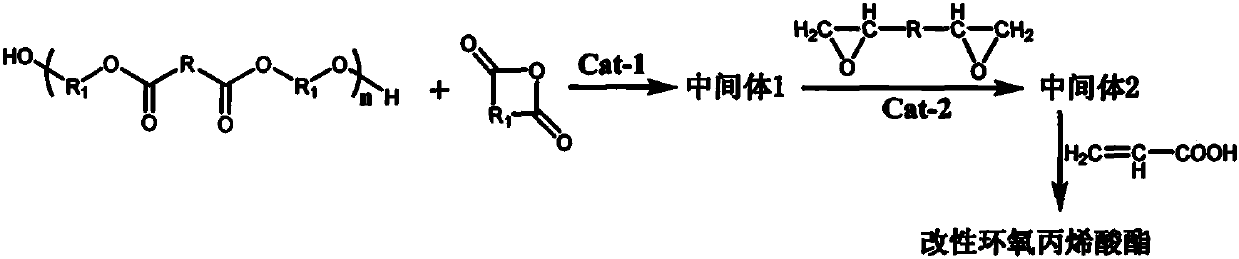

Method for preparing modified propylene oxide ester

The invention discloses a method for preparing modified propylene oxide ester, which comprises the following steps: (1) reacting polyester polyol with acid anhydride at 60-90 DEG C for 1-2 hours underthe action of 4-dimethylaminopyridine to synthesize carboxyl-terminated polyester polyol, namely an intermediate 1; (2) reacting the intermediate 1 with epoxy resin for 1-2 hours at 80-100 DEG C under the action of a catalyst 1 to prepare polyester polyol toughened and modified epoxy resin, namely an intermediate 2; wherein the catalyst 1 is one of triethylamine, N,N-dimethylaniline and pyridine;(3) reacting the intermediate 2 with acrylic acid for 5-7 hours at 100-120 DEG C under the action of a polymerization inhibitor and a catalyst 2 to prepare modified epoxy acrylate; and wherein the catalyst 2 is one or a combination of tetraethylammonium bromide, benzyl trimethyl ammonium chloride and triphenylphosphine. After the modified epoxy propylene ester prepared by the method is cured, theflexibility of a film is good.

Owner:LIMING RES INST OF CHEM IND

Anti-mite finishing method for silk fabrics

InactiveCN105648764AGood avoidance effectLong term contactBiochemical fibre treatmentAnimal fibresMethacrylateSilanes

The invention discloses an anti-mite finishing method for silk fabrics. The anti-mite finishing method includes steps of adding finishing agents into water to prepare aqueous solution; spraying the aqueous solution on the surfaces of the fabrics by the aid of high-pressure spraying processes; drying the fabrics. The finishing agents comprise, by weight, 5-6 parts of sodium alginate, 4-8 parts of trimethoxysilyl propyl methacrylate, 5-10 parts of vinyl versatate, 3-6 parts of silicon dioxide, 2-4 parts of benzyltrimethylammonium chloride, 4-8 parts of sodium citrate, 2-6 parts of potassium oxalate, 3-7 parts of didecyl dimethyl ammonium chloride, 2-6 parts of sodium xylene sulfonate, 7-11 parts of vinyl trimethoxy silane, 10-12 parts of talc powder and 15-20 parts of 2-methyl-4-isothiazolines biocide-3-ketone. The anti-mite finishing method has the advantages that the silk fabrics finished by the aid of the anti-mite finishing method are excellent in avoidance performance for dust mites, gamasid mites and chigger mites; the fabrics are safe and are free of allergy even if the fabrics are in contact with the skin surfaces of users for a long time, and accordingly comfortable family life environments can be created for people.

Owner:HUZHOU HONGXIN SILK FACTORY

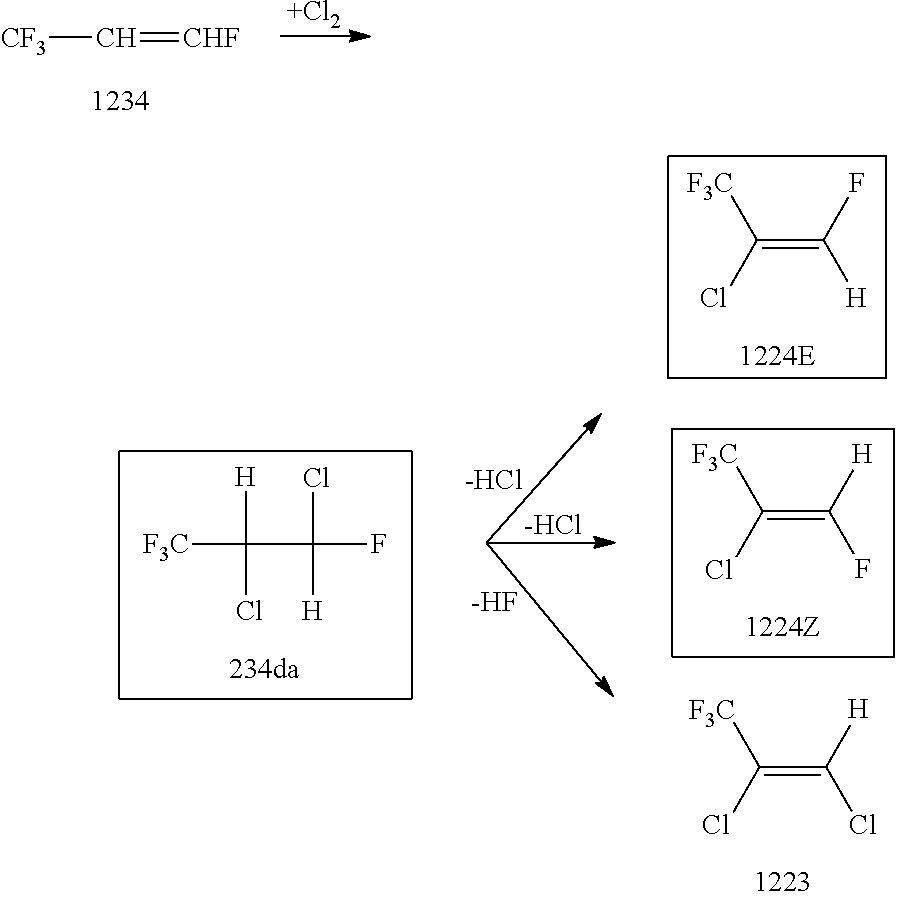

Method for Producing 2-Chloro-1,3,3,3-Tetrafluoropropene

ActiveUS20160023968A1Efficient productionSuppress generationPreparation by hydrogen halide split-offOrganic-compounds/hydrides/coordination-complexes catalysts1,3,3,3-TetrafluoropropeneChloride

A production method of 2-chloro-1,3,3,3-tetrafluoropropene (1224) according to the present invention includes bringing 2,3-dichloro-1,1,1,3-tetrafluoropropane (234da) into contact with an inorganic base having a pKa of 4.8 or greater in an aqueous medium in the presence of a phase transfer catalyst. Preferably, the inorganic base has a pKa of 10 or greater. Further, the phase transfer catalyst is preferably at least one selected from the group consisting of tetrabutylammonium bromide, methyltri-n-octylammonium chloride, benzyltrimethylammonium chloride and tetraethylammonium chloride. It is possible by this method to selectively produce 1224 from 234da.

Owner:CENT GLASS CO LTD

Aluminum sol furniture coating and preparation method thereof

InactiveCN105969111AIncrease crosslink densityHigh tensile strengthPolyester coatingsCross-linkStearic acid

The invention discloses an aluminum sol furniture coating, which is composed of the following raw materials: calcium chloride, aluminium isopropoxide, N-ethyl-p-toluenesulfonamide, diphenyl methane diisocyanate, tung oil, sodium hydroxide, methanol, perfluorosulfonate resin, acetic acid, 26-30% hydrogen peroxide, tetraethyl orthosilicate, Y-chloropropyltrimethoxysilane, unsaturated polyester resin, methylethyl ketone peroxide, montmorillonite powder, tert-butylhydroquinone, stearic acid, phthalic anhydride, benzyltrimethylammonium chloride, fatty alcohol polyoxyethylene ether ammonium sulfate and a cross-linking agent taic. By using aluminium isopropoxide as an aluminium source, the obtained aluminium sol can effectively improve compatibility of all the raw materials, and stability strength of a film of the finished product is boosted.

Owner:丁顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com