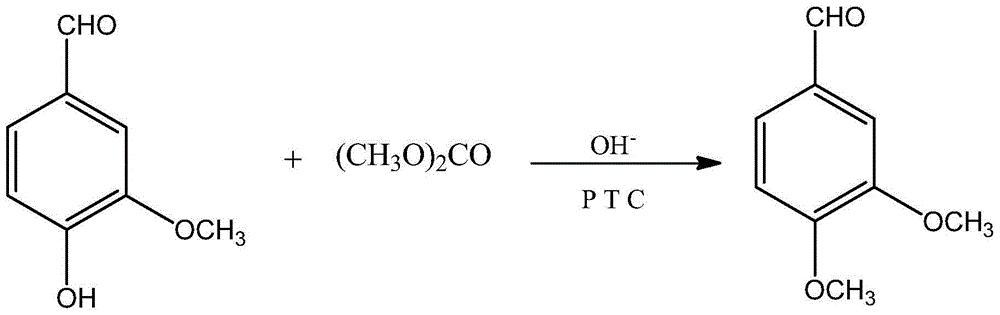

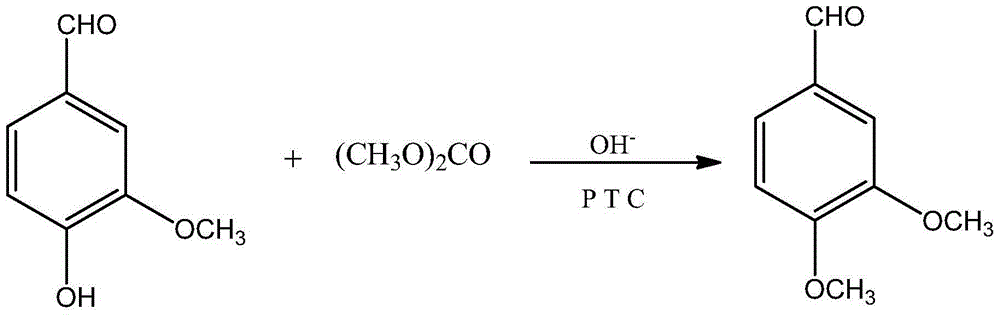

Veratraldehyde preparation method

A technology of veratraldehyde and vanillin, which is applied in the field of preparation of veratraldehyde, can solve the problems of residues, environmental pollution, and inapplicability to industrial production, and achieve the effects of flat yield, environmental friendliness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In the 1000ml three-necked flask equipped with stirring, condenser, thermometer, add 50.6 grams of vanillin, 300 grams of dimethyl carbonate (dimethyl carbonate: vanillin weight ratio is 5.93:1), 46 grams of potassium carbonate and 53.6 gram of tetrabutylammonium bromide (tetrabutylammonium bromide:vanillin weight ratio is 1.06:1), reflux reaction for about 40 hours (about 88 ℃), cooling, add 200ml of clear water to dissolve the solid in the bottle, After decanting, the layers were separated, the aqueous layer was extracted once with toluene, the extract was combined with the upper layer, and washed three times with 200ml salt water until the pH value was neutral. After the solvent was recovered, it was distilled under reduced pressure to obtain 52.32 grams of veratraldehyde with a content of 99.2%, the yield is 94.68%.

Embodiment 2

[0014] In the 1000ml there-necked flask equipped with a condenser, a thermometer adds 50.6 gram of vanillin, 150 gram of dimethyl carbonate (dimethyl carbonate: vanillin weight ratio is 2.96:1), 36.8 gram of potassium carbonate and 43 gram of tetrabutylammonium bromide, reflux for about 30 hours (about 88°C), cool, add 200ml of water to dissolve the solid in the bottle, pour it out and separate the layers, extract the water layer with toluene once, and combine the extract with the upper layer , washed three times with 200ml salt water, washed to a neutral pH value, after recovering the solvent, distilled under reduced pressure to obtain 46.2 grams of veratraldehyde, the content was 99.1%, and the yield was 83.6%.

Embodiment 3

[0016] In the 1000ml there-necked flask equipped with stirring, condenser, thermometer, add 50.6 grams of vanillin, 450 grams of dimethyl carbonate (dimethyl carbonate: vanillin weight ratio is 8.89:1), 55.25 grams of potassium carbonate and 64.4 gram of tetrabutylammonium bromide, reflux for about 50 hours (about 88°C), cool down, add 200ml of clear water to dissolve the solid in the bottle, pour it out and separate the layers, extract the water layer once with toluene, and combine the extract with the upper layer , washed three times with 200ml salt water, washed to a neutral pH value, after recovery of the solvent, vacuum distillation to obtain 50.71 grams of veratraldehyde, the content is 99.12%, and the yield is 91.77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com