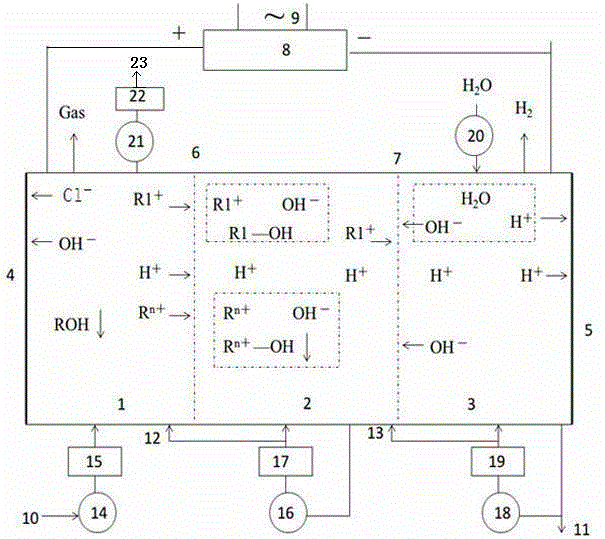

Method for preparing high-purity benzyltrimethylammonium hydroxide by carrying out continuous electrolysis by virtue of three chambers and two membranes

A technology of benzyltrimethylammonium hydroxide and high-purity benzyltrimethyl is applied in electrolysis process, electrolysis components, electrolysis organic production and other directions, which can solve the problem of difficult large-scale safe production, low product purity and poor yield. Advanced problems, to achieve the effect of improving current efficiency and product conversion rate, reducing energy consumption, improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] At a temperature of 25°C, add a 30% benzyltrimethylammonium chloride solution into the anode compartment 1, and the current density is 800A / m 2 , after the electrolysis reaction, the middle chamber 2 and the cathode chamber 3 have a concentration of 25% benzyltrimethylammonium hydroxide. The concentration of each metal ion in the product is less than 20 ppb, and the chloride ion is less than 1ppm (see Table 1); the current efficiency is 61%, and the product conversion rate is 98.2%.

Embodiment 2

[0038] At 25°C, add a 50% benzyltrimethylammonium chloride aqueous solution into the anode chamber 1, and use a current density of 1500 A / ㎡. After the electrolysis reaction, the concentration of the middle chamber 2 and the cathode chamber 3 is 25%. benzyltrimethylammonium hydroxide. The concentration of each metal ion in the product is less than 20 ppb, and the chloride ion is less than 1ppm (see Table 1); the current efficiency is 63%, and the product conversion rate is 98.3%.

Embodiment 3

[0040] At a temperature of 50°C, add a 50% benzyltrimethylammonium chloride aqueous solution into the anode chamber 1, and the current density is 1500 A / m 2 , after the electrolysis reaction, the middle chamber 2 and the cathode chamber 3 have a concentration of 25% benzyltrimethylammonium hydroxide. The concentration of each metal ion in the product is less than 20 ppb, and the chloride ion is less than 1ppm (see Table 1); the current efficiency is 69%, and the product conversion rate is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com