Method for reducing anions in quaternary ammonium base by virtue of continuous electrolysis

A technology of quaternary ammonium base and anion, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems that the purification process cannot be continuously produced in small batches, and the concentration of anions is high, so as to improve product conversion rate, reduce safety accidents, Effects of Safety and Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

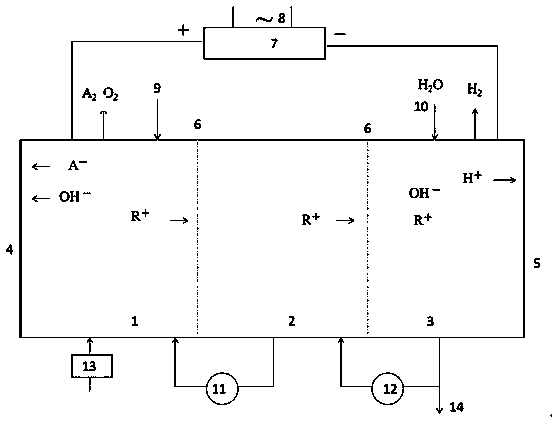

[0039] Add 25% tetrabutylammonium hydroxide crude product into anode chamber 1, add 5% tetrabutylammonium hydroxide aqueous solution into intermediate chamber 2, add 20% tetrabutylammonium hydroxide aqueous solution into cathode chamber 3, open circulation pump 11 etc., connect direct current 7, Start electrolysis. Control the concentration of tetrabutylammonium hydroxide in the electrolytic cell of anode chamber 1 at 15%~25%, control the temperature of each chamber at 65 °C, and control the current density at 300 A / m 2 , Continuous electrolysis reaction for 7 days to obtain a tetrabutylammonium hydroxide aqueous solution with a finished product content of 20.6%. Its bromide ion concentration is 0.81 ppm; the current efficiency is 26%.

Embodiment 2

[0041] Add 25% tetrabutylammonium hydroxide crude product into the anode chamber 1, add 10% tetrabutylammonium hydroxide aqueous solution into the middle chamber 2, add 20% tetrabutylammonium hydroxide aqueous solution into the cathode chamber 3, open the circulation pump 11 etc., connect the direct current 7, Start electrolysis. Control the concentration in the electrolytic cell of anode chamber 1 at 15-25%, control the temperature of each chamber at 75 °C, and control the current density at 300 A / m 2 , continuous electrolytic reaction for 7 days, to obtain tetrabutylammonium hydroxide with a finished product content of 20.1%. The bromide ion concentration is 0.68 ppm; the current efficiency is 45%.

Embodiment 3

[0043] Add 25% tetrabutylammonium hydroxide crude product into the anode chamber 1, add 8% tetrabutylammonium hydroxide aqueous solution into the middle chamber 2, add 20% tetrabutylammonium hydroxide aqueous solution into the cathode chamber 3, open the circulation pump 11, etc., connect the direct current 7, Start electrolysis. Control the concentration in the electrolytic cell of the anode chamber 1 at 15-25%, control the temperature of each chamber at 70 °C, and control the current density at 1000 A / m 2 , continuous electrolytic reaction for 7 days, to obtain tetrabutylammonium hydroxide with a finished product content of 20.2%. The bromide ion concentration is 0.72 ppm; the current efficiency is 43%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com