Method for preparing modified propylene oxide ester

An epoxy acrylate and modified technology, applied in application, coating, ink and other directions, can solve the problem of high viscosity of bisphenol A epoxy acrylate finished product, limited flexibility of epoxy acrylate, and limited flexibility improvement and other problems, to achieve the effect of toughness advantage, strong designability, and wide adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

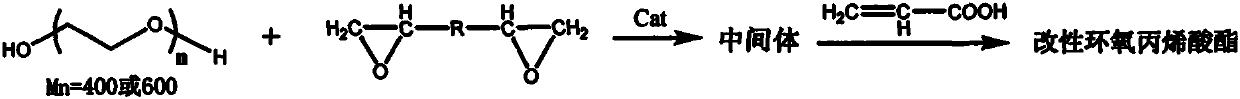

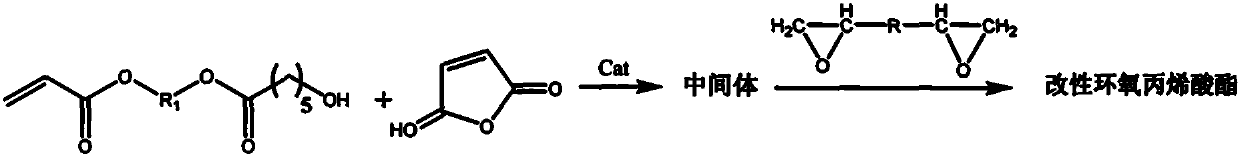

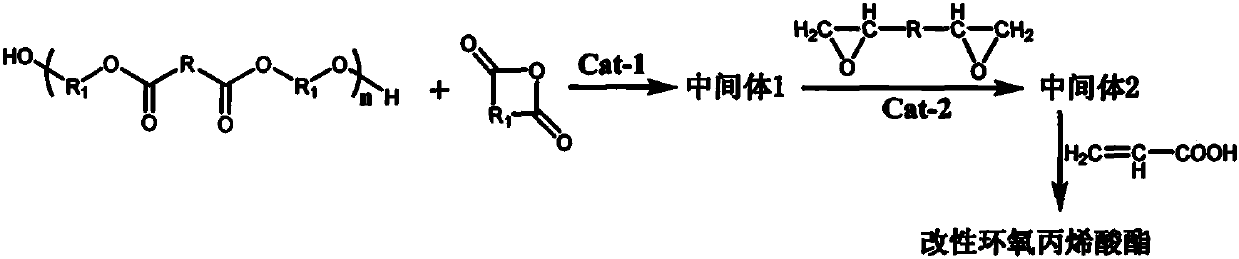

Method used

Image

Examples

Embodiment 1

[0023] (1) Add polyhexamethylene adipate 100g, succinic anhydride 40g, triethylamine 0.56g, N 2 Under protection, it was reacted at 70-80°C for 2h to obtain Intermediate 1.

[0024] (2) Add epoxy resin (epoxy equivalent 185-195g / eq, 248.3g) and tetraethylammonium bromide (2.1g) to intermediate 1, and react at 80-90°C for 2h to obtain the intermediate 2.

[0025] (3) Add acrylic acid (67.2g), hydroquinone (0.20g), and triphenylphosphine (1.0g) to intermediate 2, and react at 100-105°C for 4h to obtain modified epoxy acrylate a.

Embodiment 2

[0027] (1) Add polyhexamethylene adipate (100g), succinic anhydride (40g), triethylamine (0.56g), N 2 React at 70-80°C for 2h under protection to obtain Intermediate 1.

[0028] (2) Add epoxy resin (epoxy equivalent 185-195g / eq, 186.2g) and tetraethylammonium bromide (1.8g) to intermediate 1, and react at 80-90°C for 2h to obtain intermediate 2 .

[0029] (3) Add acrylic acid (43.2g), hydroquinone (0.18g), and triphenylphosphine (0.8g) to intermediate 2, and react at 100-105°C for 4h to obtain modified epoxy acrylate b.

Embodiment 3

[0031] (1) Add polyhexamethylene adipate (100g), succinic anhydride (40g), triethylamine (0.56g), N 2 Under protection, it was reacted at 70-80°C for 2h to obtain Intermediate 1.

[0032] (2) Add epoxy resin (epoxy equivalent 185-195g / eq, 149.0g) and tetraethylammonium bromide (1.5g) to intermediate 1, and react at 80-90°C for 2h to obtain intermediate 2 .

[0033] (3) Add acrylic acid (28.8g), hydroquinone (0.16g), and triphenylphosphine (0.8g) to intermediate 2, and react at 100-105°C for 4h to obtain modified epoxy acrylate c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com