Patents

Literature

95results about How to "Affect mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

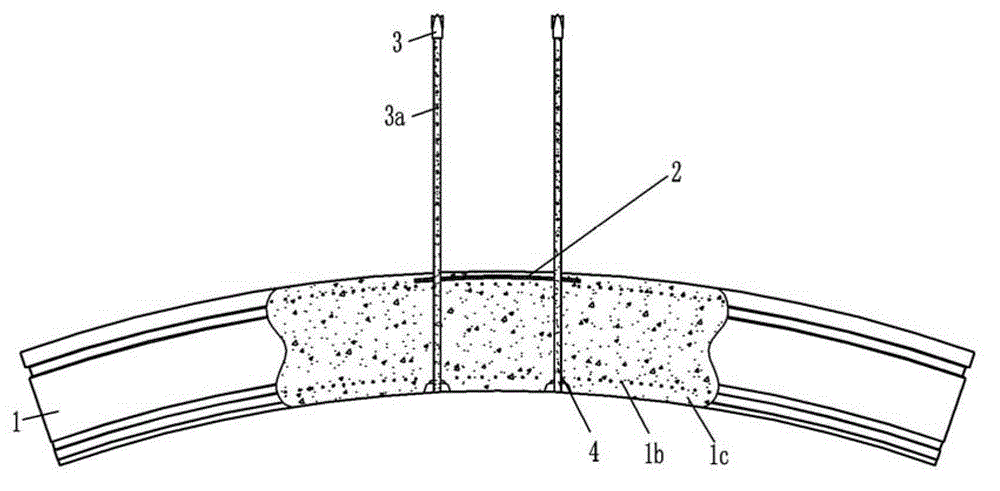

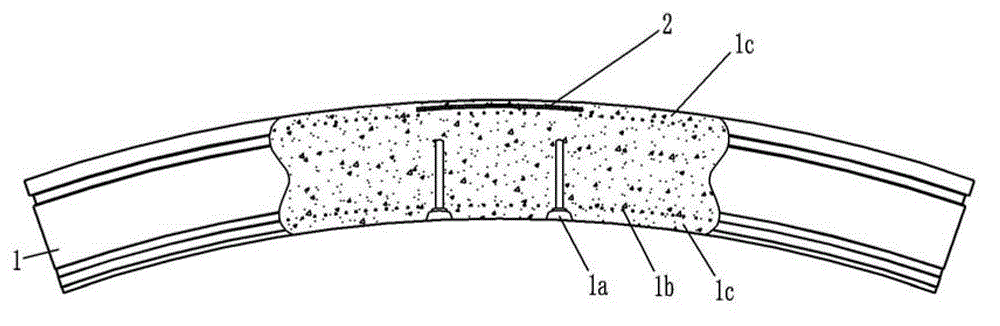

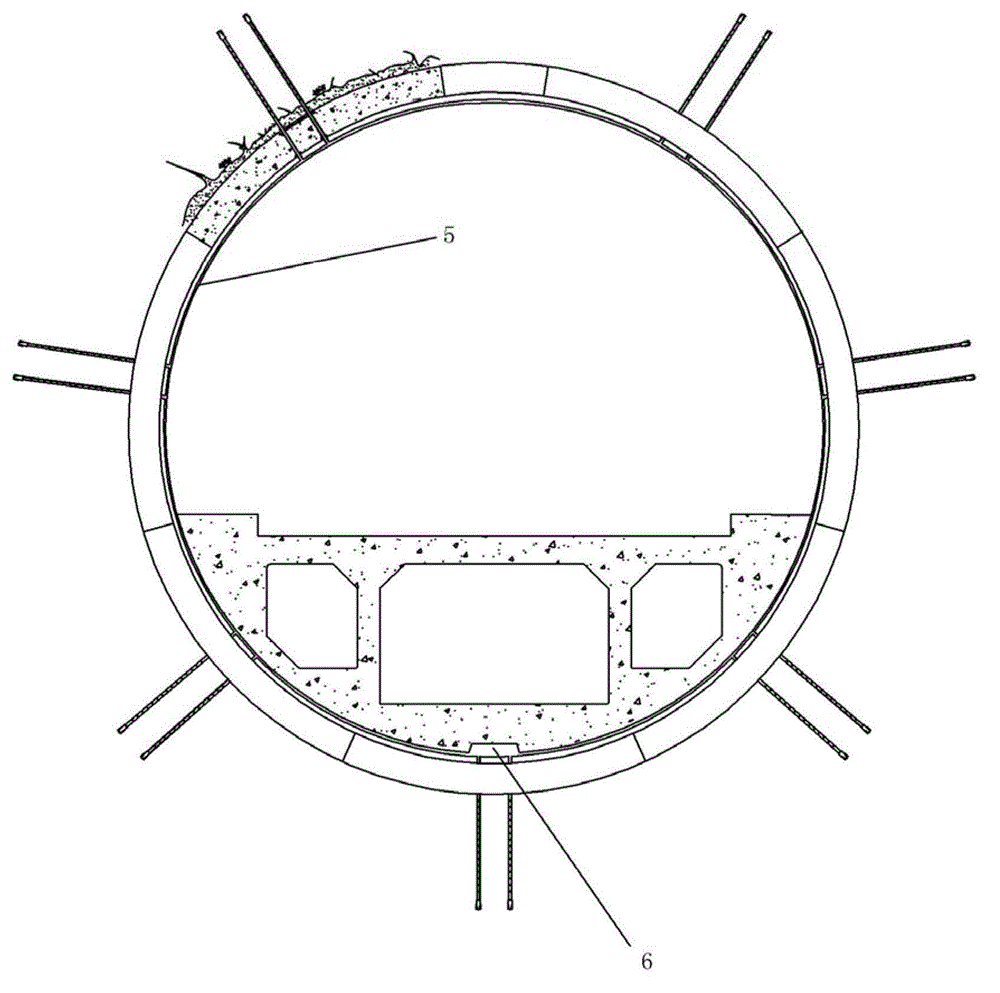

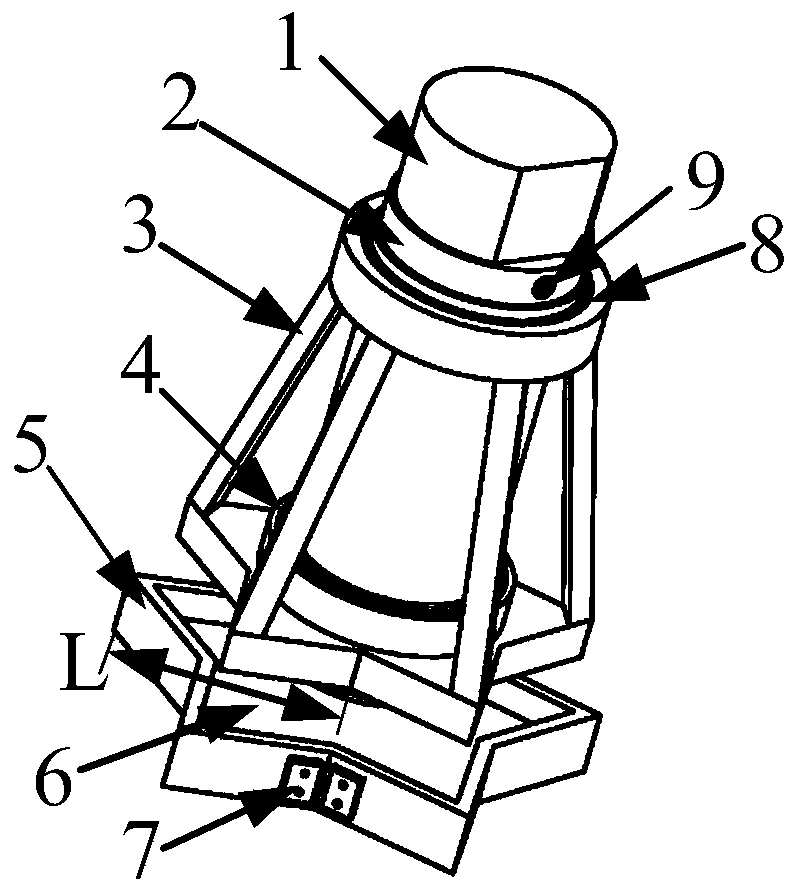

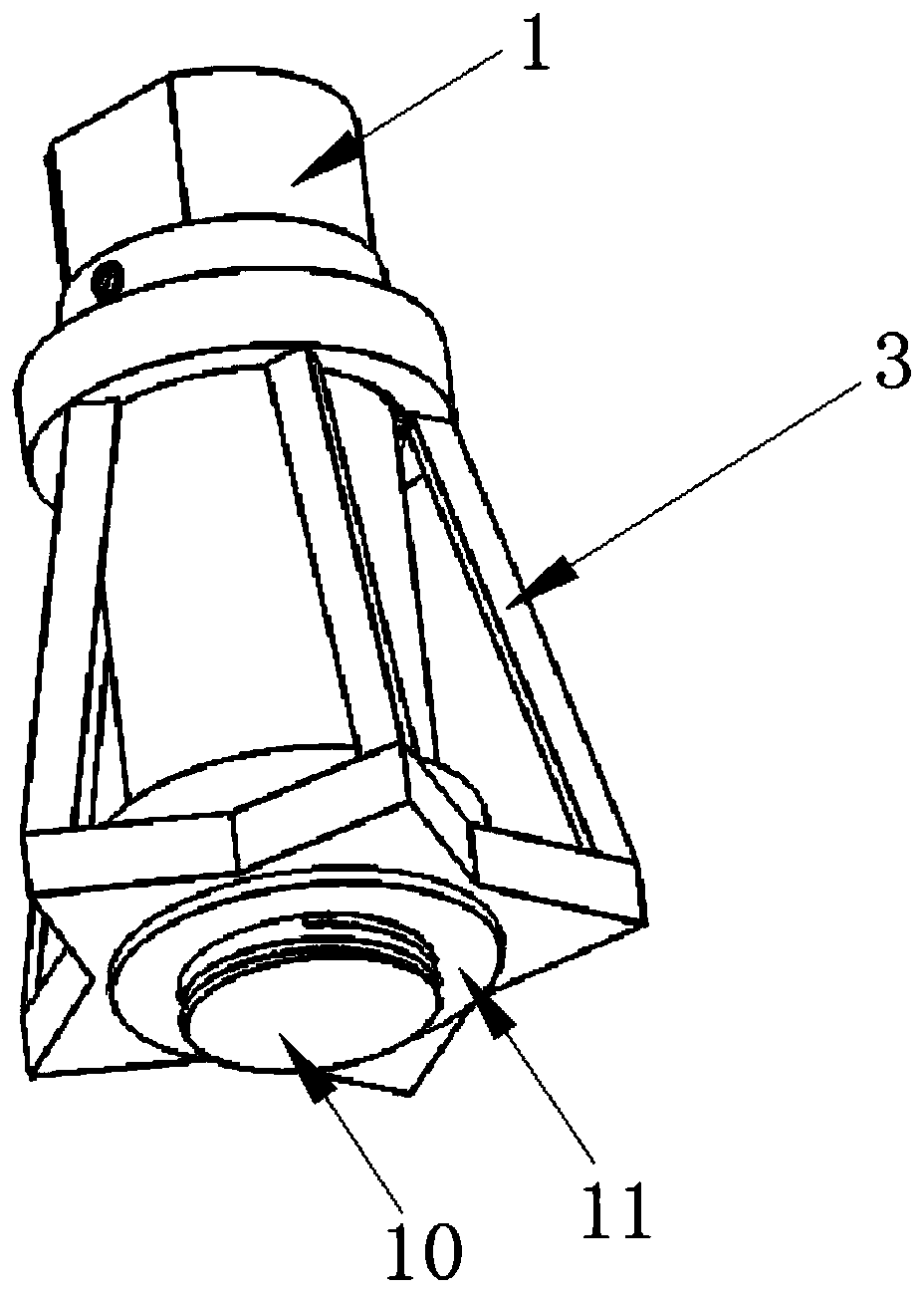

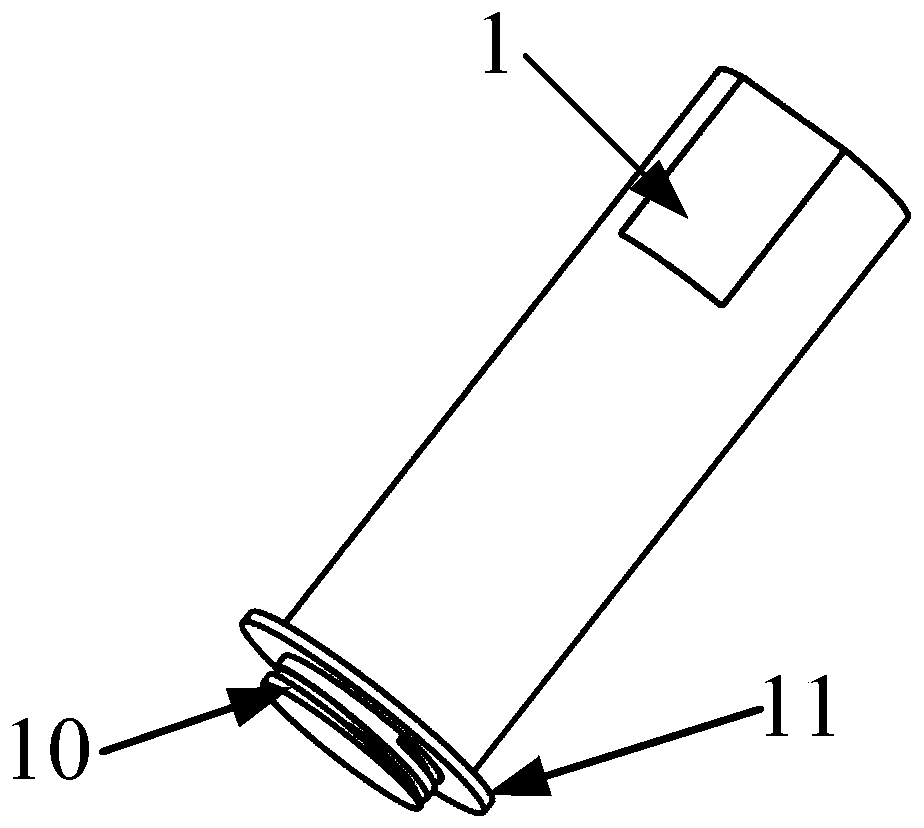

Drain-type pipe piece for tunnel lining

ActiveCN102979535ANo need to increase intensityEnsure safetyUnderground chambersDrainageReinforced concreteSlurry

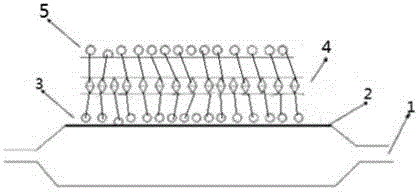

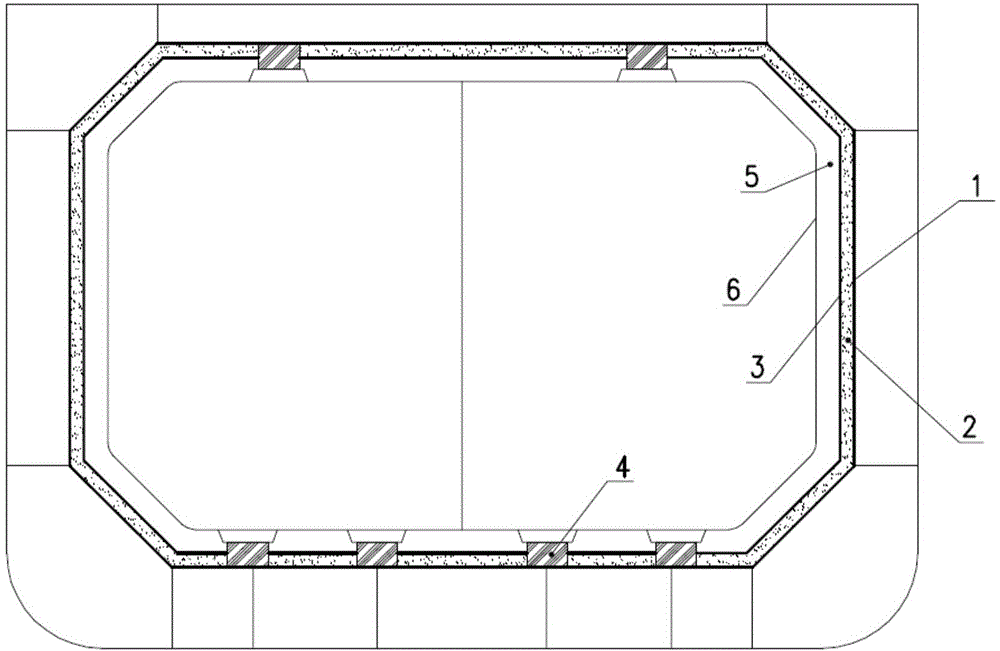

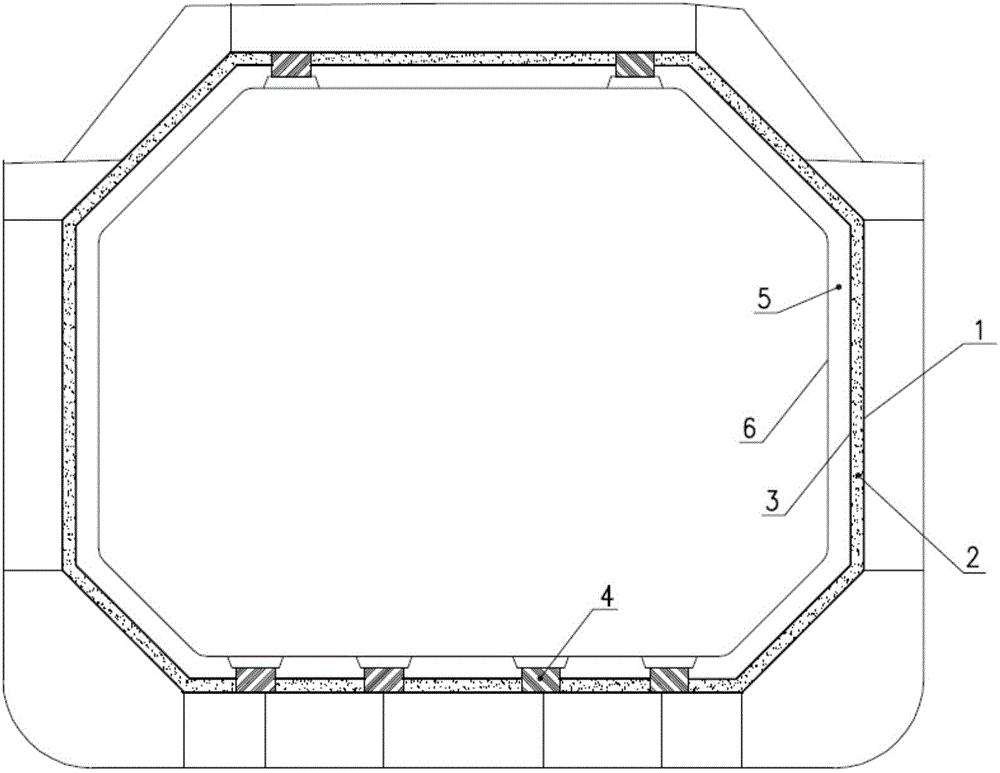

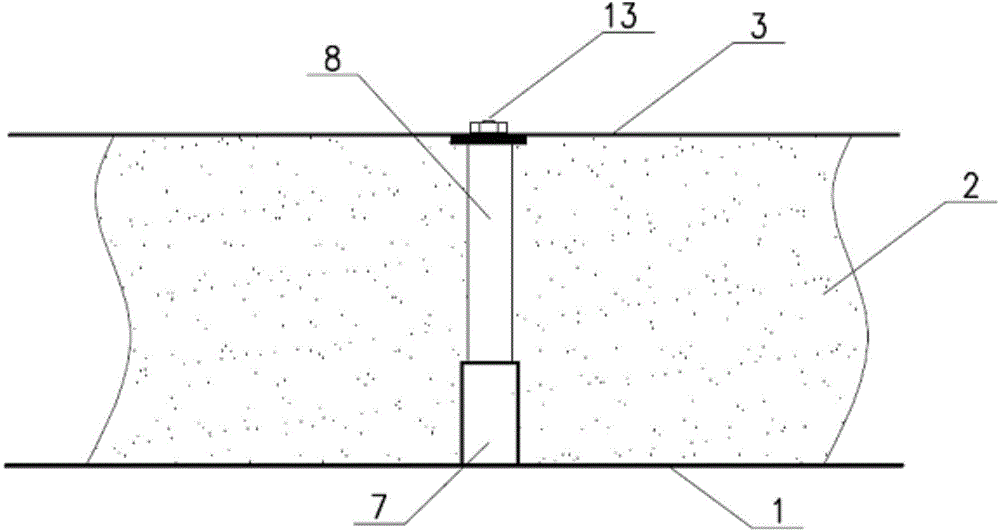

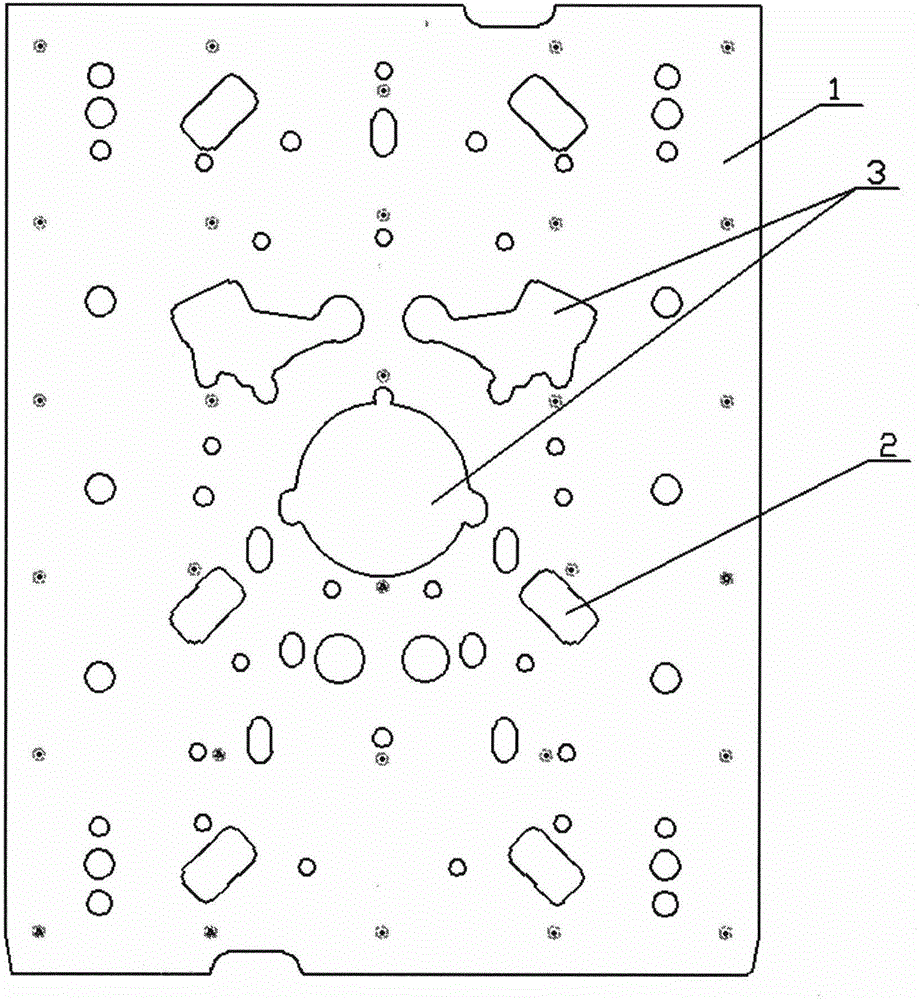

The invention discloses a drain-type pipe piece for tunnel lining. The drain-type pipe piece comprises a reinforced concrete pipe piece (1), a slurry injection hole (or a hoist hole) (1a) in the pipe piece (1), a load bearing steel bar (1b), and a concrete protective layer (1c) on the outer side; a water stop rubber block (2) capable of being expanded when being in contact with water is preburied in the concrete protective layer (1c) right opposite to one or two slurry injection holes (1a) of the pipe piece (1); a self-advancing type hollow anchor rod (3) is inserted in the slurry injection holes (or the hoist hole) (1a) of the pipe piece (1), then penetrates the water stop rubber block (2), and shoots out of the concrete protective layer (1c); and drain holes (3a) are formed in the rod wall of the outer end of the self-advancing type hollow anchor rod (3), and a filter column (4) used for filtering sand is plugged in the inner cavity of the self-advancing type hollow anchor rod (3). Lining built with the pipe pieces has a reliable drain function, and can reduce water pressure around the structure to ensure tunnel safety; and construction is convenient, small damage is caused to the pipe piece lining structure, and construction cost of the pipe piece lining is low.

Owner:SOUTHWEST JIAOTONG UNIV

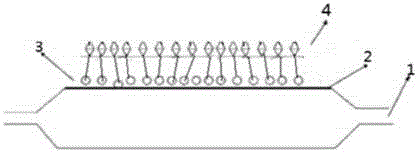

Novel drug eluting balloon catheter

PendingCN104874090AReduce lossesGood lipophilic and hydrophilic propertiesBalloon catheterMedical devicesDrug eluting balloonBalloon catheter

The invention provides a novel drug eluting balloon catheter. The novel drug eluting balloon catheter comprises a catheter body, a balloon body (1) and a balloon surface (2) and further comprises a hydrophilic and lipophilic bottom layer (3) and a drug loading coating layer (4). The hydrophilic and lipophilic bottom layer (3) is arranged on the upper surface of the balloon surface (2), the drug loading coating layer (4) is arranged on the upper surface of the hydrophilic and lipophilic bottom layer (3), and the drug loading coating layer (4) is composed of polymer and drug. The novel drug eluting balloon catheter has the advantages of simple structure, simple production process and procedures, low drug loss during delivery and low drug residues on the balloon after interventional operation.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

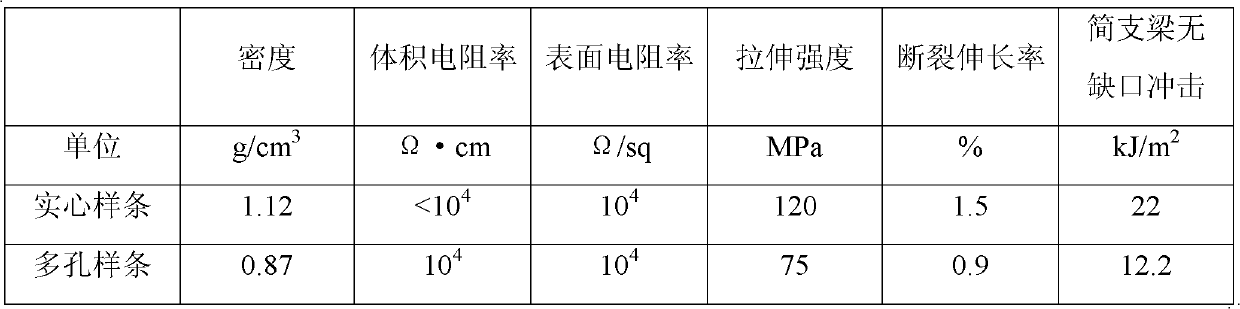

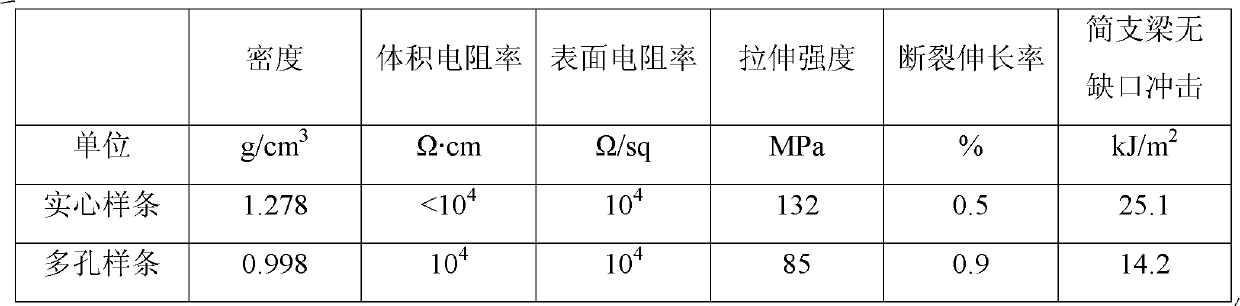

Composition for processing polystyrene porous material, polystyrene porous material and preparation method thereof

The invention discloses a composition for processing a polystyrene porous material, a polystyrene porous material and a preparation method thereof. The composition comprises the following components in percentage by weight: 65-88% of polystyrene, 7-30% of conductive filler and 0.1-5% of assistant, wherein the assistant at least comprises antioxidant. The porous material can be subjected to extrusion molding or injection molding by an extruder or other corresponding apparatuses, and has the advantages of permanent antistatic performance, electric conduction and low cost. Compared with the traditional material, the porous material disclosed by the invention can lower the cost by about 20% on the premise of keeping the volume resistivity and surface resistivity.

Owner:5ELEM HI TECH CORP

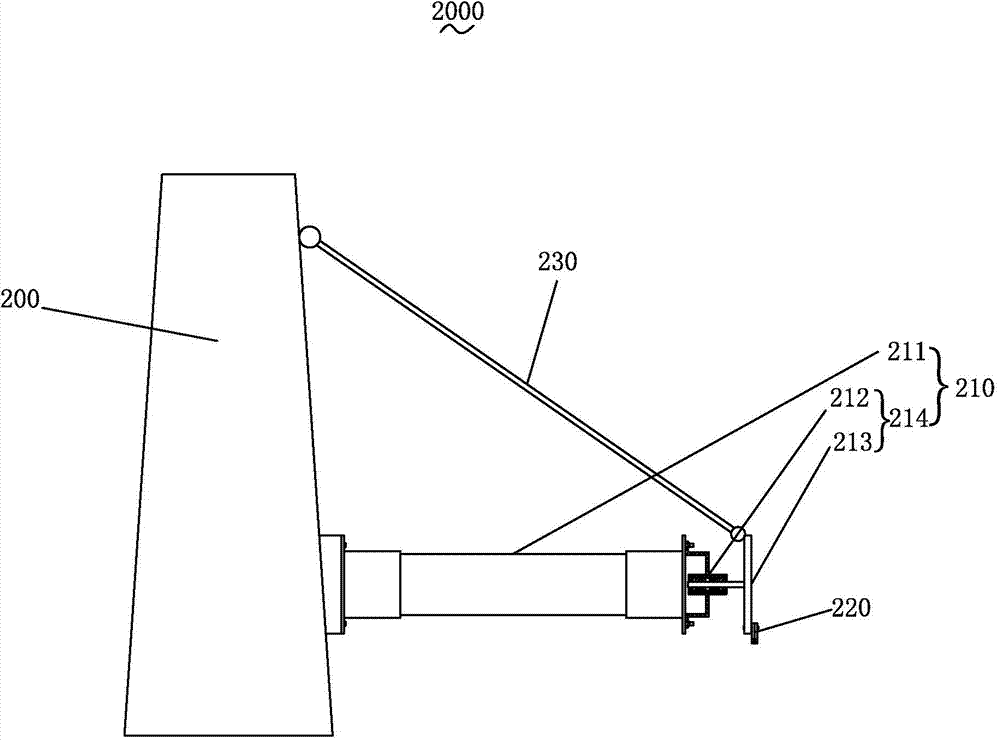

Power transmission tower

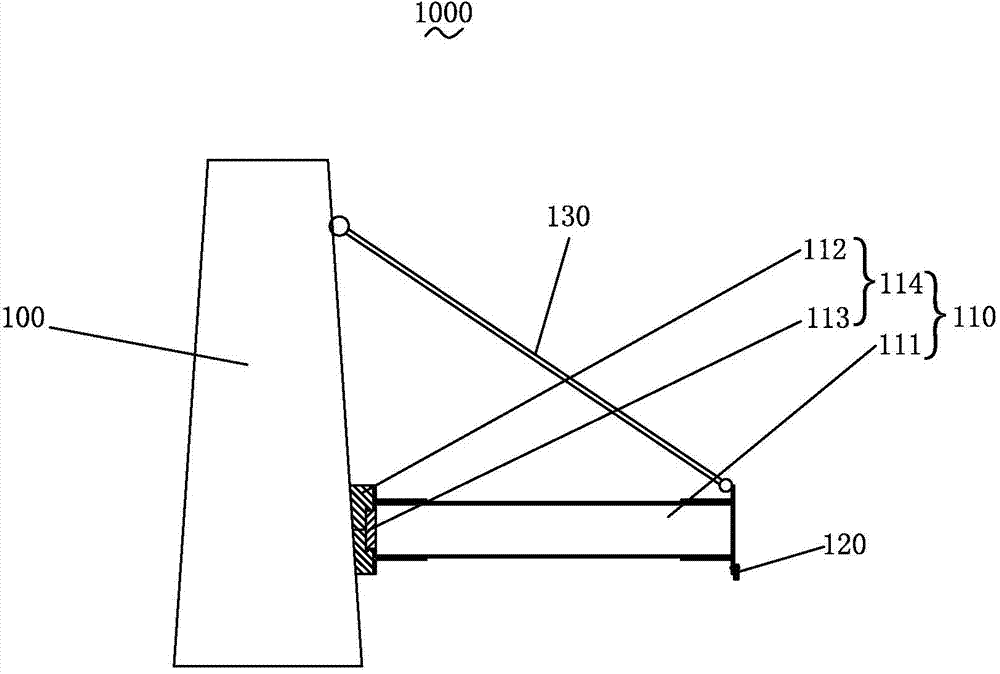

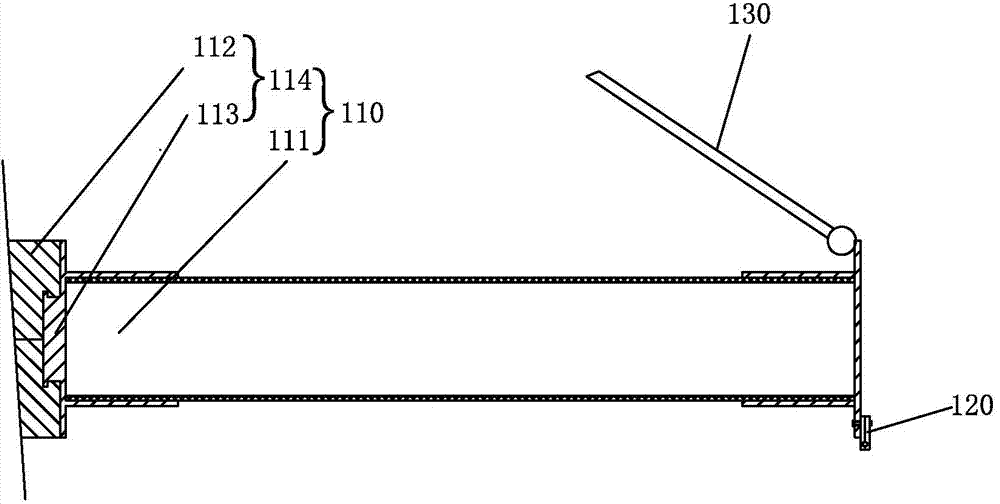

ActiveCN104746935AAffect mechanical propertiesOvercome the disadvantage of poor torsion resistanceTowersTransmission towerEngineering

The invention discloses a power transmission tower. The power transmission tower comprises a tower body, a cross arm connected to the tower body, and a wire clamp hardware connected to the tail end of the cross arm, wherein the wire clamp hardware is used for connecting a power transmission wire; the cross arm comprises an insulator, and a rotating device arranged on the insulator; the wire clamp hardware is rotated around an axis of the cross arm through the rotating device. The power transmission tower can overcome the shortage of poor twisting resistance of the combined cross arm, and can greatly improve the adaptability of the combined cross arm.

Owner:SHANGHAI SHEMAR POWER ENG CO LTD

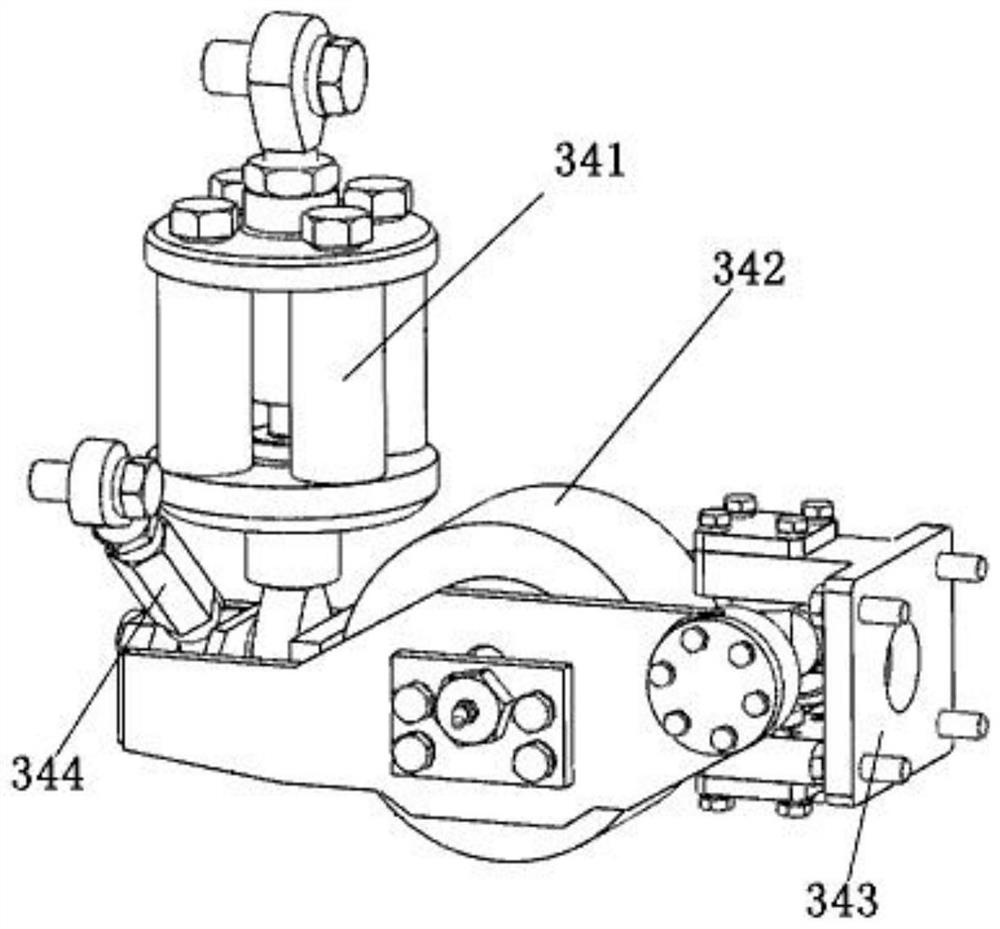

Device and method for manufacturing radial additive by friction stir welding

ActiveCN110640294AAdditive Manufacturing RealizedHigh strengthAdditive manufacturing apparatus3D object support structuresFriction weldingUltrasonic cavitation

The invention relates to a device and method for manufacturing a radial additive by friction stir welding. The device is a set of special-shaped stationary shaft shoulder body and comprises a stirringhead, a stationary shaft shoulder body and a mould, wherein the outer side of the stirring head is coaxially provided with the stationary shaft shoulder body in a sleeved mode, and the stationary shaft shoulder body is matched with the mould to be installed. The mould is used to pass through the radial additive for several times, and thus the required additive manufacturing parts are obtained. Inthe additive manufacturing process, auxiliary processes such as ultrasonic, auxiliary heating, etc. are added to ensure the performances of the additive manufacturing parts. In a semi-solid state, ultrasonic cavitation can refine grains to form ultrafine / nanocrystalline materials; and in a solid state, ultrasonic can promote the atomic diffusion ability and can also reduce the residual stress, which is conducive to obtaining an additive structure with high bearing capacity. Meanwhile, for the of metal-matrix composites, the addition of ultrasonic can also promote the violent mixing of materials to avoid the phenomenon of segregation in the process of additive manufacturing.

Owner:SHENYANG AEROSPACE UNIVERSITY

Local secondary screen bulkhead applied to B type independent cabin and boat or ocean structure

The invention provides a local secondary screen bulkhead applied to a B type independent cabin and a ship or an ocean structure. The local secondary screen bulkhead is completely separated from a B type independent liquid cargo cabin shell and attached to a ship inner shell, and an airtight space is formed outside the B type independent liquid cargo cabin shell. An insulation layer attached to the ship inner shell has the insulation function, a splash-proof film ensuring the airtightness is fixed to the ship inner shell through a fixing device, the B type independent cabin is supported through pressure bearing wood, the bottom of a ship is designed to be a strengthening film and used for bearing a small amount of leaked cargo load. The airtight space between the B type cabin shell and the splash-proof film can serve as a construction space and an overhaul space, and the B type cabin shell and the splash-proof film are detected. According to the technical scheme, the structure is simple, installation is convenient, the construction cost of a ship factory can be saved, and the construction period is shortened.

Owner:708TH RES INST OF CSSC

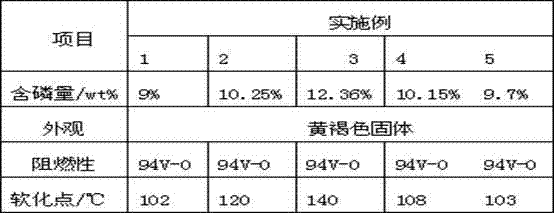

Preparation method of modified phenolic resin

ActiveCN102766242AHigh in phosphorusImprove flame retardant performanceSimple Organic CompoundsPolymer science

The invention relates to the technical field of phenolic resin, and in particular relates to a preparation method of modified phenolic resin. The preparation method comprises the following steps of: mixing a phenol organic compound with an aldehyde organic compound at pH of 7-11, and reacting until a matter which is insoluble in alkaline aqueous solution occurs, namely a phenol-aldehyde prepolymer is generated; and adding a phosphorus-containing organic compound in the phenol-aldehyde prepolymer, adjusting pH to be lower than 3, introducing inert gas, and reacting until phenol content is lower than 1% to obtain the modified phenolic resin. The preparation method for preparing modified phenolic resin is wide in production raw material sources and simple in synthesis process; and the phenolic resin prepared by using the preparation method is high in phosphorus content, so that the flame retardance of the phenolic resin is greatly improved and the synthesis ratio of the resin is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

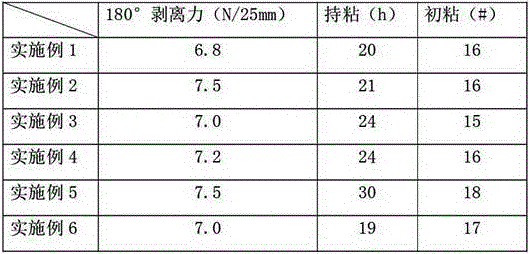

Acrylate pressure-sensitive adhesive emulsion for PP film gum and use thereof and preparation method

InactiveCN106833446AImprove wettabilityImprove stabilityEster polymer adhesivesEmulsionEmulsion polymerization

The invention discloses an acrylate pressure-sensitive adhesive emulsion for PP film gum as wellas use and a preparation method the acrylate pressure-sensitive adhesive emulsion. The acrylate pressure-sensitive adhesive emulsion is prepared by adopting a pre-emulsification semi-continuous seed polymerization technology, adding a monomer to a water solution of a reactive emulsifier for pre-emulsification, initializing pre-emulsion polymerization reaction, finally adding assistants such as a defoaming agent, a wetting agent and a bactericide and stirring evenly. A pressure-sensitive adhesive coats the surface of a PET release film to be dried, and then is transferred to the back surface of a PP film; the thickness of the dry adhesive is 20 microns; the wettability is good; the adhesive surface is free of defects of bubbles and sinkholes; the release force reaches 7N / 25mm; and the durable viscosity is not lower than 24h.

Owner:WUXI HAITE NEW MATERIAL RES INST

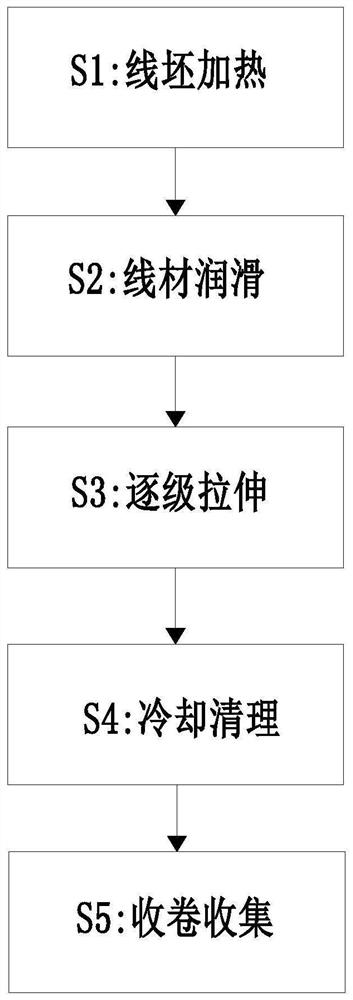

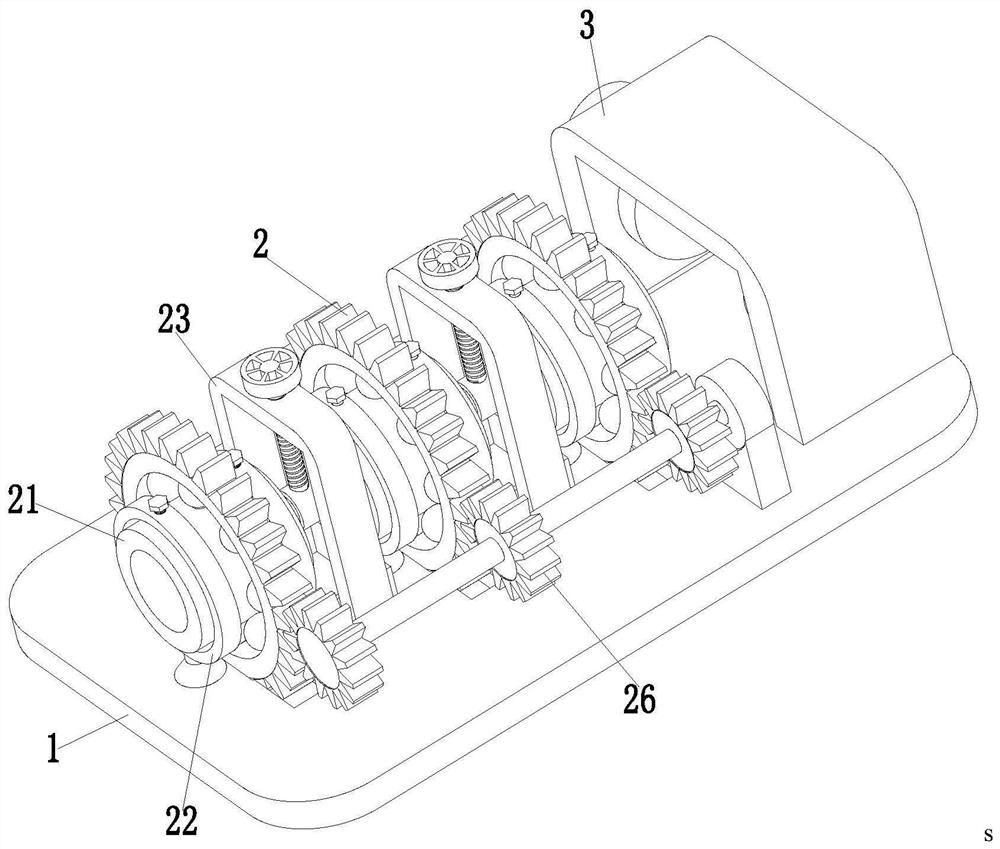

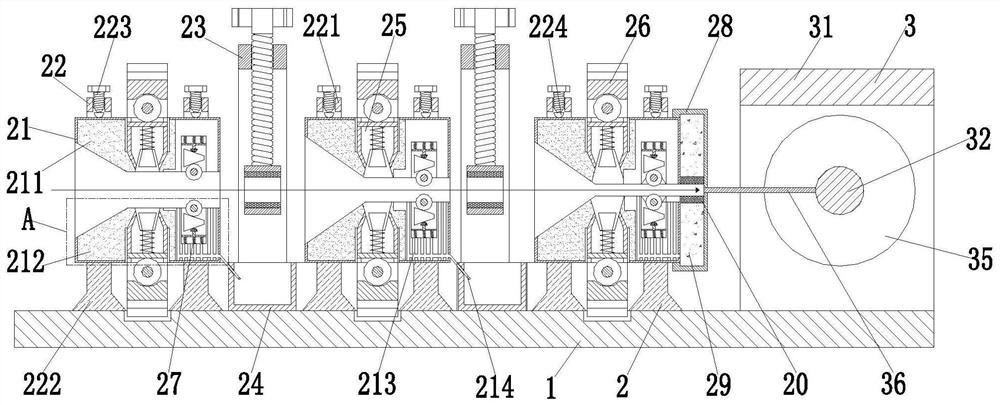

Stainless steel wire manufacturing process

InactiveCN112427470AAffect mechanical propertiesAvoid breakageExtrusion cleaning devicesWire rodMetallurgy

The invention relates to a stainless steel wire manufacturing process, in particular to a stainless steel wire manufacturing device. The stainless steel wire manufacturing device comprises a bottom plate, a stretching mechanism and a traction mechanism, the stretching mechanism is installed in the middle of the upper end face of the bottom plate, and the traction mechanism is arranged on the rightside of the stretching mechanism and fixedly installed on the right side of the upper end face of the bottom plate. The problems that most existing stainless steel wire manufacturing devices adopt aone-time wire stretching mode, stainless steel wires cannot be stretched step by step, consequently, the wires become thinner suddenly, drawing force changes suddenly, the stainless steel wires are prone to being snapped, and the quality and the mechanical property of the formed stainless steel wires are affected are solved; and the problems that an existing stainless steel wire manufacturing device cannot evenly coat the surface of a stainless steel wire with a lubricating agent, so that the lubricating degree is insufficient when the wire is stretched, and burrs are likely to appear on the surface of the stretched wire are solved.

Owner:刘静

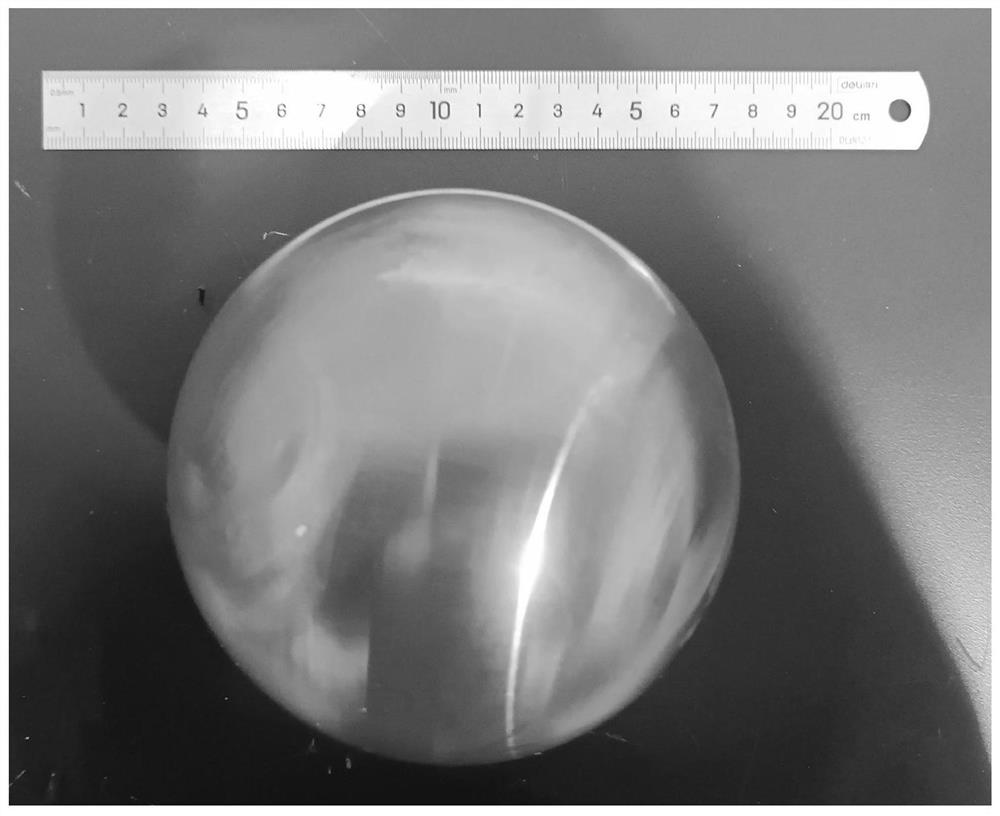

Large-size silicon nitride ceramic ball and preparation method thereof

The invention provides a silicon nitride ceramic ball and a preparation method thereof, and belongs to the technical field of ceramic materials. According to the invention, a vacuum injection-coagulation forming method is adopted, so that the forming of large-size and oversized silicon nitride ceramic balls with high sphericity degree and uniform density can be realized. Microwave drying is adopted, the drying speed is high, and deformation of a green body is small. According to the invention, the cold isostatic pressing treatment is carried out on the degummed ceramic balls, so that the compactness of the sintered ceramic balls is improved. A two-step air pressure sintering process is adopted, so that internal air holes of the ceramic ball can be removed, and the density can be further improved. According to the invention, the surfaces and the core parts of the large-size and oversized silicon nitride ceramic balls prepared by adopting the method of combining injection coagulation forming with cold isostatic pressing forming and two-step air pressure sintering have no obvious difference in properties such as relative density, Vickers hardness and fracture toughness. Homogenization of density and mechanical properties of large-size and oversized silicon nitride ceramic balls can be realized.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD +1

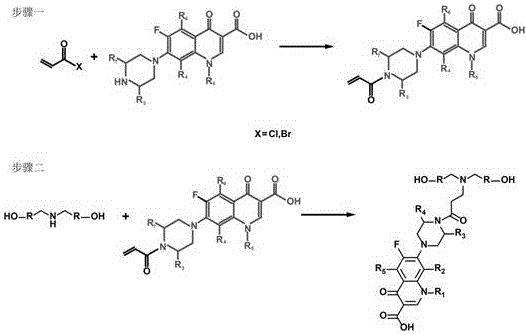

Preparation method for chain extender used for structurally antibacterial polyurethane

InactiveCN106084164ABroad spectrum antibacterialStrong antibacterial activityOrganic chemistrySolventLong acting

The invention discloses a preparation method for a chain extender used for structurally antibacterial polyurethane. The preparation method comprises the following steps: subjecting fluoroquinolone to vinylation modification by using an acylation reaction; and then introducing a dihydroxyl group into vinylated fluoroquinolone molecules according to the principles of the Michael addition reaction so as to obtain the dihydroxyl chain extender with an antibacterial fluoroquinolone group in its side chain. The chain extender is applicable to synthesis of solvent type or waterborne polyurethane for preparation of structurally antibacterial polyurethane, endows a polyurethane product with lasting and long-acting antibacterial and mildew-resistant performance without influence the main chain structure of polyurethane, and has application prospects in the fields of leather / synthetic leather coatings, bio-medical instruments, etc.

Owner:SICHUAN UNIV

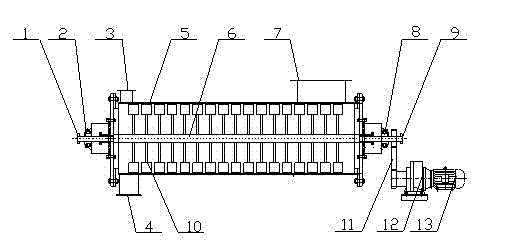

Rake drying method for drying sludge by utilization of high-temperature flue gas

InactiveCN102730933ALow running costReduce power consumptionSludge treatment by de-watering/drying/thickeningProcess engineeringFlue gas

The invention relates to a rake drying method for drying sludge by the utilization of high-temperature flue gas and a device thereof. Sludge drying is a sludge disposal method, and the level of energy consumption during the drying process relates directly to the operation cost of sludge drying. Therefore, according to the invention, high-temperature flue gas generated from an incinerator is directly used for drying sludge, thus greatly reducing the operation cost of sludge drying. The method comprises the following steps of: allowing high-temperature flue gas to enter from a drying medium inlet (4) at one end of a sludge rake drier, allowing wet sludge to enter from a sludge inlet (3) at the same end to operate together with the high-temperature flue gas, letting the wet sludge in the sludge rake drier directly contact with the hot flue gas so as to realize the drying process, crushing massive sludge and pushing the sludge towards the other end of the sludge rake drier from the inlet by the use of a rake teeth (10) part, allowing the dried sludge to leave the sludge rake drier together with the flue gas from a drying medium outlet (7), letting the dried sludge to enter a gas-solid separator in a subsequent system, further utilizing the collected dry sludge, and discharging the dedusted flue gas into the atmosphere from a chimney.

Owner:SOUTHEAST UNIV

Composition for processing porous polycarbonate material, porous polycarbonate material and preparation method thereof

The invention discloses a composition for processing a porous polycarbonate material, the porous polycarbonate material and a preparation method thereof. The composition comprises the following components and content thereof, by weight, 65-88% of polycarbonate, 10-30% of conductive filler and 0.1-5% of auxiliaries, wherein the auxiliaries at least include antioxidant. A porous material processed by the composition is a porous polycarbonate material with permanent antistatic and conductive performance and is formed in an extrusion or injection manner by corresponding equipment such as an extruder. Compared with that of the conventional material, cost can be reduced by 20% around on the basis of keeping volume resistivity and surface resistivity constant.

Owner:5ELEM HI TECH CORP

Manufacturing method of multi-functional modified acrylic fibers with high moisture absorption and flame resistance

InactiveCN101845745AGood moisture absorptionImprove flame retardant performancePhysical treatmentFibre typesPolymer scienceMoisture absorption

The invention relates to a manufacturing method of multi-functional modified acrylic fibers with high moisture absorption and flame resistance, which is characterized by directly complexing and cyclizing acrylic fibers into the acrylic fibers with high moisture absorption and flame resistance by using a method of chemical complexing and cyclization. The method comprises the following steps of: firstly, adding the acrylic fibers into a water solution containing copper ions for reaction to produce acrylic fibers containing the copper ions; then, adding the acrylic fibers containing the copper ions into a mixture of hydrazine hydrate and reaction assistants to immerse for a certain period of time; and finally, drying the acrylic fibers by squeezing or tossing to obtain acrylic fibers containing a certain amount of water solution, and steaming the acrylic fibers in a dry or gas mode in a high-temperature high-pressure steam setting vessel for a certain period of time to produce the acrylic fibers with high moisture absorption and flame resistance. The method can process the acrylic fibers into the acrylic fibers with high moisture absorption and flame resistance only with one simple high-temperature high-pressure steam setting vessel and fewer matching processes and equipment, which greatly reduces the traditional manufacturing process of the acrylic fibers with high moisture absorption and flame resistance; the invention has simple production process, low equipment investment, low production cost and easy realization of industrialization.

Owner:SHANDONG UNIV OF TECH

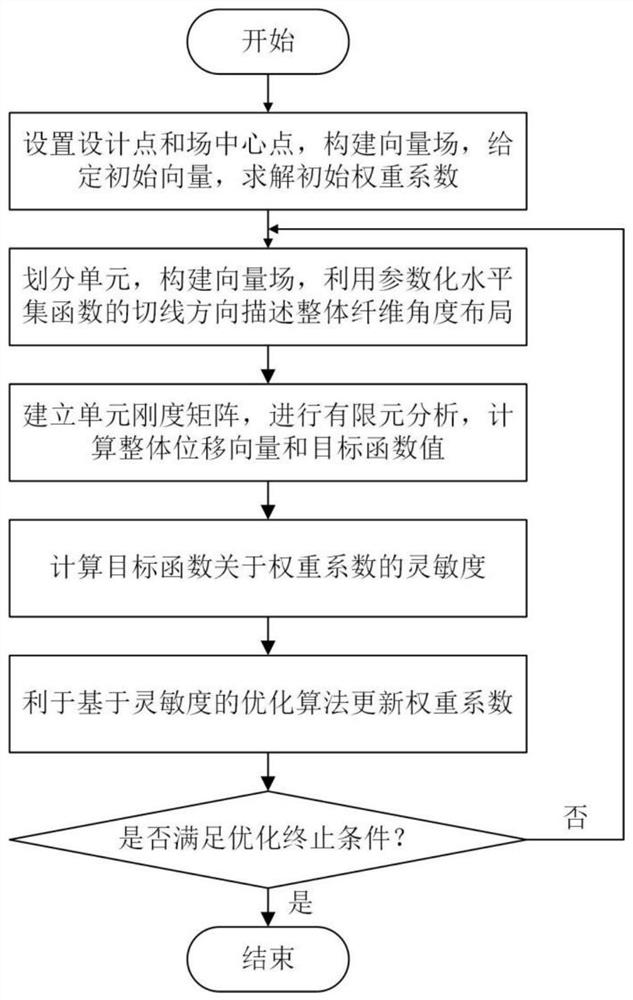

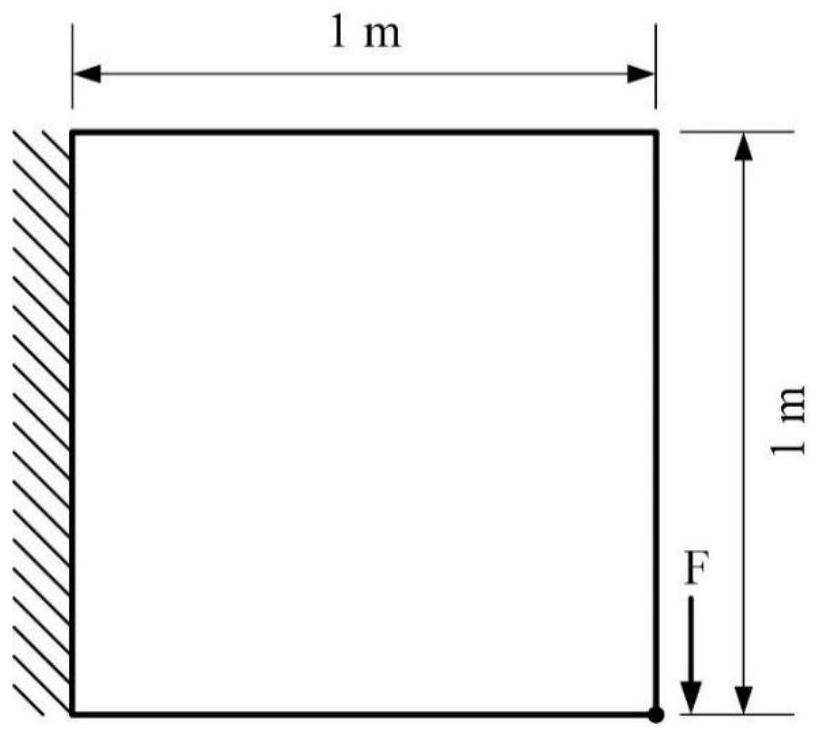

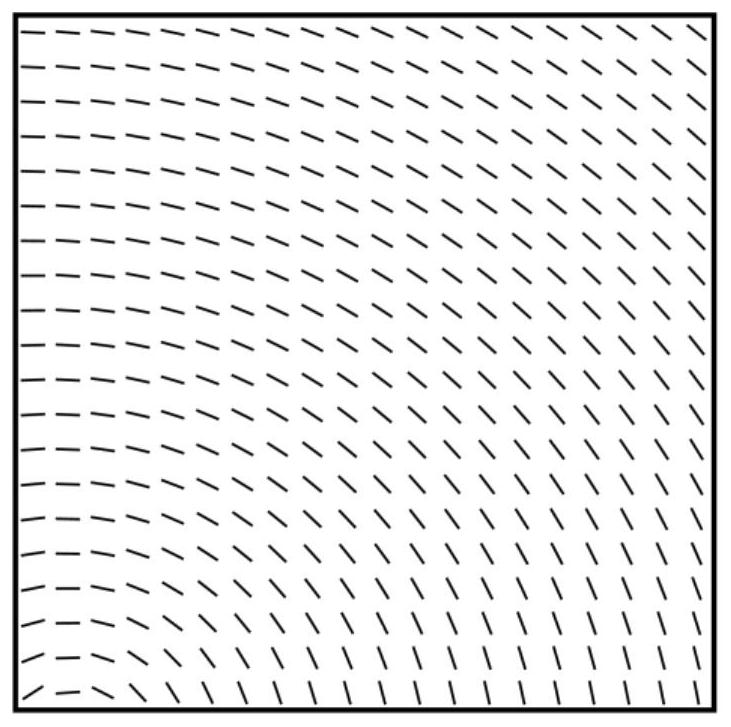

Level set method for optimal design of fiber curve laying variable stiffness structure

ActiveCN111723457AAngular Layout OptimizationImprove structural rigidityGeometric CADDesign optimisation/simulationFiberAlgorithm

The invention belongs to the related technical field of structural optimization design, and discloses a level set method for optimal design of a fiber curve laying variable stiffness structure, whichcomprises the following steps of: firstly, setting a series of design points and field center points in a structural design domain, constructing a vector field, and further solving an initial weight coefficient at each field center point; secondly, dividing a structural design domain into limited units, constructing a vector field according to the central points of the units and the central pointof the field, and describing the overall fiber angle layout by utilizing the tangential direction of a parameterized level set function; thirdly, establishing a unit stiffness matrix to solve an overall displacement vector and a target function value, and calculating the sensitivity of a target function about a design variable by taking a weight coefficient as the design variable and minimizing the flexibility as a design target; and secondly, repeatedly iterating after updating the design variable until an optimization termination condition is met. According to the method, the fibers can be parallel to each other, and the situation of fiber overlapping or gaps in the manufacturing process of the optimal structure is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

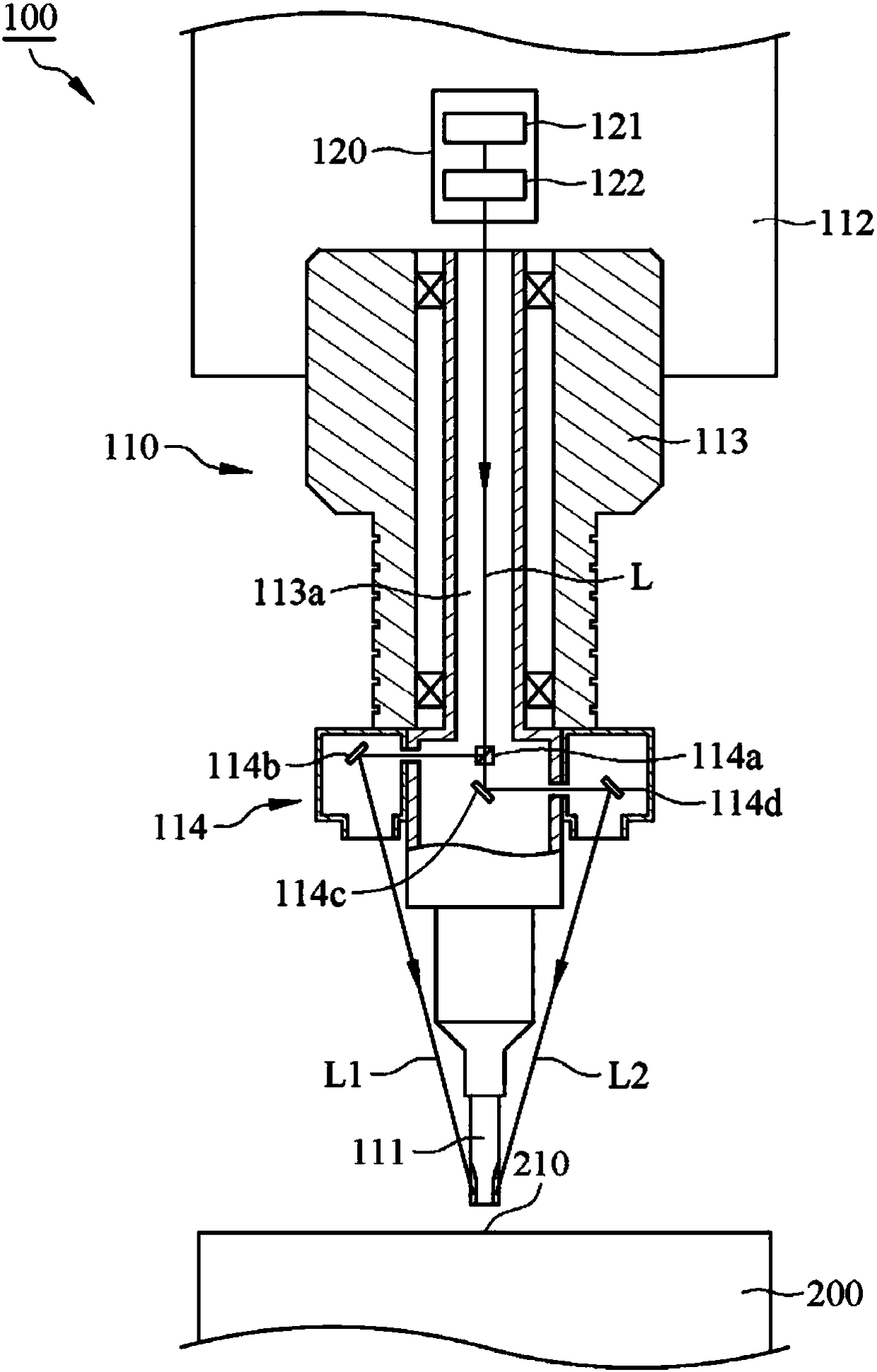

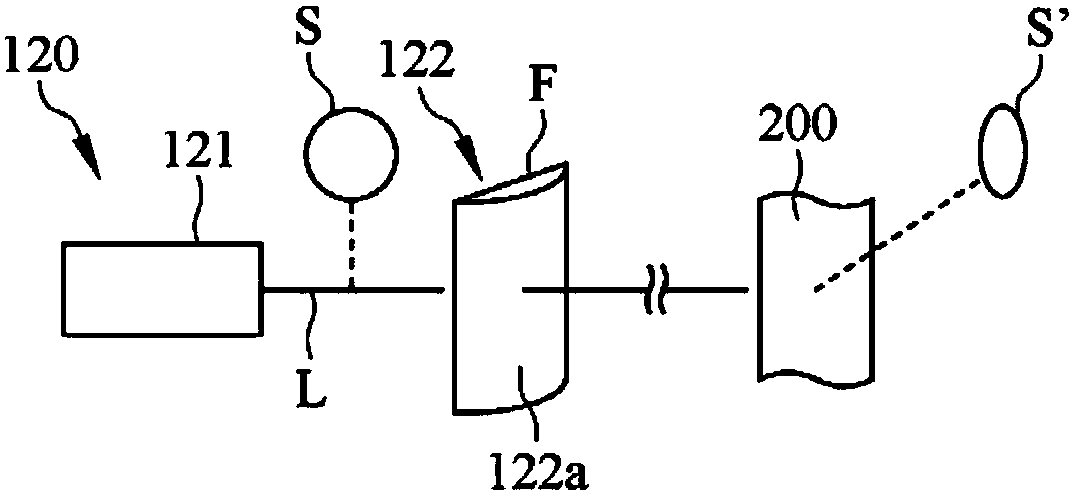

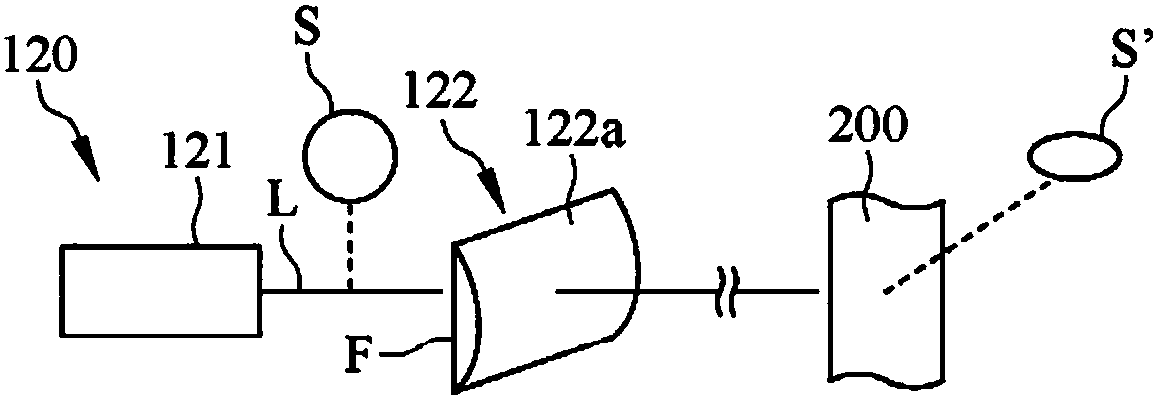

Laser assisted machining system and workpiece preheating device thereof

InactiveCN108241215AAffect mechanical propertiesNot limited by geometryOptical elementsLight beamTemperature difference

The invention relates to a laser assisted machining system. The laser assisted machining system includes a machining tool and a workpiece preheating device; the machining tool is used for machining aworkpiece; the workpiece preheating device is provided with a laser source and a modulation mirror group; the laser source emits a laser beam to the modulation mirror group; the modulation mirror group modulates the laser beam to focus the laser beam, so that a laser spot can be formed on the workpiece, and therefore, a to-be-machined area of the workpiece can be preheated and softened; and the modulation mirror group is used for modulating the shape and / or direction of the laser spot, so that the energy density of the laser spot can be uniformly distributed on the to-be-machined area, and therefore, poor processing efficiency and workpiece material variation which are brought about by the excessive temperature difference of the to-be-machined area can be avoided.

Owner:METAL INDS RES & DEV CENT

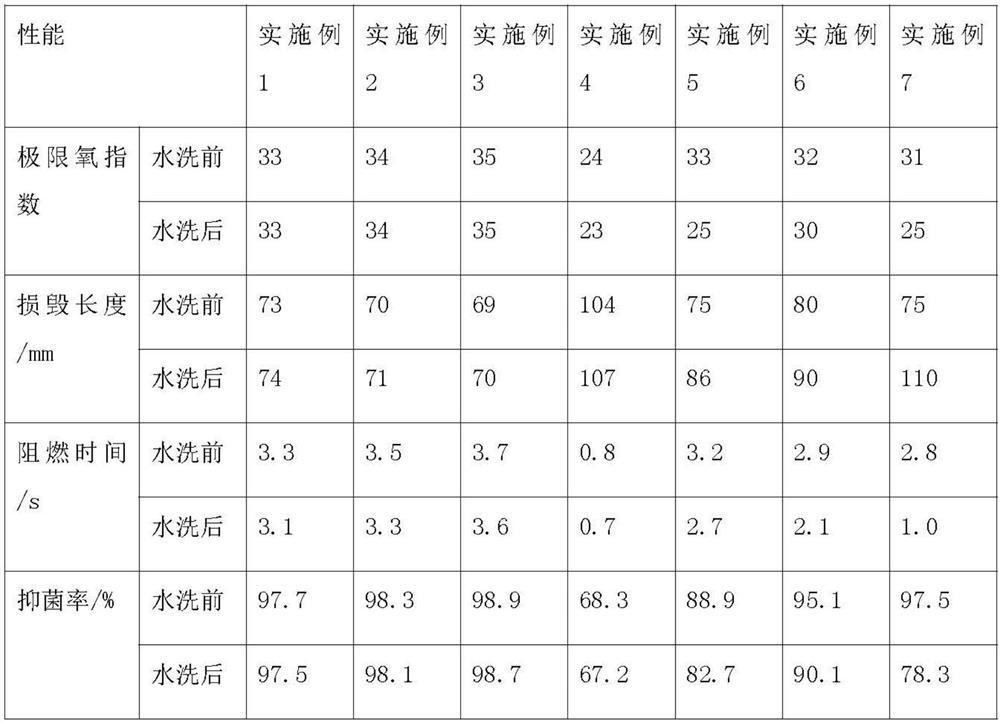

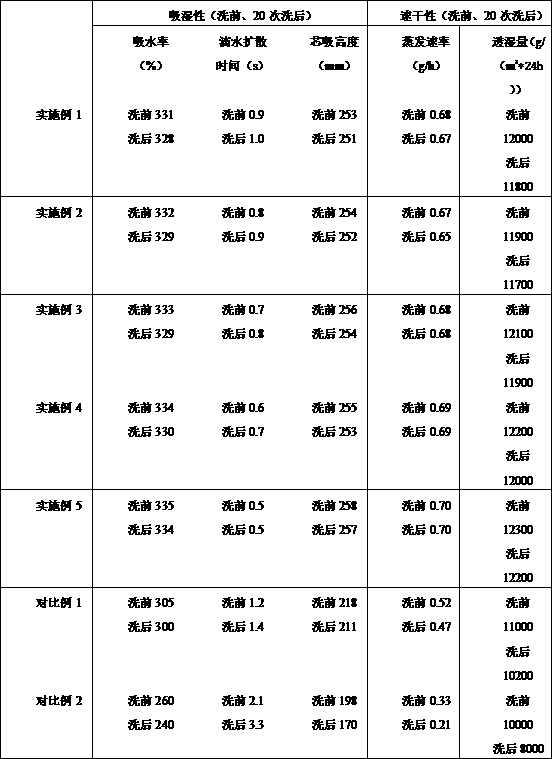

Antibacterial flame-retardant vortex spinning blended yarn and preparation method thereof

The invention discloses an antibacterial flame-retardant vortex spinning blended yarn and a preparation method thereof. The antibacterial flame-retardant vortex spinning blended yarn is prepared fromthe following raw material components of combed cotton fibers, ramie fibers, microporous polyurethane fibers, antibacterial plant essential oil and a modified adhesive. The flame-retardant substance used in the blended yarn is safe and non-toxic, and the risk that black smoke and toxic gas are generated in the combustion process of fabric made of the blended yarn to cause secondary harm to peopleis avoided; the blended yarn has excellent flame-retardant, antibacterial and odor-removing functions, and after 30 times of washing, the flame-retardant and antibacterial capabilities are still not obviously changed, the fabric has an excellent washing-resistant function, and the fabric is soft and comfortable and has very high practicability.

Owner:涟水县亚泰纺织有限公司

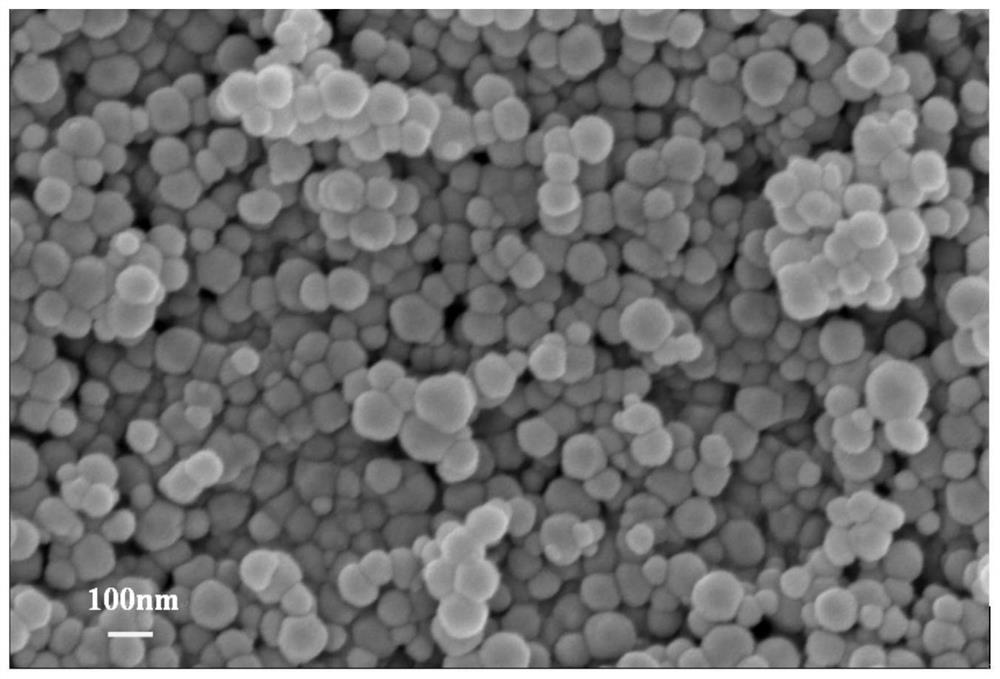

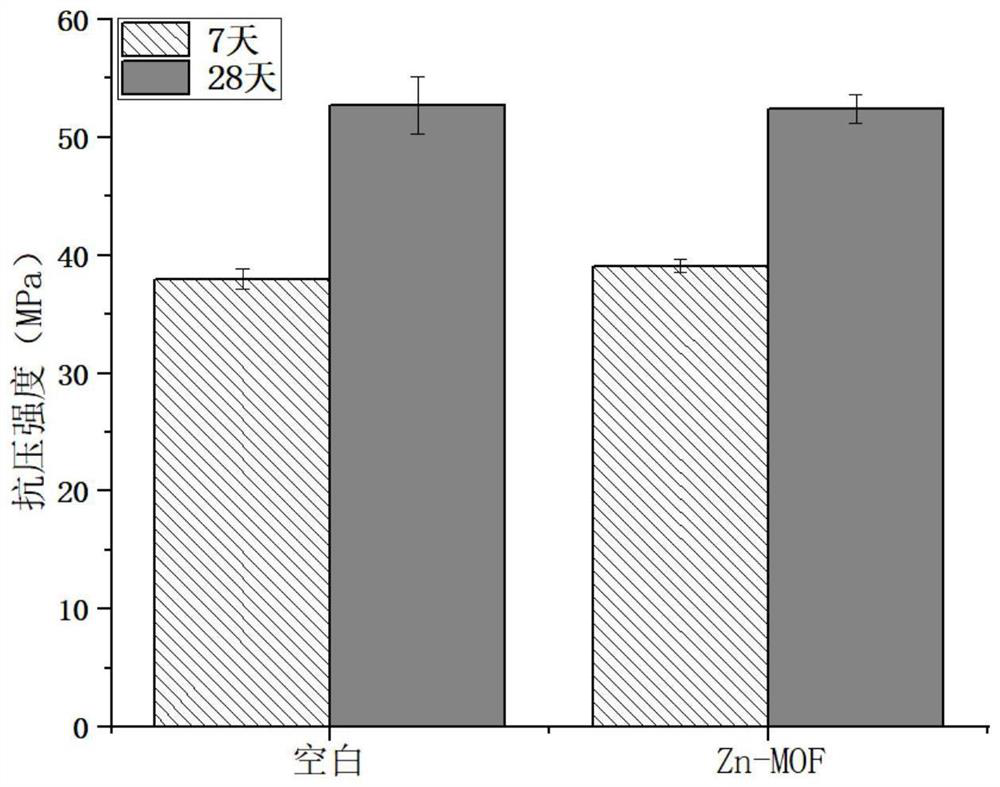

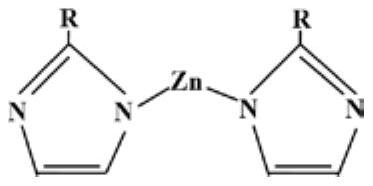

Zeolite-like zinc-based imidazolate metal organic framework steel bar corrosion inhibitor as well as preparation method and application thereof

The invention belongs to the field of steel bar corrosion inhibitors for concrete engineering, and discloses a zeolite-like zinc-based imidazolate metal organic framework steel bar corrosion inhibitor, and a preparation method and an application thereof. Zinc ions are adopted as metal nodes, and are subjected to coordination self-assembly with imidazole organic ligands to form the zeolite-like zinc-based imidazolate steel bar corrosion inhibitor, wherein the structural formula of the zeolite-like zinc-based imidazolate MOFs is shown in the specification, and R is one of methyl, nitro and formyl. According to the invention, the zeolite-like zinc-based imidazolate MOFs have the advantages of high chemical stability, strong adsorption effect on the surface of the steel bar, high hydrophobicity after adsorption and film formation and the like under the high-alkalinity condition of concrete, and play a role in efficiently inhibiting corrosion of the steel bar in the concrete.

Owner:SOUTH CHINA UNIV OF TECH

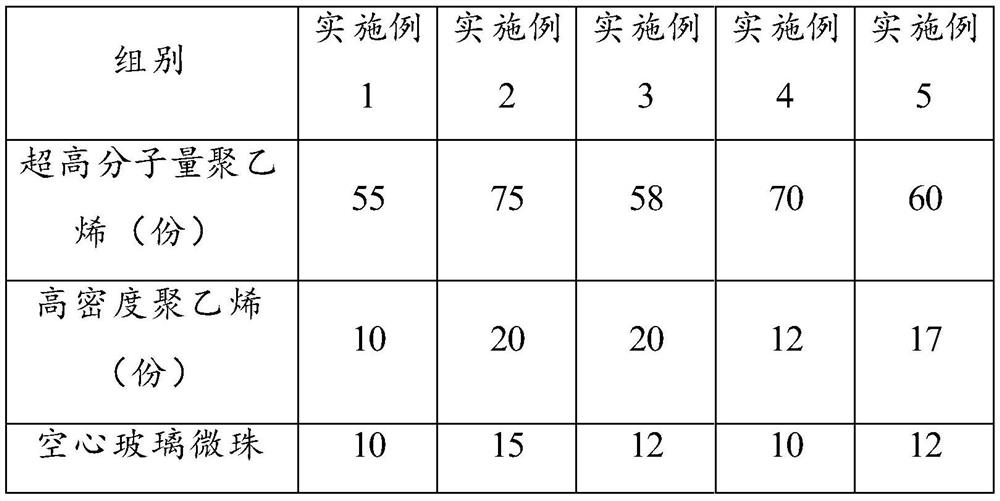

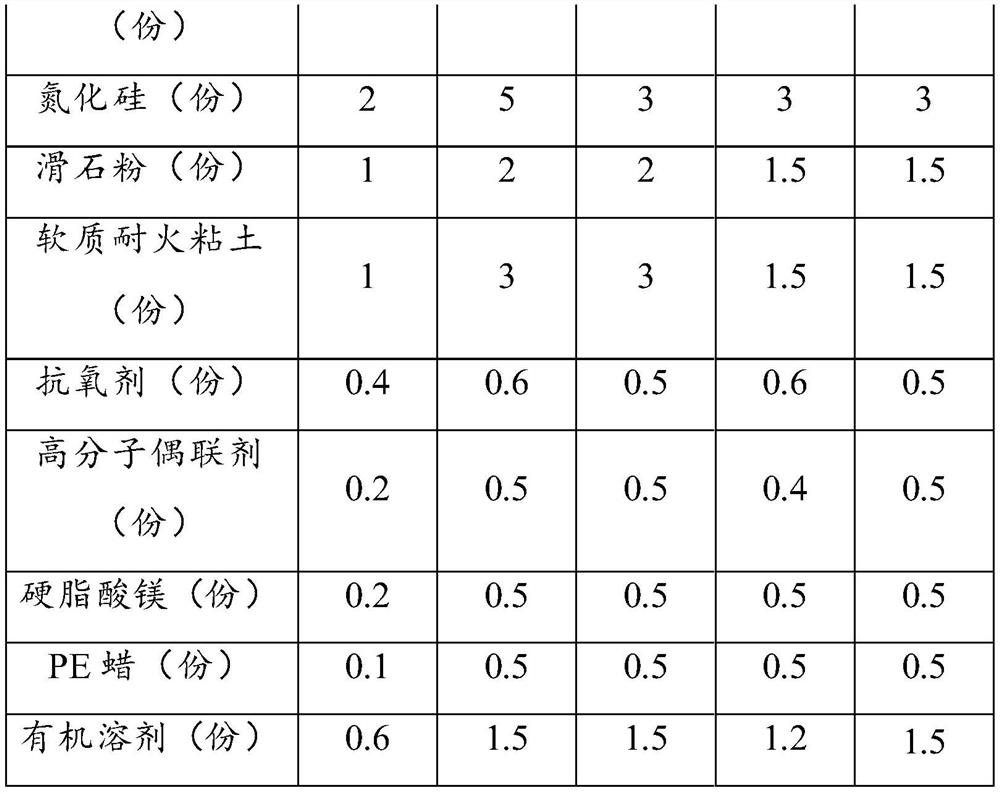

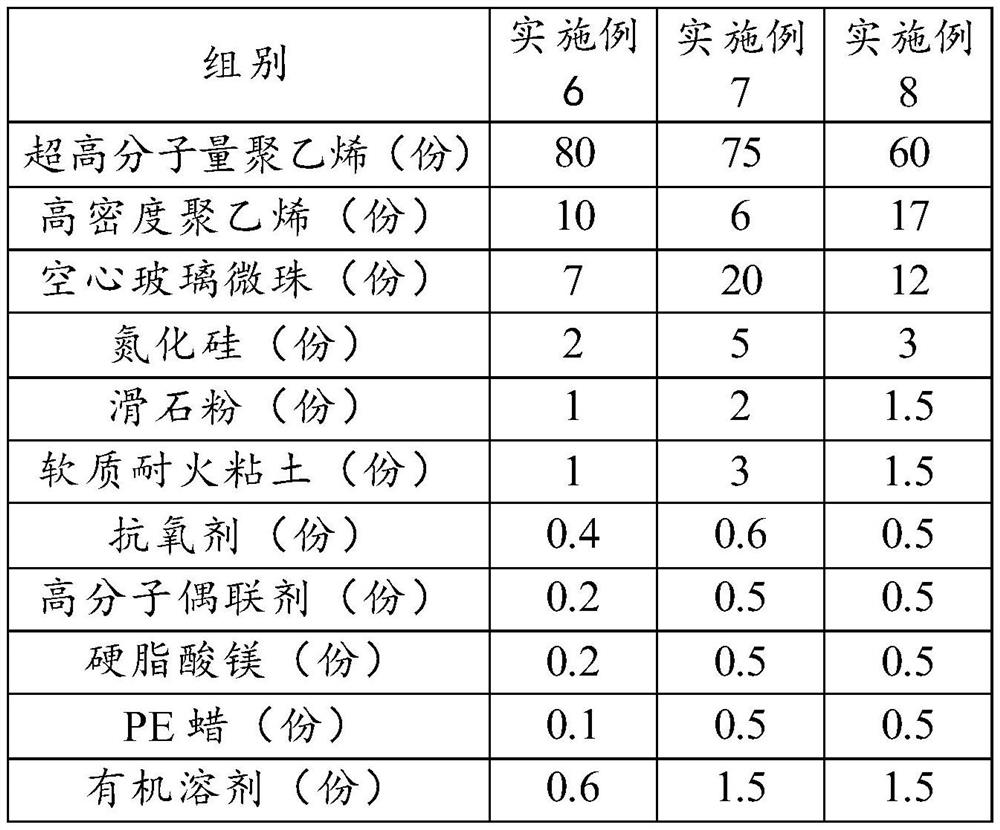

Polyethylene composite material and application thereof in preparation of high-temperature-resistant lining oil pipe

The invention provides a polyethylene composite material and application thereof in preparation of a high-temperature-resistant lining oil pipe, and relates to the technical field of special pipes. The polyethylene composite material is mainly prepared from ultra-high molecular weight polyethylene, high-density polyethylene, a heat-resistant filler and auxiliaries, wherein the heat-resistant filler comprises hollow glass beads, silicon nitride, talcum powder and soft refractory clay; the auxiliaries comprise an antioxidant, a macromolecular coupling agent, magnesium stearate, PE wax and an organic solvent. According to the polyethylene composite material prepared by compatibility of the raw materials, all the raw materials achieve a synergistic compounding effect, and the polyethylene composite material has good temperature resistance and aging resistance, is stable in mechanical property and can cover basic characteristics of a conventional lining oil pipe product. Experiments verify that the composite material can resist high temperature of 150 DEG C effectively, and the technical requirements for use in a deep well oil extraction environment are fully met.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

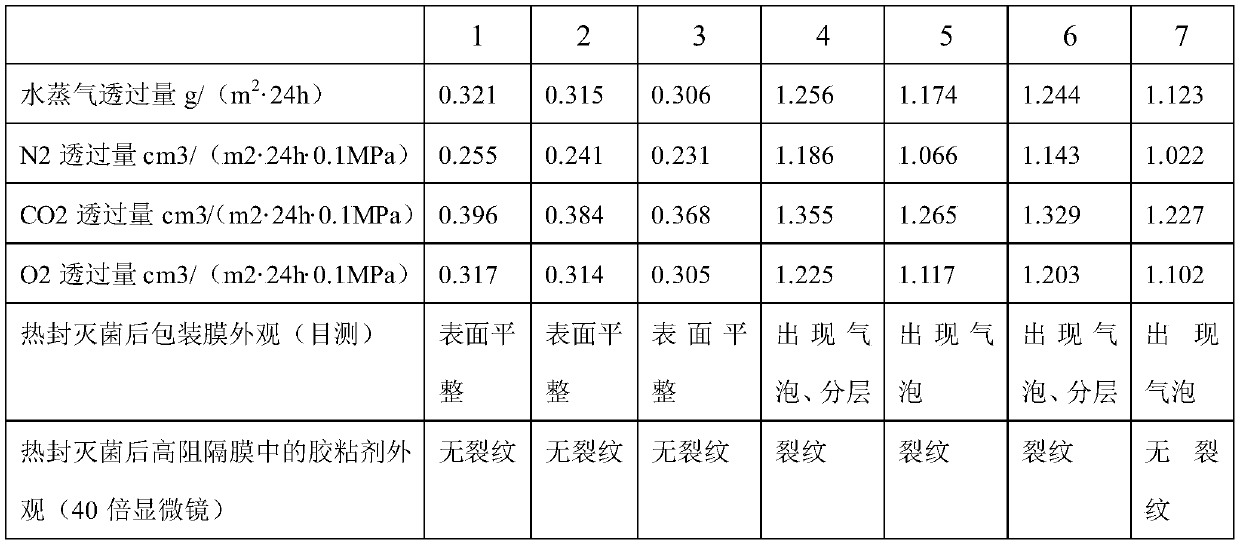

High-barrier medicine packaging film and preparation method thereof

ActiveCN110091557AHigh crystallinityImprove barrier propertiesFlexible coversWrappersCarboxymethyl celluloseEpoxy

The invention discloses a high-barrier medicine packaging film. The high-barrier medicine packaging film comprises an aluminum layer and a base layer, the aluminum layer and the base layer are bondedby an adhesive, and the adhesive is prepared from polyvinylidene chloride, epoxy resin, nanometer titanium dioxide, nano-alumina, carboxymethyl cellulose, graphene, a plasticizer, a coupling agent, acuring agent and a stabilizer. The barrier film has high barrier to water and air, and can significantly prolong the shelf life of medicines. The invention also provides a preparation method of the high-barrier medicine packaging film.

Owner:SICHUAN HUILI IND

Anti-ablation coating material for resin-based composite material and preparation method of anti-ablation coating material

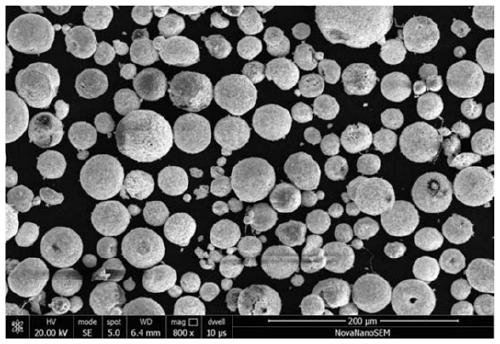

ActiveCN110387148AHas sweating and exothermic propertiesLow thermal conductivityFireproof paintsSpherical granuleSpray Granulation

The invention relates to an anti-ablation coating material for a resin-based composite material and a preparation method of the anti-ablation coating material. The anti-ablation coating material is auniform mixture of yttria-stabilized zirconia (YSZ), resin, Cu and SiO2, and the mixture is spherical particles or spherical granule materials. The preparation method of the anti-ablation coating material comprises the steps of powder mixing, ball milling and spray granulation. The anti-ablation coating material for the resin-based composite material and the preparation method of the anti-ablationcoating material have the beneficial effects that a YSZ ceramic surface layer is composited by adding specific components with heat release, so that on the one hand, the ceramic layer realizes good heat insulation and anti-ablation effects, and on the other hand, the anti-ablation and heat insulation properties of the composite material are further improved through ablation-phase gasification heat dissipation at the high temperature.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

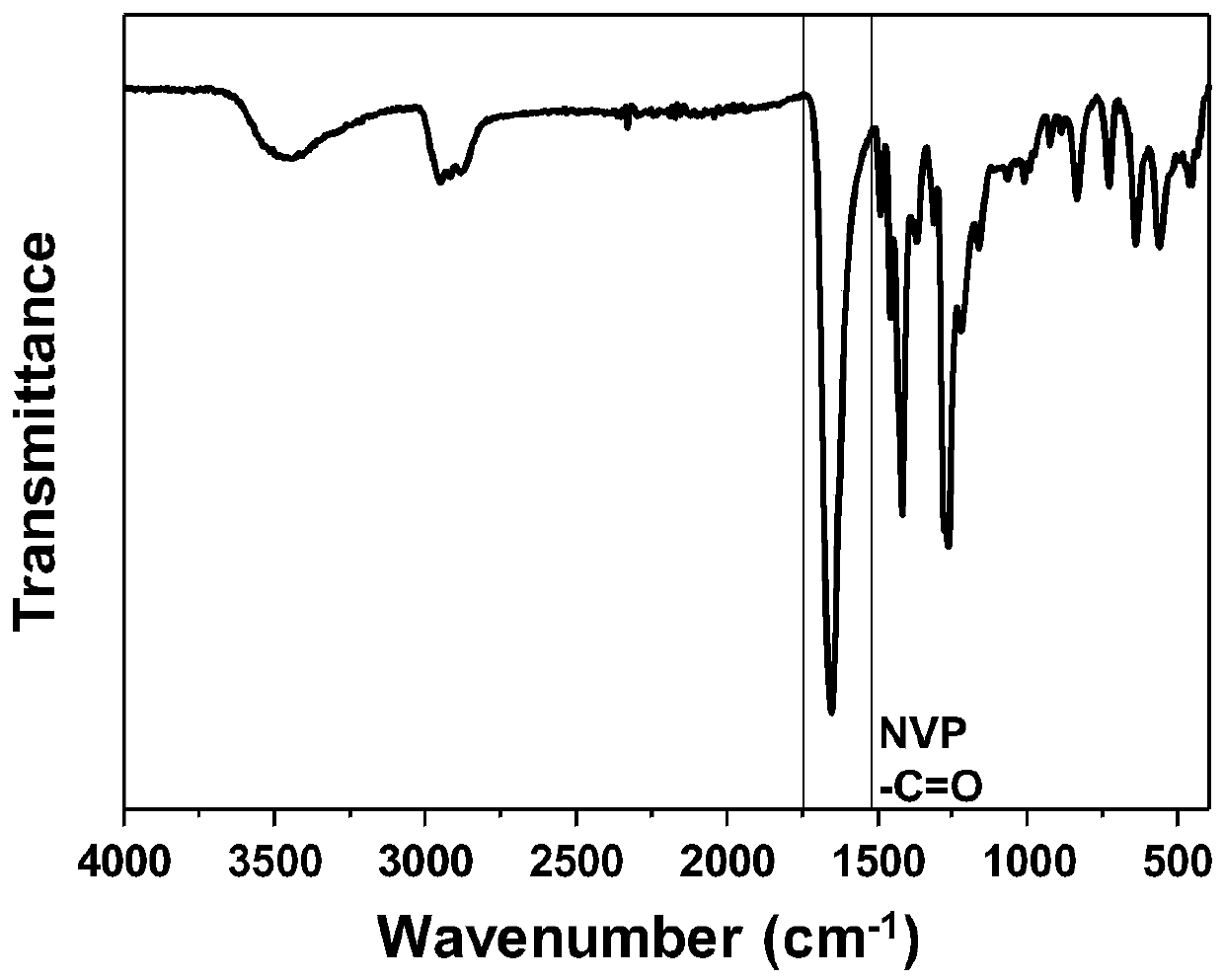

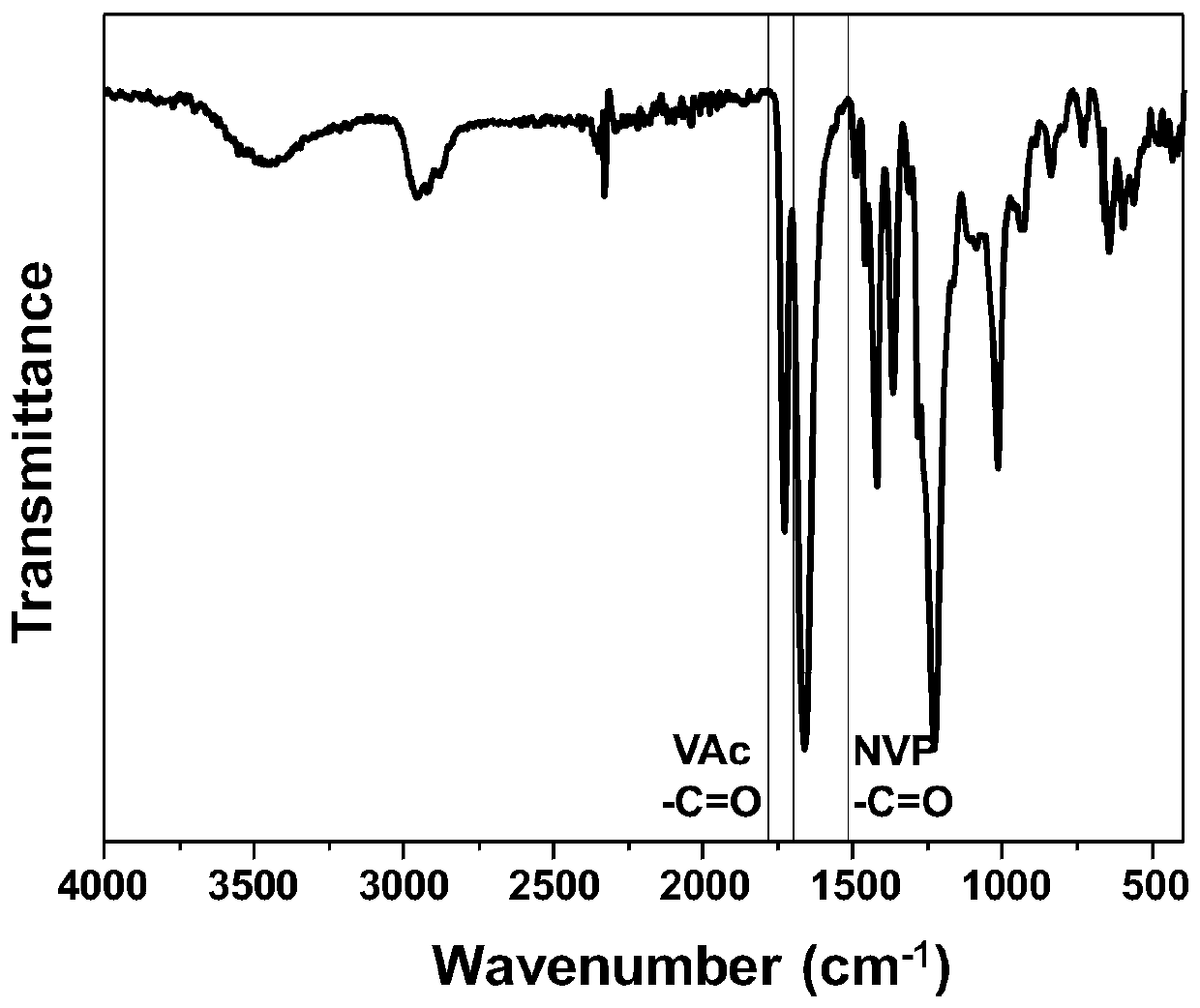

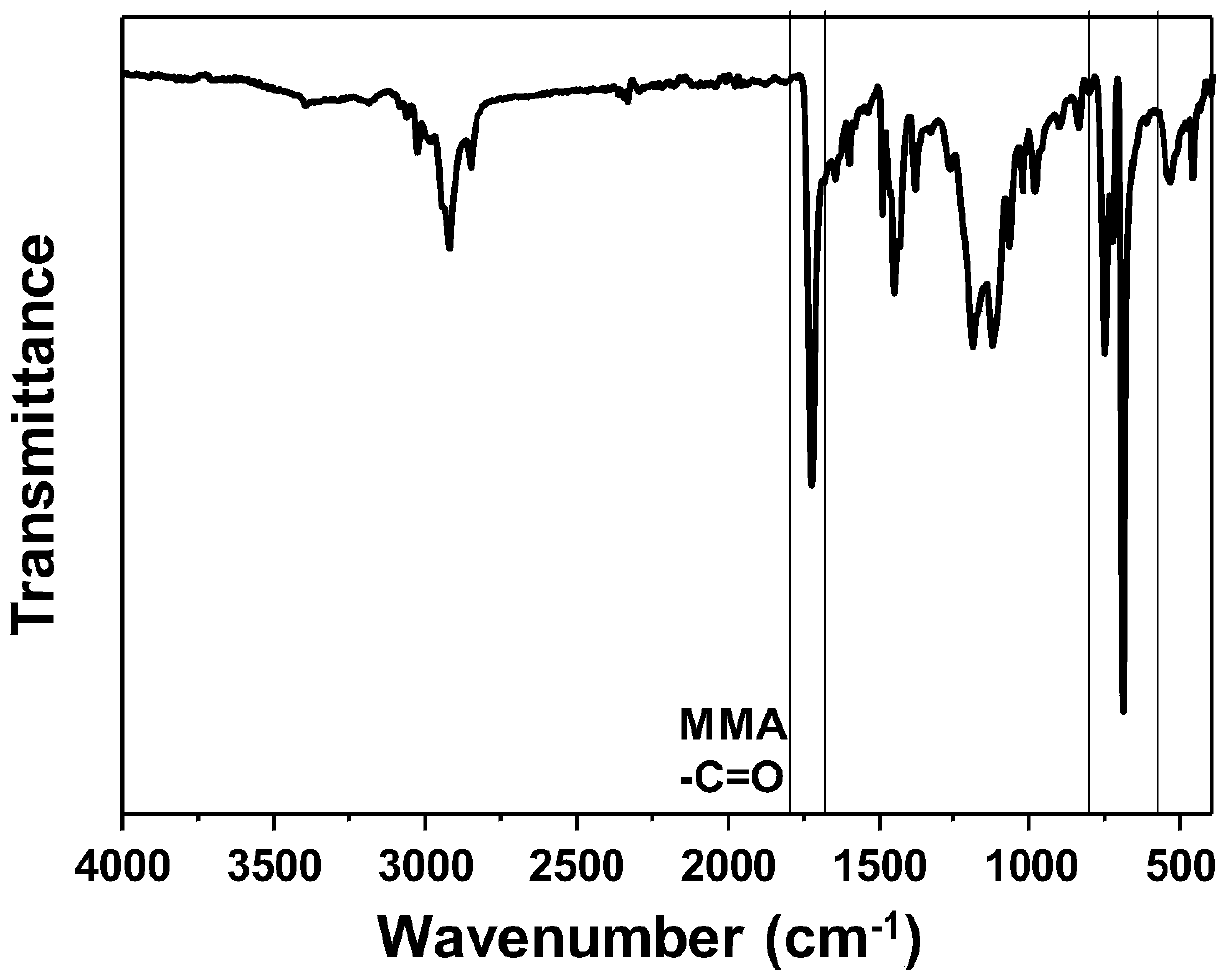

High polymer material for modifying explosive, and preparation method thereof, and method for modifying explosive

InactiveCN110511311APerformance impactAffect mechanical propertiesNon-explosive/non-thermic compositionsDeflagrationHigh polymer

The invention discloses a high polymer material for modifying an explosive, wherein the material is characterized in that the molecule contains a pyrrolidone group, and the material can be prepared bycarrying out copolymerizing vinyl pyrrolidone and other polymerization monomers or by carrying out self-homopolymerization, can be matched with epoxy resins, acrylic resins and other polymer resins so as to be used as a modification material for explosives, and can be mixed with explosives in a powder form, or mixed with explosives under a heating condition. The invention further discloses a method for modifying explosives by using the polymer modification material, wherein direct mixing or heating melting mixing can be performed, and a mass ratio of an explosive material to the modificationmaterial is any ratio. The invention further discloses a method for modifying an explosive, wherein the high polymer material is adopted as an additive, and is mixed with an explosive material so as to affect the performance of the explosive material, wherein the performances comprise: mechanical performance, color, compatibility with other components, deflagration performance and the like.

Owner:XIAN UNIV OF TECH

Manufacturing method of multi-functional modified acrylic fibers with high moisture absorption and flame resistance

InactiveCN101845745BGood moisture absorptionImprove flame retardant performancePhysical treatmentFibre typesPolymer scienceMoisture absorption

The invention relates to a manufacturing method of multi-functional modified acrylic fibers with high moisture absorption and flame resistance, which is characterized by directly complexing and cyclizing acrylic fibers into the acrylic fibers with high moisture absorption and flame resistance by using a method of chemical complexing and cyclization. The method comprises the following steps of: firstly, adding the acrylic fibers into a water solution containing copper ions for reaction to produce acrylic fibers containing the copper ions; then, adding the acrylic fibers containing the copper ions into a mixture of hydrazine hydrate and reaction assistants to immerse for a certain period of time; and finally, drying the acrylic fibers by squeezing or tossing to obtain acrylic fibers containing a certain amount of water solution, and steaming the acrylic fibers in a dry or gas mode in a high-temperature high-pressure steam setting vessel for a certain period of time to produce the acrylic fibers with high moisture absorption and flame resistance. The method can process the acrylic fibers into the acrylic fibers with high moisture absorption and flame resistance only with one simple high-temperature high-pressure steam setting vessel and fewer matching processes and equipment, which greatly reduces the traditional manufacturing process of the acrylic fibers with high moisture absorption and flame resistance; the invention has simple production process, low equipment investment, low production cost and easy realization of industrialization.

Owner:SHANDONG UNIV OF TECH

Novel high-efficiency flame-retardant weather-resistant master batch and preparation method thereof

The invention relates to a novel high-efficiency flame-retardant weather-resistant master batch and a preparation method thereof. The master batch comprise the following components: carrier resin, a flame retardant, an anti-light aging additive, an antioxidant and a processing additive, wherein the carrier resin accounts for 8-75% of the total mass of the master batch, the mass ratio of the anti-light aging additive to the flame retardant is 1: 2-30, the mass ratio of the antioxidant to the anti-light aging additive is 1: 6-30, and the addition amount of the processing additive accounts for 0.5-5% of the total mass. The invention discloses the novel high-efficiency flame-retardant weather-resistant master batch and the preparation method thereof, which can endow an auxiliary agent with multifunctionality by means of a very small amount of acid absorbent, lubricant and processing stabilizer, and thus double effects of flame retardance and weather resistance are achieved without damagingthe basic properties of resin, and the effects of safety, environmental protection and no harm to human bodies are achieved.

Owner:宿迁联宏新材料有限公司

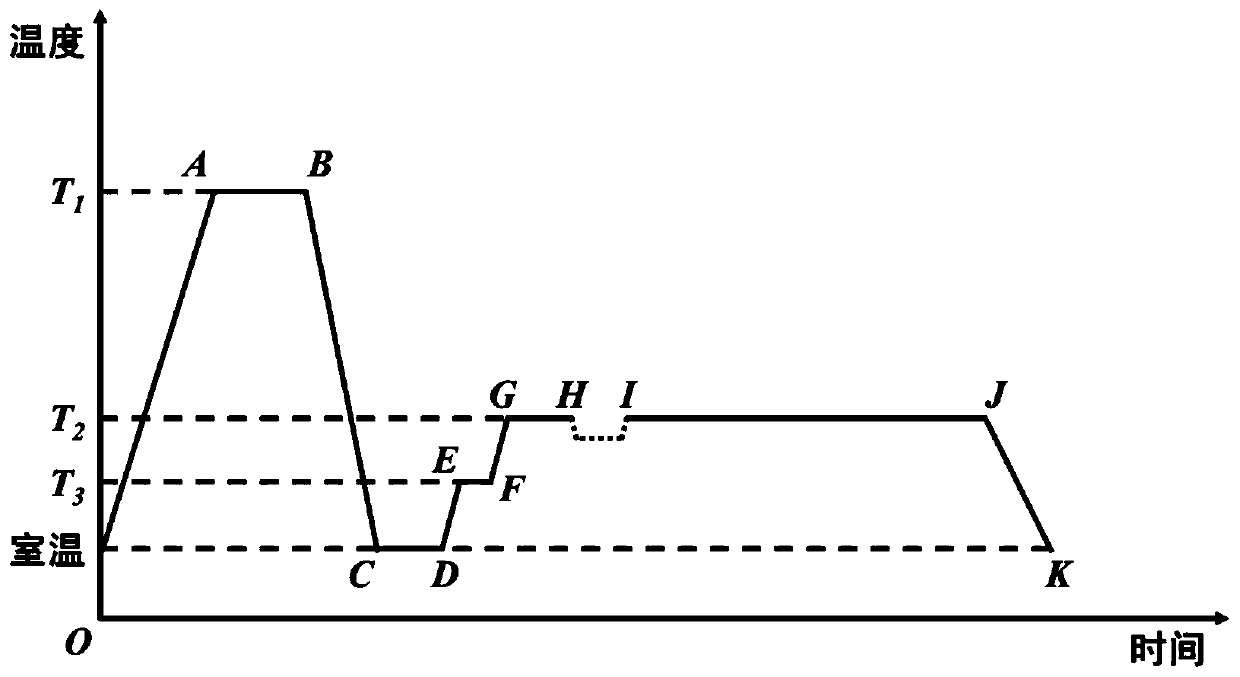

CFRP/aluminum alloy composite structure heat-forming and co-curing integrated forming method

The invention discloses a CFRP / aluminum alloy composite structure heat-forming and co-curing integrated forming method. The method comprises the following steps that a heat-treatable aluminum alloy plate is placed in a heating furnace for complete solution treatment, the aluminum alloy plate is taken out for water quenching and surface roughening treatment, then prepreg is laid on an aluminum alloy surface for hot-pressing co-curing through stepped heating, and finally the CFRP / aluminum alloy part is placed in the heating furnace for artificial aging. According to the method, CFRP and aluminumalloy integrated forming can be realized, the impact resistance of a composite structure is effectively improved, meanwhile, the material and manufacturing cost is reduced, the forming period is shortened, and the process efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

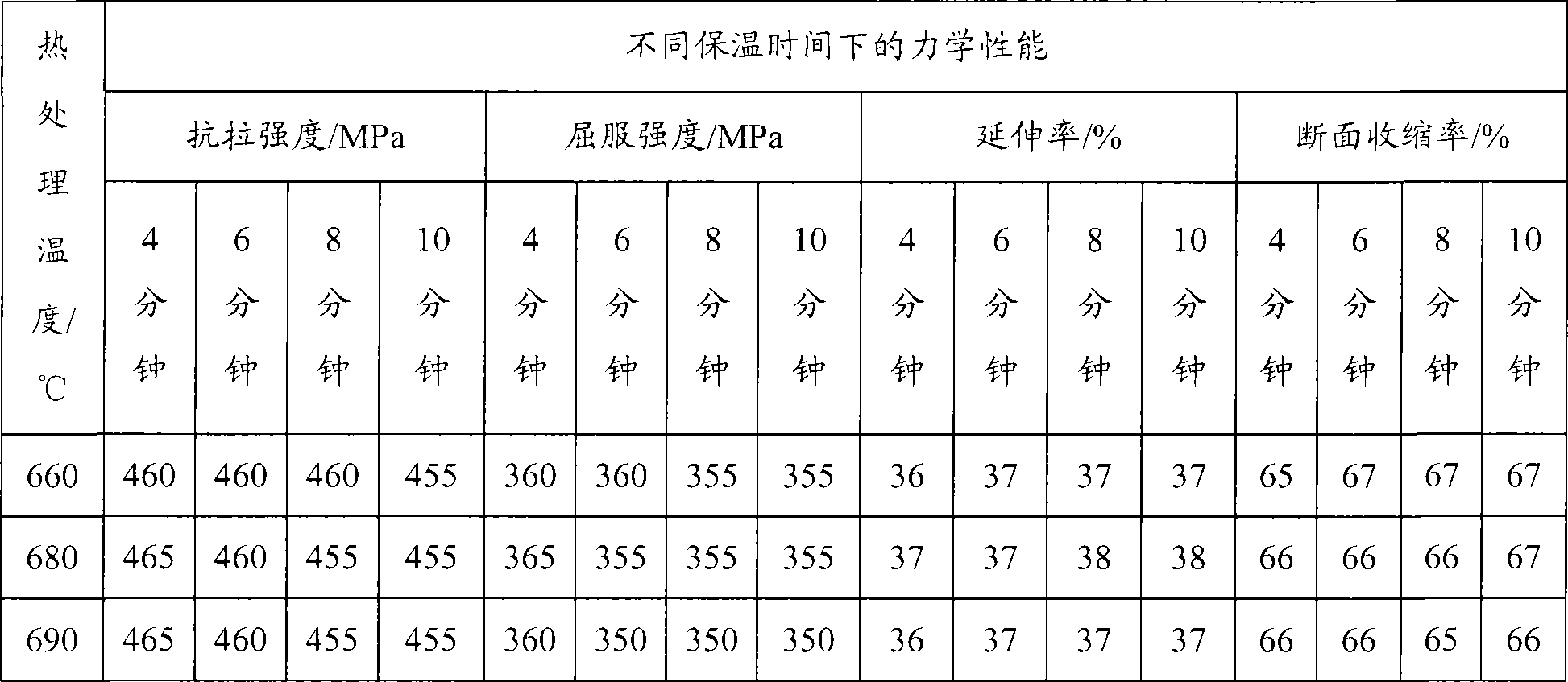

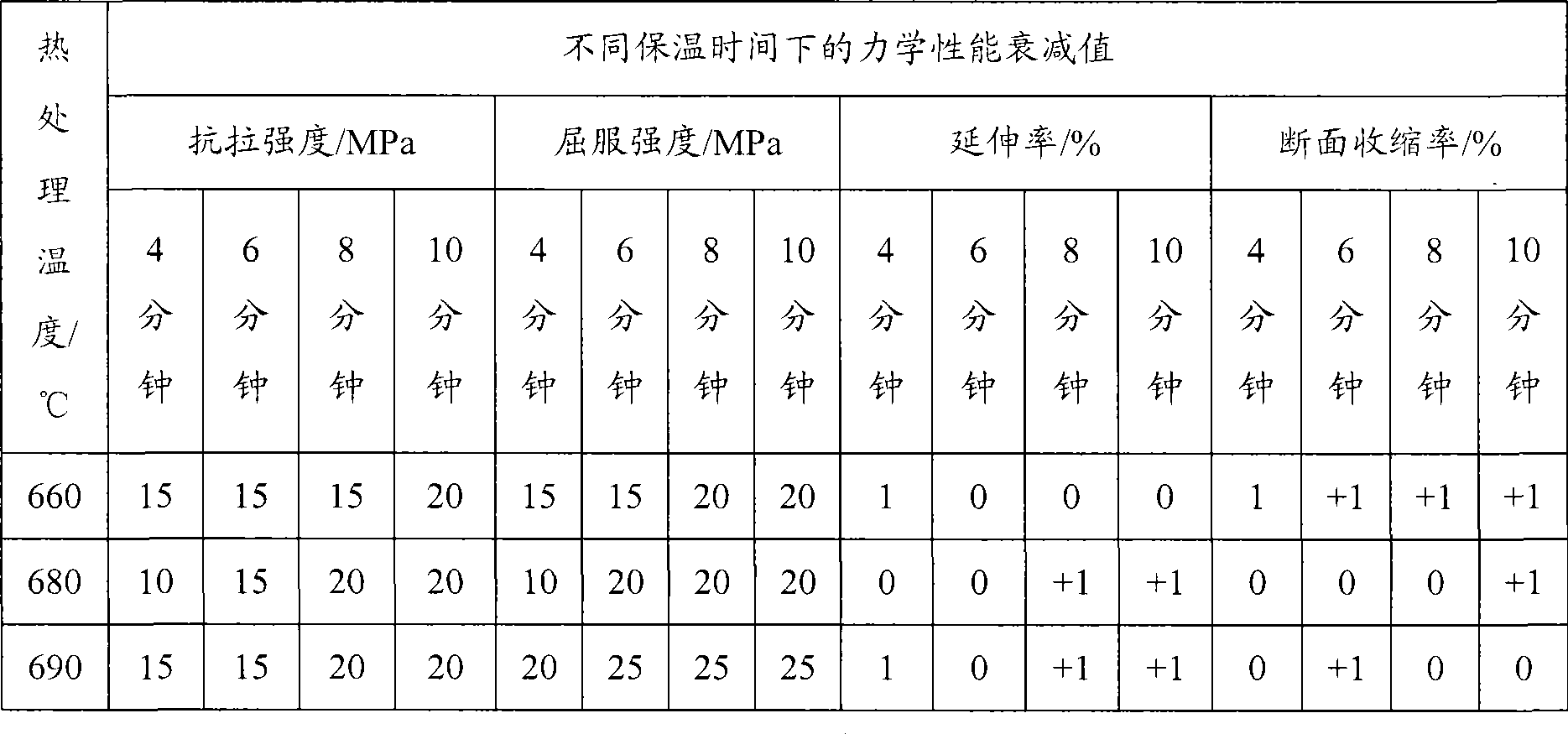

Heat treatment method for steel cylinder for liquefied petroleum gas

InactiveCN101476027AAffect mechanical propertiesReduce plasticityFurnace typesHeat treatment furnacesMechanical propertyLiquefied petroleum gas

The invention relates to a thermal treatment method for liquefied petroleum gas containers made of hot rolled steel plates.The thermal treatment method comprises the following steps: heating a heat treatment furnace to a temperature in the range of 660 DEG C - 690 DEG C, putting the liquefied petroleum gas containers into the heat treatment furnace, when the temperature of the liquefied petroleum gas containers reach 660 DEG C - 690 DEG C, preserving the temperature for 4-10 minutes, taking out the liquefied petroleum gas containers from the heat treatment furnace and cooling them in the air; according to the invention, the liquefied petroleum gas containers after thermal treatment have excellent and synthetic mechanical properties through the thermal treatment processes of controlling heating temperature, temperature-preserving time, cooling mode and the like.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

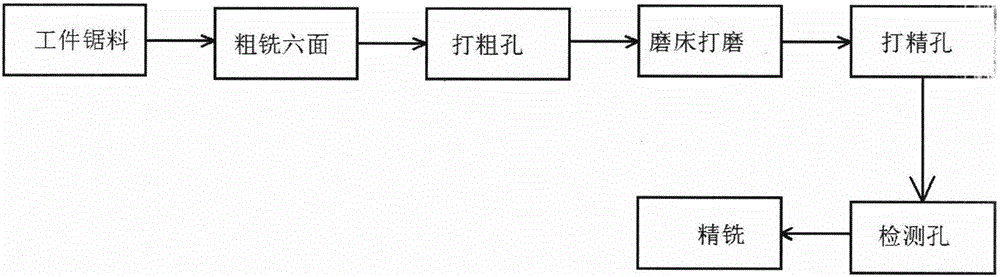

Machining method for eliminating needle plate deformation

The invention discloses a machining method for eliminating needle plate deformation. The machining method is characterized by comprising workpiece sawing, six-surface rough milling, rough hole punching, fine hole punching, hole detection and finish milling. The machining method creatively classifies holes in a needle plate to two types of rough holes and fine holes for the first time, adopts a two-step procedure of machining the fine holes after machining the rough holes, discards a traditional process of once punching, can effectively guarantee the needle plate to have no high deformation in a short time due to quick thermal alteration, can machine the holes in the needle plate in a dispersed manner by the two-step method, and guarantees no stress concentration of the needle plate to influence the mechanical performance.

Owner:宁波龙尚模架科技有限公司

Copper ammonia fiber fabric and preparation method thereof

ActiveCN111350007AGood moisture absorption and quick dryingImprove mechanical propertiesArtificial filaments from cellulose solutionsFibre typesCuprammonium rayonPolymer science

The present invention provides a copper ammonia fiber fabric and a preparation method thereof. The method comprises the steps of firstly preparing cotton linter natural cellulose, a copper compound concentrated ammonia solution, gamma-aminopropyltriethoxy silane modified nano alumina as raw materials into modified copper ammonia fibers, then forming mixed filaments I by the modified copper ammoniafibers, methyl acryloxypropyl trimethoxy silane modified superfine polyamide fibers and a water-soluble vinylon fiber network, then forming mixed filaments II by the modified copper ammonia fibers and a superfine polyester fiber network, and finally weaving the mixed filaments I and the mixed filaments II into warps and wefts by using a loom to obtain a grey fabric, and performing vacuum heatingand finishing to remove water-soluble vinylon fibers so as to obtain the copper ammonia fiber fabric. The copper ammonia fiber fabric has excellent moisture-absorbing and quick-drying performance andgood mechanical performance.

Owner:汕头市现代服饰有限公司

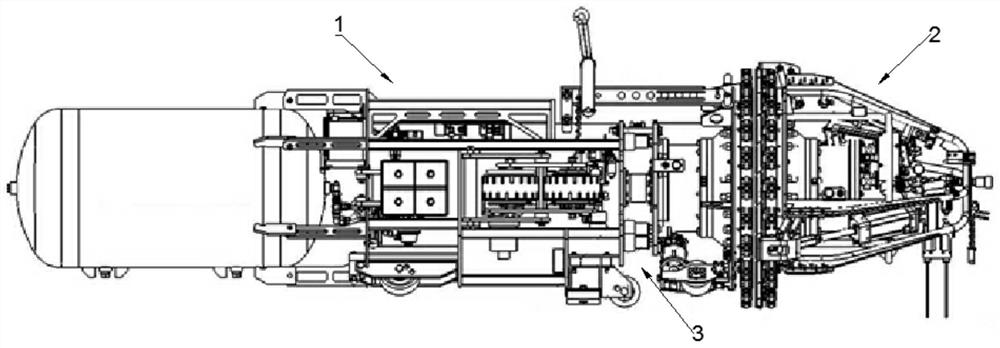

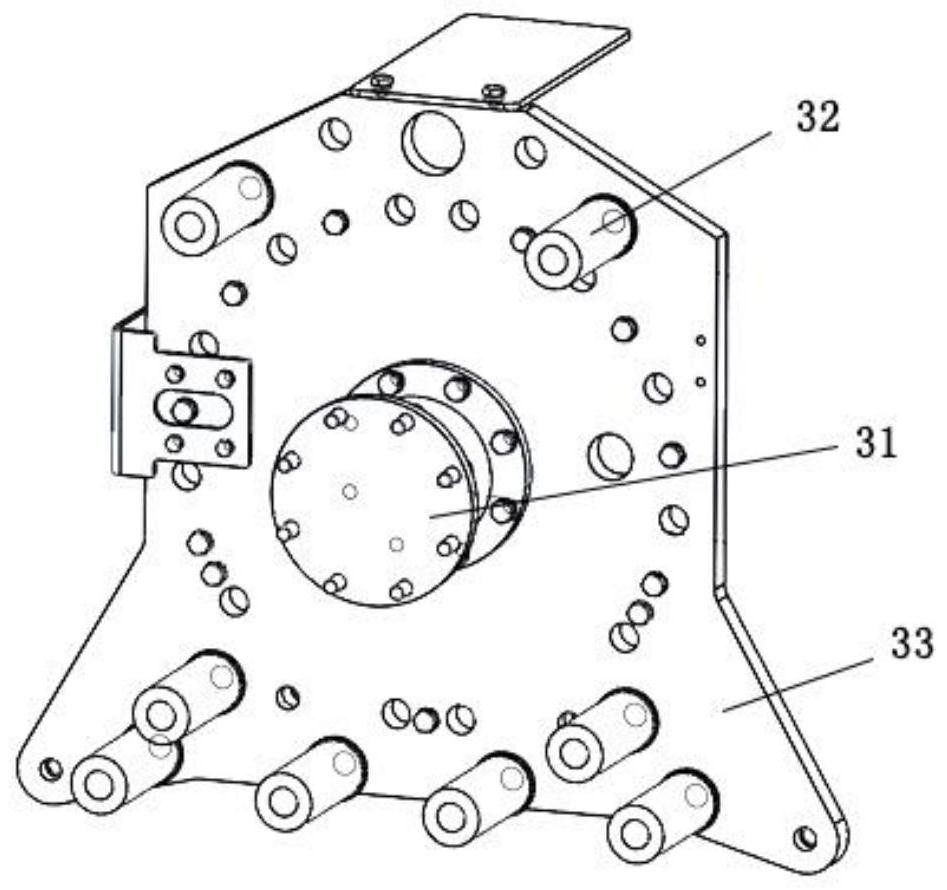

Pipe liner internal aligning device system

PendingCN112171169AExtended service lifeGuaranteed matching accuracyWelding/cutting auxillary devicesAuxillary welding devicesUniversal jointEngineering

The invention discloses a pipeline liner internal aligning device system. The pipeline liner internal aligning device system comprises a machine body system and a conical head system and further comprises a flexible connection system; and the flexible connection system comprises a universal joint used for connecting the machine body system and the conical head system and a first elastic connectionpiece used for supporting the machine body system. The flexible connection system is arranged, the rigid connection mode of a traditional pipeline liner internal aligning device is changed, the machine body system and the conical head system are connected through the flexible connection system, and flexible connection of the machine body system and the conical head system is achieved; and throughthe structural design of the pipeline liner internal aligning device system, the aligning precision and the coaxiality between the aligned conical head system and a steel pipe are greatly improved, and the problems that an aligning device is short in service life, long in auxiliary aligning time and low in aligning precision, and copper seeping exists in the welding process are solved.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

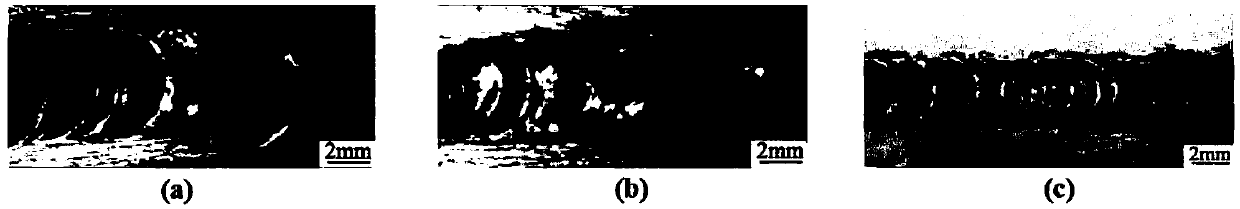

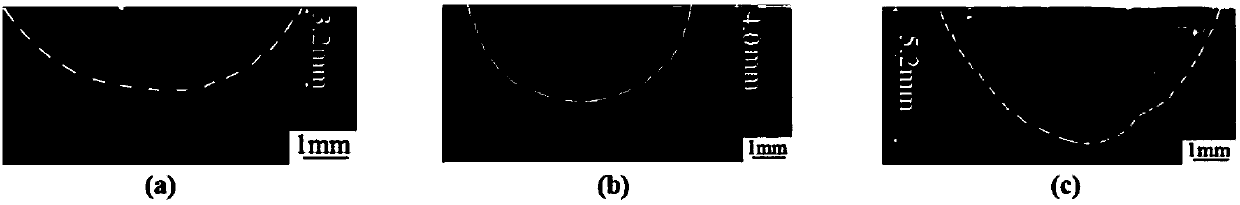

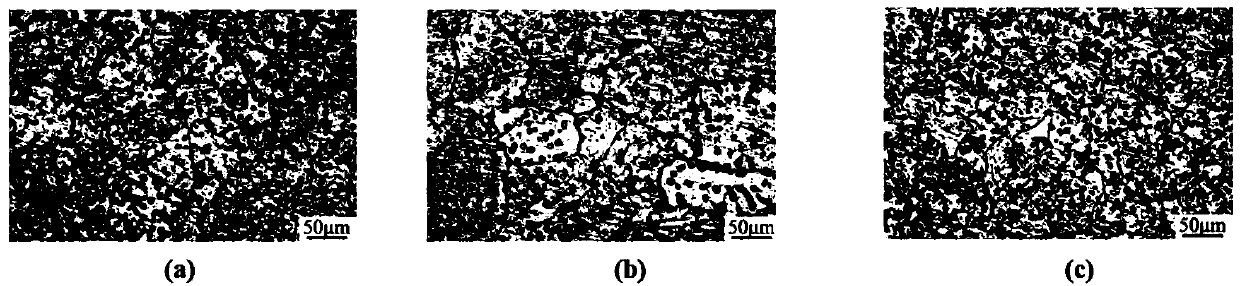

Mixed active agent for activing flux tungsten inert gas arc welding of magnesium alloy

InactiveCN108032002AStrong penetrating powerAffect mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentMolten bath

Provided is a mixed active agent for activing flux tungsten inert gas arc welding of a magnesium alloy. A method comprises the following steps that (1), the mixed active agent is formed by mixing MnCl2 with ZnO, wherein the mixed active agent comprises, by weight percentage, 65%-75% of MnCl2 and 25%-35% of ZnO; (2), according to a use method of the active agent, MnCl2 and ZnO active agent powder is fully ground, after even mixing, an appropriate amount of acetone is evenly added, and the mixture is made into a paste; (3), the upper surface of a sample is evenly coated with the pasty active agent with a flat hairbrush, the coating width is about 40 mm, and the average coating amount of the active agent is 6 mg.cm<-2>; (4), TIG is conducted after acetone is volatilized; and (5), after welding is completed, the morphology and the microstructure of a welding joint and a molten bath are observed, and representation of the mechanical property is conducted.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com