Polyethylene composite material and application thereof in preparation of high-temperature-resistant lining oil pipe

A composite material and polyethylene technology, which is used in the preparation of high temperature resistant lined oil pipes, in the field of polyethylene composite materials, can solve problems such as unusability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] According to one aspect of the present invention, a kind of preparation method of above-mentioned polyethylene composite material, described preparation method comprises the following steps:

[0065] First, dilute the polymer coupling agent with an organic solvent to obtain solution A; then use solution A to modify the surface of the heat-resistant filler to obtain a surface-modified filler; then mix the raw materials including the surface-modified filler and dry , to obtain polyethylene composites.

[0066] The preparation method of the polyethylene composite material provided by the present invention, the preparation method first dilutes the polymer coupling agent with an organic solvent to obtain solution A; then uses solution A to modify the surface of the heat-resistant filler to obtain the surface modified Filler; then, the raw materials including the surface-modified filler are mixed and then dried to obtain a polyethylene composite material. The above preparati...

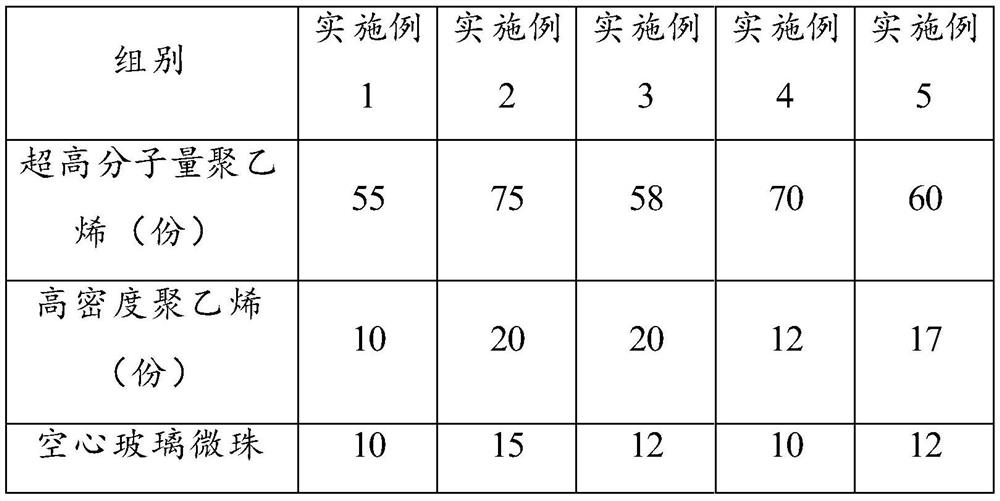

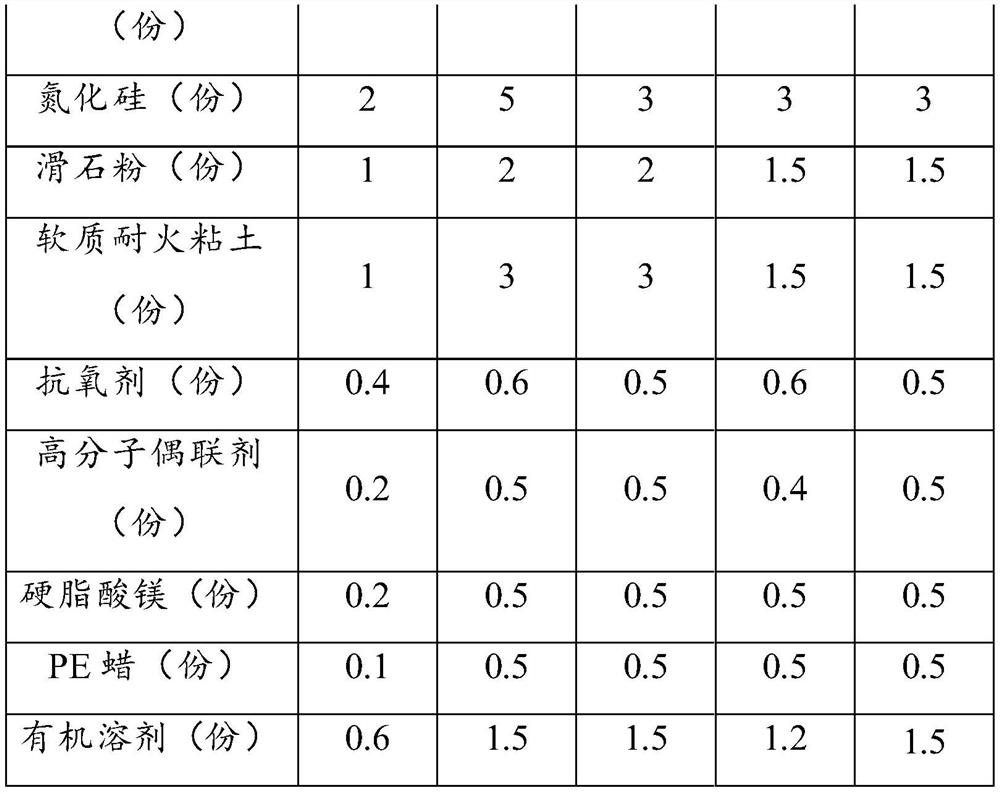

Embodiment 1~5

[0078] A polyethylene composite material, in parts by mass, said polyethylene composite material comprises the following components:

[0079]

[0080]

[0081] Among them, the ultra-high molecular weight polyethylene GK02 with a number-average molecular weight of 2.6-3.2 million; the high-density polyethylene DMDA-8008H with a number-average molecular weight of 250,000-400,000; Beads are processed from borosilicate raw materials, with a particle size of 10-250 microns and a wall thickness of 1-2 microns; silicon nitride (Si3N4) is in powder form, with a particle size of 10-18 nanometers; the main component of talc powder is hydrated Magnesium silicate, talc powder with a particle size of 2000 mesh obtained by crushing natural talc; polymer coupling agent selection silane coupling agent A-171 (vinyltrimethoxysilane); antioxidant selection BASF antioxidant Irganox1010 .

[0082] The preparation method of described polyethylene composite material, comprises the following s...

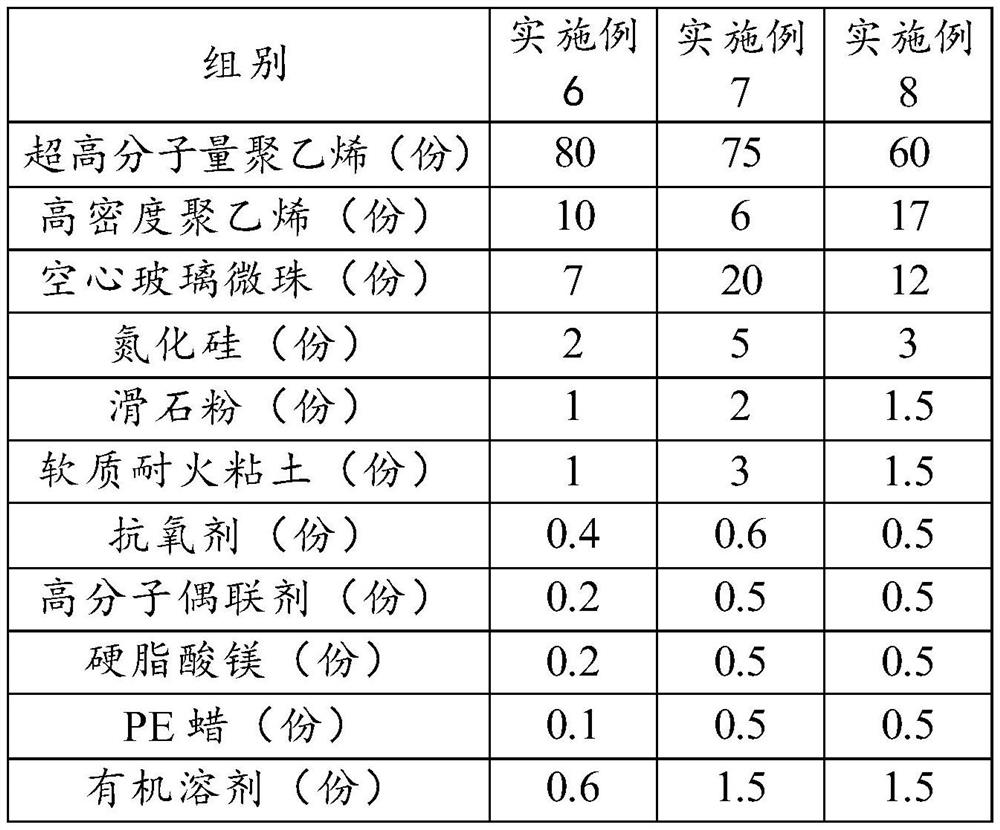

Embodiment 6~8

[0086] A polyethylene composite material, in parts by mass, said polyethylene composite material comprises the following components:

[0087]

[0088] Wherein, the number average molecular weight of the ultra-high molecular weight polyethylene in Example 8 is 2.4 million, and the number average molecular weight of the high-density polyethylene is 200,000.

[0089] The preparation method of the polyethylene composite material is the same as in Example 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com