Preparation method of modified phenolic resin

A phenolic resin, modified technology, applied in the field of preparation of modified phenolic resin, to achieve the effects of environmental protection, increase synthesis rate, and improve flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

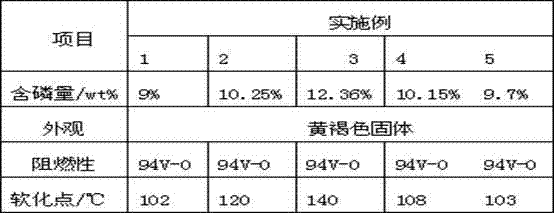

Examples

Embodiment 1

[0030] The obtained modified phenolic resin is subjected to post-treatment so that the phenol content is 0.8%, and the phosphorus-containing modified phenolic resin is obtained.

[0031] Example 2

[0032] The preparation method of modified phenolic resin comprises the steps:

[0033] (1) Mix 0.4 mol of phenol, 0.3 mol of m-phenol, and 0.3 mol of p-phenol into the reaction vessel, dissolve it in water at a temperature of 55-60 ° C, add barium hydroxide to adjust the pH to 7.5, and then add 1 mol of formaldehyde, Acetaldehyde 0.3mol, and heat up to 75-80°C, react, take a sample to detect if there is a substance insoluble in alkaline aqueous solution, stop the reaction, that is, generate a phenolic prepolymer;

Embodiment 2

[0035] The obtained modified phenolic resin is decompressed to -0.70~-0.60MPa, distilled, dehydrated and dephenolized, the phenol content is less than 0.9%, discharged, and cooled to obtain the desired phosphorus-containing modified phenolic resin.

[0036] Example 3

[0037] The preparation method of phosphorus-containing phenolic resin described in the present embodiment may further comprise the steps:

[0038] (1) Mix m-phenol 0.5mol and p-phenol 0.5mol, heat at 55-60°C to dissolve in water, add ammonium hydroxide to adjust pH to 11, then add formaldehyde 1.2mol, acetaldehyde 0.5mol, and heat up React at 75-80°C, take a sample to detect if there are substances insoluble in alkaline aqueous solution, stop the reaction, and generate a phenolic prepolymer;

Embodiment 3

[0040] The obtained modified phenolic resin is decompressed to -0.70~-0.60MPa, distilled, dehydrated and dephenolized, the phenol content is 0.5%, discharged, and cooled to obtain the desired phosphorus-containing modified phenolic resin.

[0041] Example 4

[0042] The preparation method of phosphorus-containing phenolic resin described in the present embodiment may further comprise the steps:

[0043] (1) Mix 0.4mol o-phenol, 0.4mol m-phenol, and 0.2mol p-phenol and heat at 45-50°C to dissolve in water, add sodium hydroxide and barium hydroxide to adjust the pH to 9.5, then add acetaldehyde 1.9mol, and heat up to 65-70°C to react, take a sample to detect if there are substances insoluble in alkaline aqueous solution, stop the reaction, and generate phenolic prepolymer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com