Anti-ablation coating material for resin-based composite material and preparation method of anti-ablation coating material

A technology of composite materials and coating materials, applied in the direction of coatings, fireproof coatings, etc., can solve problems such as low bonding strength, mismatched interlayer stress, low thermal conductivity, etc., to reduce thermal conductivity and block thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

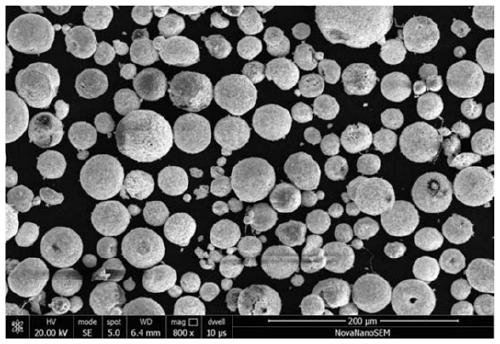

[0020] An anti-ablation coating material for resin-based composite materials is provided, and the anti-ablation coating material is yttria-stabilized zirconia, resin, Cu and SiO 2 A homogeneous mixture that is a spherical particle or spherical aggregate material.

[0021] Further, wherein, yttria stabilized zirconia, resin, Cu, SiO 2 The mass ratio between them is: 72:3:8:17.

[0022] Further, wherein, the resin includes phenolic resin, modified silicone resin and polyester; the mass ratio between the phenolic resin, modified silicone resin and polyester is: 1:2:1.

[0023] Provided is a method for preparing an anti-ablation coating material for resin-based composite materials. Yttria-stabilized zirconia (YSZ) powder with a particle size of 10-20 nm, resin powder with a particle size of 1-2 μm, and Yttria-stabilized zirconia (YSZ) powder with a particle size of 3-5 μm are provided. Cu powder and SiO with a particle size of 3-5 μm 2 The powder is uniformly mixed to form a mi...

Embodiment 2

[0028] On the basis of the foregoing embodiments, the steps of this embodiment are:

[0029] An anti-ablation coating material for resin-based composite materials is provided, and the anti-ablation coating material is yttria-stabilized zirconia, resin, Cu and SiO 2 A homogeneous mixture that is a spherical particle or spherical aggregate material.

[0030]Further, wherein, yttria stabilized zirconia, resin, Cu, SiO 2 The mass ratio between them is: 72:4:8:16.

[0031] Further, wherein, the resin includes phenolic resin, modified silicone resin and polyester; the mass ratio between the phenolic resin, modified silicone resin and polyester is 2:2:1.

[0032] Provide a method for preparing an anti-ablation coating material for resin-based composite materials. Yttria-stabilized zirconia (YSZ) powder with a particle size of 15 nm, resin powder with a particle size of 1 μm, Cu powder with a particle size of 3 μm and Cu powder with a particle size of 3 μm are provided. SiO 2 The ...

Embodiment 3

[0037] On the basis of the foregoing embodiments, the steps of this embodiment are:

[0038] An anti-ablation coating material for resin-based composite materials is provided, and the anti-ablation coating material is yttria-stabilized zirconia, resin, Cu and SiO 2 A homogeneous mixture that is a spherical particle or spherical aggregate material.

[0039] Further, wherein, yttria stabilized zirconia, resin, Cu, SiO 2 The mass ratio between them is: 74:8:8:10.

[0040] Further, wherein, the resin includes phenolic resin, modified silicone resin and polyester; the mass ratio between the phenolic resin, modified silicone resin and polyester is 2:2:2.

[0041] Provide a method for preparing an anti-ablation coating material for resin-based composite materials. Yttria-stabilized zirconia (YSZ) powder with a particle size of 15nm, resin powder with a particle size of 2μm, Cu powder with a particle size of 2μm and Cu powder with a particle size of 4μm SiO 2 The powder is uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com