A method of forming an anti-ablation coating on the surface of a resin-based composite material

A composite material and resin-based technology, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problems of interlayer stress mismatch, shedding, low bonding strength, etc., and achieve improved heat insulation and heat protection function, extended time bounds, effect of reduced input rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

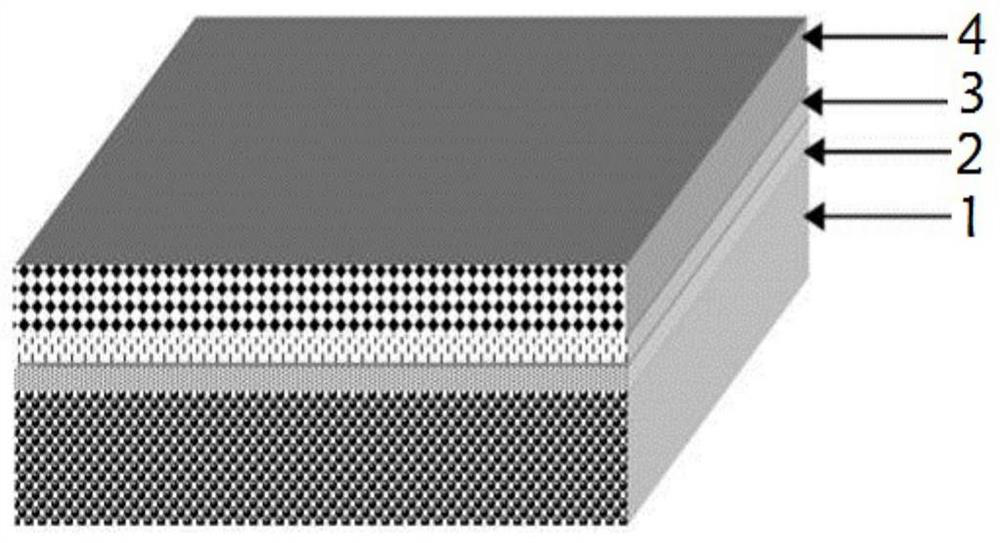

Image

Examples

Embodiment 1

[0029] A preparation method for sweating anti-ablation composite coating for thermal protection of polyimide resin-based composite materials, comprising the following steps:

[0030] Step 1: First select Zn, Al, and Cu powders with a particle size of 1 μm, wherein the mass percentage range ratio of Zn powder: Al powder: Cu powder is 30:40:30.

[0031] Step 2: The mixed powder obtained in Step 1 is then ball milled and mixed in a liquid medium (alcohol) at a speed of 10 rpm / s, and mixed for 10 hours; then ultrasonicated at a frequency of 15 Hz for 1 hour; dried at 60°C for 1 hour, A mixed powder of Zn, Al and Cu is obtained.

[0032] Step 3: Add the mixed powder obtained in Step 2 to polyvinyl alcohol with a mass ratio of 10%, heat to 60° C., and stir for 60 min at a stirring speed of 500 rpm / min. The stirred and mixed liquid material is sprayed and granulated under vacuum conditions to obtain a Zn / Al / Cu composite spraying material with a particle size of 30-40 μm, which is us...

Embodiment 2

[0043] On the basis of the foregoing embodiments, the steps of this embodiment are:

[0044] Step 1: First select Zn, Al, and Cu powders with a particle size of 2 μm, wherein the mass percentage range ratio of Zn powder: Al powder: Cu powder is 35:45:20.

[0045] Step 2: Then the mixed powder obtained in step 1 was ball milled and mixed in a liquid medium (alcohol) at a speed of 12rpm / s, and mixed for 12 hours; then ultrasonically treated at a frequency of 17Hz for 1.4 hours; dried at 70°C for 1.4 hours, A mixed powder of Zn, Al and Cu is obtained.

[0046] Step 3: Add the mixed powder obtained in Step 2 to polyvinyl alcohol with a mass ratio of 12%, heat to 70° C., and stir for 70 minutes at a stirring rate of 600 rpm / min. The stirred and mixed liquid material is sprayed and granulated under vacuum conditions to obtain a Zn / Al / Cu composite spraying material with a particle size of 30 μm to 40 μm, which is used as a primer layer for thermal spraying.

[0047] Step 4: Mix Al ...

Embodiment 3

[0057] On the basis of the foregoing embodiments, the steps of this embodiment are:

[0058] Step 1: First select Zn, Al, and Cu powders with a particle size of 3 μm, wherein the mass percentage range ratio of Zn powder: Al powder: Cu powder is 35:50:15.

[0059] Step 2: Then the mixed powder obtained in step 1 was ball-milled and mixed in a liquid medium (alcohol) at a speed of 15 rpm / s, and mixed for 15 hours; then ultrasonically treated at a frequency of 20 Hz for 2 hours; dried at 90°C for 2 hours, A mixed powder of Zn, Al and Cu is obtained.

[0060] Step 3: Add the mixed powder obtained in Step 2 into polyvinyl alcohol with a mass ratio of 15%, heat to 80° C., and stir for 90 minutes at a stirring speed of 700 rpm / min. The stirred and mixed liquid material is sprayed and granulated under vacuum conditions to obtain a Zn / Al / Cu composite spraying material with a particle size of 30 μm to 40 μm, which is used as a primer layer for thermal spraying.

[0061] Step 4: Mix Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com