CFRP/aluminum alloy composite structure heat-forming and co-curing integrated forming method

A composite structure, aluminum alloy laminate technology, applied in the field of sheet forming, can solve the problems of inability to achieve full solid solution of alloy elements in the aluminum alloy sheet, unable to meet the rapid integrated forming of composite structures, and reducing the utilization rate of hot forming molds, etc. Achieve the effect of reducing material cost, shortening forming cycle and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

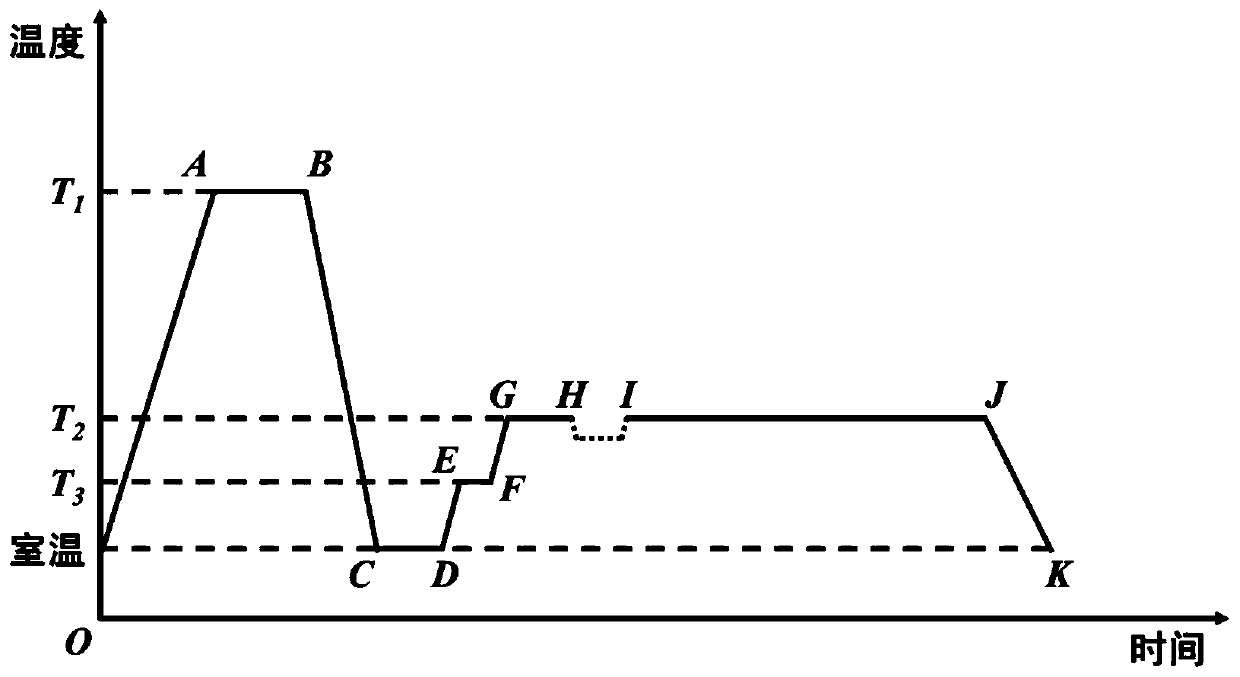

[0051] The present embodiment adopts aforementioned method to carry out, and concrete steps are as follows:

[0052] (1) Section A-B is the solid solution stage. Put the aluminum alloy 6069 in a heating furnace and keep it warm for 50 minutes at 520°C to fully dissolve the precipitated phase in the alloy;

[0053] (2) Section B-C is the quenching stage, and the aluminum alloy plate is taken out and quenched in water to obtain a supersaturated solid solution;

[0054] (3) Section C-D is the pretreatment stage. The surface of the aluminum alloy is roughened by surface sandblasting, and the carbon fiber prepreg (CFSJ-1000Z, Shandong Jiangshan Fiber Technology Co., Ltd.) is laid on the rough surface of the aluminum alloy plate , to obtain prepreg / aluminum alloy laminate;

[0055] (4) The D-E section is the first heating stage. Place the prepreg / aluminum alloy laminate on the mold at room temperature, make the lower surface of the aluminum alloy contact the upper surface of the lo...

Embodiment 2

[0064] The present embodiment adopts aforementioned method to carry out, and concrete steps are as follows:

[0065] (1) Section A-B is the solid solution stage. Put the aluminum alloy in a heating furnace and keep it warm for 180 minutes at 450°C to fully dissolve the precipitated phase in the alloy;

[0066] (2) Section B-C is the quenching stage, and the aluminum alloy plate 2024 is taken out and quenched in water to obtain a supersaturated solid solution;

[0067] (3) Section C-D is the pretreatment stage. The surface of the aluminum alloy is roughened by surface sandblasting, and the carbon fiber prepreg (CFSJ-1000Z, Shandong Jiangshan Fiber Technology Co., Ltd.) is laid on the rough surface of the aluminum alloy plate , to obtain prepreg / aluminum alloy laminate;

[0068] (4) The D-E section is the first heating stage. Place the prepreg / aluminum alloy laminate on the mold at room temperature, make the lower surface of the aluminum alloy contact the upper surface of the l...

Embodiment 3

[0077] The present embodiment adopts aforementioned method to carry out, and concrete steps are as follows:

[0078] (1) Section A-B is the solid solution stage. Put the aluminum alloy 7075 in a heating furnace and keep it warm for 30 minutes at 575°C to fully dissolve the precipitated phase in the alloy;

[0079] (2) Section B-C is the quenching stage, and the aluminum alloy plate is taken out and quenched in water to obtain a supersaturated solid solution;

[0080] (3) Section C-D is the pretreatment stage. The surface of the aluminum alloy is roughened by anodic oxidation, and the carbon fiber prepreg (CFSJ-1000Z, Shandong Jiangshan Fiber Technology Co., Ltd.) is laid on the rough surface of the aluminum alloy plate. Obtain prepreg / aluminum alloy laminates;

[0081] (4) The D-E section is the first heating stage. Place the prepreg / aluminum alloy laminate on the mold at room temperature, make the lower surface of the aluminum alloy contact the upper surface of the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com