Antibacterial flame-retardant vortex spinning blended yarn and preparation method thereof

A technology of blended yarn and vortex spinning, applied in yarn, textile and paper making, etc., can solve the problems of low limit oxygen index, prone to burning, secondary injury to human body, etc. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

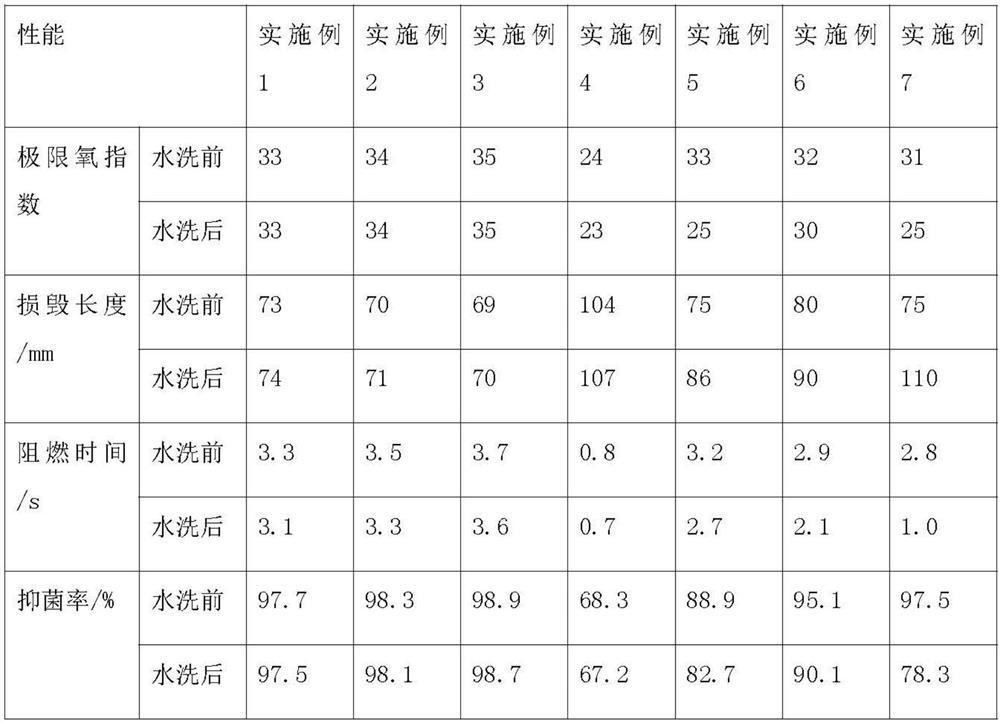

Examples

Embodiment 1

[0063] An antibacterial and flame-retardant vortex spinning blended yarn, the raw material components are as follows, in parts by weight, 30 parts of combed cotton fiber, 30 parts of ramie fiber, 60 parts of microporous polyurethane fiber, and 20 parts of modified adhesive.

[0064] The raw material components of the modified adhesive are as follows: in parts by weight, 20 parts of modified flame retardant powder, 15 parts of connecting monomer, and 80 parts of emulsion type acrylate.

[0065] The raw material components of the modified flame retardant powder are as follows, in parts by weight, 40 parts of silica airgel, 10 parts of γ-(methacrylamide) propyl trimethoxysilane, 20 parts of flame retardant, 30 parts of zinc nitrate , 15 parts of sodium citrate, 10 parts of urea, 8 parts of 1-allyl-3-methylimidazole hydrochloride, 20 parts of guanidine chitosan, 10 parts of acetic acid, 8 parts of sodium sulfate, 8 parts of nitric acid, 30 parts of high carbon phosphorus flake gra...

Embodiment 2

[0084] An antibacterial and flame-retardant vortex spinning blended yarn, the raw material components are as follows, in parts by weight, 40 parts of combed cotton fiber, 40 parts of ramie fiber, 80 parts of microporous polyurethane fiber, and 25 parts of modified adhesive.

[0085] The raw material components of the modified adhesive are as follows: in parts by weight, 25 parts of modified flame retardant powder, 20 parts of linking monomer, and 90 parts of emulsion type acrylate.

[0086] The raw material components of the modified flame retardant powder are as follows, in parts by weight, 50 parts of silica airgel, 15 parts of γ-(methacrylamide) propyl trimethoxysilane, 30 parts of flame retardant, and 35 parts of zinc nitrate , 20 parts of sodium citrate, 15 parts of urea, 9 parts of 1-allyl-3-methylimidazole hydrochloride, 25 parts of guanidine chitosan, 15 parts of acetic acid, 10 parts of sodium sulfate, 10 parts of nitric acid, 35 parts of high carbon phosphorus flake ...

Embodiment 3

[0105] An antibacterial and flame-retardant vortex spinning blended yarn, the raw material components are as follows, in parts by weight, 50 parts of combed cotton fiber, 50 parts of ramie fiber, 100 parts of microporous polyurethane fiber, and 30 parts of modified adhesive.

[0106] The raw material components of the modified adhesive are as follows: in parts by weight, 30 parts of modified flame retardant powder, 25 parts of connecting monomer, and 100 parts of emulsion type acrylate.

[0107] The raw material components of the modified flame retardant powder are as follows, in parts by weight, 60 parts of silica airgel, 20 parts of γ-(methacrylamide) propyl trimethoxysilane, 40 parts of flame retardant, 40 parts of zinc nitrate , 25 parts of sodium citrate, 20 parts of urea, 10 parts of 1-allyl-3-methylimidazole hydrochloride, 30 parts of guanidine chitosan, 20 parts of acetic acid, 12 parts of sodium sulfate, 12 parts of nitric acid, 40 parts of high carbon phosphorus flak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com