Patents

Literature

57results about How to "Has antibacterial and antifungal effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent preparation of cellulose fiber releasing anion and use thereof

InactiveCN101230495ANon-volatileEasy to recycleMonocomponent cellulose artificial filamentWet spinning methodsTotal solid contentCellulose fiber

The invention relates to a method of preparing a cellulose fibre releasing anions by using the solvent method and the application. The method has the following steps: firstly, the comminuted cellulose, tourmaline powder and addition agent are well mixed with an ironic liquid, dissolved at a temperature of 35 to 160 DEG C, deaerated for 1 to 120 hours and a homogeneous and stable spinning solution with a total solid content of 3 to 30 percent is formed, wherein, the mixed mass ratio of the tourmaline powder is 0.01 to 20 percent and the added mass ratio of the addition agent is 0 to 10 percent; secondly, the spinning solution is filtered, deaerated, spinned and solidified through a coagulation bath; and thirdly, a composite fibre of cellulose and tourmaline powder is obtained after the procedures of stretching, water cleaning, bleaching, oiling and drying. The composite fibre has the functions of releasing anions, generating far infrared radiation, generating biocurrent and suppressing bacteria and is applicable to the fields of garments, ornaments and medical textiles. The ironic liquid used in the invention has high production efficiency, is easy for callback and conforms to the requirement of a green production. The prepared composite fibre has excellent mechanical strength and mechanical property, and the fabric made of the composite fibre can release anions, resist bacteria and prevent mildew.

Owner:DONGHUA UNIV

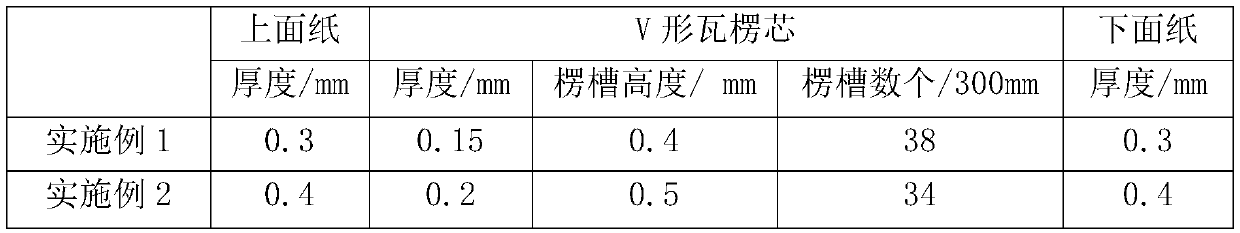

Wear resistant high-strength corrugated board and preparation method thereof

ActiveCN110344279ASimple preparation processEasy to operateSpecial paperPaper/cardboardSodium sorbatePolyvinyl alcohol

The invention discloses a wear resistant high-strength corrugated board and a preparation method thereof. The corrugated board is formed by compounding upper-faced paper, a V-shaped corrugated core and lower-faced paper, the V-shaped corrugated core is composed of a corrugated core base layer and protective layers sizing on both sides of the base layer, the corrugated core base layer is prepared from the following raw materials in parts: 100 parts of red pine wood pulp, 30-50 parts of bamboo pulp, 20-30 parts of fluff pulp, 40-60 parts of waste paper pulp, 1-5 parts of cyclodextrin, 10-15 parts of oxidated cassava starch, 4-8 parts of composite reinforced fibers, 1-3 parts of cationic polyacrylamide, 0.01-0.1 part of sodium sorbate, 0.1-0.3 part of antimonous oxide, 0.1-0.5 part of poval,5-7 parts of polydimethylsiloxane, and each protective layer is prepared from the following components in percentage by weight: 40-60% of a hydroxylation graphene modified ylate emulsion, 5-10% of sodium caseinate, 20-30% of cationic rosin size and 15-20% of montmorillonite. The corrugated board has the high mechanical strength, excellent wear resistance, excellent shock resistance, excellent water resistance and excellent moisture resistance, has certain antibacterial and mildew-proof effects, the preparation technology is simple, operation is convenient and fast, and repeat sizing is not needed.

Owner:纸享家(上海)环保科技有限责任公司

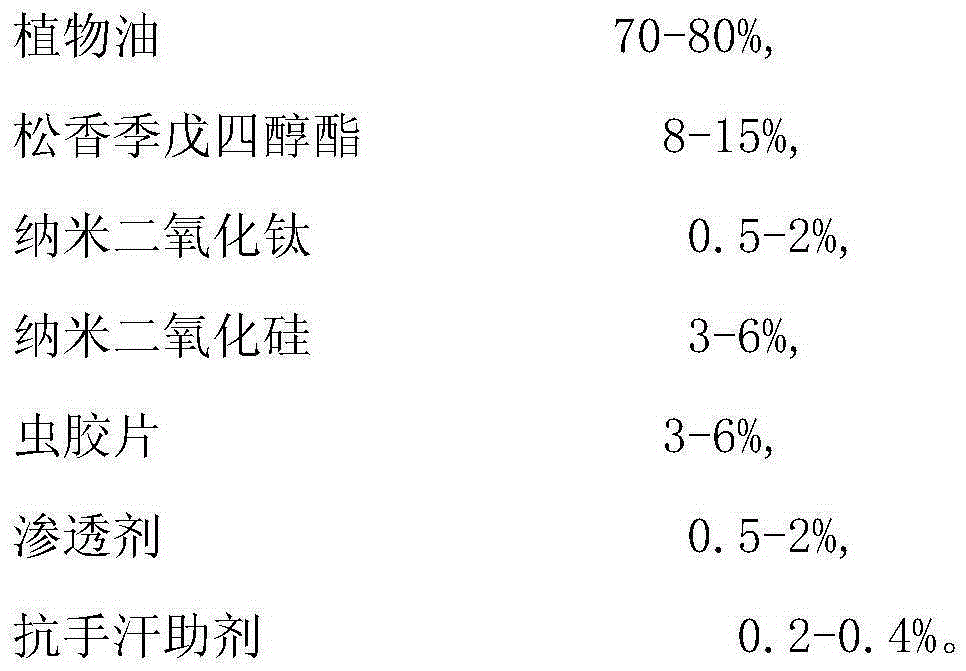

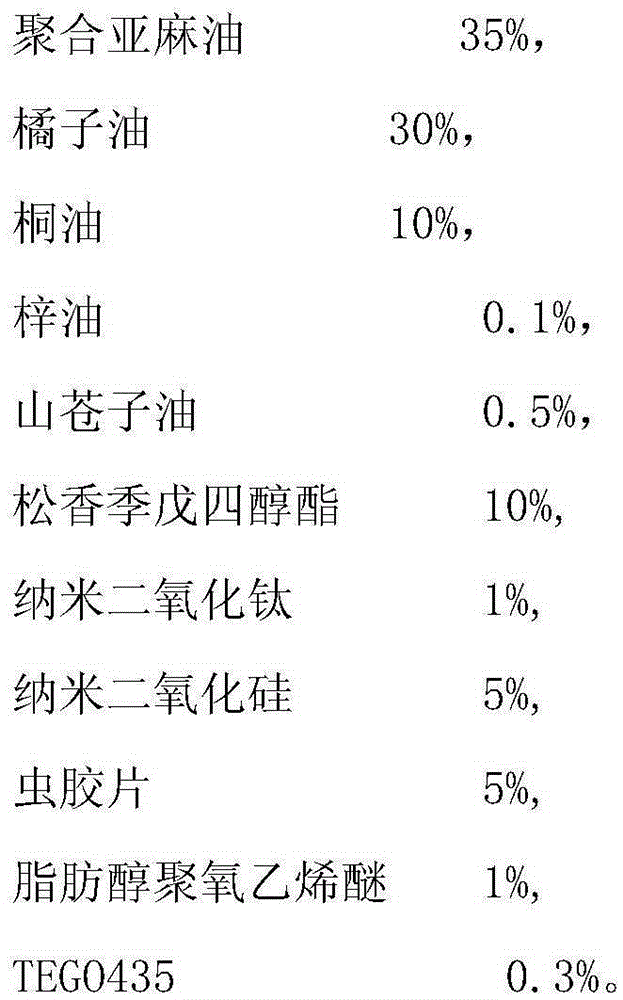

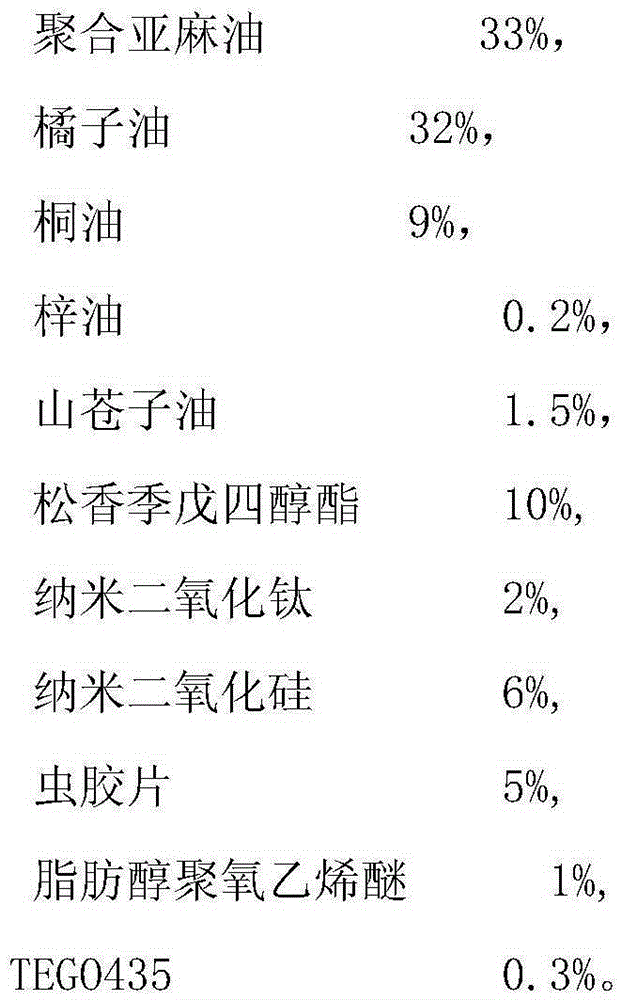

Stain-removing and furniture-servicing film plating oil and preparation method therefor

ActiveCN105238267AEasy to handleHigh hardnessAntifouling/underwater paintsPaints with biocidesVegetable oilShellac

The invention discloses stain-removing and furniture-servicing film plating oil and a preparation method therefor. The film plating oil contains the following ingredients in percentage by weight: 70-80% of vegetable oil, 8-15% of pentalyn, 0.5-2% of nano titanium dioxide, 3-6% of nano-silica, 3-6% of flake shellac, 0.5-2% of penetrant and 0.2-0.4% of hand perspiration resisting assistant, wherein the vegetable oil consists of polymerized flaxseed oil, mandarin oil, tung oil, stillingia oil and litsea cubeba oil. The film plating oil disclosed by the invention is a novel material for cleaning, nursing and serving the surface of furniture, stains of the surface of the furniture can be rapidly and conveniently treated, and the hardness, hand feeling and glossiness of a coat surface can be improved; and meanwhile, the film plating oil can protect the surface of the furniture and plays roles in antisepticizing and mildew-proofing.

Owner:JIANGMEN GUOMEI CHEM

Epoxy blackboard paint

The invention discloses epoxy blackboard paint and relates to the technical field of paint. The epoxy blackboard paint comprises following components, by weight: 40-60 parts of an aqueous epoxy emulsion, 0.1-0.5 parts of a dispersing agent, 40-60 parts of a pigment filling material, 0.1-0.5 parts of a foam-removing agent, 1.0-2.0 parts of film forming resin, 0.5-1.0 part of a thickening agent and 40-60 parts of water. The blackboard paint is excellent in dry writing performance, is high in hardness, is good in mechanical performances, is strong in adhesive force and is suitable for coating of various white boards specially used for teaching.

Owner:DRAGON FISH PAINT

Adhesive for floor and preparation method of adhesive

InactiveCN107151543AHigh bonding strengthFast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementParaffin wax

The invention discloses an adhesive for floor and a preparation method of the adhesive, and relates to the technical field of adhesives. The adhesive is prepared from the following raw materials: 85-95 parts of reactive resin, 55-57 parts of paraffin phase change microspheres, 45-50 parts of corn starch, 40-42 parts of polyvinyl alcohol, 25-35 parts of nanometer titanium dioxide, 20-25 parts of nano-alumina, 18-20 parts of a gelatinizing agent, 15-17 parts of filler, 10-15 parts of tricyclodecenyl acetate, 10-13 parts of ethyl laurate, 5-10 parts of an acid solution, 15-20 parts of an aid and 80-10 parts of deionized water. The adhesive has relatively high adhesive strength and high curing speed, facilitates construction and is safe and environmentally friendly.

Owner:合肥市淑芹美装饰工程有限公司

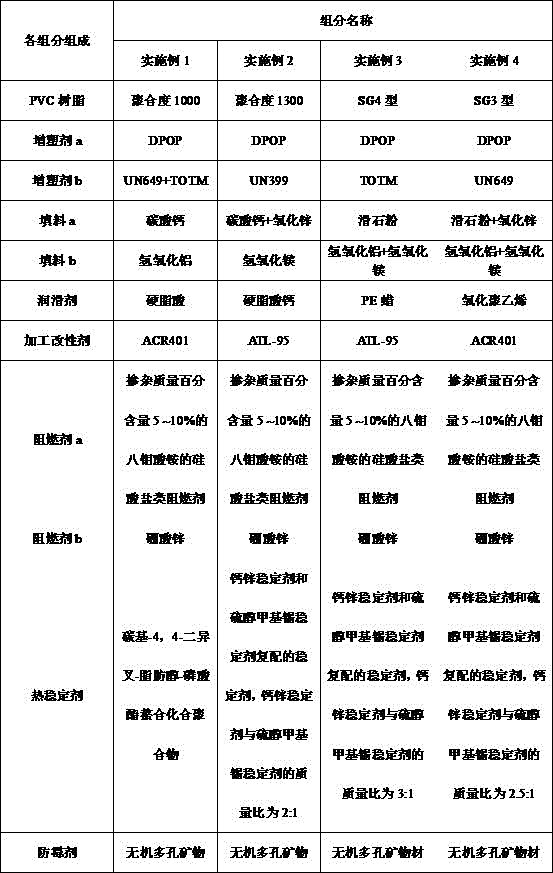

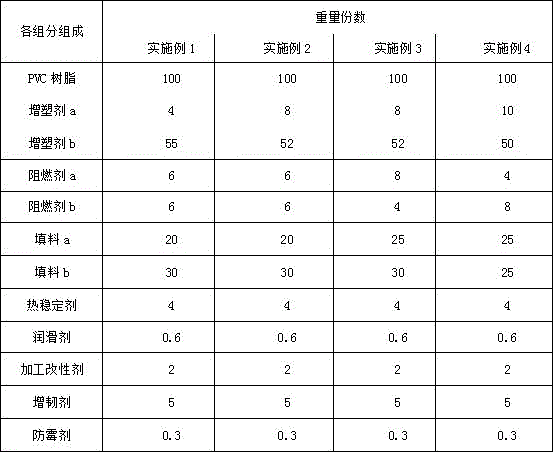

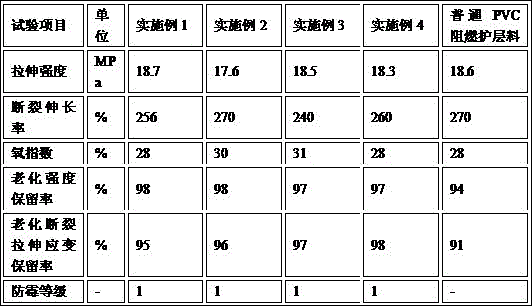

Novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material

ActiveCN106496863AGood compatibilityGood weather resistancePlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention discloses a novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 2-8 parts of a plasticizer a, 30-55 parts of a plasticizer b, 5-10 parts of a flame retardant a, 5-10 parts of a flame retardant b, 10-40 parts of packing a, 20-30 parts of packing b, 2-10 parts of a thermal stabilizer, 0.5-2 parts of a lubricant, 1-3 parts of a processing modifier, 0.2-0.4 part of an anti-mold agent and 5-10 parts of a toughening agent, wherein the anti-mold agent is an antibacterial anti-mold agent which is compounded from an inorganic porous mineral material loaded with inorganic antibacterial factors and organic anti-mold factors. Compared with a common PVC flame-retardant protection layer material, the novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material disclosed by the invention is very good in anti-mold property, and the service life of the protection layer material is greatly prolonged.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

Antibacterial durable aqueous polyurethane printing ink

The invention relates to the field of printing ink, and in particular to an antibacterial durable aqueous polyurethane printing ink. The printing ink is composed of the following raw materials by weight: 4-5 parts of methylated-beta-cyclodextrin, 0.1-0.2 part of calcium propionate, 1-3 parts of tea polyphenols, 6-8 parts of binary vinyl chloride-acetate, 2-4 parts of cellulose ether, 4-7 parts of magnesium aluminum silicate, 30-50 parts of deionized water, 15-18 parts of an aqueous pigment, 2-3 parts of pentaerythritol, 20-25 parts of a waterborne polyurethane emulsion and 2-4 parts of an auxiliary. The printing ink of the invention has low toxic volatile organic compound content, and little harm to environment and human body; methylated-bet-cyclodextrin, calcium propionate and tea polyphenols can improve the dispersion and compatibility with resin of the aqueous pigment, but also endow the pigment with certain antibacterial and mildewproof effect, improve the durability of the color. The final product has strong adhesive ability even ink color, and clear and beautiful appurtenance on a substrate, does not easily mold or fall off, and has high safety and wide scope of application.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

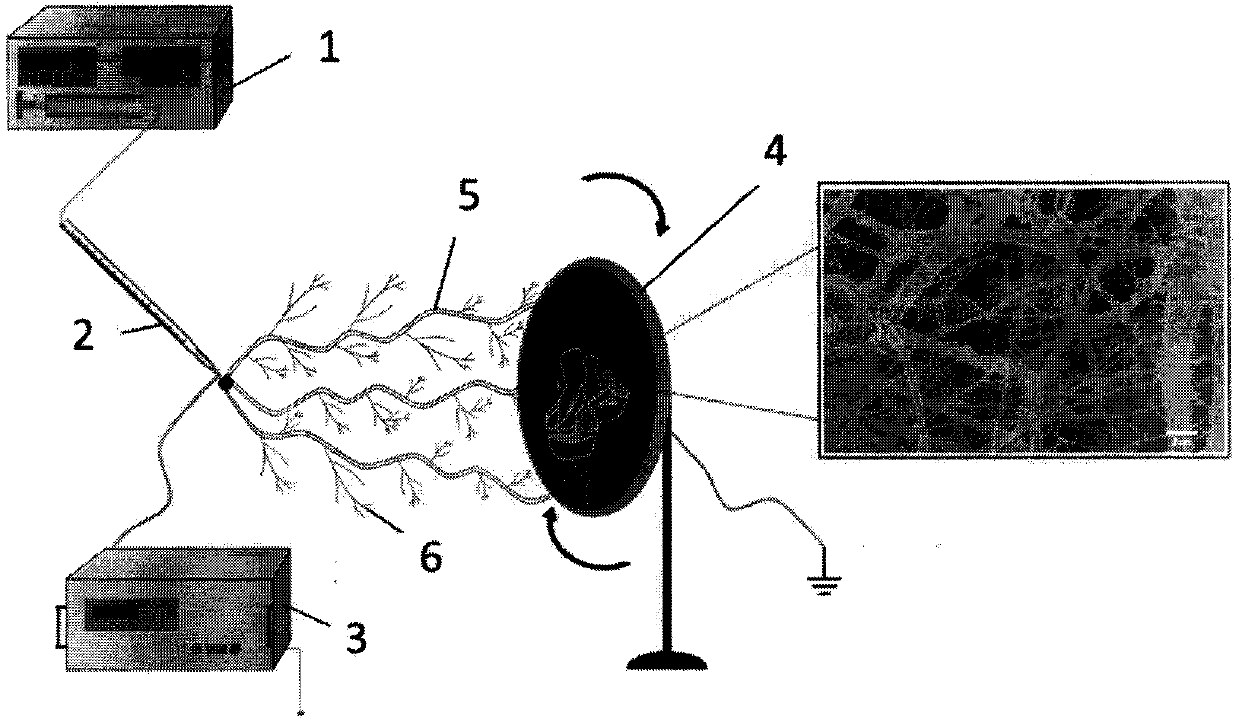

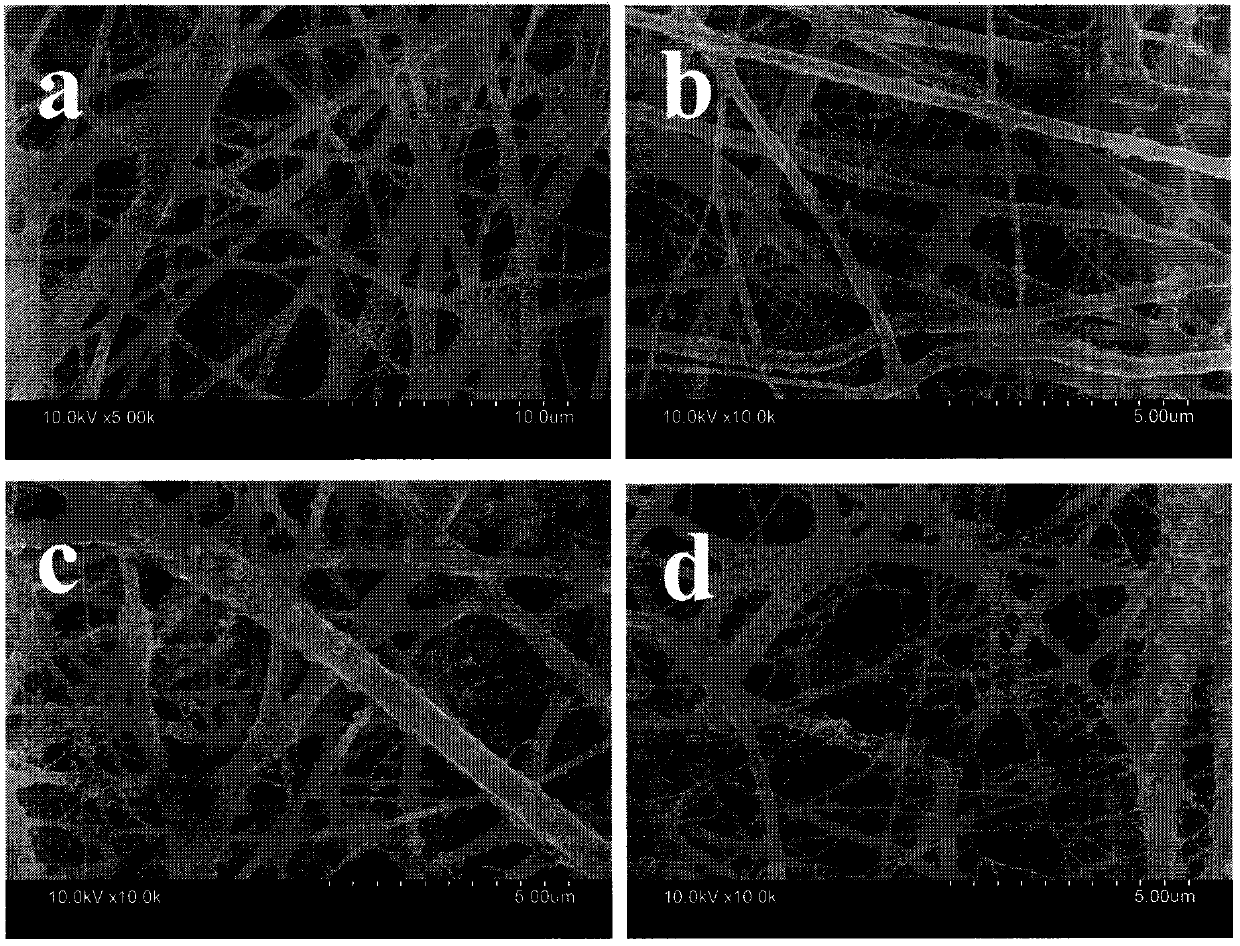

Antibacterial waterproof moisture-permeable nano fiber membrane and preparation method thereof

InactiveCN107829213AGood moisture permeabilityImprove hydrophilicityMonocomponent synthetic polymer artificial filamentNon-woven fabricsChemistryMicrometer

The invention relates to an antibacterial waterproof moisture-permeable nano fiber membrane and a preparation method thereof. The nano fiber membrane comprises the following components: 80-90% of polyurethane, 8-15% of tetrabutylammonium bromide and 2-5% of a zirconium phosphate silver-loaded antibacterial agent, and the average particle size of the zirconium phosphate silver-loaded antibacterialagent does not exceed 0.3 micrometer. The preparation method comprises the following steps: (1) preparing a polyurethane / tetrabutylammonium bromide / N,N-dimethylformamide solution of which the concentration ranges from 5% to 10%; (2) uniformly dispersing zirconium phosphate silver-loaded antibacterial agent particles into a solution prepared in step (1) to obtain a spinning solution; and (3) preparing a thick and thin double-scale-structured nano fiber membrane under high-pressure static action force.

Owner:TIANJIN POLYTECHNIC UNIV

Moldproof finishing agent for silk fabrics

InactiveCN103757892AWon't breakHas antibacterial and antifungal effectsAnimal fibresFiberPyrophosphate

The invention discloses a moldproof finishing agent for silk fabrics, which is prepared from the following components in parts by weight: 10-15 parts of citric acid, 8-13 parts of fatty alcohol polyethenoxy ether sodium sulfate, 6-11 parts of sodium tripolyphosphate, 4-9 parts of sodium benzoate, 3-8 parts of boric acid, 3-8 parts of fatty acyl diethanolamine, 3-8 parts of ethoxylated straight-chain primary alcohol, 3-8 parts of sodium alginate, 20-25 parts of ethanol and 7-12 parts of sodium pyrophosphate. The finishing agent has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:WUJIANG CITY QIDU TOWN MIAOGANG YADI KNITTING GARMENT FACTORY

Moisture-wicking, antibacterial and antistatic multifunctional fabric and production method thereof

ActiveCN104389076BImprove wearing comfortGuaranteed antistatic functionWoven fabricsYarnYarnMoisture absorption

The invention discloses a multifunctional fabric with moisture absorption and perspiration, antibacterial and antistatic properties and a production method thereof. The multi-functional fabric is made of 95-99% multi-functional blended yarn and 1-5% stainless steel anti-static yarn or conductive anti-static yarn; the multi-functional blended yarn is made of moisture-wicking fiber 50-80%, cotton Fiber 15-45% and silver fiber 5-10% are blended; stainless steel antistatic yarn is made of moisture-wicking fiber 35-45%, cotton fiber 10-30%, silver fiber 3-7% and stainless steel fiber 25-40% % blended; conductive yarn antistatic yarn is twisted from 3-5% organic conductive yarn and 95-97% multifunctional blended yarn. The multifunctional fabric produced by the invention has antistatic function, moisture absorption and perspiration function and antibacterial function, which can not only ensure the antistatic function of the fabric, but also greatly improve the air permeability of the fabric, improve the wearing comfort of the fabric, and have good antibacterial function.

Owner:ZHENGZHOU NO 4 COTTON TEXTILE

Wear-resistant light curing UV (ultraviolet) paint

InactiveCN109401612AEasy to cleanImprove performanceAntifouling/underwater paintsPaints with biocidesGlass fiberWear resistant

The invention discloses wear-resistant light curing UV (ultraviolet) paint. The paint is prepared from the following ingredients in parts by weight: 30-40 parts of modified acrylate, 10-20 parts of aphotoinitiator, 4-14 parts of talcum powder, 3-10 parts of extinction powder, 5-12 parts of a reactive diluent, 3-8 parts of a flatting agent, 2-5 parts of diamond powder, 5-8 parts of glass fiber, 10-20 parts of nano filler and 25-35 parts of other ingredients. Compared with related technologies, the wear-resistant light curing UV paint is fast in curing speed, strong in adhesive force and good in wear resistance.

Owner:HUARONG COUNTY HENGXING BUILDING MATERIALS CO LTD

Ceramic coating sprayed on SMC plate

InactiveCN109929455AHigh strengthImprove overall performanceAntifouling/underwater paintsFibre typesOxidePolyresin

Owner:常州天瑞新材料科技有限公司

Antibacterial plastic

InactiveCN104277374AStrong heat resistanceHas antibacterial and antifungal effectsGlycerolPolyvinyl chloride

The invention discloses an antibacterial plastic. The antibacterial plastic comprises the following components in parts by weight: 55 parts of polyvinyl chloride, 1-2 parts of phenyl silicone oil, 2-3 parts of phenylamine, 1-2 parts of vinyltrimethoxysilane, 4-5 parts of calcium zinc salt, 2-3 parts of titanate, 1-2 parts of glycerin monostearate, 5-6 parts of methyl propylene glycol and 1-2 parts of isomeric decanol polyoxyethylene ether. The antibacterial plastic disclosed by the invention has the advantages of strong heat resistance and antibacterial and antifungal effects.

Owner:常熟市帅红塑料制品厂

Preparation method of beef-soybean paste

The invention provides a preparation method of beef-soybean paste, comprising the following steps: washing beef and cutting 5-6 cm cubes; adding a pickling material, uniformly stirring and pickling for 3 h; stewing cattle coccyx with slow fire for 3-4 h, extracting beef bulalo and concentrating and purifying, adding gelatin, cooling and coagulating to prepare jellied beef bulalo; cleaning soybeansand removing impurities, immersing with clear water for 5-6 h, steaming at high pressure for 15-20 min, and rolling to obtain crude soybean pehtze; adding flavoring into the pickled beef and stewingwith big fire for 40-60 min, and grinding with a meat grinder to obtain minced beef; mixing the jellied beef bulalo, soybean pehtze and minced beef according to the ratio of 0.3-0.5: 1: 1, adding flour paste, salt, monosodium glutamate, pepper and five spices powder, and stir-frying in salad oil of 100-120 DEG C for 20-25 min so as to obtain the beef-soybean paste. According to the beef-soybean paste of the invention, shelf life can be effectively prolonged, and nutrients in beef and soybeans can be reserved to the maximum.

Owner:朱新科

Fragrant, antibacterial and mildew-proof plastic particles for storage box and preparation method for plastic particles

InactiveCN102796329AImprove performanceHas antibacterial and antifungal effectsPolyvinyl chloridePlastic property

The invention relates to fragrant, antibacterial and mildew-proof plastic particles for a storage box. The plastic particles are characterized by being prepared from the following components in part by weight: 100 parts of polyvinyl chloride (PVC), 0.8 to 2 parts of glycerol monostearate, 0.4 to 1.2 parts of talcpowder, 1.5 parts of antibacterial and mildew-proof master batch and 1 to 2 parts of essence. The invention also relates to a preparation method for the fragrant, antibacterial and mildew-proof plastic particles for the storage box. The produced plastic storage box has special fragrance, high plastic property and antibacterial and mildew-proof effects and meets the requirement of high-quality living level.

Owner:薛申生

Ceramic glaze with antibacterial and mildew-proof effects as well as preparation method and application thereof

PendingCN111548015AWith anti-mildew functionHigh active ingredientAlkaline earth metalSodium phosphates

The invention belongs to the technical field of ceramics, and discloses a ceramic glaze with antibacterial and mildew-proof effects. Feldspar, alkaline earth metal carbonate, nano-silver, yttrium oxide, an antibacterial agent and sodium hexametaphosphate are effectively proportioned, all the components are compounded to achieve a synergistic effect, the obtained ceramic glaze is high in effectivecomponent content, and a nanoscale antibacterial agent can be uniformly distributed in a ceramic glaze layer matrix after the ceramic glaze is glazed, dried and sintered, so that a ceramic glaze layerhas relatively strong antibacterial performance and a remarkable antibacterial effect. The invention also discloses a preparation method of the ceramic glaze. A specific inorganic antibacterial agentand a specific organic antibacterial agent are compounded; in the compounded antibacterial agent, the organic antibacterial agent part and the inorganic antibacterial agent part cooperate with each other and influence each other, the antibacterial performance of the organic antibacterial agent part and the inorganic antibacterial agent part is enhanced; the antibacterial performance is enhanced under the synergistic effect of the organic antibacterial agent part and the inorganic antibacterial agent part, the antibacterial performance is stable, and the invention is a ceramic glaze with long-acting antibacterial and mildew-proof effects.

Owner:FOSHAN UNIVERSITY

Compression-resisting and fireproof plate and preparation method thereof

InactiveCN108358590AImprove mechanical propertiesImprove waterproof performanceCeramicwareFiberEngineering

The invention discloses a compression-resisting and fireproof plate and a preparation method thereof and relates to the technical field of fireproof plates. The compression-resisting and fireproof plate is prepared from raw materials according to the following parts: 95 to 105 parts of modified magnesium oxysulfate cement slurry, 30 to 35 parts of modified fibers, 20 to 30 parts of desulfurizationgypsum, 15 to 20 parts of modified diatomite, 15 to 20 parts of silica sol, 5 to 10 parts of polyacrylamide, 15 to 20 parts of auxiliary agent and 30 to 35 parts of water. The compression-resisting and fireproof plate disclosed by the invention has good mechanical properties and compression resistance.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Self-cleaning antibacterial material for air conditioning and self-cleaning and antibacterial air conditioner

The invention relates to a self-cleaning antibacterial material for air conditioning. The self-cleaning antibacterial material comprises a plastic base material, a zinc-based antimicrobial agent, inorganic filler and a dispersant, wherein the mass percentage of the plastic base material is 70-90%, the mass percentage of the zinc-based antimicrobial agent is 1-15%, the mass percentage of the inorganic filler is 3-15%, and the mass percentage of the dispersant is 1-6%. The invention also relates to a self-cleaning and antibacterial air conditioner, wherein a material of a fan of the self-cleaning and antibacterial air conditioner comprises a first self-cleaning antibacterial material for air conditioning; and the first self-cleaning antibacterial material for air conditioning comprises a plastic base material, a zinc-based antimicrobial agent, inorganic filler and a dispersant, wherein the mass percentage of the plastic base material is 70-90%, the mass percentage of the zinc-based antimicrobial agent is 1-15%, the mass percentage of the inorganic filler is 3-15%, and the mass percentage of the dispersant is 1-6%. According to the self-cleaning and antibacterial air conditioner, self-cleaning and antibacterial functions are realized by using the self-cleaning antibacterial material, so that the quality of air-conditioned air is improved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

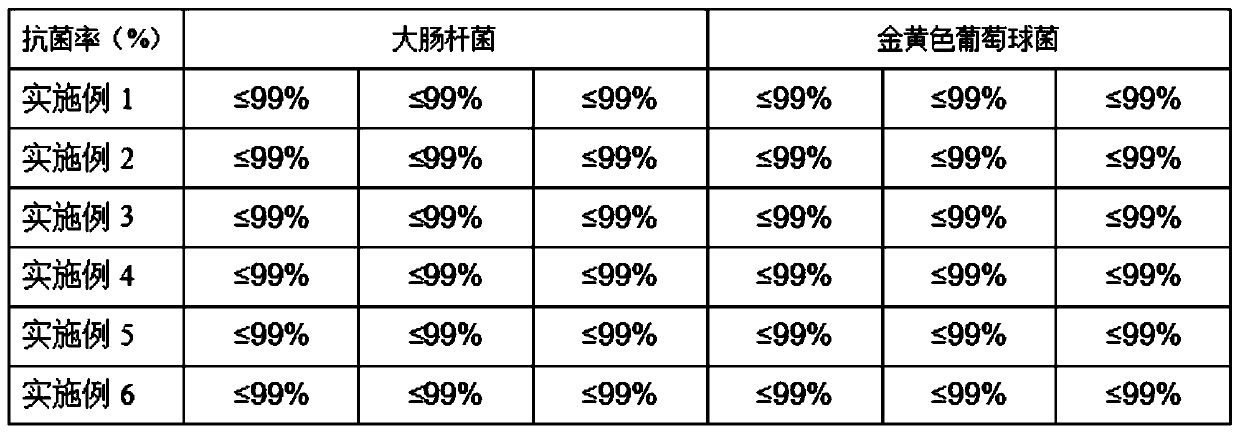

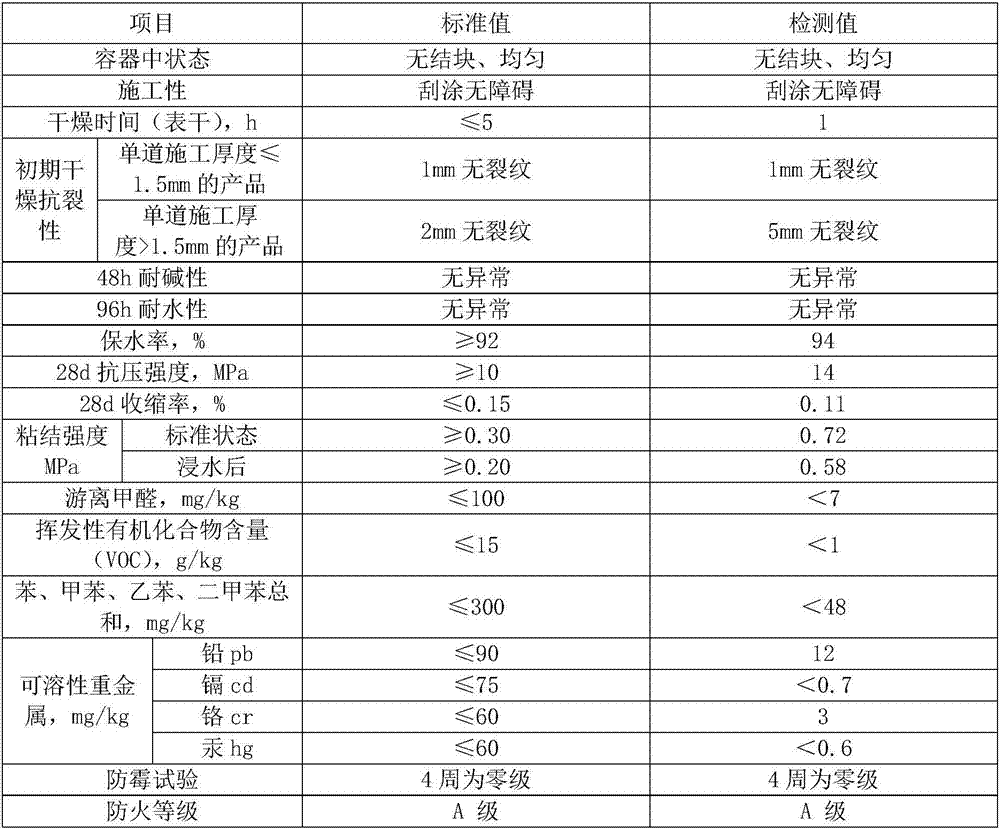

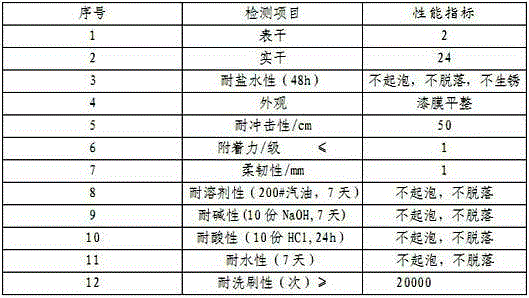

Formula and preparation method of anti-mildew coating

InactiveCN107474597AAdaptableHas antibacterial and antifungal effectsAntifouling/underwater paintsPaints with biocidesFiberSpray coating

The invention discloses a formula of anti-mildew paint, which is composed of cement, quartz sand, heavy calcium powder, light calcium carbonate, lime calcium powder, talcum powder, anti-cracking fiber and additives, and the weight ratio of each component is cement 19 %, quartz sand 28%, heavy calcium powder 29%, light calcium carbonate 6%, ash calcium powder 12%, talcum powder 4%, anti-crack fiber 1.5%, additive 0.5%; the additive is hydroxypropyl methylcellulose , preservatives, fungicides and light stabilizers. The anti-mildew paint of the present invention is stirred with a mixer to form a dry mixture, which can be used after adding a certain proportion of water and stirred at the construction site, and can be constructed by spraying or scraping. The coating of the present invention has strong adaptability to mildew-prone environments, has the advantages of antibacterial and anti-mildew effects, moisture resistance, water resistance, strong adhesion, etc., and generally can reach a service life of more than 10 years. The invention also provides a preparation method of the paint.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

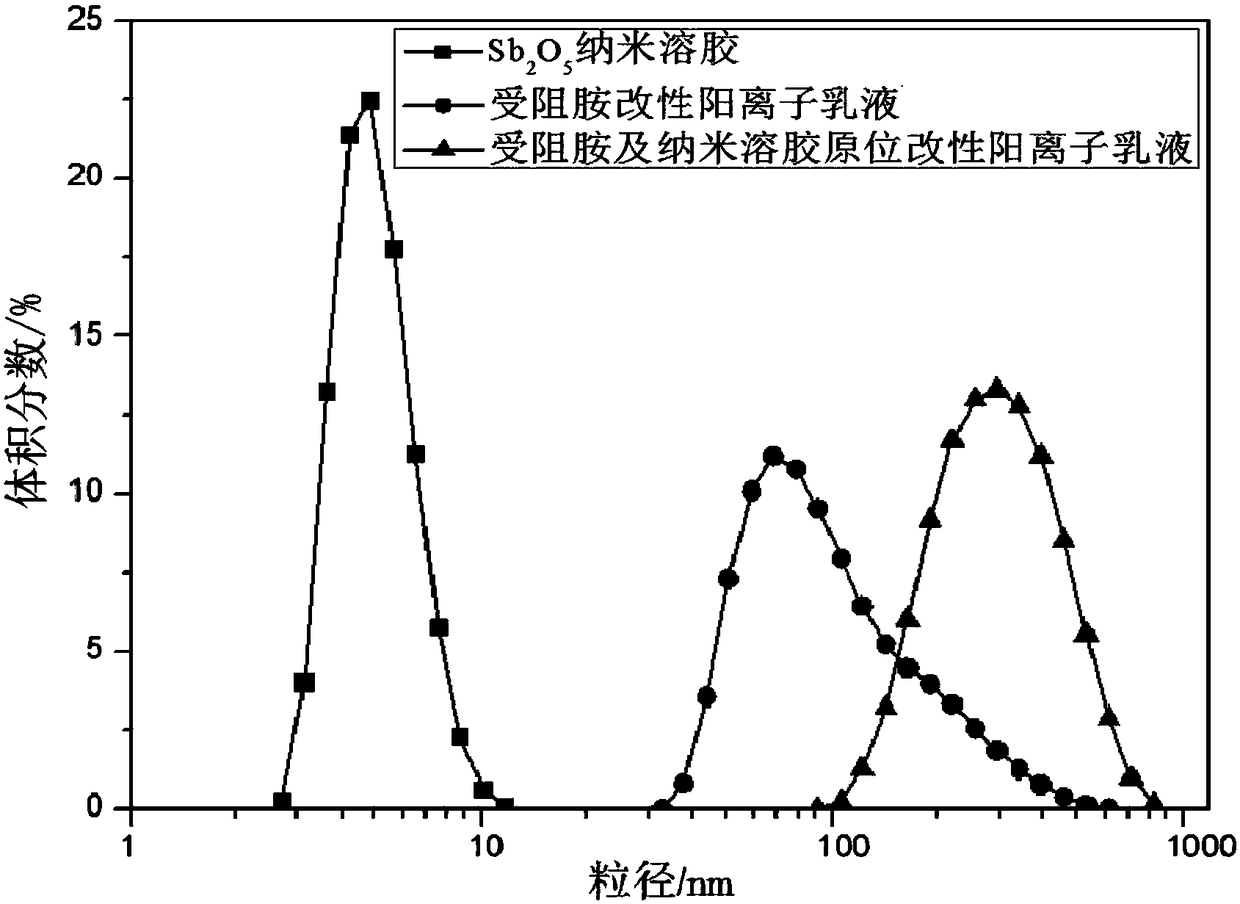

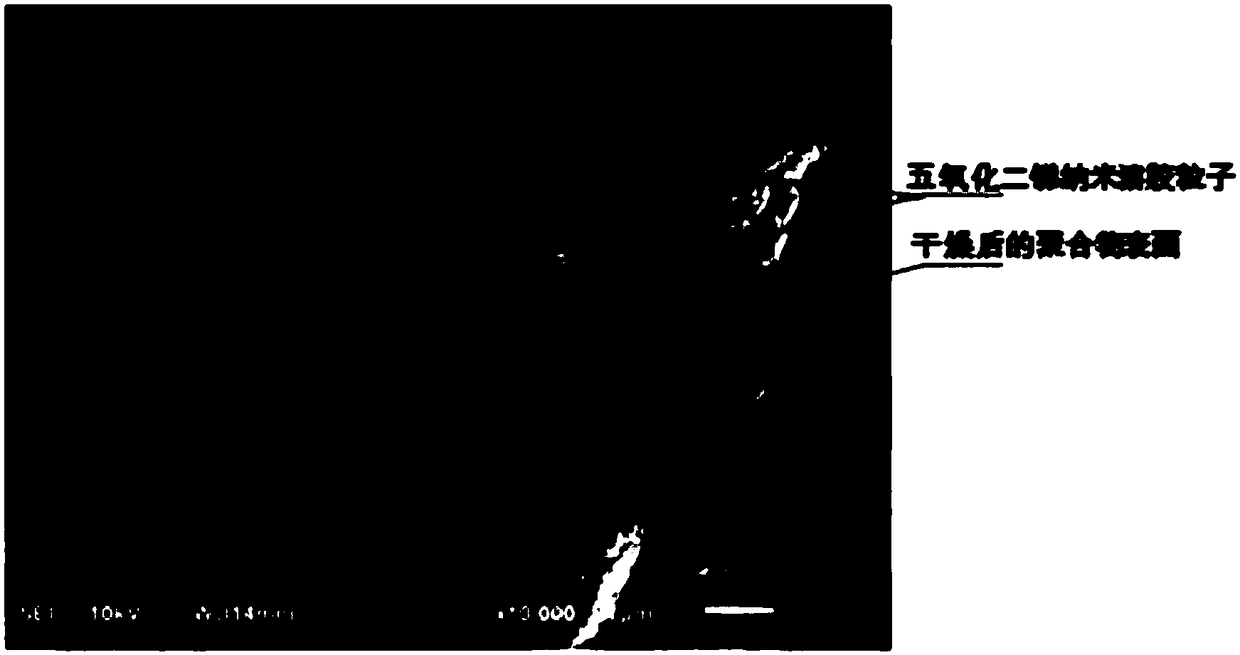

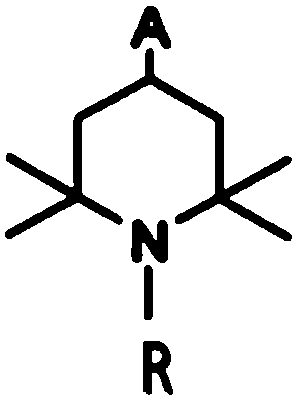

Nano-material in-situ modified halogen-free efficient flame-retardant cationic emulsion and preparation method therefor

ActiveCN108546313AEfficient flame retardant effectEnvironmentally friendlyIn situ polymerizationNanoscopic scale

The invention discloses a nano-material in-situ modified halogen-free efficient flame-retardant cationic emulsion. The nano-material in-situ modified halogen-free efficient flame-retardant cationic emulsion is obtained through subjecting raw materials to cationic in-situ polymerization, wherein based on 100 parts by weight, the raw materials comprises 40-60 parts of water, 25-35 parts of acrylatemonomer, 3-15 parts of antimony pentoxide nano-hydrosol, 0.5-5 parts of hindered amine free radical capturing agent, 0.1-1.5 parts of azo diisobutyl amidine hydrochloride, 0.1-3 parts of emulsifier, 4-7 parts of cationic starch dispersion solution and 0-0.5 parts of silane coupling agent. The invention further discloses a preparation method for the halogen-free efficient flame-retardant cationic emulsion. According to the halogen-free efficient flame-retardant cationic emulsion disclosed by the invention, a flame-retardant system, prepared from antimony pentoxide nano-sol and the hindered amine free radical capturing agent through cooperation, is effectively distributed on the surfaces of or in the acrylic polymer emulsion particles in a nano scale; and the flame-retardant effect is very efficient, and the emulsion is halogen-free and environmentally friendly.

Owner:JIANGSU RUIKANG NEW MATERIAL TECH CO LTD

Polyurethane synthetic leather material with antibacterial and mildewproof functions and preparation method of polyurethane synthetic leather material

InactiveCN108312677AGood high and low temperature resistanceImprove insulation performanceSynthetic resin layered productsCoatingsChemical structureMoisture absorption

The invention discloses a polyurethane synthetic leather material with antibacterial and mildewproof functions. The polyurethane synthetic leather material comprises a synthetic leather main body, wherein inner silk layers and PI film layers are respectively arranged on both sides of the synthetic leather main body; and the synthetic leather main body is prepared from amino-acid resin. By the arrangement of the PI film layers, a PI solution turns into a PI film when being solidified, and the synthetic leather main body and the PI film are integrated; furthermore, the PI film is high in low andhigh-temperature resistance, electrical insulation property, radiation resistance and medium resistance, so that the prepared synthetic leather material can be applied to any severe conditions, and the application range of the synthesis leather is greatly expanded; and by the arrangement of the inner silk layers, the chemical structure of a silk fiber is completely consistent with 18 amino acidsin the human skin, when the human skin is in contact with the fabric, people feel just like the own skin according to a similarly compatible theory, so that the moisture absorption property, the breathability, the comfort and the softness of the material which is in contact with the skin are greatly improved.

Owner:HEFEI ANSHAN COATING FABRICS

Clothing microbiostatic deodorant

The present invention relates to a bacteriostatic stink prevention agent which can be used in the course of drying washed clothes in the air. Its composition includes (by weight portion) 1-10 portions of bacteriostatic agent, 1-10 portions of pH regulating agent, 0-0.8 portion of perfume additive, 1-10 portions of ethyl alcohol, 0.1-5 portions of thickening, stabilizing and binding agent and 1-10 portions or proper quantity of water. Said invention also provides its application method.

Owner:SHANDONG UNIV

Waterborne epoxy wall finish paint and preparation method thereof

InactiveCN104087130AAvoid moldEliminate air bubblesEpoxy resin coatingsPolyester coatingsChemistryTitanium dioxide

The invention discloses waterborne epoxy wall finish paint and a preparation method thereof and relates to the technical field of chemical engineering. The waterborne epoxy wall finish paint comprises a component A and a component B, wherein the component A comprises 20-30 parts of waterborne epoxy acrylate resin and 5-10 parts of water; the component B comprises 10-15 parts of water-soluble saturated polyester resin, 2-5 parts of water-soluble amino resin, 0.2-0.5 part of polyether-modified silicone, 10-20 parts of titanium dioxide powder, 10-30 parts of calcium carbonate, 8-15 parts of talc powder and 7.5-11.8 parts of water. Compared with the prior art, waterborne epoxy acrylate resin, water-soluble saturated polyester resin and water-soluble amino resin as film-forming materials are added and reacted to generate amino bonds with fungicidal and antifungal effects and thus the generation of mycete is prevented.

Owner:DRAGON FISH PAINT

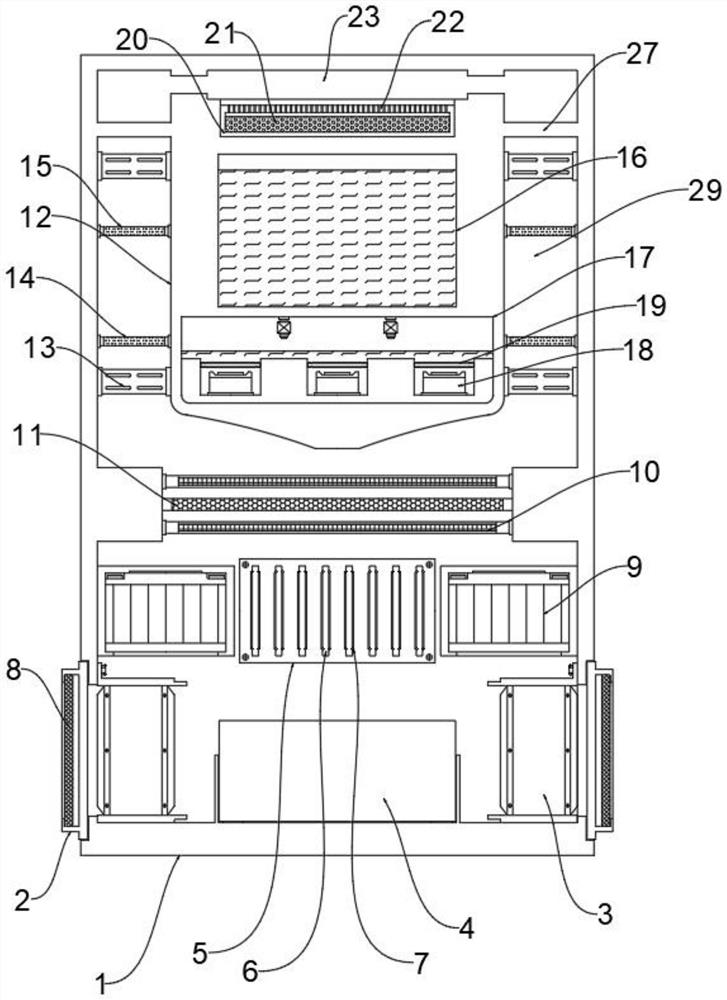

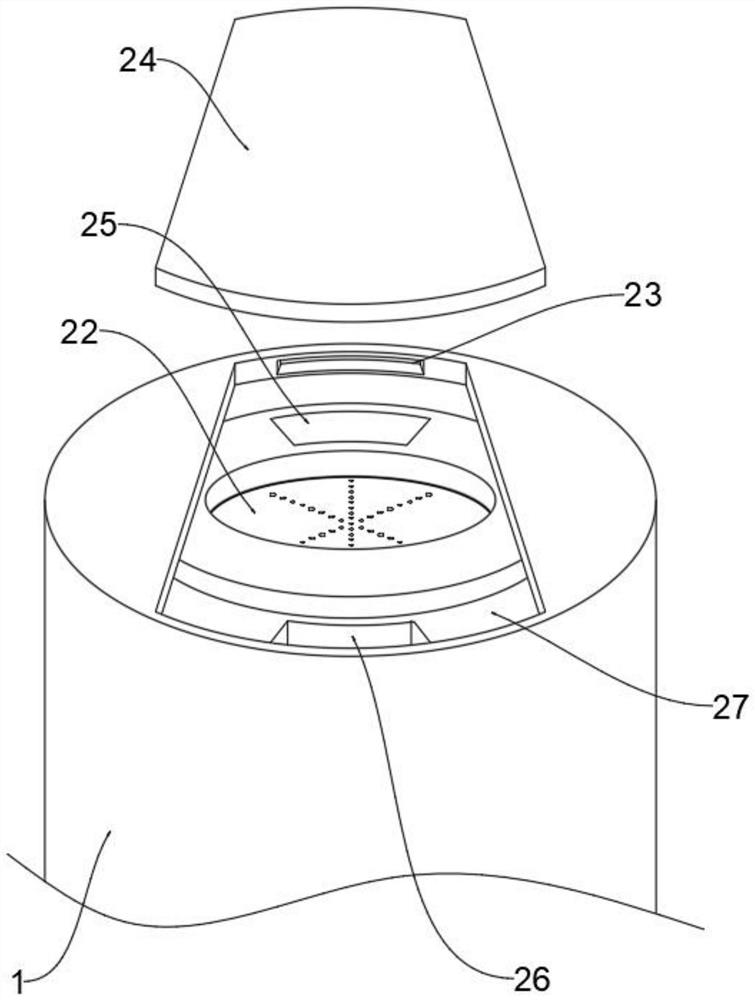

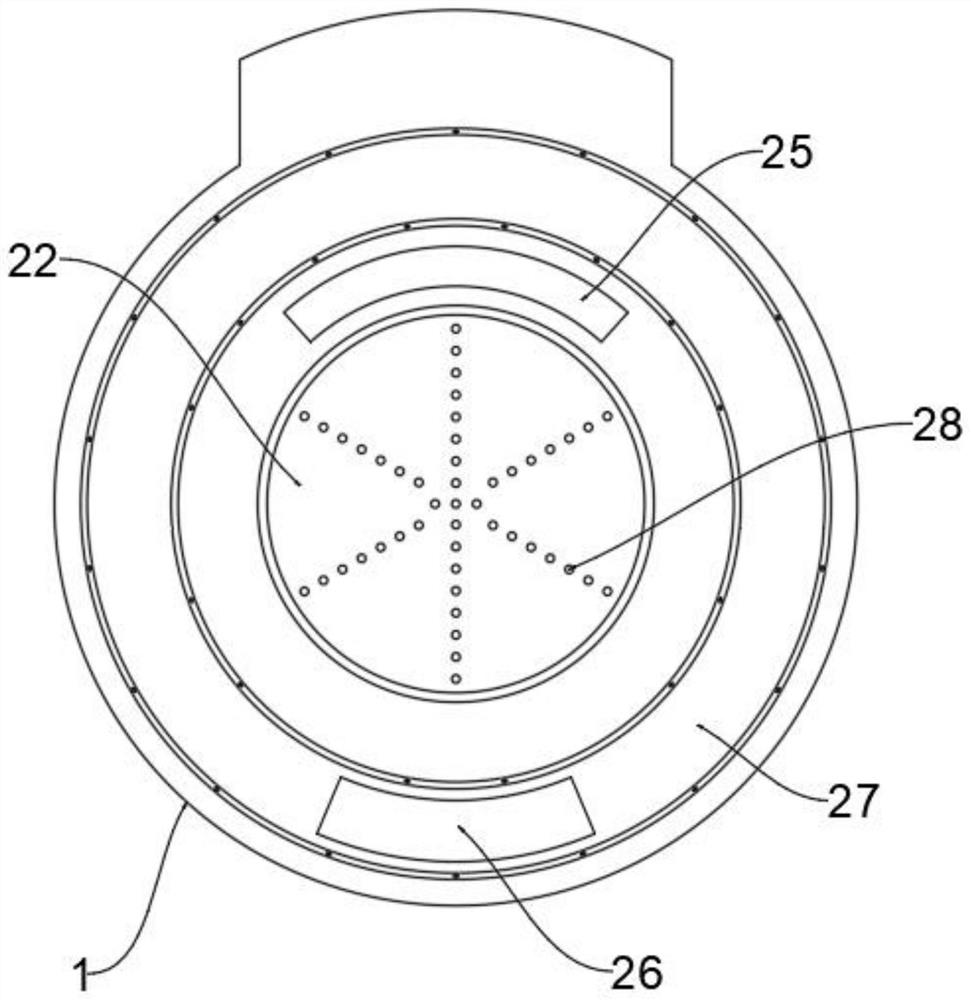

Portable air purifier with fragrance atomization function and use method of portable air purifier

PendingCN113465093AImprove permeabilityGuaranteed cleanlinessMechanical apparatusLighting and heating apparatusAir decontaminationEnvironmental engineering

The invention discloses a portable air purifier with a fragrance atomization function and a use method of the portable air purifier, relates to the technical field of plant essential oil air purification, and aims to solve the problem of how to improve environmental comfort on the premise of guaranteeing air purification in the prior art. A purification cavity is formed in the interior of a shell, air inlets are formed in the two sides of the bottom of the purification cavity, negative pressure fans are fixedly installed in the interiors of the air inlets, an electrostatic adsorption mechanism is installed at the lower end of the interior of the purification cavity, storage batteries are arranged on the two sides of the electrostatic adsorption mechanism, an atomization mechanism is arranged at the upper end of the interior of the purification cavity, the atomization mechanism and the shell are fixed through a supporting frame, the supporting frame is annularly arranged on the exterior of the atomization mechanism, a water storage cavity is formed in the atomization mechanism, an atomization cavity is formed below the water storage cavity, a water mist outlet is formed in the rear end of the atomization cavity, a fragrance storage box is arranged at the upper end of the atomization mechanism, and the interior of the fragrance storage box is filled with plant essential oil.

Owner:南京润中生物科技有限公司

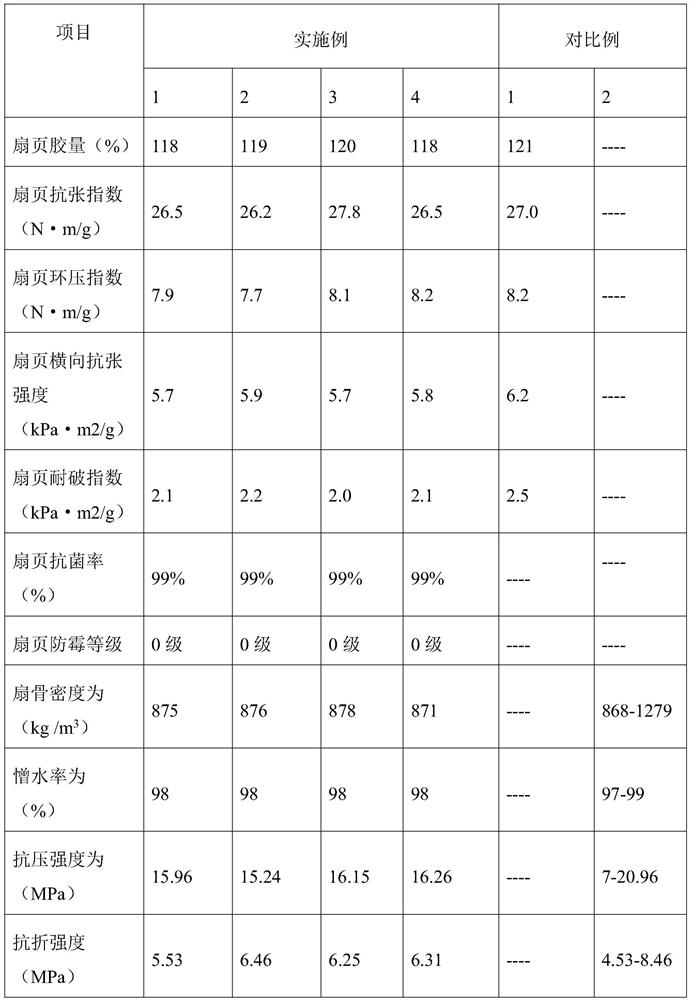

Fan with health-care function, and preparation method thereof

PendingCN112609499AConducive to environmental protectionLow costPretreatment with water/steamNon-macromolecular adhesive additivesNano zinc oxideSaposhnikovia divaricata

The invention provides a fan with a health care function, and a preparation method thereof. The fan comprises fan ribs and fan blades, wherein the fan ribs are prepared from an adhesive and divaricate saposhnikovia, the fan blades are prepared from a plant mixture, a plant fermentation broth, aminomethylbenzoic acid, sodium sulfamate and nano zinc oxide, the adhesive is prepared from, by weight, 20-30 parts of silica sol, 2-5 parts of zinc oxide, 1-3 parts of a curing agent and 0.5-1 part of a stabilizer, the divaricate saposhnikovia root accounts for 30-50 parts by weight, the plant mixture is prepared from the following components in parts by weight: 30-50 parts of soybean residues and 20-30 parts of wormwood, the plant fermentation broth is prepared by fermenting 20-30 parts by weight of aloe, the aminomethylbenzoic acid account for 3-8 parts by weight, the sodium sulfamate accounts for 5-10 parts by weight, and the nano zinc oxide accounts for 2-6 parts by weight. According to the invention, the fan ribs and the fan blades prepared from divaricate saposhnikovia, soybean residues, wormwood and aloe as raw materials have a certain health-care effect while plant waste residues can be effectively utilized, so that environmental protection is facilitated.

Owner:黑龙江边外香农业有限责任公司

Edible fungus culture material additive and application thereof

InactiveCN109328872APromote growthImprove survival rateCultivating equipmentsMushroom cultivationHeavy metalsBiology

The embodiment of the invention discloses an edible fungus culture material additive and application thereof. The additive comprises 96-98 parts of zeolite powder and 1-3 parts of calcium peroxide; the additive uses the specific selection of the zeolite powder and the calcium peroxide, can absorb harmful gases and heavy metals in edible fungus culture materials, and has antibacterial and anti-mildew effects. In addition, appropriate oxygen and trace elements can be provided for edible fungi, a good growth environment is provided for edible fungi, the growth of the edible fungi is promoted, thesurvival rate of the edible fungi is improved, and the rotten bag caused by the hot season is reduced.

Owner:吴德顺

Production for cellulosic composite fiber emitting negative ion and application thereof

InactiveCN101245493AHas the function of releasing negative ionsProduce far infrared radiationMonocomponent cellulose artificial filamentWet spinning methodsCelluloseFiber

The invention relates to preparation and application of a cellulose / inorganic breeze compound fiber that releases negative ions. The preparation: (1) ground cellulose, inorganic breeze, an assistant are evenly mixed with ionic liquid, dissolved and defoamed at 35-160 DEG C for 1-120 hours, thus forming even and stable spinning solution with the total solid content of 3-30 percent, wherein, the mass mixture ratio of the inorganic breeze is 0.01-20 percent and the added mass of the assistant is 0-10 percent; (2) the mixture is carried out by spinning and curing of solidifying bath after being filtered and defoamed; (3) the cellulose / inorganic breeze compound fiber is obtained by stretching, water washing, blanching and the procedures of oiling and drying. The compound fiber not only has the function of releasing negative ions, but also has the functions of producing far-infrared radiation, generating biocurrent and inhibiting bacteria, etc., thus being applicable to the fields of costume, decoration and medical textile product. The preparation and application of the cellulose / inorganic breeze compound fiber uses the ionic liquid, which has high production efficiency and easy recycle and meets the requirement of green production and the obtained compound fiber has good mechanical strength and mechanical property; fabrics made from the compound fiber can release negative ions and has the effect of antibacterium and rot resistance.

Owner:DONGHUA UNIV

A water-dispersible environmental-friendly water-based wood paint with insecticidal and anion-releasing properties and its preparation method

ActiveCN106634553BAchieve decorative effectHas antibacterial and antifungal effectsAntifouling/underwater paintsPaints with biocidesWater basedWater dispersible

The invention discloses water-dispersible environment-friendly waterborne wood coating with insect-killing and anion-releasing properties and a preparation method thereof; the waterborne wood coating comprises, by weight, 50-80% of water-dispersible modified acrylic emulsion, 0.2-0.5% of a mildew-proof bactericide, 0.2-0.5% of a defoaming agent, 0.2-0.6% of a dispersing wetting agent, 0.2-0.6% of a base wetting agent, 1.5-2.5% of a leveling agent, 3-6% of a film-forming aid, 0.05-0.2% of a multifunctional aid, 0.5-2% of a co-surfactant, 2-4% of an antibacterial insecticidal agent, 3-6% of anion powder, 0.2-0.5% of anti-adhesion aid, 0.2-1% of a polyurethane thickener, 0-20% of filling material, and the balance of deionized water, wherein the anion powder is yellow river jade anion powder, the antibacterial insecticidal agent is compounded from activated crystal antibacterial slow-release capsules and nano silver. The waterborne wood coating of the invention is waterborne, nontoxic, environmentally friendly, highly decorative, high in hardness, fine to touch, and short in drying time, and has the effects of preventing and killing insects, releasing anions and other effects.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

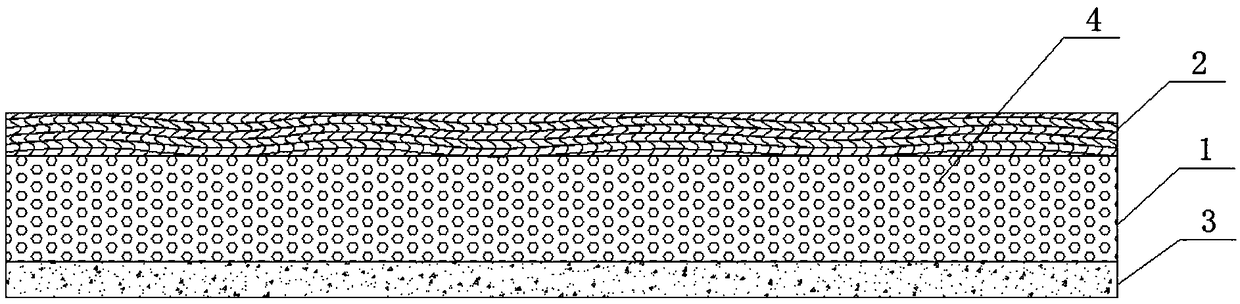

One-time forming pvc composite floor manufacturing process

ActiveCN107587694BSimple preparation processImprove controllabilityDomestic articlesFlooringSurface layerPolyvinyl chloride

The invention belongs to the technical field of decorative sheet machining, and relates to PVC floors, in particular to a one-time forming type PVC composite floor manufacturing process. The manufacturing process comprises the following steps that parts of a surface layer and parts of a bottom layer are mixed by weight, put onto the upper layer of a co-extrusion double-cone machine and sequentially enter the upper layer and the bottom layer of a calendaring forming machine; parts of a core layer are mixed by weight, put onto the lower layer of the co-extrusion double-cone machine, then subjected to foaming at 210-220 DEG C and enter the middle layer of the calendaring forming machine; one-time calendaring composite forming is conducted, meanwhile, a polyvinyl chloride (PVC) heat transfer film, a polypropylene (PP) heat transfer film or a polyethylene (PE) heat transfer film veneer which is formed through calendaring of the calendaring forming machine is used as a decorative layer to bepasted on the upper surface of the surface layer, and one-time roll forming is conducted through a four-roller press or a five-roller press; and integral forming is achieved through die pressing andcompositing, and one-time forming, cooling and slitting are conducted. The one-time forming type PVC composite floor manufacturing process is simple and high in controllability, a manufactured PVC composite floor has the advantages of being free of formaldehyde, environmentally friendly, non-poisonous, safe, dampproof and the like and has certain anti-microbial and anti-mold effects.

Owner:圣象实业(江苏)有限公司

Antibacterial mildew-proof degradable plastic and preparation method thereof

InactiveCN112143187AGood mechanical propertiesImprove mechanical propertiesAnti bacterialCaprolactone

The invention belongs to the technical field of plastic processing, and particularly relates to antibacterial mildew-proof degradable plastic and a preparation method thereof. The preparation method includes the steps that firstly, p-dioxanone-epsilon-caprolactone copolymer is subjected to an epoxidation reaction to obtain an epoxidation product, and then the epoxidation product and modified nanofiller are subjected to a ring-opening reaction to obtain a modified polymer; the modified polymer and the modified collagen are mixed, melted, extruded, cast and post-treated to obtain the antibacterial mildew-proof degradable plastic, the antibacterial mildew-proof degradable plastic is biodegradable and good in mechanical property, the biodegradability and the mechanical property of the plasticproduct are both considered, and the antibacterial mildew-proof degradable plastic has a good antibacterial mildew-proof effect.

Owner:卢丽容

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com