Antibacterial waterproof moisture-permeable nano fiber membrane and preparation method thereof

A nanofiber membrane, waterproof and moisture-permeable technology, used in textiles, papermaking, non-woven fabrics, etc., can solve the problems of small inter-fiber pore size, high porosity, and inability to meet the practical application requirements of medical protective clothing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

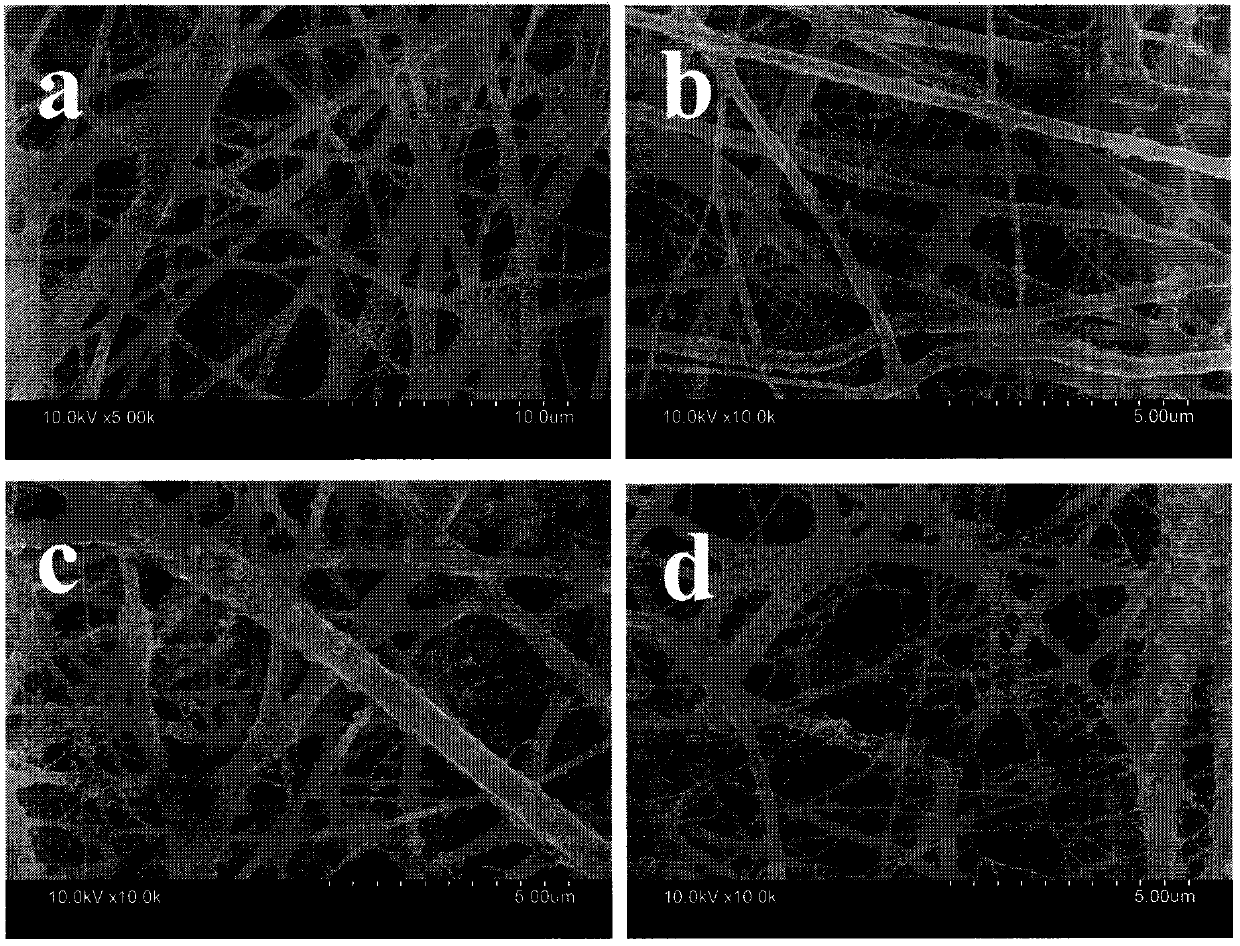

Embodiment 1

[0025] (1) in the present invention, at first needs to configure the spinning solution of electrostatic solution blowing, and its specific steps are: under room temperature tetrabutylammonium bromide (mass fraction is 8%) and N, N-dimethylformamide according to Mix evenly in a certain proportion, then add an appropriate proportion of thermoplastic polyurethane (mass fraction is 7%) and stir to dissolve, finally weigh a certain amount of zirconium phosphate silver-loaded antibacterial agent particles (mass fraction is 2%) and slowly pour it into The prepared solution was then stirred under air for 12 hours to form a uniform solution to obtain an electrospinning spinning solution.

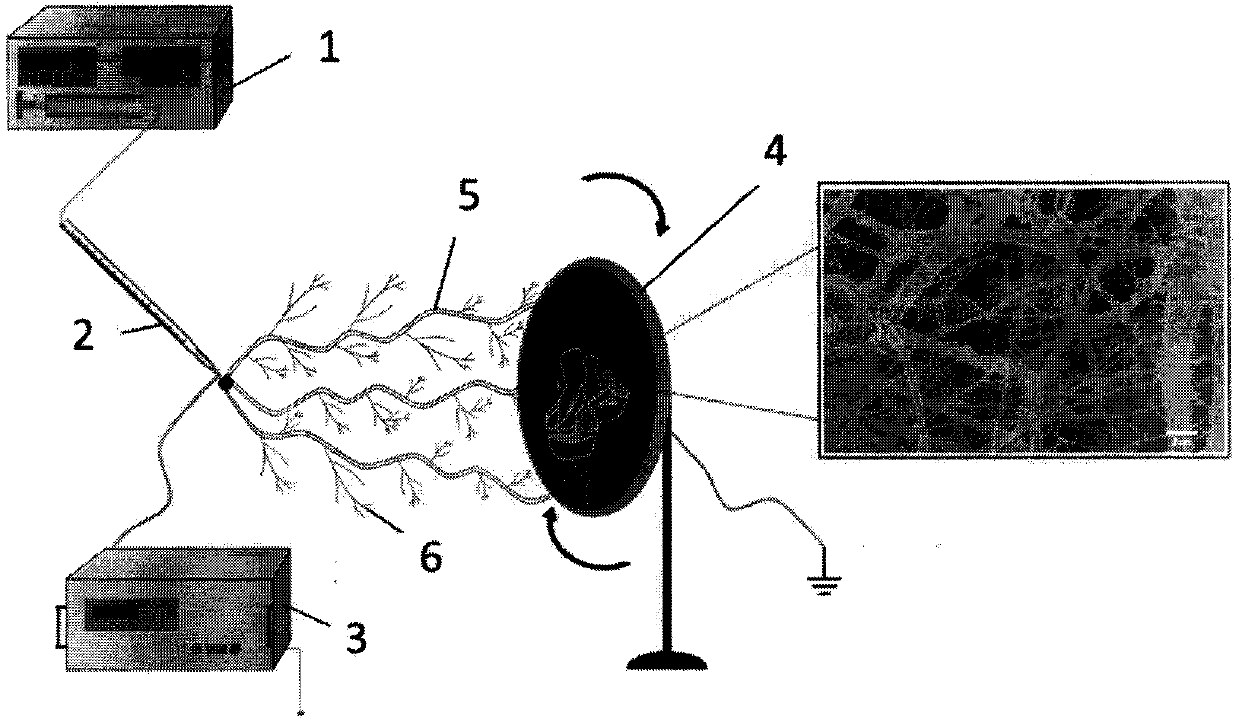

[0026] (2) Slowly add the solution in the above step (1) into the syringe 2, the diameter of the needle tightly connected with the syringe is 0.45mm, and the solution supply volume of the needle is kept at 0.5mL h -1 . A rotating disk covered with aluminum foil was used as the receiving device and a...

Embodiment 2

[0029] (1) in the present invention, at first needs to configure the spinning solution of electrostatic solution blowing, and its concrete steps are: under room temperature tetrabutylammonium bromide (mass fraction is 10%) and N, N-dimethylformamide according to Mix evenly in a certain proportion, then add an appropriate proportion of thermoplastic polyurethane (mass fraction is 7%) and stir to dissolve, finally weigh a certain amount of zirconium phosphate silver-loaded antibacterial agent particles (mass fraction is 2%) and slowly pour it into The prepared solution was then stirred under air for 12 hours to form a uniform solution to obtain an electrospinning spinning solution.

[0030] (2) Slowly add the solution in the above step (1) into the syringe, the diameter of the needle tightly connected with the syringe is 0.45mm, and the solution supply volume of the needle is kept at 0.5mL h-1. A rotating disk covered with aluminum foil was used as the receiving device and a spi...

Embodiment 3

[0033] (1) in the present invention, at first needs to configure the spinning solution of electrostatic solution blowing, and its concrete steps are: under room temperature tetrabutylammonium bromide (mass fraction is 10%) and N, N-dimethylformamide according to Mix evenly in a certain proportion, then add an appropriate proportion of thermoplastic polyurethane (mass fraction is 7%) and stir to dissolve, finally weigh a certain amount of zirconium phosphate silver-loaded antibacterial agent particles (mass fraction is 5%) and slowly pour it into The prepared solution was then stirred under air for 12 hours to form a uniform solution to obtain an electrospinning spinning solution.

[0034] (2) Slowly add the solution in the above step (1) into the syringe, the diameter of the needle tightly connected with the syringe is 0.45mm, and the solution supply volume of the needle is kept at 0.3mL h-1. A rotating disk covered with aluminum foil was used as the receiving device and a spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com