Waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material and preparation method thereof

A water-based polyurethane, waterproof and moisture-permeable technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of single function, inability to provide antibacterial and anti-ultraviolet, etc., to improve uniform dispersion, good waterproof and moisture-permeable performance, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

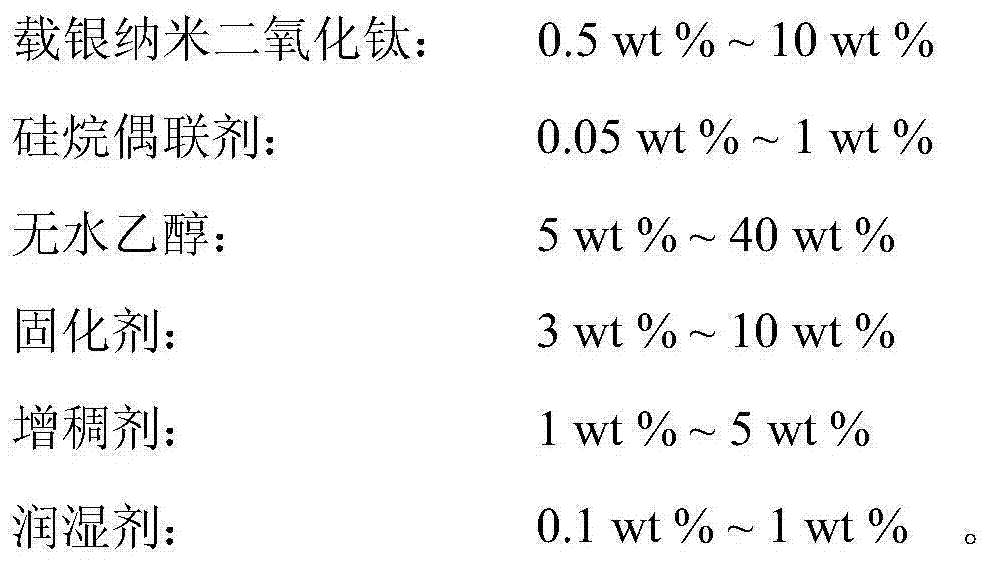

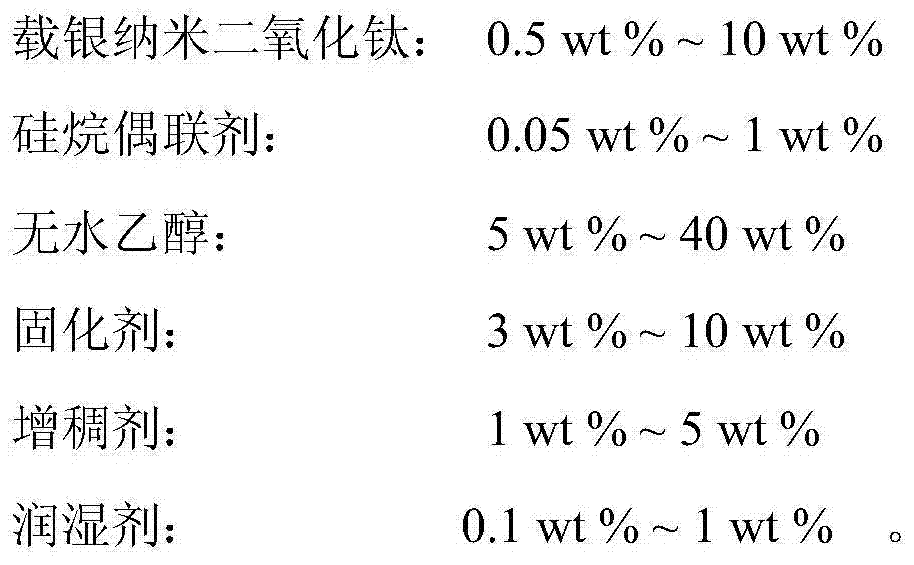

Method used

Image

Examples

Embodiment 1

[0026] At 25°C, 21.3g of polyethylene glycol with a molecular weight of 1000, 49.63g of polyethylene glycol with a molecular weight of 2000, 61.45g of polytetrahydrofuran diol with a molecular weight of 2000, 6g of dimethylolbutyric acid, and 1.67g of 1, Add 4-butanediol and 60g of isophorone diisocyanate into the reaction kettle at the same time, raise the temperature to 60°C, and react for 9 hours to obtain a polyurethane prepolymer terminated with isocyanate groups; cool down the polyurethane prepolymer to 20°C , and add 40g of butanone to dilute, then add 4.10g of triethylamine to carry out neutralization reaction for 0.5h, and obtain a neutralized mixed solution, add 470g of deionized water to the neutralized mixed solution under high-speed stirring, emulsify for 0.5h, and then add 4.87g of ethylenediamine was subjected to a post-chain extension reaction for 0.5h to obtain a water-based polyurethane emulsion. The emulsion was distilled at 40°C to remove butanone under redu...

Embodiment 2

[0028] At 25°C, 21.2g of polyethylene glycol with a molecular weight of 1000, 49.37g of polyethylene glycol with a molecular weight of 2000, 61.13g of polytetrahydrofuran diol with a molecular weight of 2000, 6g of dimethylolbutyric acid, and 2.32g of 1, Add 4-butanediol and 60g of isophorone diisocyanate into the reaction kettle at the same time, raise the temperature to 70°C, and react for 8 hours to obtain a polyurethane prepolymer terminated with isocyanate groups; cool the polyurethane prepolymer to 25°C , and add 45g methyl ethyl ketone to dilute, then add 1.42g ammonia water to carry out neutralization reaction for 40min, and obtain a neutralized mixed solution, add 500g deionized water to the neutralized mixed solution under high-speed stirring, emulsify for 40min, and then add 13.06g isofor Alone diamine was subjected to post-chain extension reaction for 40 minutes to obtain a water-based polyurethane emulsion. The emulsion was distilled off under reduced pressure to r...

Embodiment 3

[0030] At 25°C, 20.9g of polyethylene glycol with a molecular weight of 1000, 48.77g of polyethylene glycol with a molecular weight of 2000, 60.38g of polytetrahydrofuran diol with a molecular weight of 2000, 6g of dimethylolbutyric acid, and 3.91g of 1, Add 4-butanediol and 60g of isophorone diisocyanate into the reaction kettle at the same time, raise the temperature to 80°C, and react for 7 hours to obtain a polyurethane prepolymer terminated with isocyanate groups; cool the polyurethane prepolymer to 30°C , and add 50g butanone to dilute, then add 3.69g triethylamine to carry out neutralization reaction for 35min to obtain a neutralized mixed solution, add 515g deionized water to the neutralized mixed solution under high-speed stirring, emulsify for 35min, then add 6.88g Diethylenetriamine was subjected to a post-chain extension reaction for 35 minutes to obtain a water-based polyurethane emulsion. The emulsion was distilled off under reduced pressure to remove butanone at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com