Patents

Literature

39results about How to "Guaranteed non-toxic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gingko planting method

InactiveCN104855231AIncrease the areaGuaranteed non-toxicFertilising methodsCultivating equipmentsDiseaseAlkali soil

The invention discloses a gingko planting method and belongs to the technical field of traditional Chinese medicine planting. The method comprises the steps of 1) land selection and preparation including land selection, fertilizer application, land leveling, ploughing and bedding; 2) seedling cultivation including seed collection, breeding nursery garden construction and seedling planting: 3) transplantation and planting including seeding hole digging, fertilizer application, transplantation at a male-female ratio of 95:5, soil covering and watering; 4) field management including intertillage, topdressing, pruning and pollination; 5) insect and disease prevention. According to the gingko planting method, during the leveling process, acid modifier composed of vinegar residue and decomposed straw fertilizer is applied, so that gingko can be planted and grow in saline-alkali soil, and further compared with the situation that saline-alkali soil is unsuitable for growth of gingko in the prior art, the gingko planting method widens the gingko planting area. The gingko planting method also has the advantages of being high in emergence rate, high in seedling disease resistance and the like.

Owner:徐富春

Manufacturing method for composite aluminium plastic decorative buckles

InactiveCN1456436AImprove flatnessFriction-resistantMetal layered productsTectorial membraneSurface oxidation

A decorative fastening aluminium-plastic plate is prepared through preparing plastic substrate from engineering plastics, filler, stabilizer, plasticizer, lubricant and assistant through mixing, granulating, extruding out, fixing shape, and cutting, preparing the coated aluminium foil through washing, removing oil, oxidizing surface, baking, painting, baking and coiling, combining said plastic substrate with aluminium foil, covering adhesive protecting film on the surface of aluminium foil, and cutting. Its advantages are high abrasion compression, fire and water resistance, good thermal and acoustic insulation, no poison and beautiful appearance.

Owner:无锡市中德装饰新材料有限公司

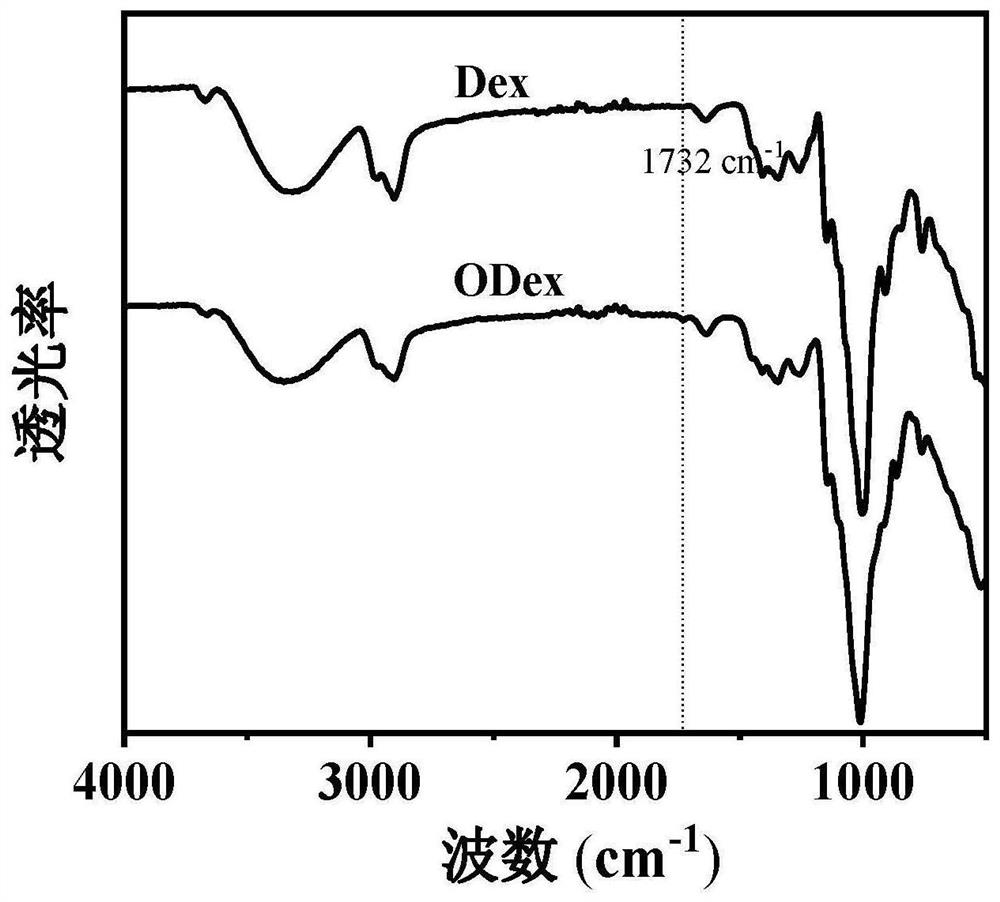

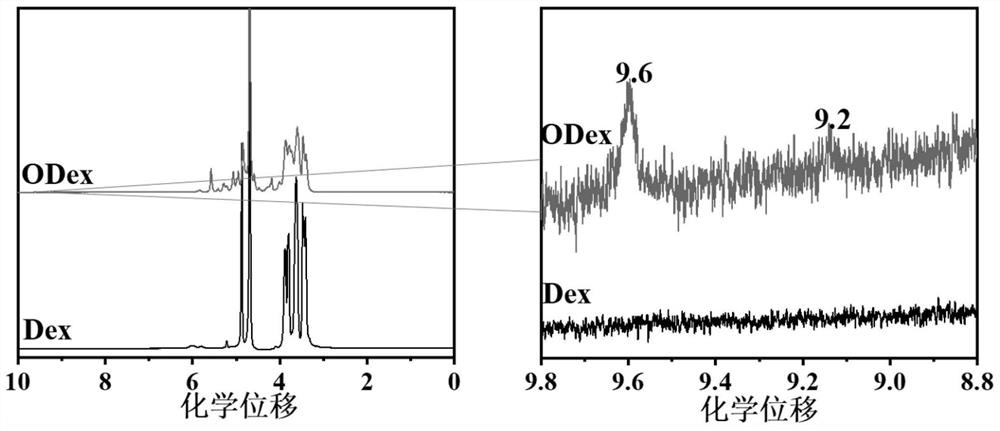

Medical anti-adhesion material with controllable degradation and preparation method thereof

InactiveCN102380121AVolatileControllable degradation rateSurgeryAbsorbent padsCross-linkBiocompatibility Testing

The invention discloses a medical anti-adhesion membrane material with controllable degradation and a preparation method thereof, belonging to the field of biomedical materials. According to the invention, the membrane material is prepared by blending sodium hyaluronate and konjac klucomannan, using lactic acid as a property-modifying additive and using a mixed solution of ammonia water and anhydrous ethanol as a cross-linking agent; sodium hyaluronate is a good anti-adhesion material, but individually used sodium hyaluronate has a fast degradation speed and can not fulfill a good anti-adhesion effect; konjac klucomannan can control the degree of cross-linking, thereby realizing the goal of controllable degradation, and blending of sodium hyaluronate and konjac klucomannan enables sodium hyaluronate to be released slowly, thereby allowing the membrane material to meet demands for anti-adhesion action at different parts. The membrane material has the advantages of nontoxic degradation products, good biocompatibility, hygroscopicity and tensile properties, and the like, and can be used for intervertebral adhesion, intestinal adhesion, skin adhesion, intrauterine adhesion, etc.

Owner:KUNMING UNIV OF SCI & TECH

Method of preparing cotton-stalk feed

InactiveCN101569347AImprove palatabilityEasy to prepareFeeding-stuffFood processingNutritive valuesAir separation

The invention discloses a method of preparing cotton-stalk feed, which comprises the following steps: the cotton-stalk core is taken as a raw material, and air separation, edulcoration, softening, stacking, loading, ammoniation are carried out on the raw material in sequence to obtain the cotton-stalk feed. The invention has the advantages of simple and convenient preparation method, low cost, needs no large-scale equipment, and is environment-friendly and safe. Moreover, the invention can make full use of existing cotton-stalk raw materials, and the prepared cotton-stalk feed has the advantages of high nutritive value, fine palatability, high digestibility, no toxicity and pollution and the like.

Owner:姜景文 +2

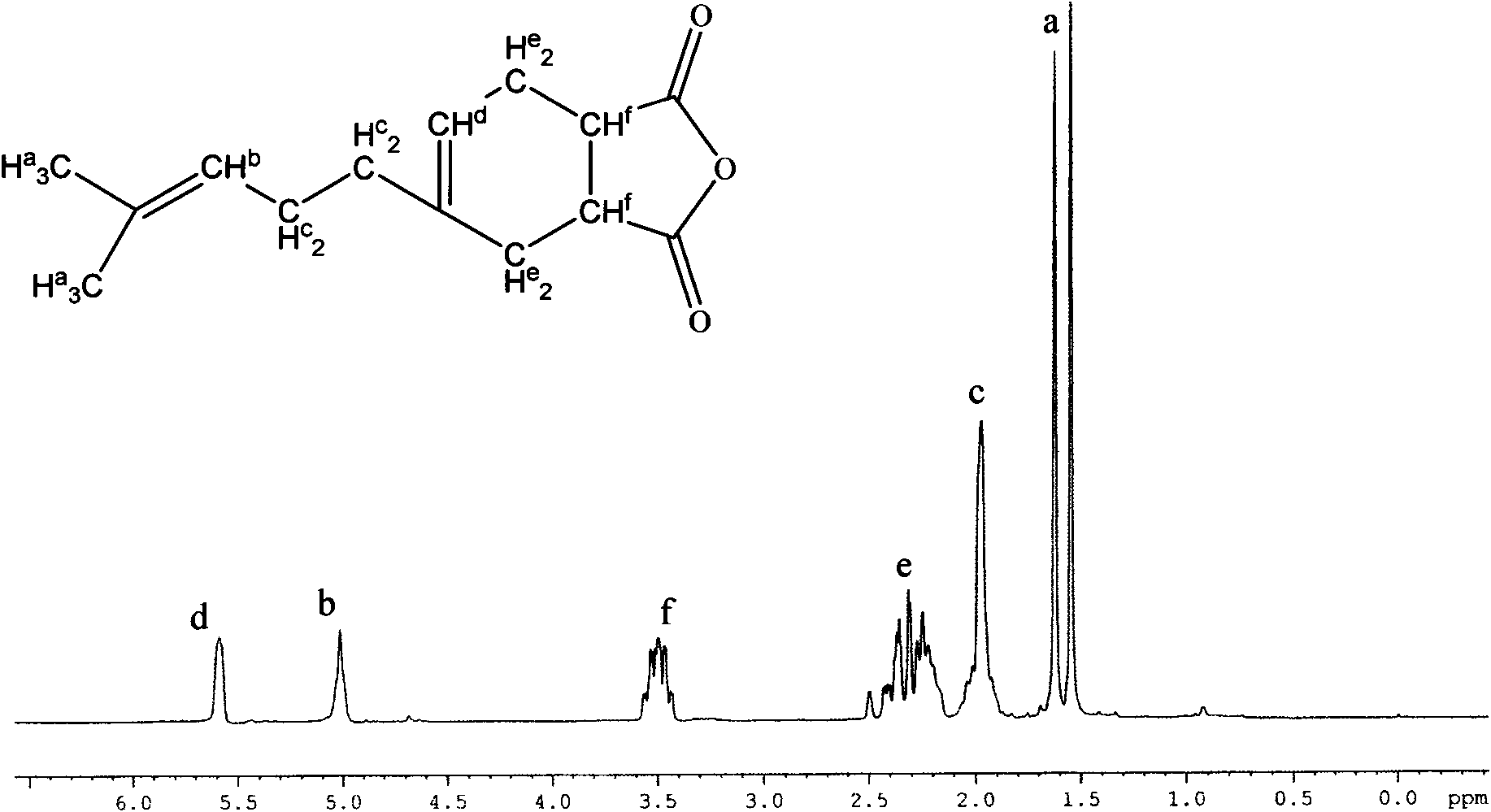

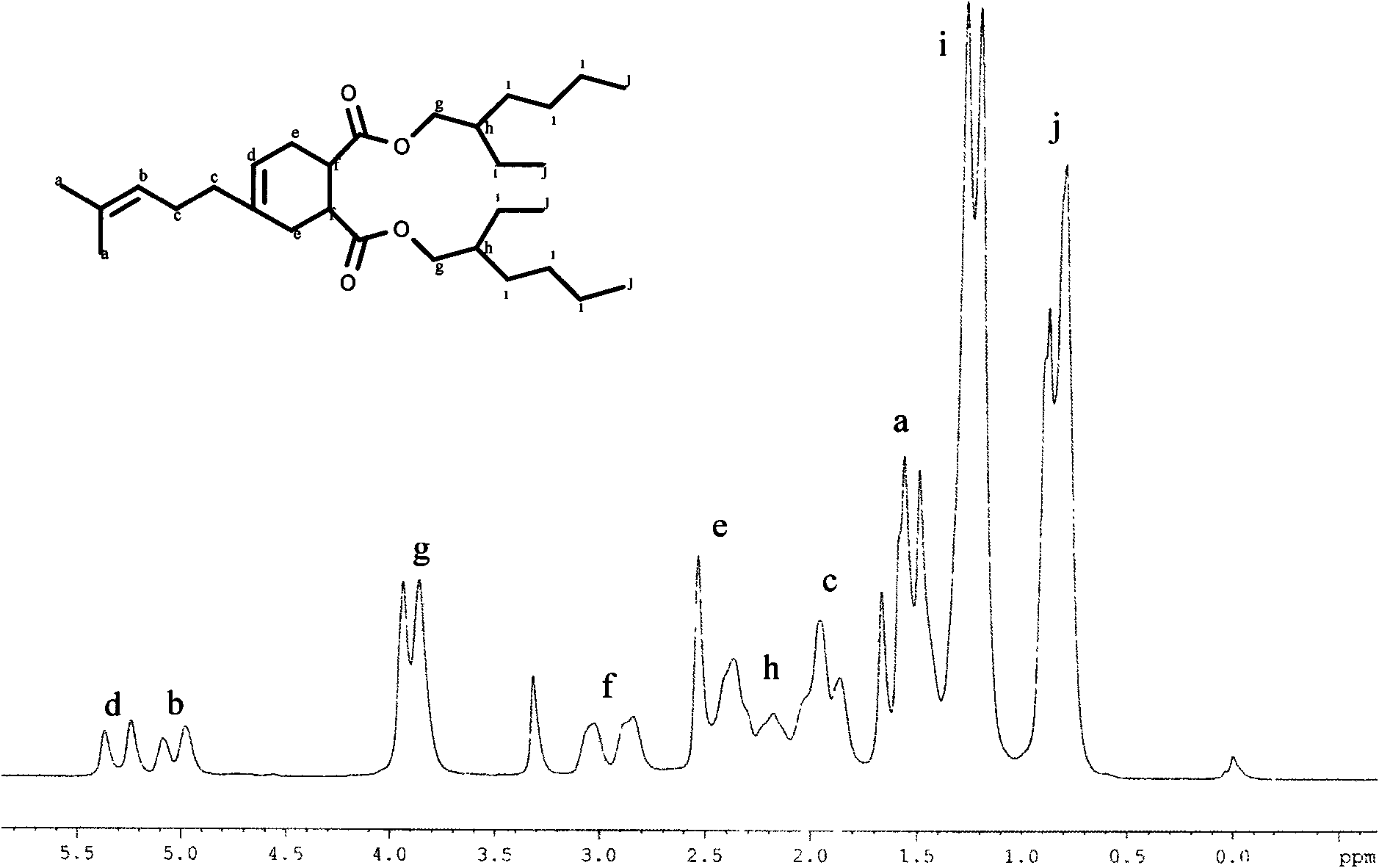

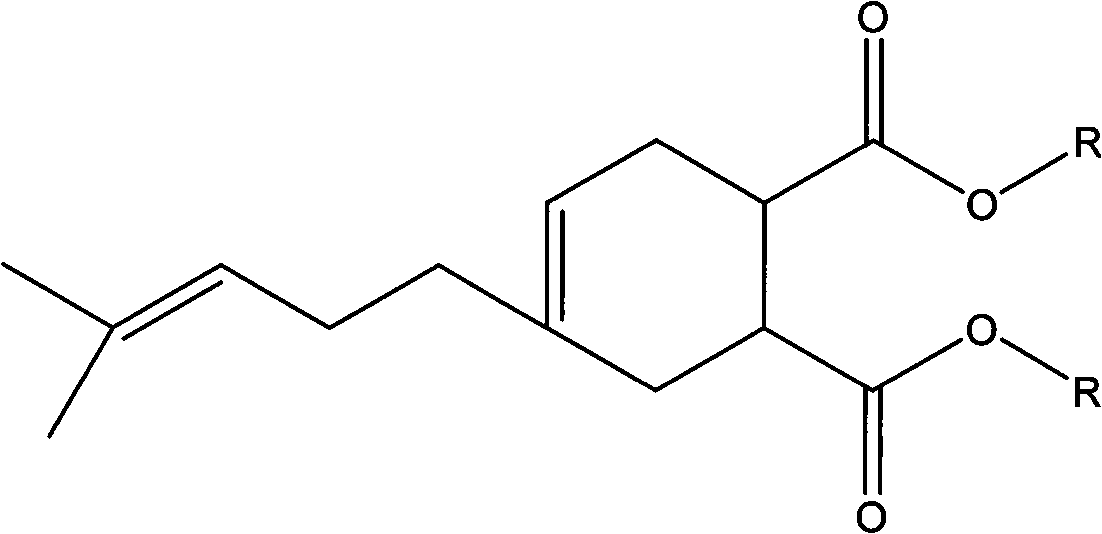

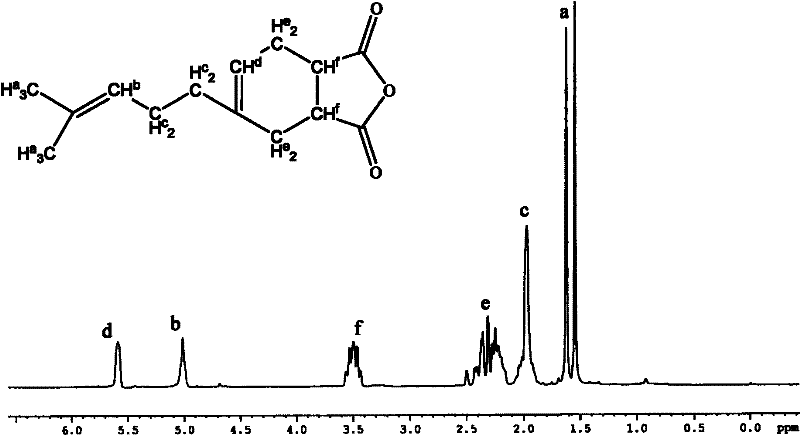

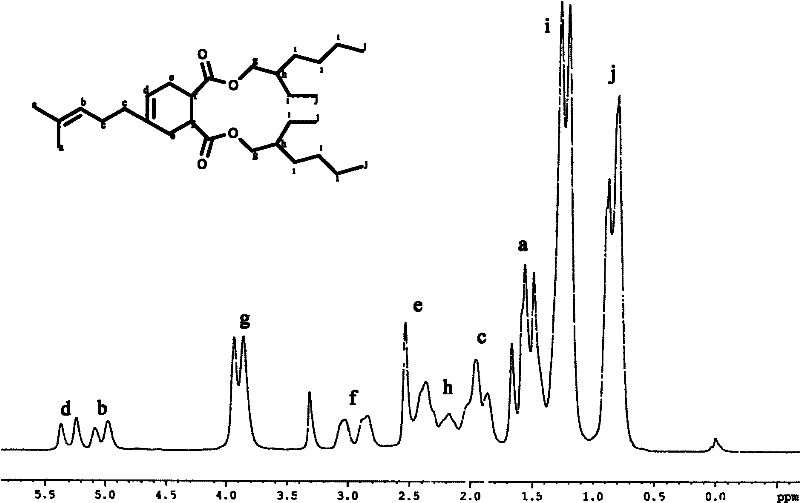

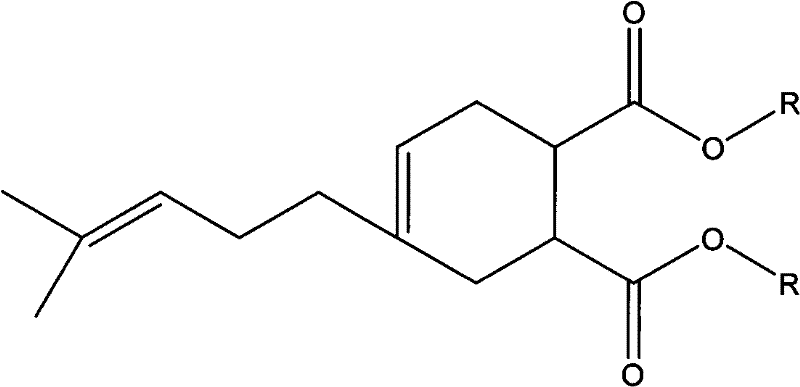

Myrcenyl plasticizer and preparation method thereof

ActiveCN101962446AGuaranteed non-toxicImprove plasticizing effectOrganic compound preparationCarboxylic acid esters preparationRefluxAlcohol

The invention discloses a myrcenyl plasticizer and a preparation method thereof. The method comprises the following steps of: 1, performing a Diels-Alder reaction on myrcene and unsaturated acid (anhydride) with equal molar weight in the absence of catalyst at the temperature of between 30 and 80 DEG C for 3 to 7 hours so as to obtain an intermediate product named 4-(4-methyl-3-pentenyl)-4-cyclohexene-1,2-acid (anhydride) (MYM for short); and 2, adding a water-carrying agent into protonic acid or Lewis acid serving as a catalyst in an using amount of 0.5 to 3 percent based on the molar weight of the MYM and performing an esterification reaction on the MYM and alcohol at a reflux keeping temperature for 0.5 to 5 hours so as to obtain a target product, namely, the plasticizer. The plasticizer prepared by the method has the characteristics of nontoxicity and degradability; and a plasticized plastic has high low-temperature resistance, high tensile strength and high resistivity and can be taken as a main plasticizer in various plastics and compounded with other plasticizers.

Owner:NANJING TELESUN S & T IND

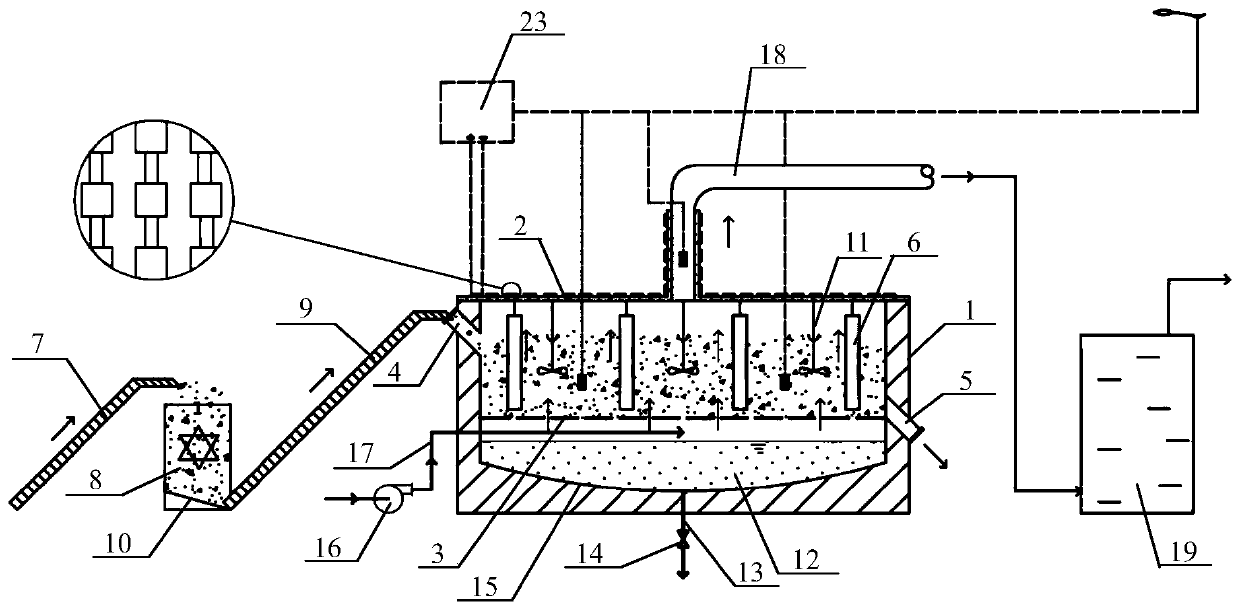

Aerobic composting waste heat power generation system and working method thereof

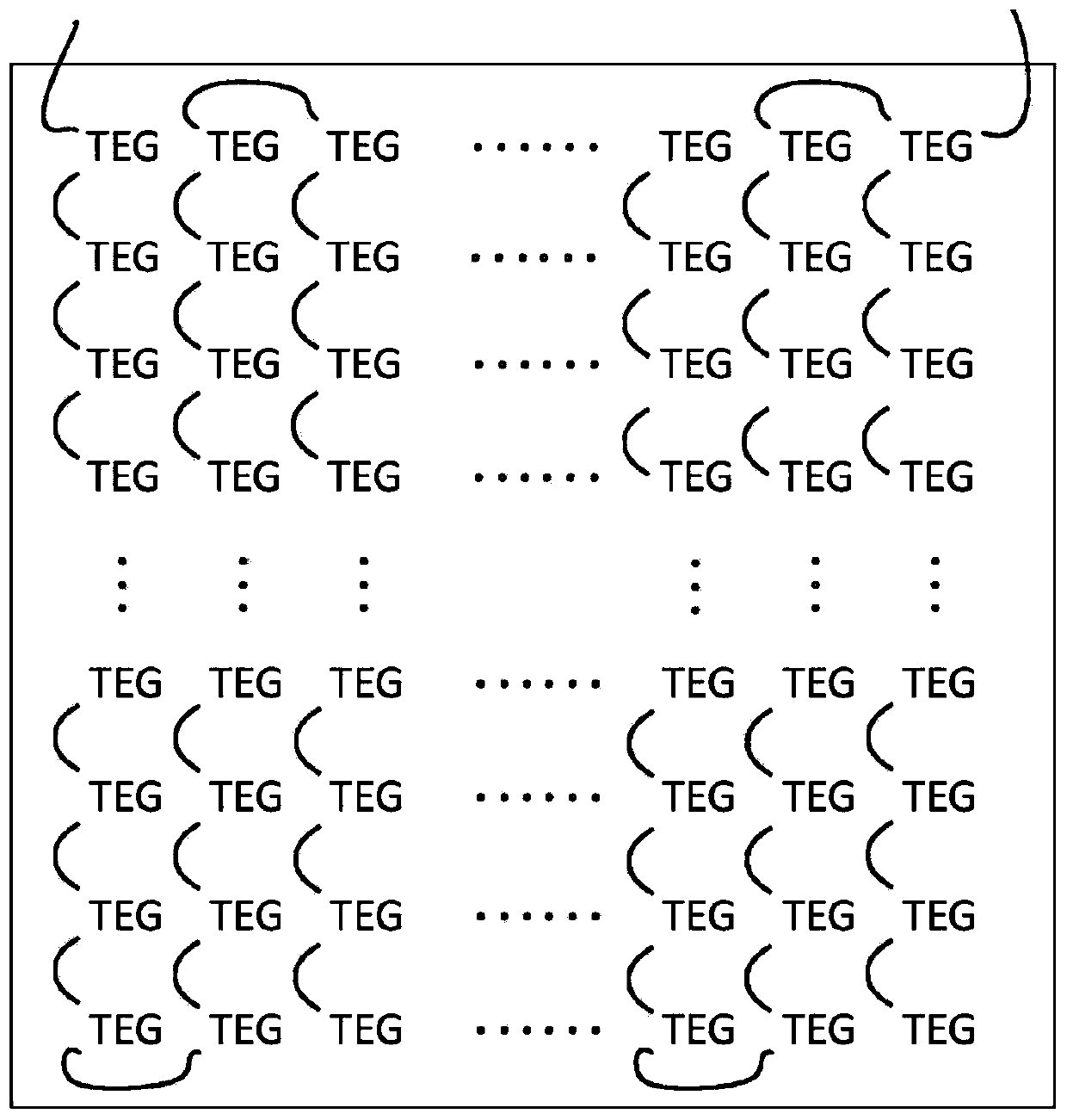

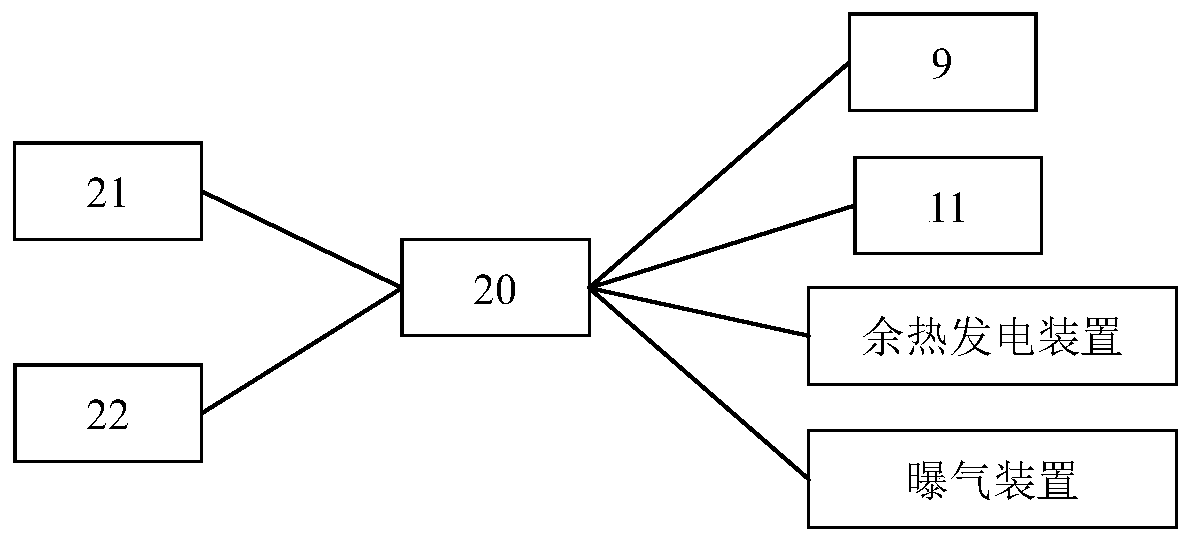

PendingCN110713400ARealize managementEfficient use ofBio-organic fraction processingEnergy inputCompostOrganic solid waste

The invention relates to an aerobic composting waste heat power generation system and a working method thereof, and belongs to the field of organic solid waste resource utilization. The system comprises a waste collection device, a main composting reaction chamber, a waste heat power generation device and a tail gas collection device, wherein a heat conduction cover is arranged at the top of the main composting reaction chamber, the upper space of the main composting reaction chamber is a waste reactor body, the lower space of the main composting reaction chamber is a leachate collection device, a filter screen is arranged between the upper space and the lower space, and the main composting reaction chamber is further connected with an aeration device; the bottom of the heat conduction cover is connected with the reactor body through a heat conduction rod; a waste heat power generation device is installed on the upper surface of the heat conduction cover and is formed by connecting a plurality of semiconductor thermoelectric power generation pieces in series, wherein the electric energy generated by the semiconductor thermoelectric power generation pieces is transmitted to an electricity storage and supply device. According to the invention, heat can be recovered from organic wastes while the organic wastes are treated, and the problem of secondary pollution caused by excessivewaste heat of traditional compost is solved.

Owner:SHANDONG UNIV

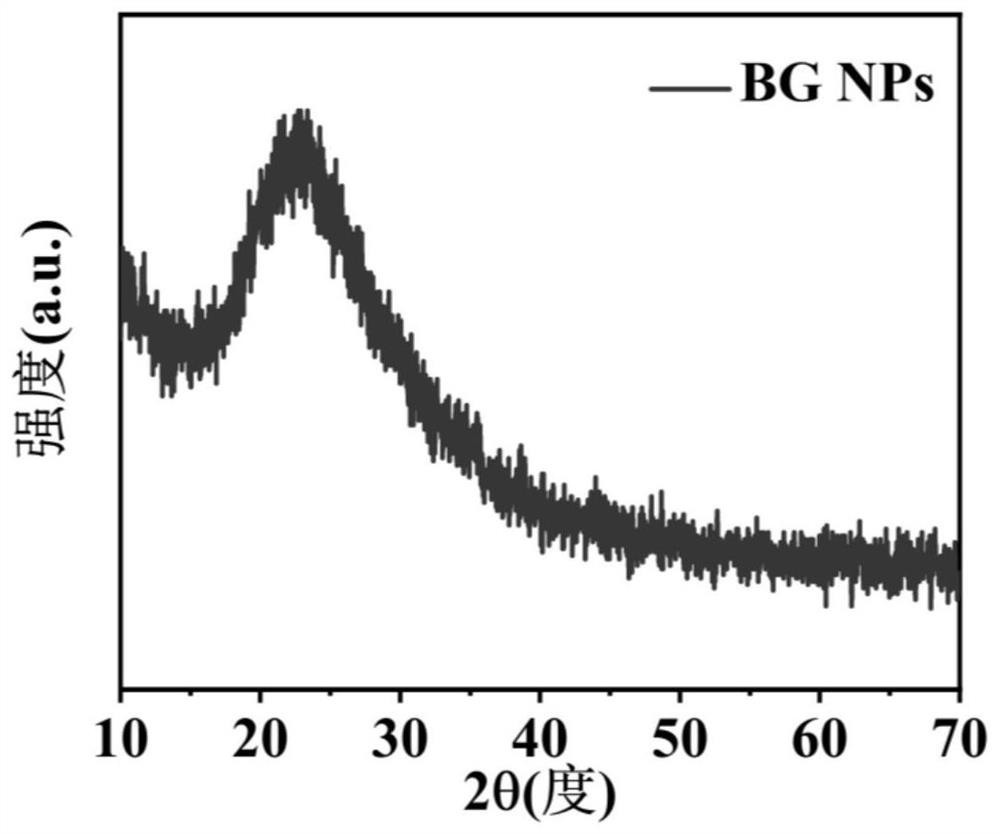

Novel injectable hydrogel for bone defect repair and preparation method thereof

ActiveCN112999427AImprove the effect of bone defect repairPromote differentiationPharmaceutical delivery mechanismTissue regenerationBioactive glassCollagenan

The invention discloses novel injectable hydrogel for bone defect repair. A preparation method of the novel injectable hydrogel comprises the steps: 1, preparing bioactive glass; 2, preparing hydrazide bond-grafted collagen and modified oxidized konjac glucomannan; 3, dispersing the bioactive glass and the hydrazide bond-grafted collagen in a PBS solution to obtain a solution A; dissolving the modified oxidized konjac glucomannan in a PBS solution to obtain a solution B; and 4, mixing the solution A and the solution B to obtain the novel injectable hydrogel for bone defect repair. The novel injectable hydrogel for bone defect repair has the advantages that in-situ injection can be achieved, operation is easy and convenient, secondary injury generated by an operation is small, the hydrogel can adapt to the shape of a defect part, in-situ filling forming of the bone defect part is achieved, and the application prospect is wide.

Owner:NORTHWEST UNIV(CN)

Special non-toxic drying agent for food packages and preparation method of special non-toxic drying agent

The invention discloses a special non-toxic desiccant for food packaging and a preparation method thereof. The components of the desiccant include 20-40 parts by weight of sweet potato starch, 5-10 parts of bentonite, 5-15 parts of coconut shell powder, and natural fiber. 2-10 parts of vegetarian ingredients, 5-10 parts of tea stems, 3-8 parts of cassia seeds, 2-12 parts of ginkgo leaves, 3-10 parts of jasmine flowers, and 2-10 parts of bamboo charcoal powder, the preparation method of the invention is simple, and the prepared desiccant It has excellent hygroscopic effect. It adopts Chinese herbal medicine formula, which is non-toxic and harmless to human body, and can be widely used in the field of food processing.

Owner:伊婕

Simple, convenient and safe war horse bag

The invention provides a simple, convenient and safe war horse bag. The bag comprises a bag body; the inner layer of the bag body is coated with a PE (Polyethylene) film layer; the bag body is formed by hermetically packaging a bag body front surface, a bag body rear surface, a bag body left side surface, a bag body right side surface and a secondary bag body right side surface. According to the bag disclosed by the invention, the bag body is excellent in protection performance, is waterproof and moisture-proof and also has a certain heat insulation effect; the bag is odorless, nontoxic, safe and reliable; by adopting the sealing mode and folding mode, the bag can be directly adhered manually during production; a machining mode is relatively complex, but 40% of the cost can be further saved based on the existing cost by adopting the mode of folding the bag body.

Owner:滁州瑞祥智能科技有限公司

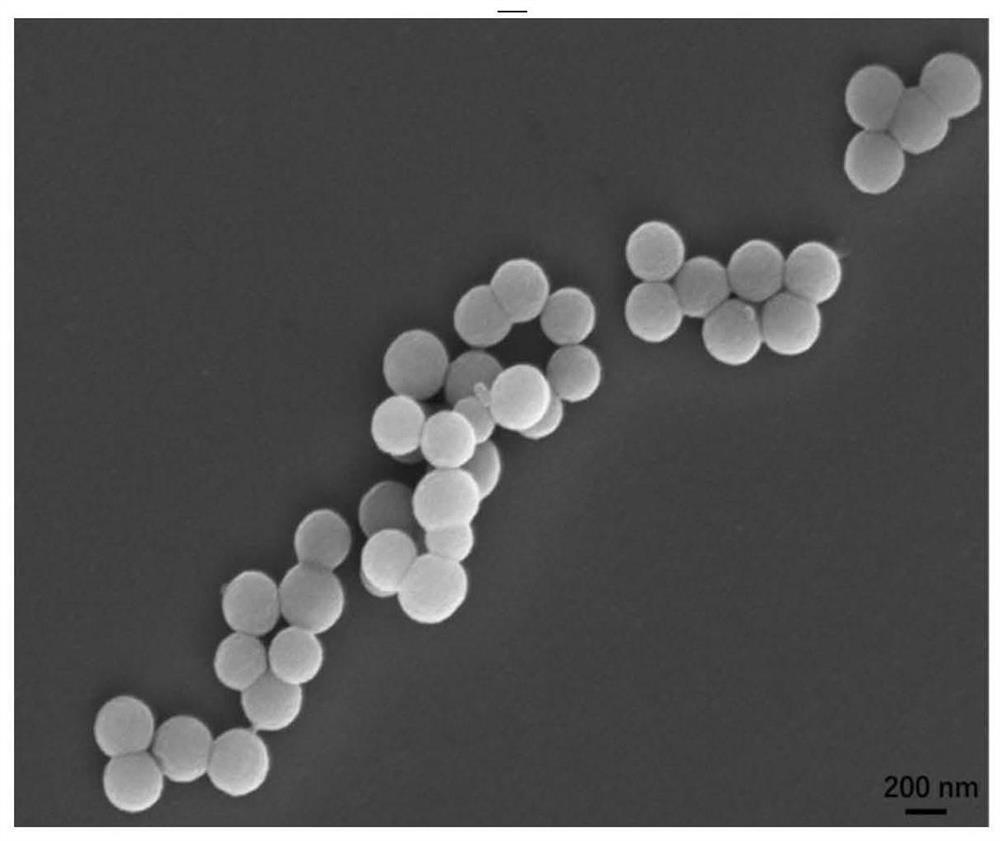

Injectable hemostatic cryogel for promoting tissue regeneration and preparation method and application thereof

ActiveCN113842494APromote healingImprove coagulation efficiencySurgical adhesivesPharmaceutical delivery mechanismAcetic acidDeep wounds

The invention discloses injectable hemostatic cryogel for promoting tissue regeneration and a preparation method and application thereof. The preparation method comprises the following steps: ultrasonically dispersing polydopamine, chitosan and collagen in deionized water, adding glacial acetic acid, and stirring until dissolving; and dissolving oxidized dextran in deionized water, adding an oxidized dextran solution into a mixed solution under vigorous stirring, transferring to a refrigerator for a reaction, and melting at room temperature to obtain the injectable hemostatic cryogel for promoting tissue regeneration. The aperture of the cryogel is 50-200 [mu] m, and the cryogel is provided with interconnected macroporous structures and stable mechanical strength, can be conveyed to a narrow and deep wound through an injector after being compressed and fixed, quickly recovers to block the wound and form a physical barrier after sucking blood, and activates a blood coagulation process through concentrated blood to achieve a hemostasis effect. The cryogel prepared by the invention has rapid shape recovery capability, injectability, good hemostatic capability and the like.

Owner:NORTHWEST UNIV(CN)

Manufacturing method for composite aluminium plastic decorative buckles

InactiveCN1221381CImprove flatnessFriction-resistantMetal layered productsTectorial membraneSurface oxidation

A decorative fastening aluminium-plastic plate is prepared through preparing plastic substrate from engineering plastics, filler, stabilizer, plasticizer, lubricant and assistant through mixing, granulating, extruding out, fixing shape, and cutting, preparing the coated aluminium foil through washing, removing oil, oxidizing surface, baking, painting, baking and coiling, combining said plastic substrate with aluminium foil, covering adhesive protecting film on the surface of aluminium foil, and cutting. Its advantages are high abrasion compression, fire and water resistance, good thermal and acoustic insulation, no poison and beautiful appearance.

Owner:无锡市中德装饰新材料有限公司

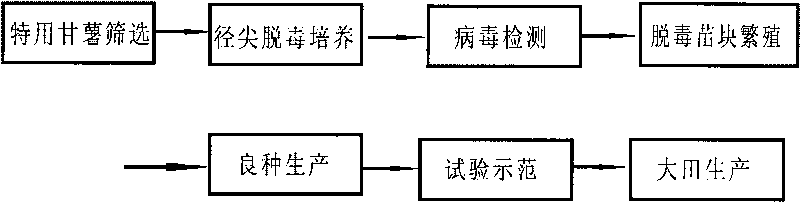

Method for raising seedlings of color virus-free sweet potatoes

InactiveCN101731143ADrought tolerantRidge resistantHorticulture methodsPlant tissue culturePharbitis nilShoot apex

The invention relates to a method for culturing and planting seedlings of color virus-free sweet potatoes. The method is characterized by utilizing the characteristic of low virus content or no virus content in stem tips of the sweet potatoes, cutting meristems of the stem tips of 0.2-0.4mm under an aseptic manipulation, forming test tube seedlings by culturing on a specific culture medium, and further detecting the virus-free seedlings by serology and indicator plant grafting. Meanwhile, the invention further provides the corresponding tissue rapid propagation technical regulations and a factorized production system according to different types, thereby accelerating the propagation of a large number of color style virus-free sweet potato seedlings. The method can propagate the potato species which has high nutritional value and bright color and is applicable to fresh-eating, baking or processing of the preserved sweet potatoes.

Owner:邱培标

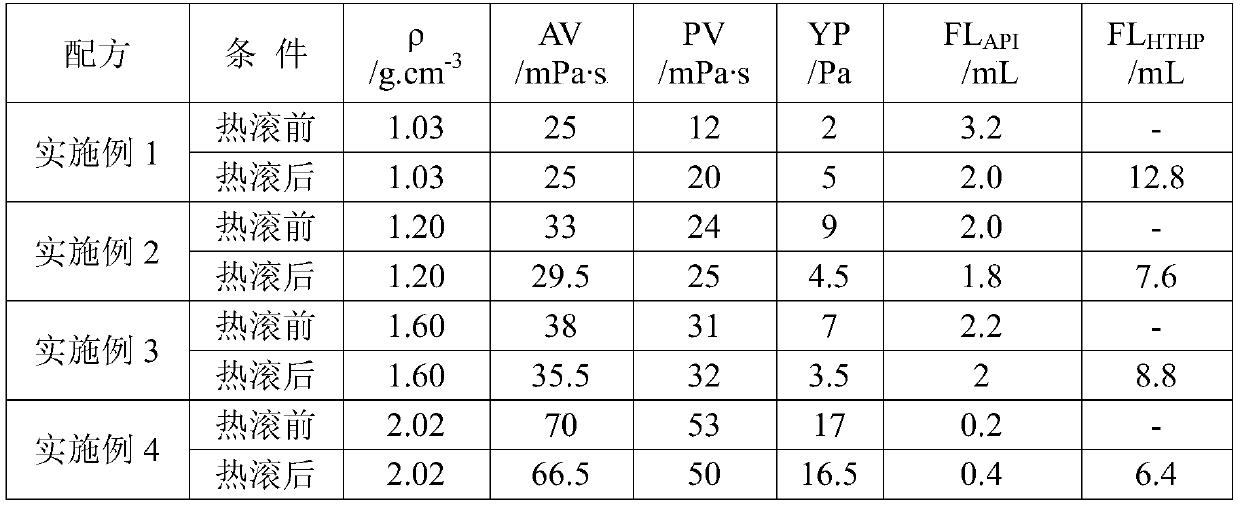

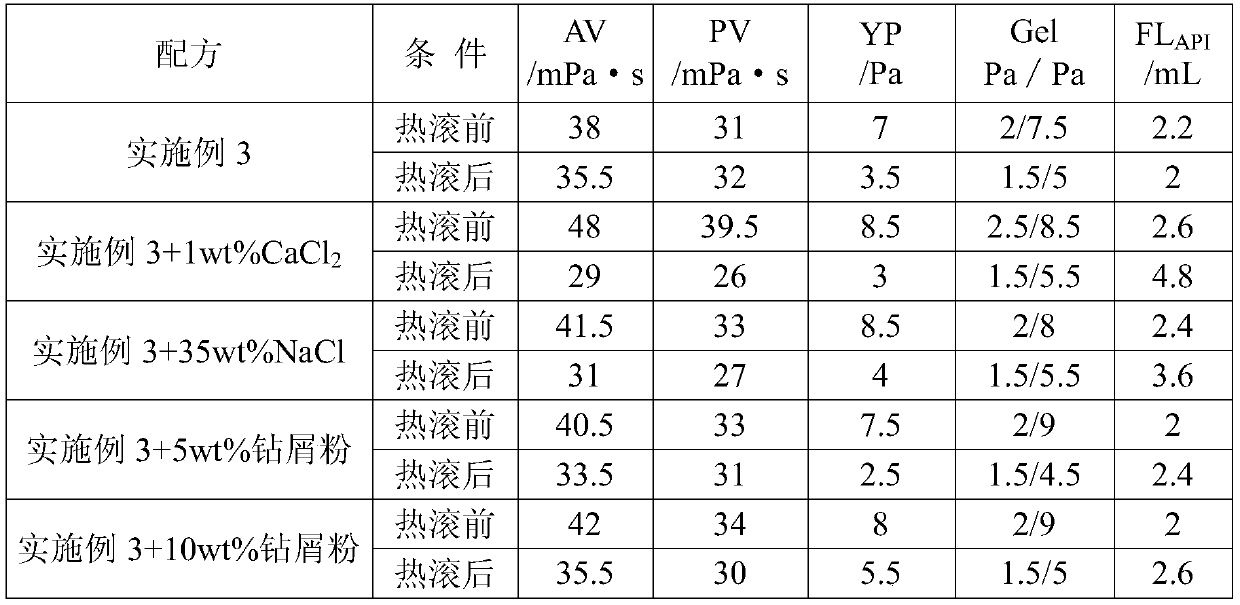

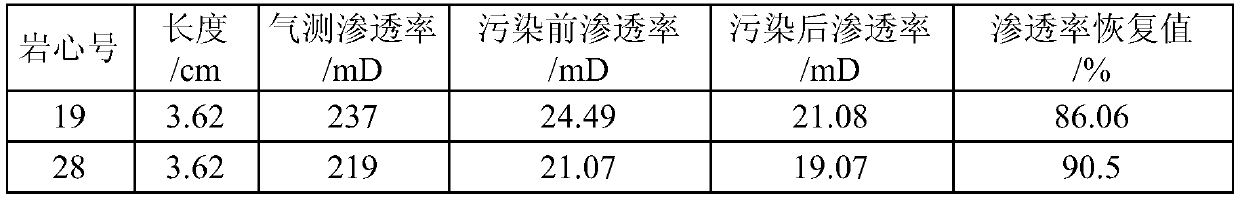

A kind of environment-friendly water-based drilling fluid and preparation method thereof

The invention provides environment-friendly water-based drilling fluid and a preparation method thereof. The water-based drilling fluid is prepared from the following raw materials in parts by weight: 100 parts of water, 1-5 parts of bentonite, 0.05-0.4 part of sodium carbonate, 0.5-3 parts of a filtrate reducer A, 0.2-3 parts of a filtrate reducer B, 0.1-1 part of a viscosity / yield boosting agent, 0.5-4 parts of an inhibitor, 1-5 parts of a lubricant, 2-6 parts of a micro / nano particle plugging agent and 0-200 parts of weighting materials. The preparation method of the drilling fluid comprises the steps of adding bentonite and sodium carbonate into water; sequentially adding the filtrate reducer A, the filtrate reducer B, the viscosity / yield boosting agent, the inhibitor, the lubricant and the micro / nano particle plugging agent; adjusting the pH value by using sodium carbonate; selectively adding the weighting materials until the density reaches the drilling requirements. The resisting temperature of the drilling fluid can reach 150 DEG C, EC50 is greater than 3.0*10<4>mg / L, and the drilling fluid is nontoxic and environmentally friendly and has good rheological property, filtration reducing property, rejection capability, lubricating property, pollution resistance and reservoir protection effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Food grade starch master batch composition, food grade starch master batch and preparation method of master batch

The invention relates to the technical field of chemistry, relates to a food-grade starch master batch and a preparation method thereof, and discloses a food-grade starch master batch composition anda method for preparing a starch master batch. Based on the total weight of the starch master batch composition, the starch master batch composition contains: thermoplastic starch 35-70 wt%, a matrix 8-35 wt%, a compatibilizer 2-15 wt%, a lubricant 1-5 wt%, and an auxiliary agent 0.1-1wt%. According to the food-grade starch master batch composition and the preparation method of the master batch, starch-based plastics can be used in food packaging materials, and it is ensured that the plastic properties of manufactured products are qualified, and further the environmental protection performanceof the products is improved.

Owner:BEIJING YISIDE LOGISTICS TECH

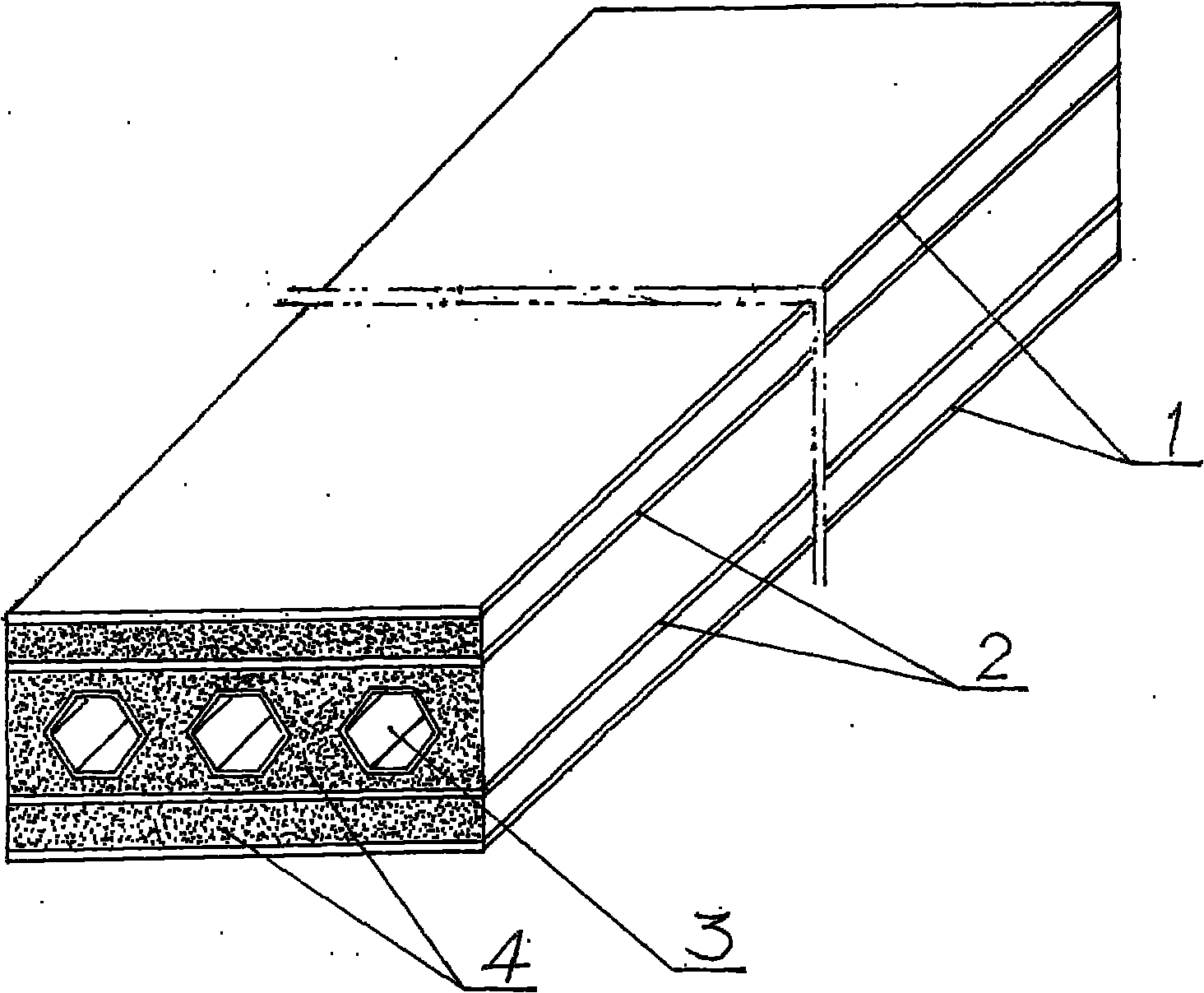

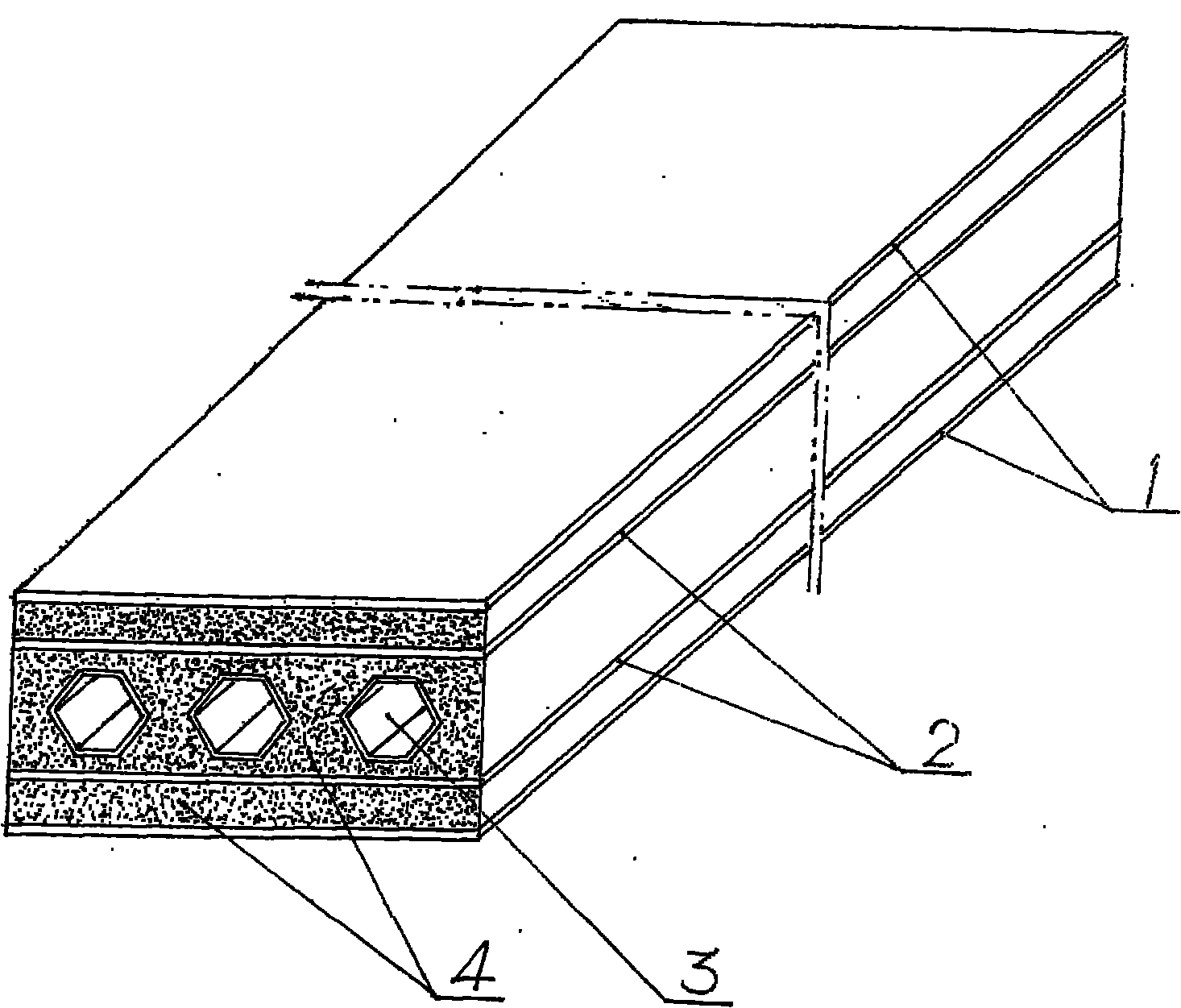

Composite floor slab of earthquake proof construction

The invention relates to a composite floor slab of an earthquake proof construction, comprising upper and lower panels, upper and lower splints, metal tubes and packing, wherein the upper and lower panels and the upper and lower splints are made of glass magnalium composite boards; the metal tubes are casting aluminum alloy tubes; and the packing is the mixture of light heat insulation flame retardant material polyurethane, kieselguhr and an adhesive; and the floor slab compounded by the material not only has light weight but also has the characteristics of heat preservation, heat insulation, fire prevention and no toxicity. Compared with the traditional heavy armored concrete precast slabs at present, on the premise of ensuring structural strength, the dead weight of the composite floor slab is reduced by more than a half, which can ensure that one adult can independently move the composite floor slab, and therefore, the composite floor slab is the ideal building material for the traditional earthquake proof construction.

Owner:ZHONGSHA CONSTR GROUP

Portable war horse bag

The invention provides a portable war horse bag. The bag comprises a bag body; the inner layer of the bag body is coated with a PE (Polyethylene) film layer; the bag body is formed by hermetically packaging a bag body front surface, a bag body rear surface, a bag body left side surface, a bag body right side surface and a bag body bottom surface; pull threads are arranged at the corresponding positions of the side surfaces of the front and rear surfaces of the bag body; the pull threads are packaged by adopting packaging threads. According to the portable war horse bag disclosed by the invention, the bag body is excellent in protection performance, is waterproof and moisture-proof and also has a certain heat insulation effect; the bag is odorless, nontoxic, safe and reliable; by adopting the sealing mode and folding mode, the bag can be manually adhered or directly adhered during production; a machining mode is relatively complex, but 40% of the cost can be further saved based on the existing cost by adopting the mode of folding the bag body.

Owner:GUANGDE COLORFUL ZEBRA PACKAGE TECH

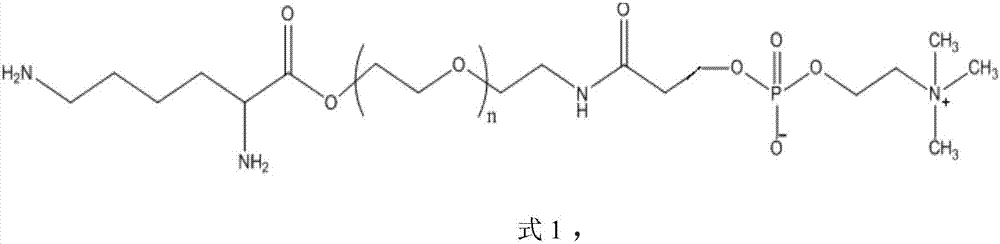

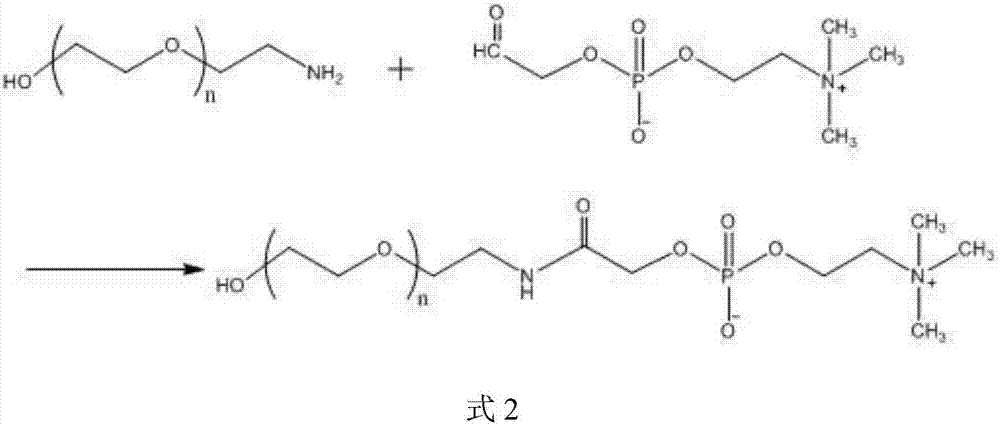

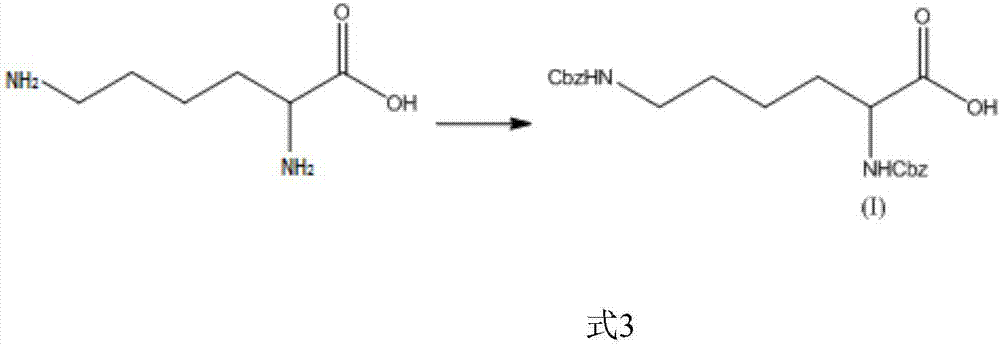

Diamido-terminated phosphorylcholine modified polyethylene glycol compound and preparation method thereof

The invention discloses diamido-terminated phosphorylcholine modified polyethylene glycol and a preparation method thereof. Diamido is introduced into the terminal on the basis of phosphorylcholine modified polyethylene glycol, so that the diamido-terminated phosphorylcholine modified polyethylene glycol has high biocompatibility, the degradation product is non-toxic and can be absorbed and metabolized by an organism, and the application space of the phosphorylcholine modified polyethylene glycol is widened. Compared with the diamido-terminated phosphorylcholine compound, the diamido-terminated phosphorylcholine modified polyethylene glycol disclosed by the invention has the advantages that phosphorylcholine groups are easily self-assembled on the material surface due to flexible chains, and the preparation method is simple, rapid, easy to purify and low in cost.

Owner:SHANDONG NORMAL UNIV

Moisture-proof and low temperature resistant fresh food packaging material

InactiveCN107698839AGuaranteed non-toxicEnsure safetySynthetic resin layered productsDomestic containersLow-density polyethyleneDecomposition

The invention discloses a moisture-proof and low-temperature-resistant fresh food packaging material, which belongs to the technical field of packaging materials. Including the fresh-keeping antibacterial layer of the inner layer and the protective layer of the outer layer, the protective layer of the outer layer is prepared from the following components by weight: 50-80 parts of low-density polyethylene, 10-15 parts of nano-zinc oxide, 2-4 parts of coupling agent, 2-5 parts of plasticizer, 1-3 parts of cross-linking agent; the fresh-keeping and antibacterial layer of the inner layer comprises the following components by weight: 15-25 parts of bamboo charcoal powder , 10-15 parts of cornstarch, 10-15 parts of peach gum, 10-15 parts of castor bean oil, 10-15 parts of konjac glucomannan, 6-8 parts of silica powder, 0.5-1.5 parts of antibacterial agent. Under the premise of guaranteeing the characteristics of the original packaging material, the present invention can be decomposed by microorganisms without causing any pollution to the environment, and meanwhile has a certain antibacterial effect, strong mechanical properties, safety and non-toxicity, and strong environmental protection.

Owner:扬州市星海塑料制品有限公司

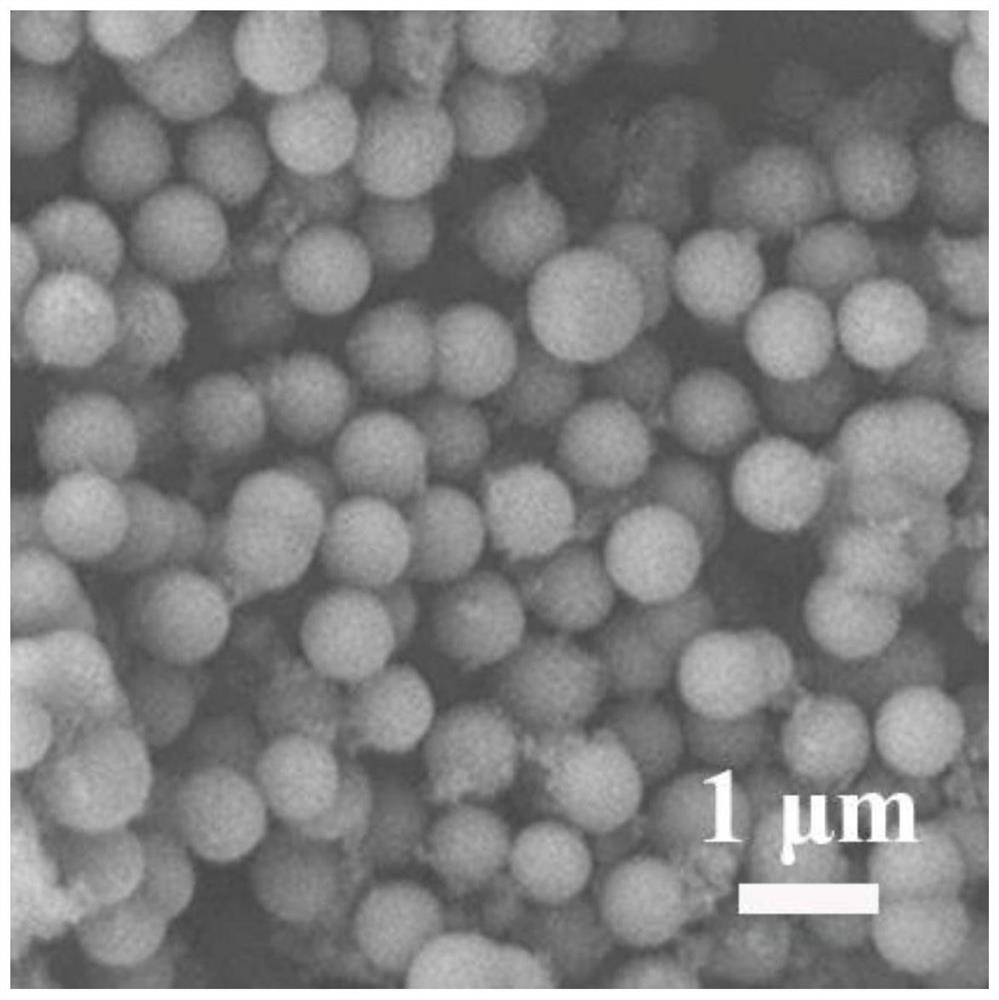

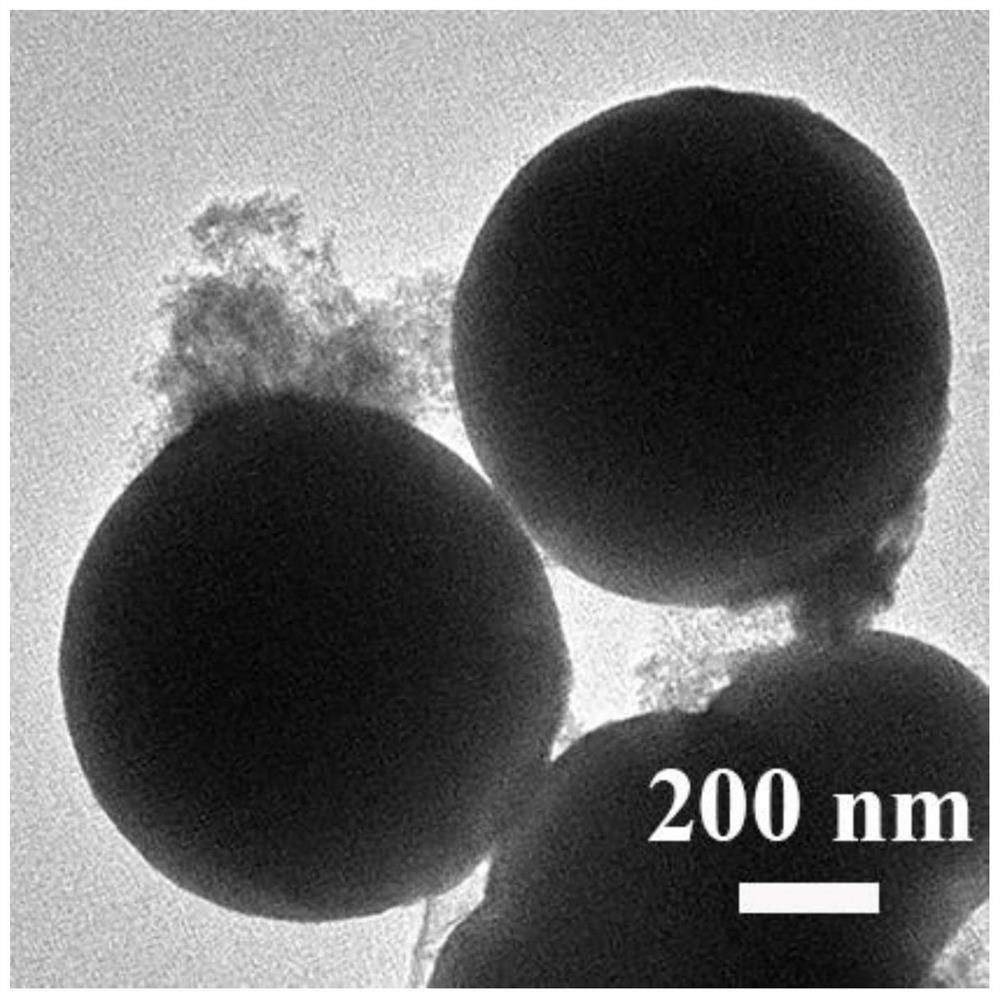

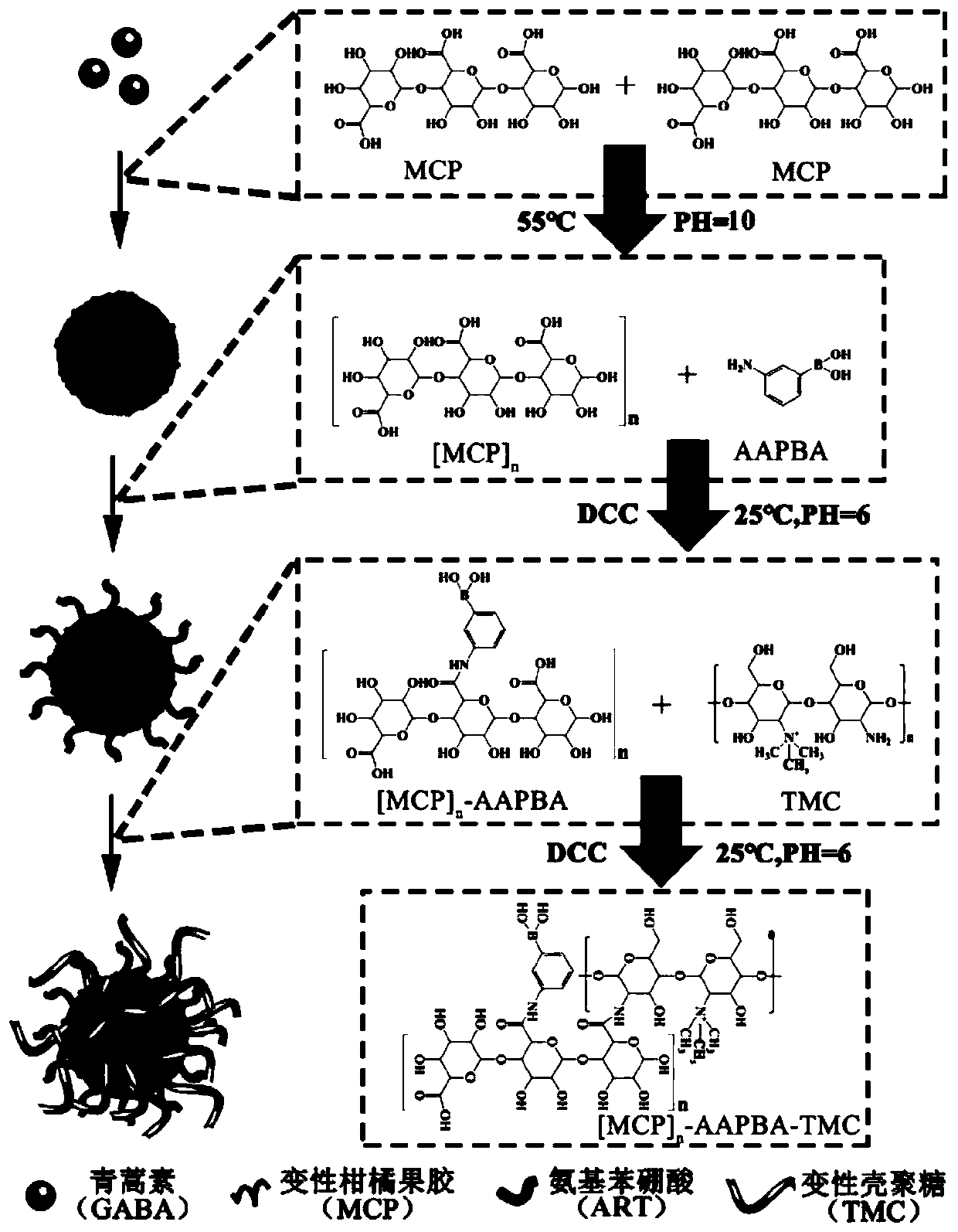

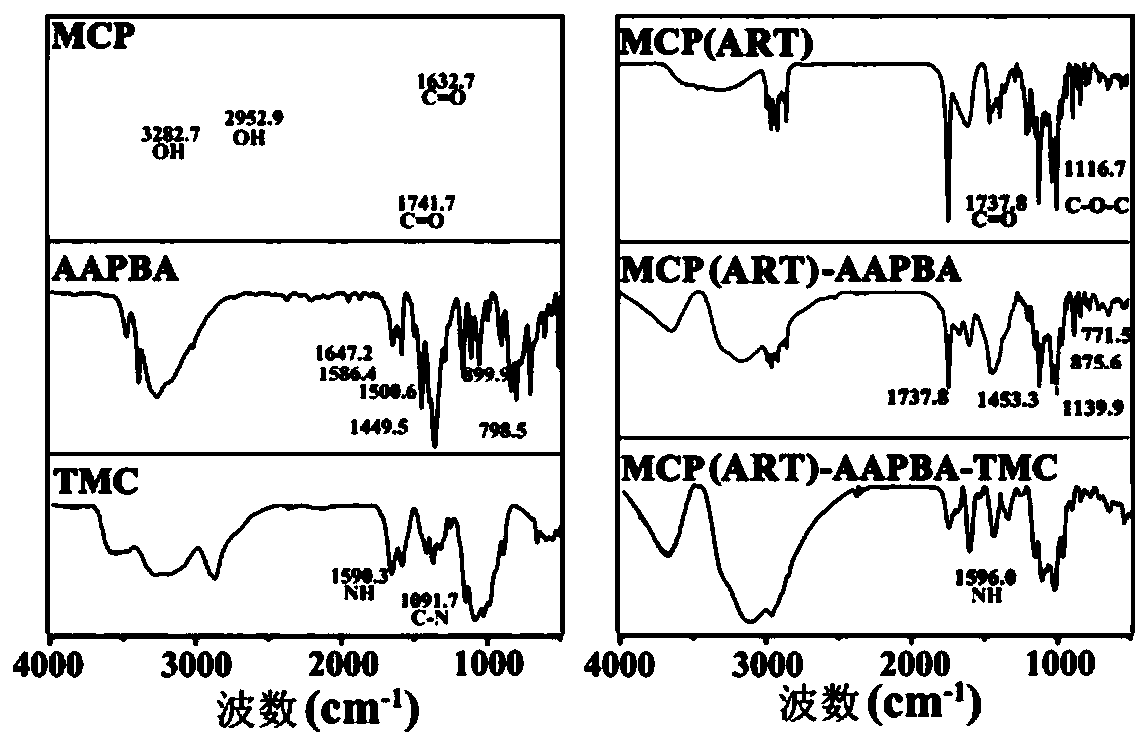

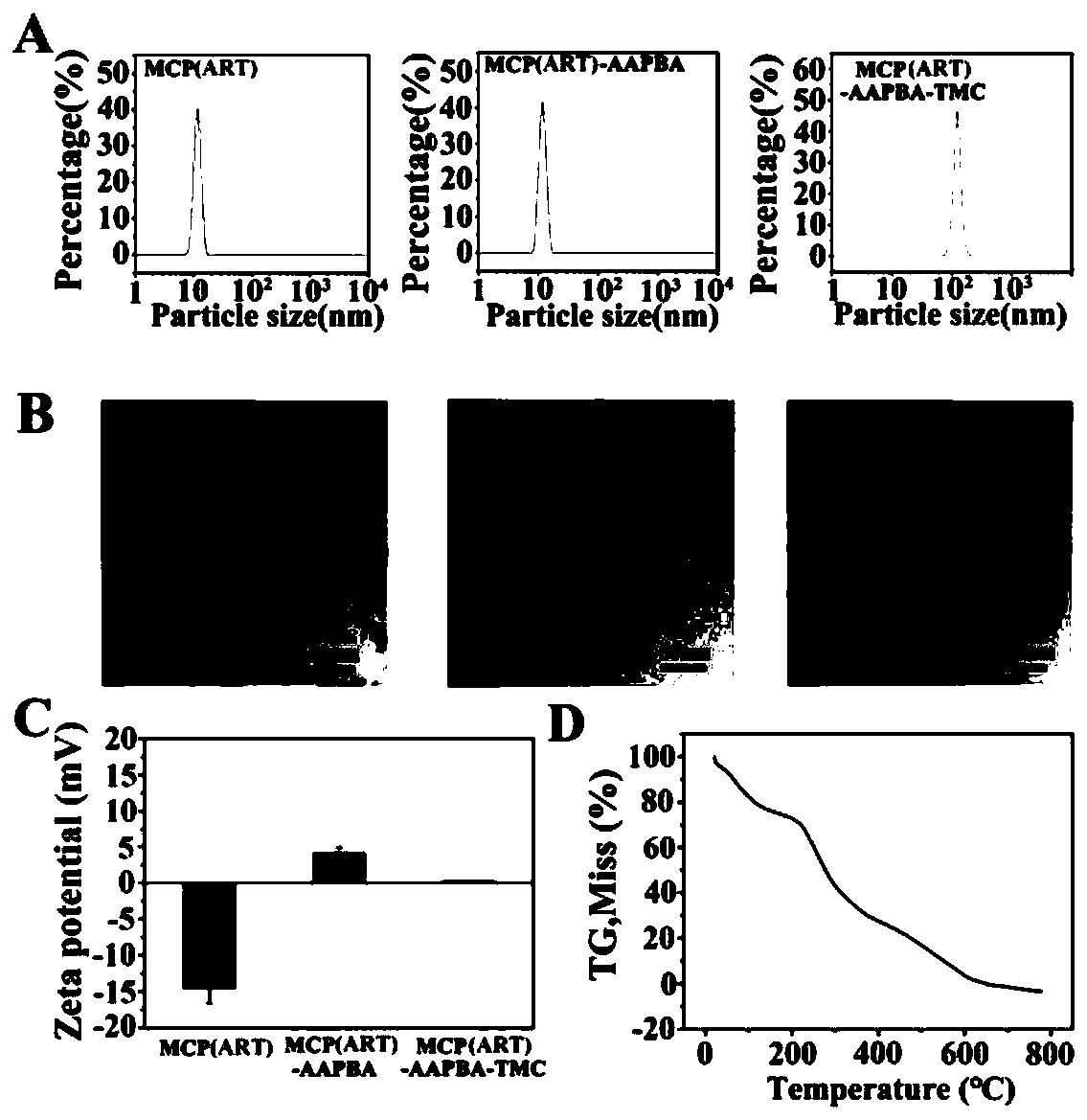

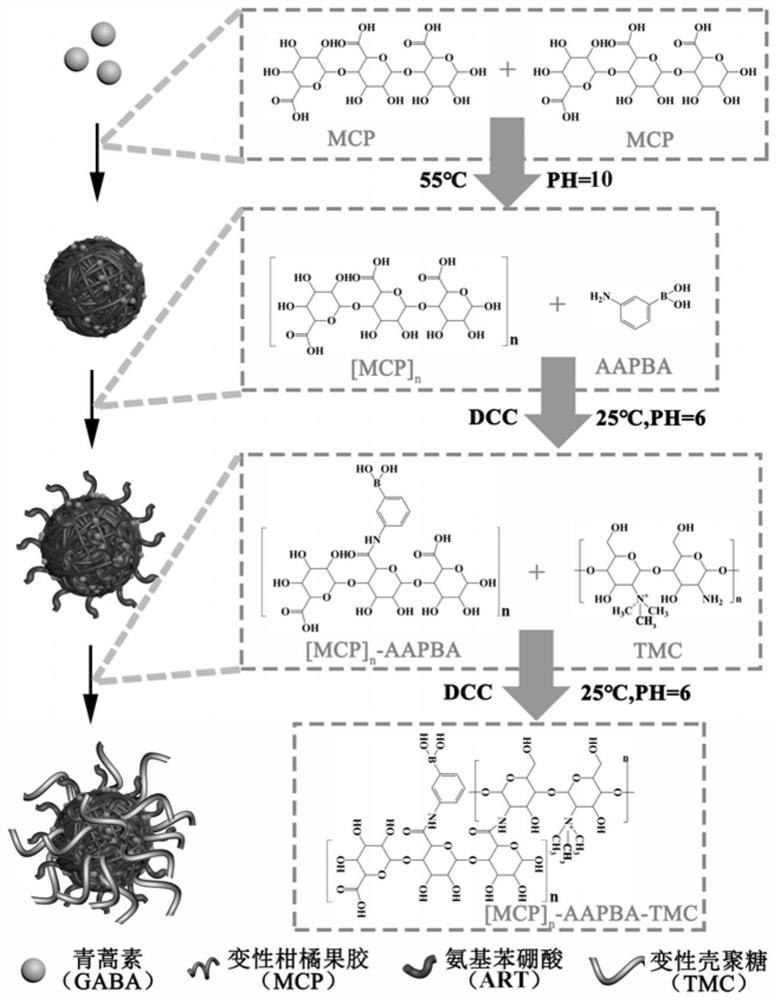

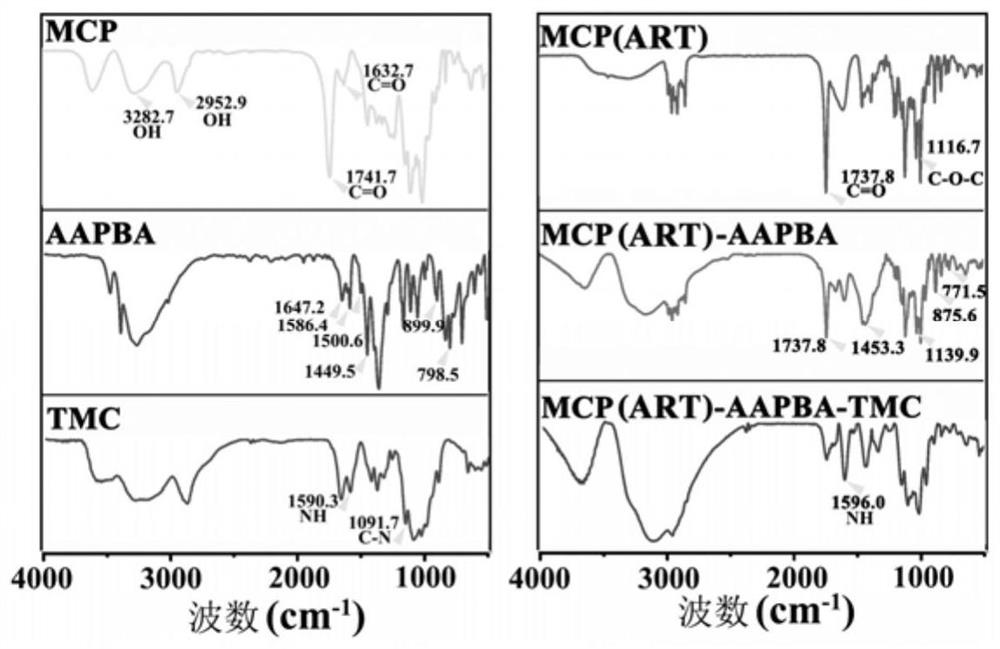

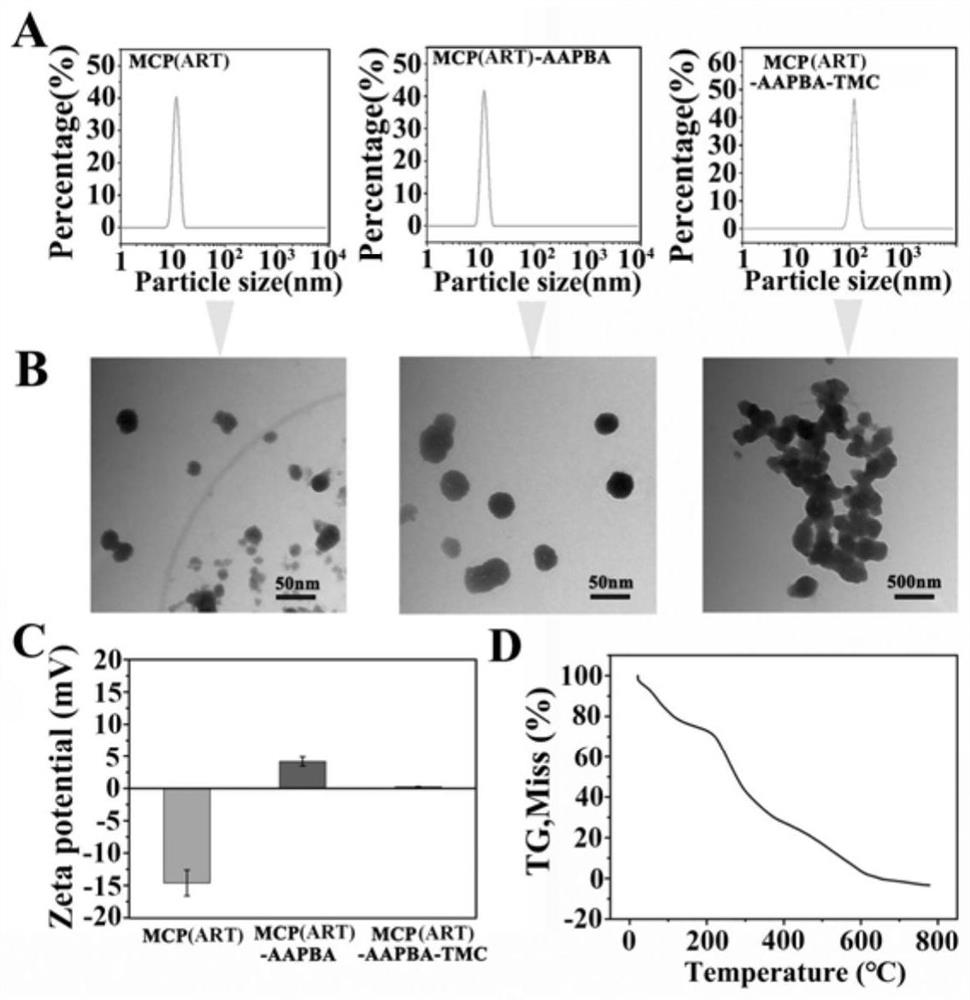

Artemisinin-loaded citrus pectin oral nanoparticle

ActiveCN110200980ANo toxicityLow toxicityMetabolism disorderBoron compound active ingredientsCitrus PectinAminophenylboronic acid

The invention discloses an artemisinin-loaded citrus pectin oral nanoparticle; a preparation method of the oral nanoparticle includes the following steps: the citrus pectin is subjected to multimolecular self-polymerization; nanoparticles are formed from the citrus pectin and wrapped and adsorbed with theartemisinin; aminophenylboronic acid is connected with the citrus pectin nanoparticles; the outer layer is wrapped with denatured chitosan. For the first time, citrus pectin and artemisinin are combined to improve insulin resistance and pancreatic beta cell injury in type II diabetes at the same time; the method of transforming pancreatic alpha cells into pancreatic beta cells is applied to nano-therapy of type II diabetes, can inhibit the secretion of glucagon and also can improve insulinsecretion; no matter drugs nor delivery materials adopt natural products from plants to ensure no toxicity and easy metabolism in the process of treatment of type II diabetes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Antibacterial hygienic packaging material for foods

The invention relates to an antibacterial hygienic packaging material for foods and belongs to the technical field of packaging materials. The antibacterial hygienic packaging material includes a fresh-keeping antibacterial layer as an inner layer, a middle thermal insulation layer and a barrier layer serving as an outer layer. The barrier layer is prepared from high-density polyethylene, allyl thiocyanate, plasticizer and a cross-linking agent. The thermal insulation layer is prepared from filler, polycaprolactone, calcium carbonate and bamboo carbon powder; and the fresh-keeping antibacterial layer is prepared from soybean oil, wheat fiber, konjac sol, silicon oxide powder, dioctyl maleate, an antibacterial agent and a silane coupling agent. The antibacterial hygienic packaging materialis easy to produce, the raw materials are rich, and the cost is low. On the premise of ensuring characteristics of original packaging materials, through microbial decomposition, no pollution is causedto the environment, and the antibacterial hygienic packaging material has a certain antibacterial effect and is high in mechanical property, safe, nonhazardous and high in environmental friendliness.

Owner:扬州市星海塑料制品有限公司

Simple and convenient Zhanma bag

The invention provides a simple and convenient Zhanma bag. The simple and convenient Zhanma bag comprises a bag body. An inner layer of the bag body is covered with a layer of PE film. The bag body is formed by encapsulating a bag body front surface, a bag body back surface, two bag body side surfaces and a bag body bottom surface in a sealed mode. The bag body side surfaces are double-layer folded layers. Pull lines are arranged on the side of the bag body front surface and the side of the bag body back surface and encapsulated through an encapsulating line. The bag body front surface, the bag body back surface, the two bag body side surfaces and the bag body bottom surface of the bag body are integrally arranged. According to the simple and convenient Zhanma bag, the protection performance of the bag body is excellent, the waterproof effect and the moisture-proof effect can be achieved, and a certain heat insulation effect is also achieved at the same time; the odourless effect, the non-toxic effect and the safety and reliability effects are achieved; in addition, pasting can be directly conducted through manual pasting during production by adopting the sealing mode and the folding mode, and the complex situation caused by a machining mode is avoided; and by means of the bag body folding mode, the cost can be further reduced by 40% on the basis of the current cost.

Owner:GUANGDE COLORFUL ZEBRA PACKAGE TECH

Method of preparing cotton-stalk feed

InactiveCN101569347BImprove palatabilityGuaranteed non-toxicFeeding-stuffFood processingNutritive valuesAir separation

The invention discloses a method of preparing cotton-stalk core feed, which comprises the following steps: the cotton-stalk core is taken as a raw material, and air separation, edulcoration, softening, stacking, loading, ammoniation are carried out on the raw material in sequence to obtain the cotton-stalk core feed. The invention has the advantages of simple and convenient preparation method, low cost, needs no large-scale equipment, and is environment-friendly and safe. Moreover, the invention can make full use of existing cotton-stalk raw materials, and the prepared cotton-stalk core feed has the advantages of high nutritive value, fine palatability, high digestibility, no toxicity and pollution and the like.

Owner:姜景文 +2

A Simple and Safe War Horse Bag

The invention provides a simple, convenient and safe war horse bag. The bag comprises a bag body; the inner layer of the bag body is coated with a PE (Polyethylene) film layer; the bag body is formed by hermetically packaging a bag body front surface, a bag body rear surface, a bag body left side surface, a bag body right side surface and a secondary bag body right side surface. According to the bag disclosed by the invention, the bag body is excellent in protection performance, is waterproof and moisture-proof and also has a certain heat insulation effect; the bag is odorless, nontoxic, safe and reliable; by adopting the sealing mode and folding mode, the bag can be directly adhered manually during production; a machining mode is relatively complex, but 40% of the cost can be further saved based on the existing cost by adopting the mode of folding the bag body.

Owner:滁州瑞祥智能科技有限公司

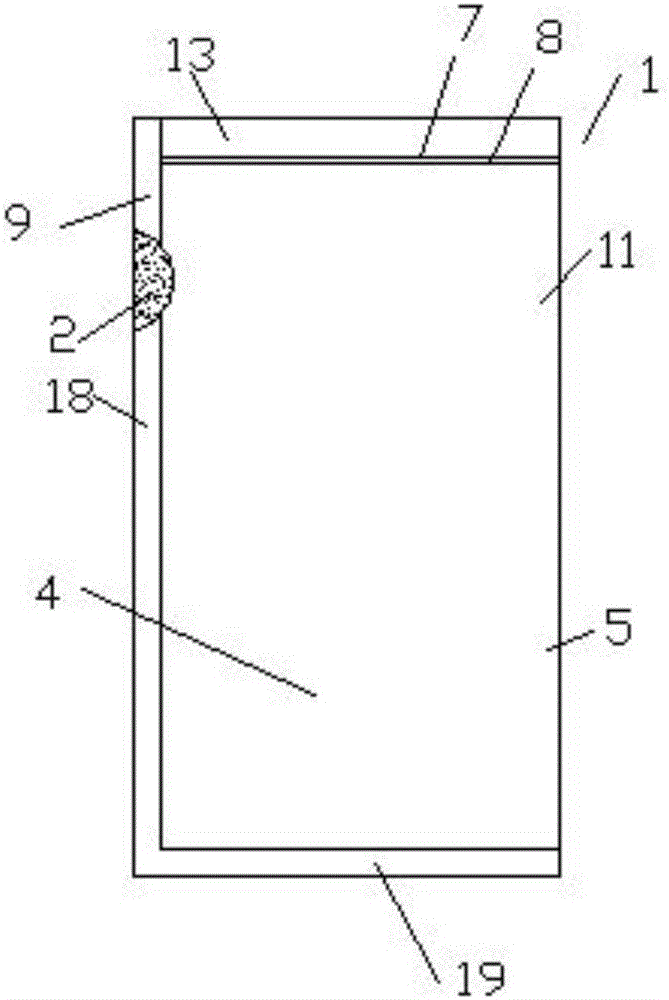

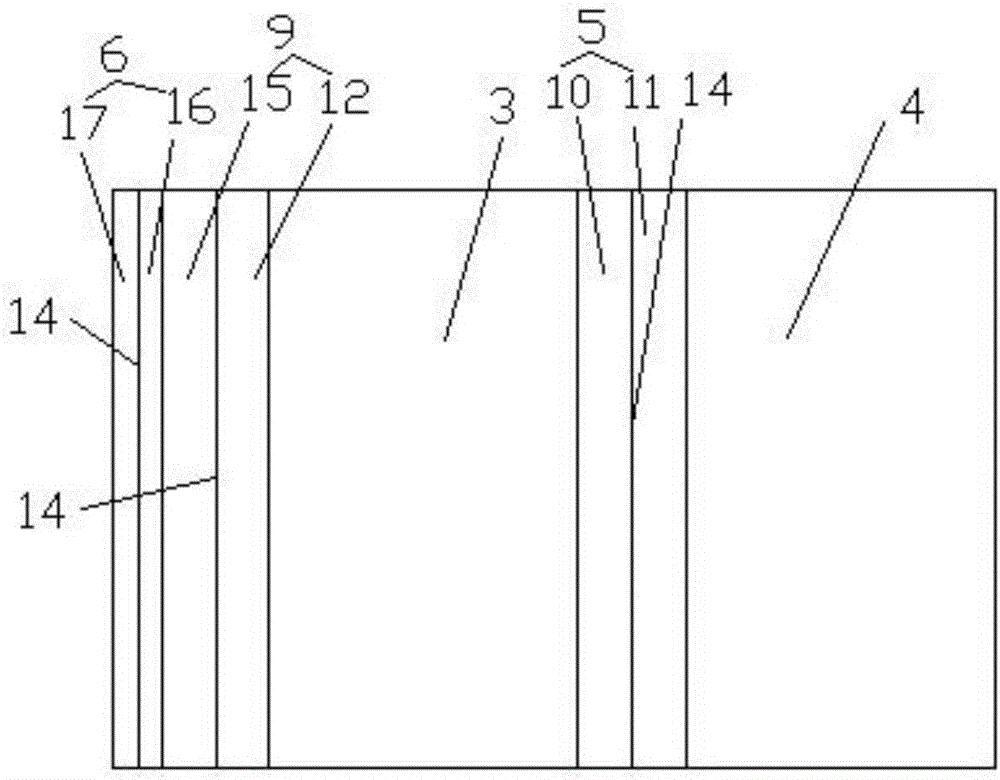

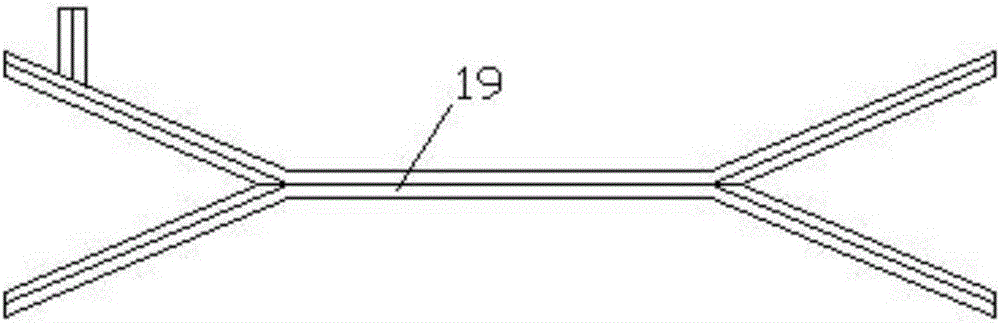

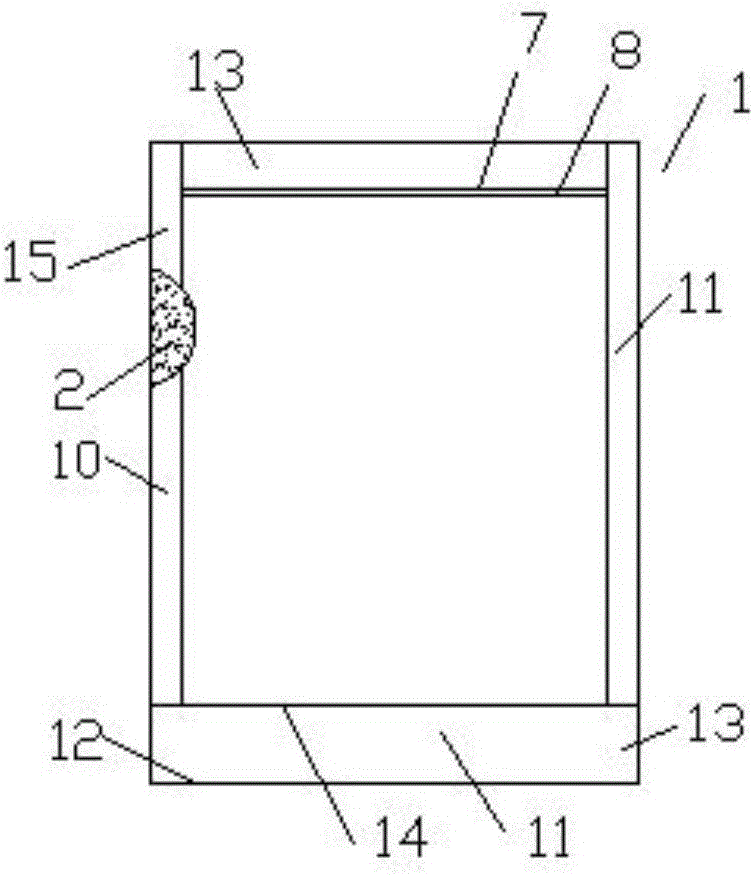

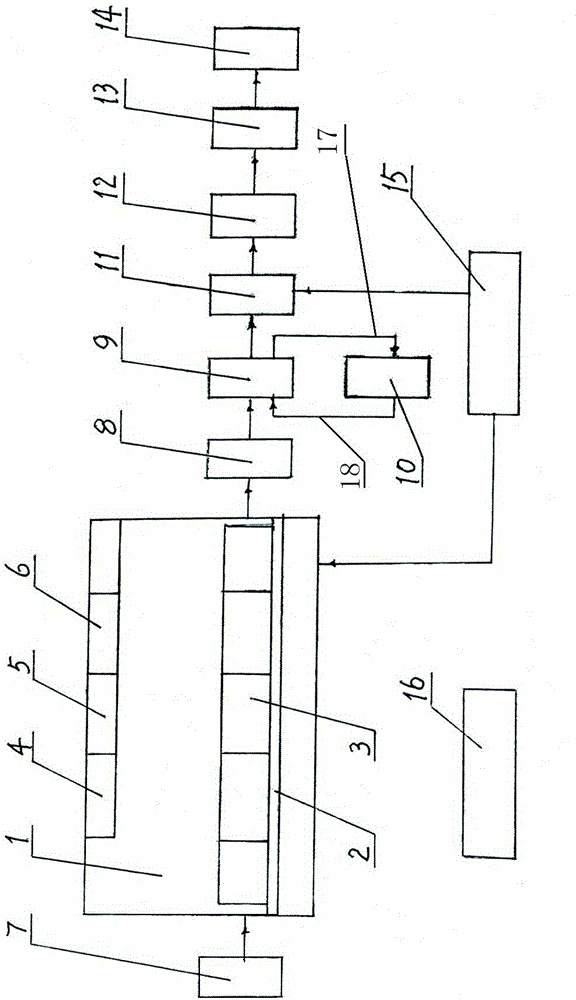

Efficient and rapid process for cultivating organic biological selenium

InactiveCN104397720BMeet the requirement of complete separationGuaranteed non-toxicFood ingredientsAgriculture gas emission reductionInorganic seleniumBiology

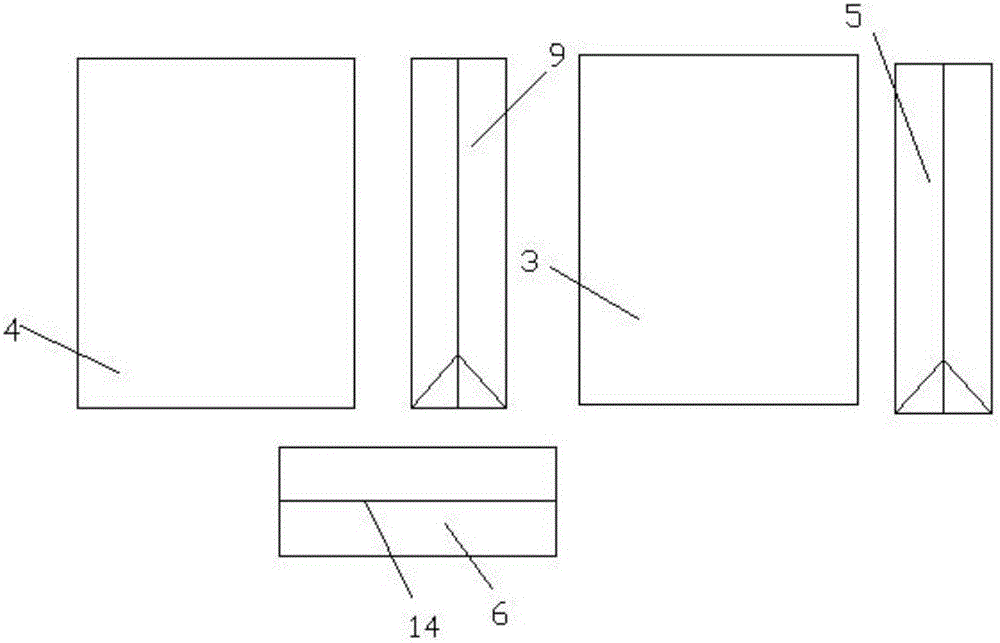

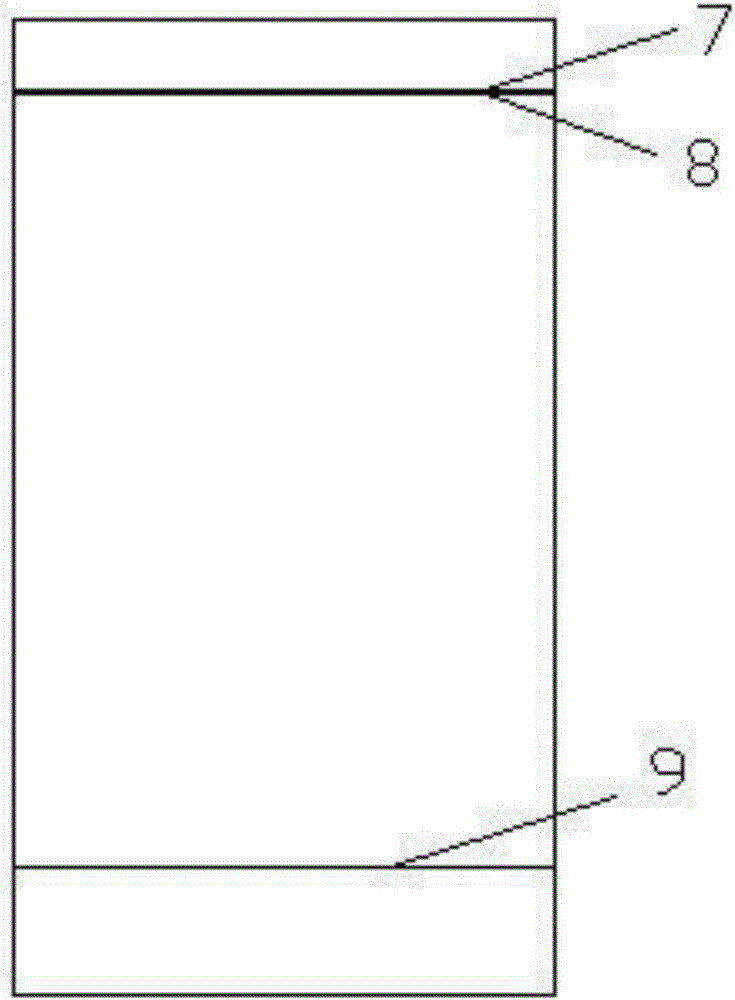

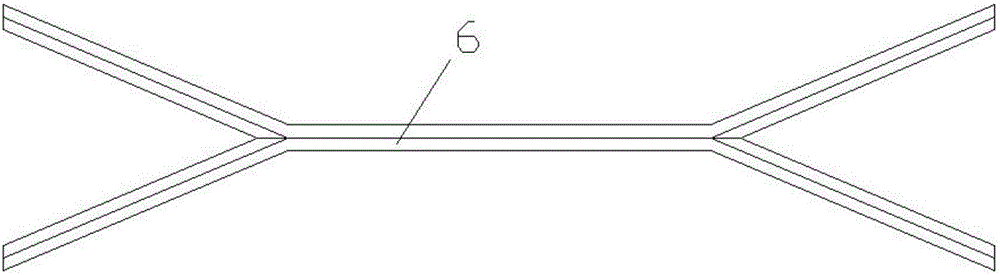

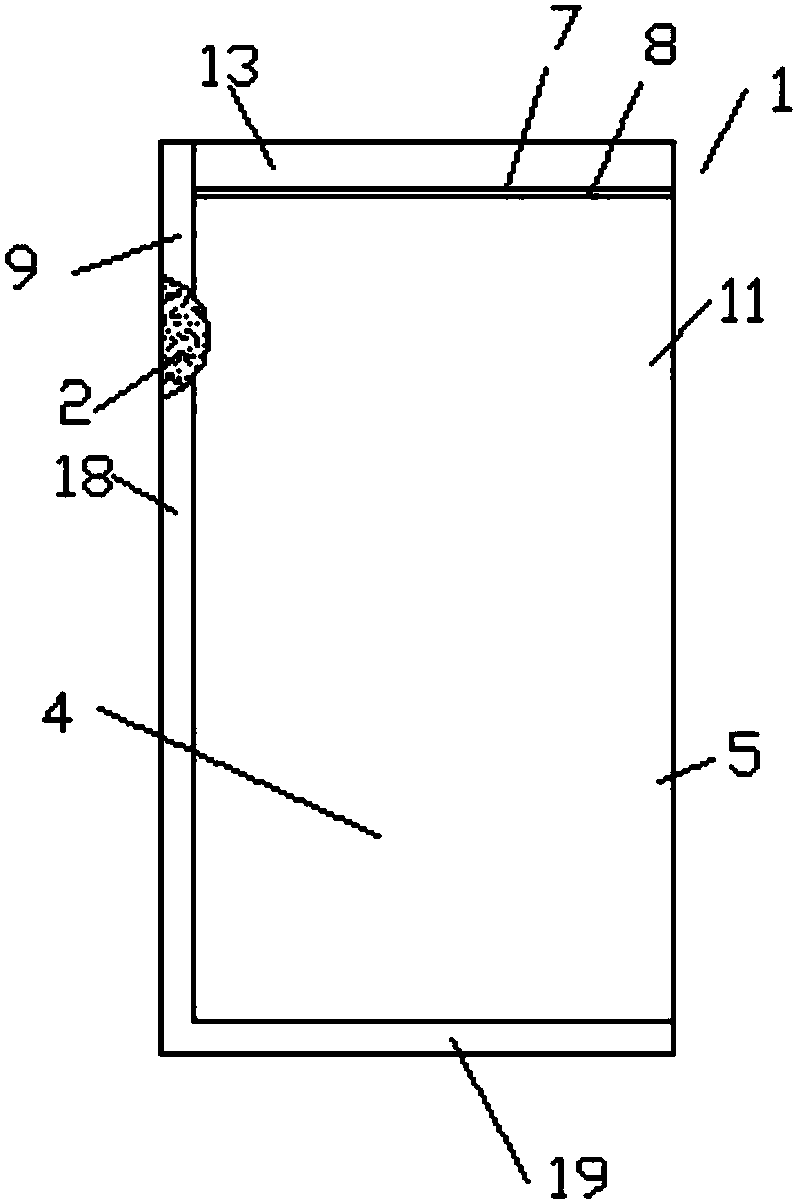

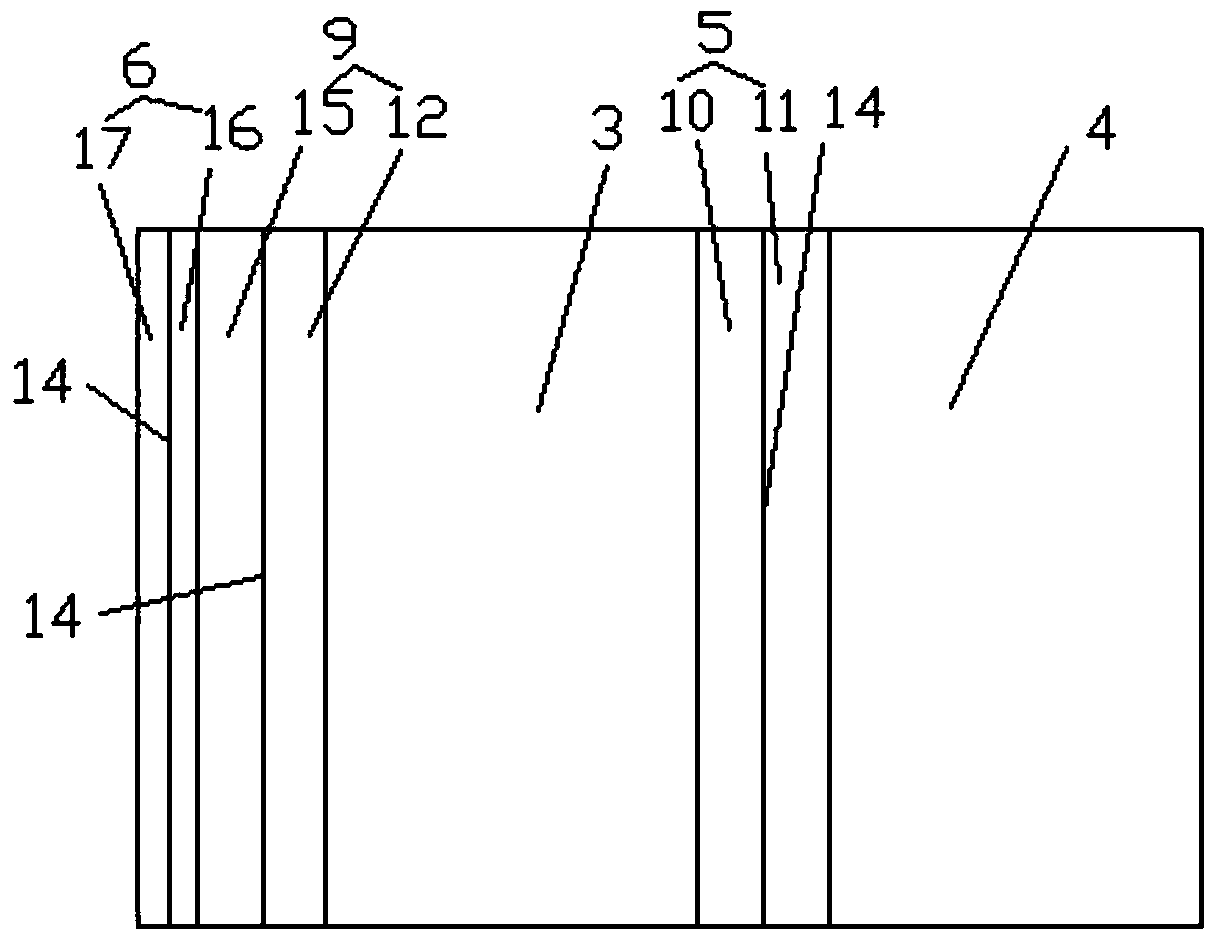

The invention discloses a technological process for efficiently rapidly cultivating organic biological selenium. The technological process comprises: putting plant and a selenium-containing aqueous solution in an incubator (3), enabling the incubator (3) to enter a cultivation box (1) through a feeding apparatus and stay on a slide track (2), acting on the plant by an ultrasonic generator (4), a light wave generator (5) and an atomizer (6), supplying heat to the cultivation box (1) by an air-energy heat source apparatus (15), monitoring and adjusting the temperature, humidity, supersonic wave, light wave and atomization situations in the cultivation box (1) by a system distribution box and instrument apparatuses which are controlled by an intelligent computer, taking 5 days as a production period, taking out plant cultivated maturely from the cultivation box and the incubator, sending to a cleaning apparatus (9) by a discharging apparatus (8), and cleaning the plant to enable the plant to reach the complete separation requirement on organic biological selenium and inorganic selenium, and further guarantee the organic biological selenium product to be free of toxicity and harm, safe and reliable.

Owner:王桂舟

Oral nanoparticles of artemisinin-loaded citrus pectin

ActiveCN110200980BNo toxicityLow toxicityMetabolism disorderBoron compound active ingredientsArtemisininsCitrus Pectin

The invention discloses an oral nanoparticle of citrus pectin loaded with artemisinin, and a preparation method thereof comprises the following steps: performing multi-molecular self-polymerization of the citrus pectin; making the citrus pectin form nanoparticles and wrapping and adsorbing the artemisinin carried out; aminophenylboronic acid was linked to citrus pectin nanoparticles; denatured chitosan was encapsulated in the outer layer. The invention combines citrus pectin and artemisinin for the first time, so that the insulin resistance of type II diabetes and the damage of pancreatic islet beta cells are simultaneously improved; the method of transforming islet alpha cells into pancreatic islet beta cells is applied to the nano-treatment of type II diabetes, This method can inhibit the secretion of glucagon, and can also increase the secretion of insulin; both the drug and the delivery material are natural products derived from plants to ensure non-toxicity and easy metabolism in the treatment of type II diabetes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Injection molding method in power line production system

InactiveCN110696316AImprove low temperature impact resistanceImprove anti-aging propertiesHeatEngineeringProcess engineering

The invention discloses an injection molding method in a power line production system. The injection molding method comprises the following steps of S1, material selecting, wherein a proper quantity of PP is selected as a raw material, and then a proper quantity of antioxygen agent and fire retardant are selected; S2, raw material inspecting, wherein the color, the grain size and the uniformity ofthe PP raw material are inspected, and the quality of the raw material is ensured; S3, drying, wherein the raw material is placed in a stirring drying box from a feeding opening, then a power switchis turned on, drying and stirring can be carried out at the same time, drying is carried out approximately for 10-15 min, and then the raw material is taken out from a discharging opening; S4, barrelcleaning, wherein the temperature of the barrel is increased to the lowest forming temperature of the PP raw material, then the PP raw material is added, continuous air injection is carried out till all residual plastic is cleaned, and the temperature is adjusted to achieve normal production. Compared with other injection molding methods, the technology price is low, space is saved, the process ismature, stress can be resisted, the work efficiency can be effectively improved, the forming effect of power lines can be improved, and safety of users can be guaranteed.

Owner:泰州市荣诚纸制品有限公司

Myrcenyl plasticizer and preparation method thereof

ActiveCN101962446BGuaranteed non-toxicImprove plasticizing effectOrganic compound preparationCarboxylic acid esters preparationRefluxAlcohol

Owner:NANJING TELESUN S & T IND

Food package printing ink and preparation method thereof

The invention discloses a food package printing ink and a preparation method thereof. The food package printing ink is prepared from the following raw materials in parts by weight: an ester solvent, a hydrocarbon solvent, a high-polymer dispersing agent, an anionic surfactant, organic silicon modified polyether, epoxy resin, organic pigment, diethylene glycol, a preservative, an antirust agent, a defoaming agent and deionized water through mixing, grinding and filtering. The food package printing ink is simple in preparation, lower in cost, environment-friendly, nontoxic, stable in performance, antiseptic and antirust, low in atmospheric pollution, free of poisonous solvent residues and beneficial to safety production and environment protection.

Owner:贵州博士化工有限公司

Method for rapid extraction and purification of epigallocatechin gallate from green tea scraps

The invention relates to a method for rapidly extracting, separating and purifying epigallocatechin gallate from leftover of green tea, which comprises the following steps: 1)extracting the leftover of the green tea by ethanol through a conventional method; 2)performing pressure reduction on an extract below the temperature of 80 DEG C and recovering ethanol until no alcohol taste; 3)absorbing an alcohol extract by polyamide resin and separating; 4)collecting epigallocatechin gallate fraction, decolouring by active carbon, performing pressure reduction at low temperature and concentrating; and 5)recrystallizing by ethanol to obtain the high purity epigallocatechin gallate. According to the invention, the method is simple to operate, only one resin is employed to reach one-step completion of adsorption, separation and purification, the used solvent has the advantages of no toxicity, safety and reliability, and the product has the advantages of high purity and low cost, and is suitable for industrial production.

Owner:SUZHOU VOCATIONAL UNIV

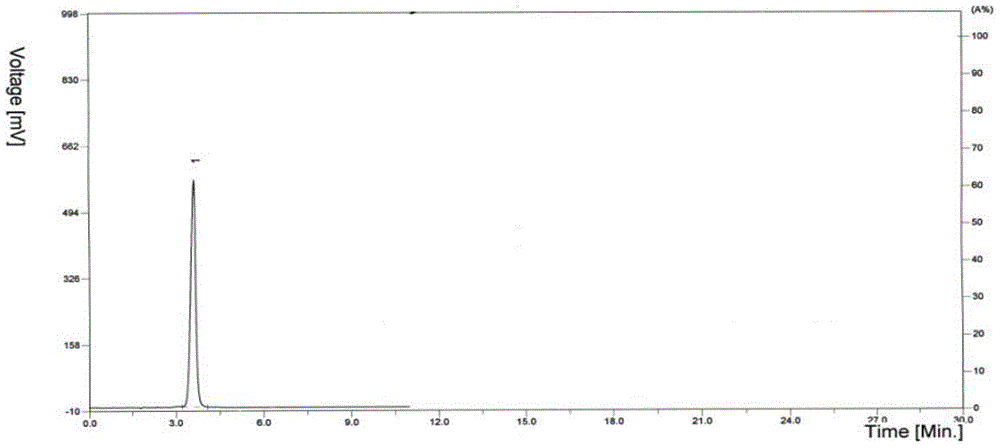

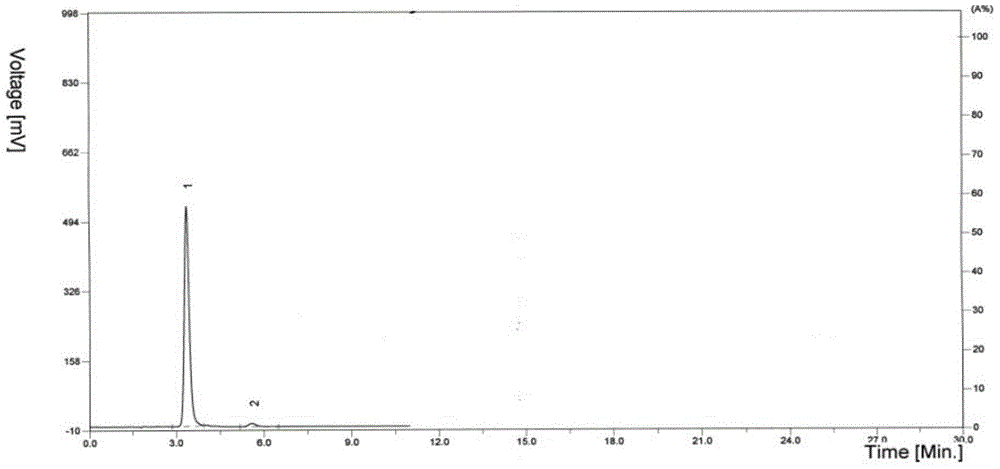

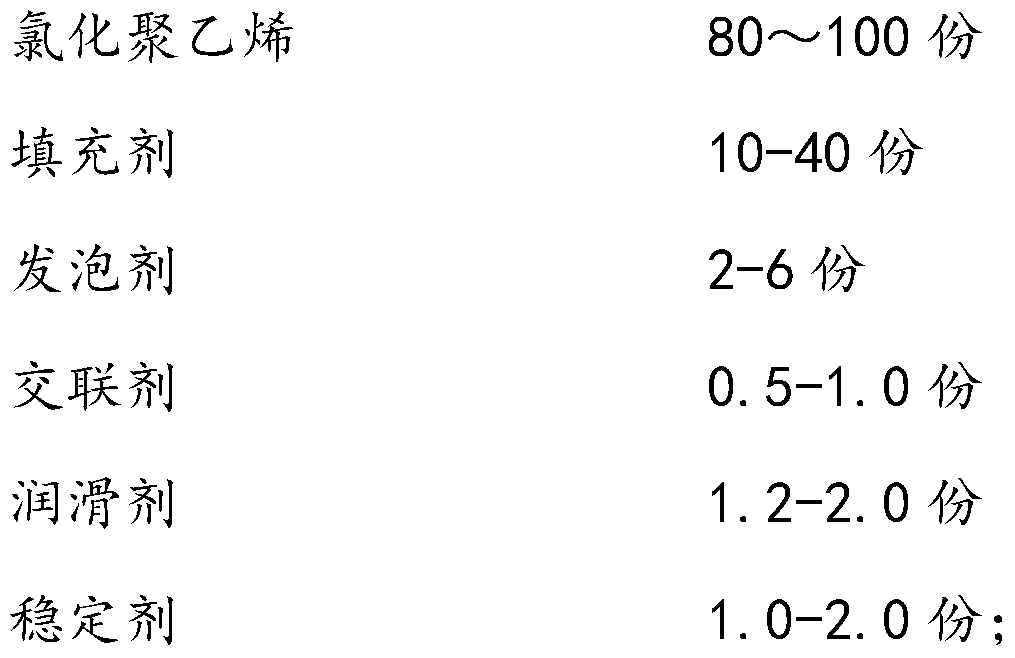

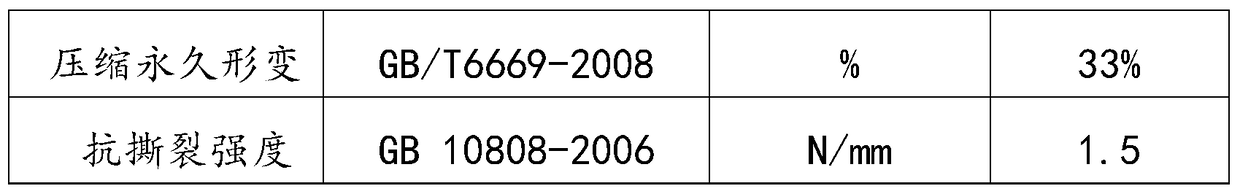

A kind of rubber type chlorinated polyethylene foam material and preparation method thereof

InactiveCN105670144BGuaranteed elastomeric propertiesGuaranteed weather resistancePolymer sciencePolyvinyl chloride

The invention discloses a rubber type chlorinated polyethylene foam material mainly prepared from raw materials in parts by weight as follows: 80-100 parts of chlorinated polyethylene, 10-40 parts of filler, 2-6 parts of a foaming agent, 0.5-1.0 part of a crosslinking agent, 1.2-2.0 parts of a lubricant and 1.0-2.0 parts of a stabilizer; chlorinated polyethylene is rubber type chlorinated polyethylene with the chlorine mass fraction being 36 plus / minus 1%, the Mooney viscosity being 45-75 (ML125 DEG C1+4) and the Shore hardness being 50-60 HA. Compared with the prior art, the rubber type chlorinated polyethylene can be applied to the foam field, direct foam processing of chlorinated polyethylene can be realized without addition of a plasticizer, the environment-friendly and non-toxic characteristics of the rubber type chlorinated polyethylene foam material are guaranteed, and the rubber type chlorinated polyethylene foam material has good mechanical properties, good softness, small permanent deformation, excellent weather resistance, chemical resistance and damping performance and can be used for replacing traditional PVC (polyvinyl chloride) foam materials to be applied to the damping field.

Owner:泉州三盛橡塑发泡鞋材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com