Method for rapid extraction and purification of epigallocatechin gallate from green tea scraps

A technology of epigallocatechin and gallate, which is applied in the field of pharmaceutical applications, can solve the problems of complex steps, high solvent toxicity, and low product yield, and achieve the effect of product safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

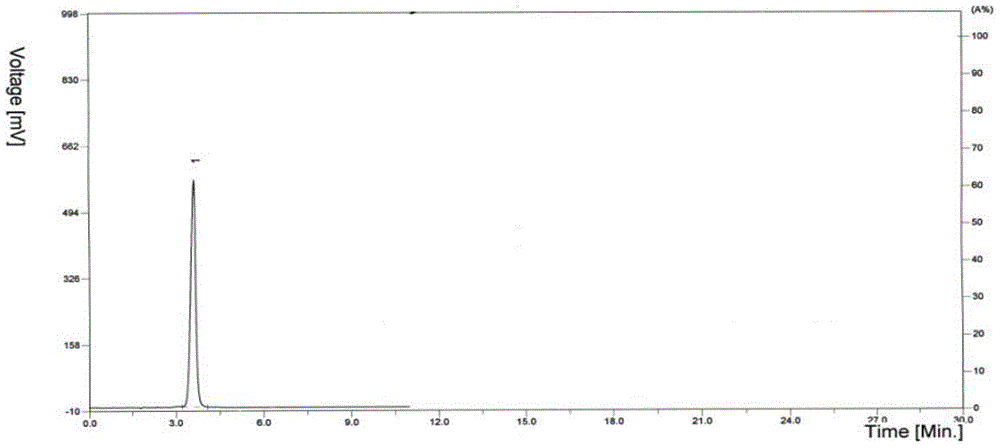

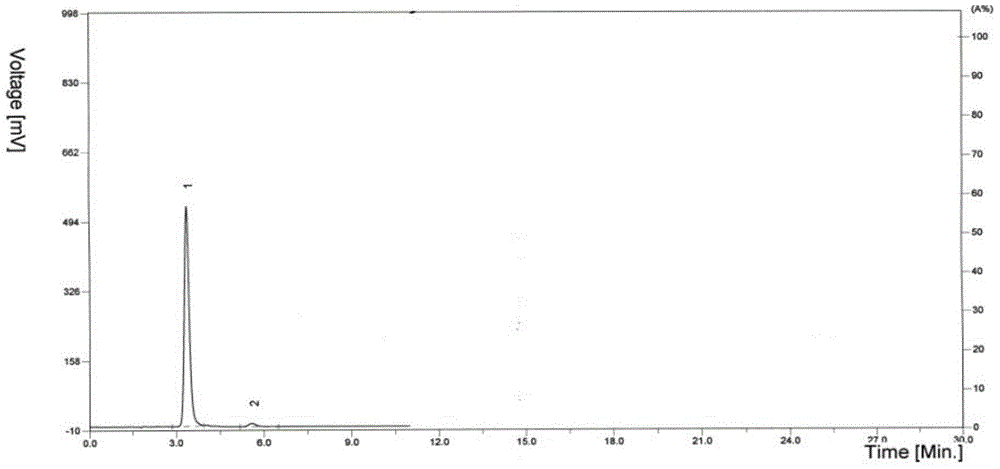

Image

Examples

Embodiment 1

[0033] Green tea waste 1 kg, add 8L of 60% ethanol to extract by ultrasonic vibration, extract twice, each time for 30 minutes, and combine the extracts; extract the extracts below 80°C to recover ethanol under reduced pressure until there is no alcohol smell, and concentrate to a relative density of 1.20 to 1.22 Clear the cream; cool it, and adsorb it on a polyamide resin column (the amount of resin used is 10 times the weight of the cream, and the diameter-to-height ratio of the column is 1:20), elute with 95% ethanol: 36% acetic acid (volume ratio is 5:1) , thin-layer chromatography tracking detection, collecting epigallocatechin gallate (EGCG) fractions, decolorized with 2% (g / 100ml) activated carbon, filtered, and the filtrate was reduced at low temperature under the protection of nitrogen at 60°C-80°C. Concentrate under pressure to a relative density of 1.15-1.18, freeze-dry. Recrystallized with ethanol to obtain epigallocatechin gallate (EGCG) with a purity of 98.3% and...

Embodiment 2

[0035] Add 1 kg of green tea leftovers, add 12L of 60% ethanol to extract by ultrasonic vibration, extract twice, each time for 30min, and combine the extracts. The extract is recovered under reduced pressure below 80°C until there is no alcohol smell, and concentrated to a clear paste with a relative density of 1.20 to 1.22. Cool, adsorb on a polyamide resin column (the amount of resin used is 15 times the paste weight, and the diameter-to-height ratio of the column is 1:20), elute with 95% ethanol: 36% acetic acid (volume ratio: 2:1), thin layer Chromatography tracking detection, collecting epigallocatechin gallate (EGCG) fractions, adsorbing with 2.5% (g / 100ml) activated carbon, filtering, and concentrating the filtrate under reduced pressure at 60°C-80°C under nitrogen protection at low temperature to The relative density is 1.15-1.18, freeze-dried. Recrystallized with ethanol to obtain epigallocatechin gallate (EGCG) with a purity of 98.6% and a yield of 12%.

Embodiment 3

[0037] Add 1 kg of green tea waste, add 16L of 60% ethanol to extract by ultrasonic vibration, extract twice, each time for 30 minutes, and combine the extracts. The extract is recovered under reduced pressure below 80°C until there is no alcohol smell, and concentrated to a clear paste with a relative density of 1.20 to 1.22. Cool, adsorb on a polyamide resin column (the amount of resin used is 20 times the paste weight, and the ratio of diameter to height of the column is 1:20), elute with 95% ethanol: 36% acetic acid (volume ratio is 1:1), thin layer Chromatography tracking detection, collecting epigallocatechin gallate (EGCG) fractions, adsorbing with 3% (g / 100ml) activated carbon, filtering, and concentrating the filtrate under reduced pressure at 60°C-80°C under nitrogen protection at low temperature to The relative density is 1.15-1.18, freeze-dried. Recrystallized with ethanol to obtain epigallocatechin gallate (EGCG) with a purity of 98.9% and a yield of 16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com