Composite floor slab of earthquake proof construction

A technology of aluminum composite panels and floor slabs, which is applied to floors, buildings, building components, etc., can solve problems such as delaying the best time to save people's lives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

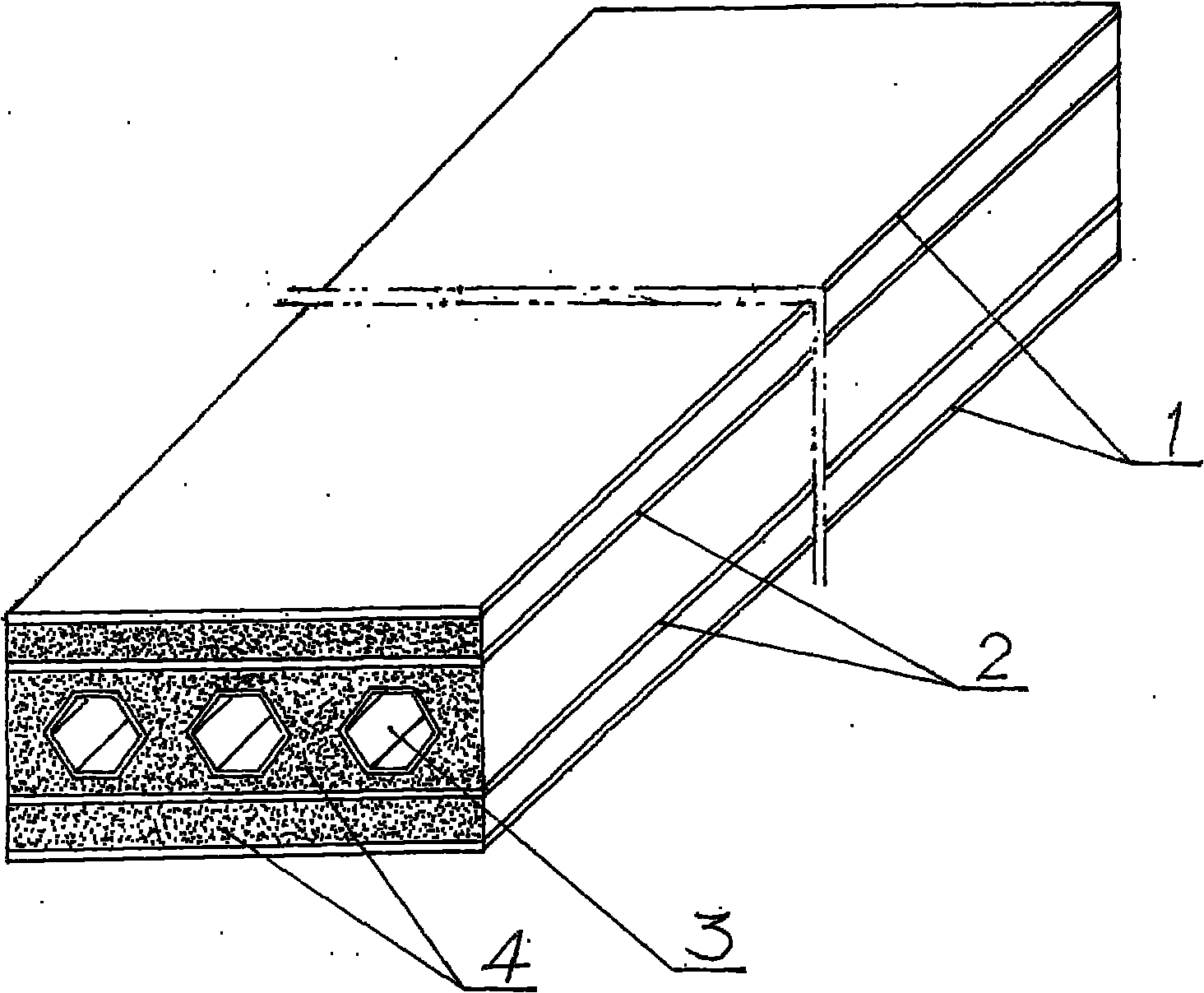

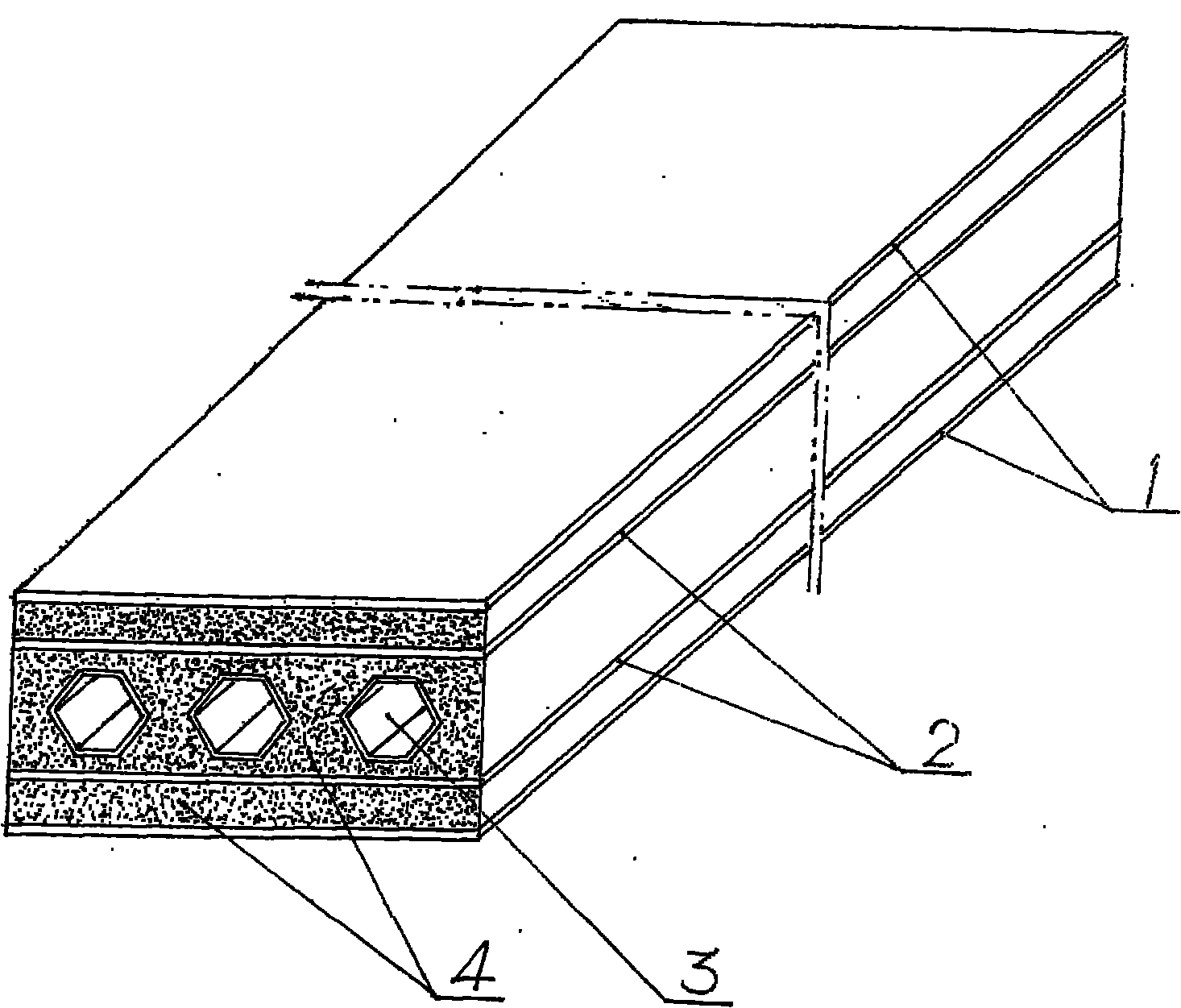

[0007] Below in conjunction with accompanying drawing, the implementation process of the composite floor slab of earthquake-resistant building of the present invention is described further:

[0008] Firstly, according to the length of the floor slab (refer to the specifications of the current reinforced concrete prefabricated slab), use a chainsaw to cut off a number of metal pipes (or shape them during casting and stretching), and cut panels and splints of the same specification with a shearing machine according to the length and width of the floor slab. (or form according to this specification during mass production); according to a certain ratio, put polyurethane, diatomaceous earth, and binder into the mixer and stir evenly to make a soft filler; then put a panel horizontally on a mold In the frame, pour the stuffing that has been stirred on top to a certain thickness, then put a splint on it, press it with rollers to flatten it, then put a layer of stuffing on it and put s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com