Three-dimensional pulp moulding decorating plate as well as manufacturing method and application thereof

A three-dimensional, pulp molding technology, applied in decorative arts, patterns imitating three-dimensional effects, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

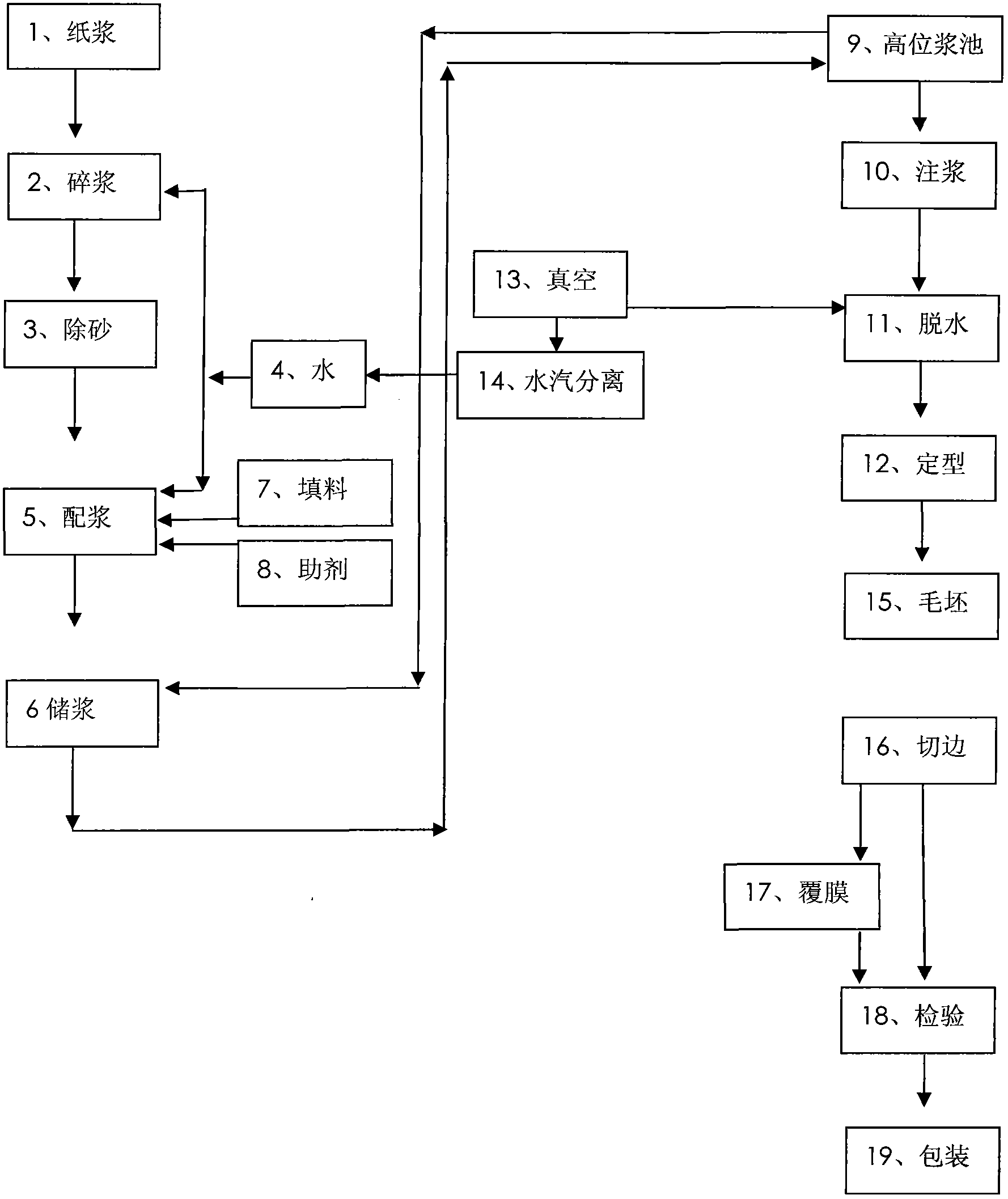

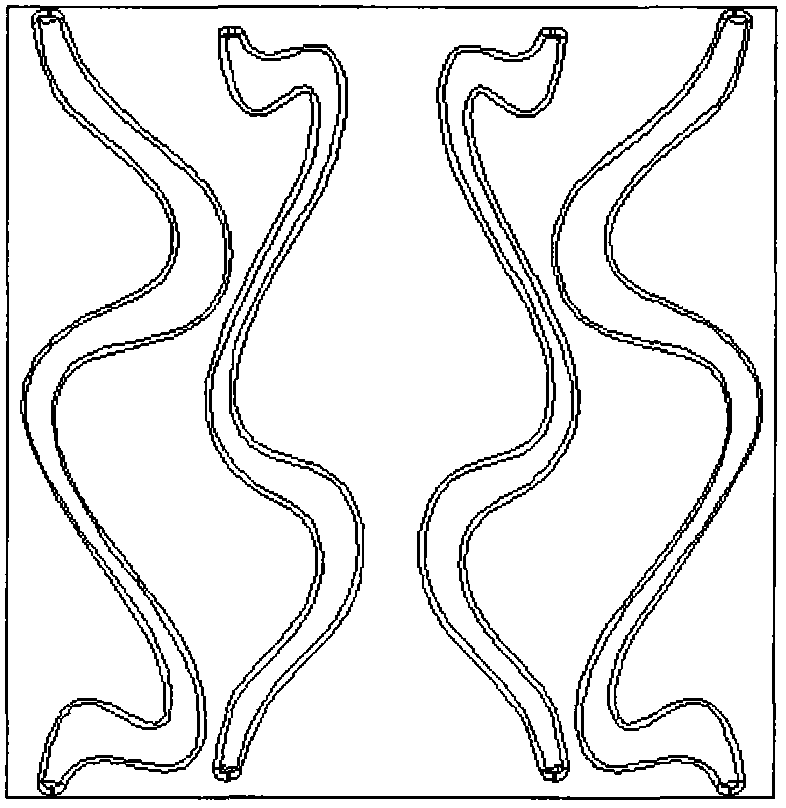

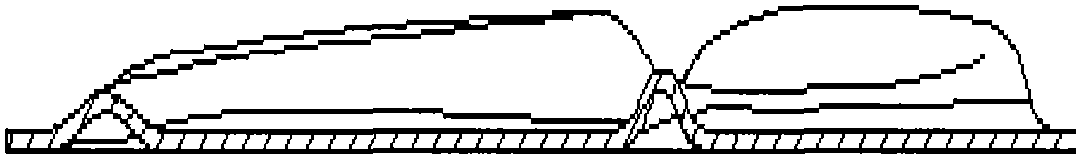

[0074] Such as Figure 1-4 As shown, the manufacturing method of the three-dimensional pulp molded decorative board is realized through the following technical scheme, and the method has the following steps:

[0075] 1. Use general-purpose pulp molding units or equipment: this equipment includes equipment produced by the pulping method or the grouting method;

[0076] 2. Use molds: use copper materials, stainless steel materials or aluminum alloy materials, and make molds for pulp molding equipment according to product design requirements. The inner cavity of the mold is a three-dimensional structure;

[0077] 3. select the paper pulp raw material pulp plate 1 of 40% by weight of papermaking softwood pulp, 20% by weight of bamboo pulp, and 40% by weight of bagasse pulp for removing sand grains and soil, and add the pulp raw material pulp plate 1 into the pulper 2, Add water with a pH value of 7 or tap water or deionized water 4, the water slurry ratio is 10:1, and pulverize t...

Embodiment 2

[0090] The manufacturing method of three-dimensional three-dimensional pulp molded decorative board is realized through the following technical scheme, and the method has the following steps:

[0091] 1. Use general-purpose pulp molding equipment: this equipment includes equipment produced by the pulping method or the grouting method;

[0092] 2. Use molds: use copper materials, stainless steel materials or aluminum alloy materials, and make molds for pulp molding equipment according to product design requirements. The cavity structure of the mold is a three-dimensional structure;

[0093] 3. Select the paper pulp raw material 1 with 50% by weight of softwood pulp, 30% by weight of bamboo pulp, and 20% by weight of leftover material from which sand and soil have been removed, and add the pulp raw material to the pulper 2, and add the pH 7 water or tap water, deionized water 4, the water slurry ratio is 8:1, pulverize the pulp, and make the pulp fiber length between 1-4 mm, wit...

Embodiment 3

[0103] The manufacturing method of three-dimensional three-dimensional pulp molded decorative board is realized through the following technical scheme, and the method has the following steps:

[0104] 1. Use general-purpose pulp molding equipment: this equipment includes equipment produced by the pulping method or the grouting method;

[0105] 2. Use molds: use copper materials, stainless steel materials or aluminum alloy materials, and make molds for pulp molding equipment according to product design requirements. The cavity structure of the mold is a three-dimensional structure;

[0106] 3. Select the paper pulp raw material 1 with 50% by weight of softwood pulp, 20% by weight of bamboo pulp, and 30% by weight of bagasse pulp from which sand grains and soil have been removed, and add the pulp raw material to the pulper 2 with a pH value of 7 Water or tap water, deionized water 4, the ratio of water slurry is 8: 1, pulverize the pulp, and make the pulp fiber length between 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com