A kind of rubber type chlorinated polyethylene foam material and preparation method thereof

A technology of chlorinated polyethylene and foaming materials, applied in the field of polymer materials, can solve problems such as non-conformity with industrial environmental protection production, environmental pollution, etc., and achieve the effects of excellent weather resistance, good flexibility, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

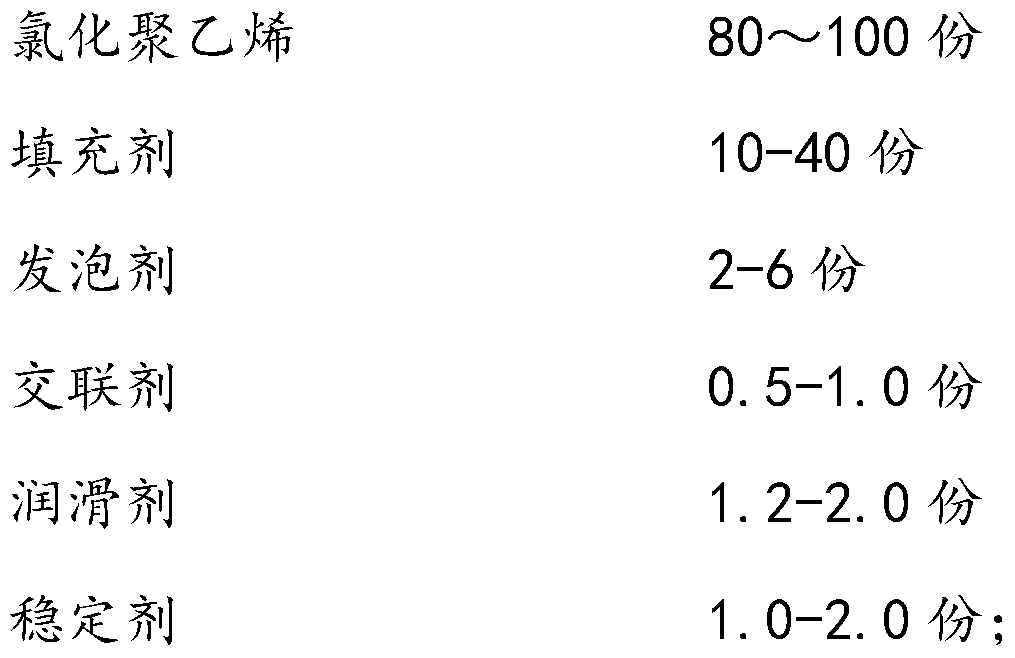

[0022] A rubber-type chlorinated polyethylene foam material in the first embodiment is mainly prepared from the following raw materials in parts by weight: 100 parts of chlorinated polyethylene, 40 parts of filler, 3 parts of foaming agent, and 1.0 parts of crosslinking agent. Parts, 2.0 parts of lubricant, 2.0 parts of stabilizer.

[0023] Among them, chlorinated polyethylene is a rubber-type chlorinated polyethylene with a chlorine content of 36%, a Mooney viscosity of 45 (ML125°C 1+4), and a Shore hardness of 50HA. The filler is talcum powder, and the lubricant is polystyrene. Ethylene wax, foaming agent is azodicarbonamide, crosslinking agent is bis-tert-butyl peroxide cumene, stabilizer is zinc stearate.

[0024] In this embodiment, the filler can also be calcium carbonate or silicon dioxide, or a mixture of two or more of calcium carbonate, silicon dioxide or talcum powder; the lubricant can also be unsaturated fatty acid zinc salt or unsaturated A mixture of fatty acid...

Embodiment 2

[0034] A rubber-type chlorinated polyethylene foam material of the second embodiment is mainly prepared from the following raw materials in parts by weight: 80 parts of chlorinated polyethylene, 10 parts of filler, 6 parts of foaming agent, and 0.5 parts of crosslinking agent parts, 1.5 parts of lubricants, and 1.0 parts of stabilizers.

[0035] Among them, chlorinated polyethylene is a rubber-type chlorinated polyethylene rubber with a chlorine content of 36%, a Mooney viscosity of 75 (ML125°C 1+4), and a Shore hardness of 60HA; the filler is silicon dioxide, and the lubricant It is unsaturated fatty acid zinc, the foaming agent is 4,4-oxobisbenzenesulfonyl hydrazide, the crosslinking agent is dicumyl peroxide, and the stabilizer is calcium stearate.

[0036] In this embodiment, the filler can also be calcium carbonate or talcum powder, or a mixture of two or more of calcium carbonate, silicon dioxide or talcum powder; the lubricant can also be polyethylene wax or unsaturated...

Embodiment 3

[0047] A kind of rubber-type chlorinated polyethylene foam material of the present embodiment 3 is mainly prepared from the following raw materials in parts by weight: 90 parts of chlorinated polyethylene, 25 parts of filler, 4 parts of foaming agent, and 0.8 parts of crosslinking agent parts, 1.5 parts of lubricant, 1.5 parts of stabilizer.

[0048] Among them, chlorinated polyethylene is a rubber-type chlorinated polyethylene rubber with a chlorine content of 36%, a Mooney viscosity of 60 (ML125°C 1+4), and a Shore hardness of 55HA; the filler is calcium carbonate, and the lubricant is Unsaturated fatty acid zinc, foaming agent is 4,4-oxobisbenzenesulfonyl hydrazide, crosslinking agent is dicumyl peroxide, stabilizer is calcium stearate.

[0049] In this embodiment, the filler can also be silicon dioxide or talcum powder, or a mixture of two or more of calcium carbonate, silicon dioxide or talcum powder; the lubricant can also be polyethylene wax or unsaturated fatty acid zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com