HAA-cured high-leveling and anti-thick-coating pinhole polyester resin, preparation method and application thereof

A polyester resin and leveling technology, used in polyester coatings, coatings, powder coatings, etc., can solve the problems of low carboxyl activity, poor film hardness and water resistance, inability to achieve high leveling, etc., and achieve anti-thick coating needles. Strong hole ability and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

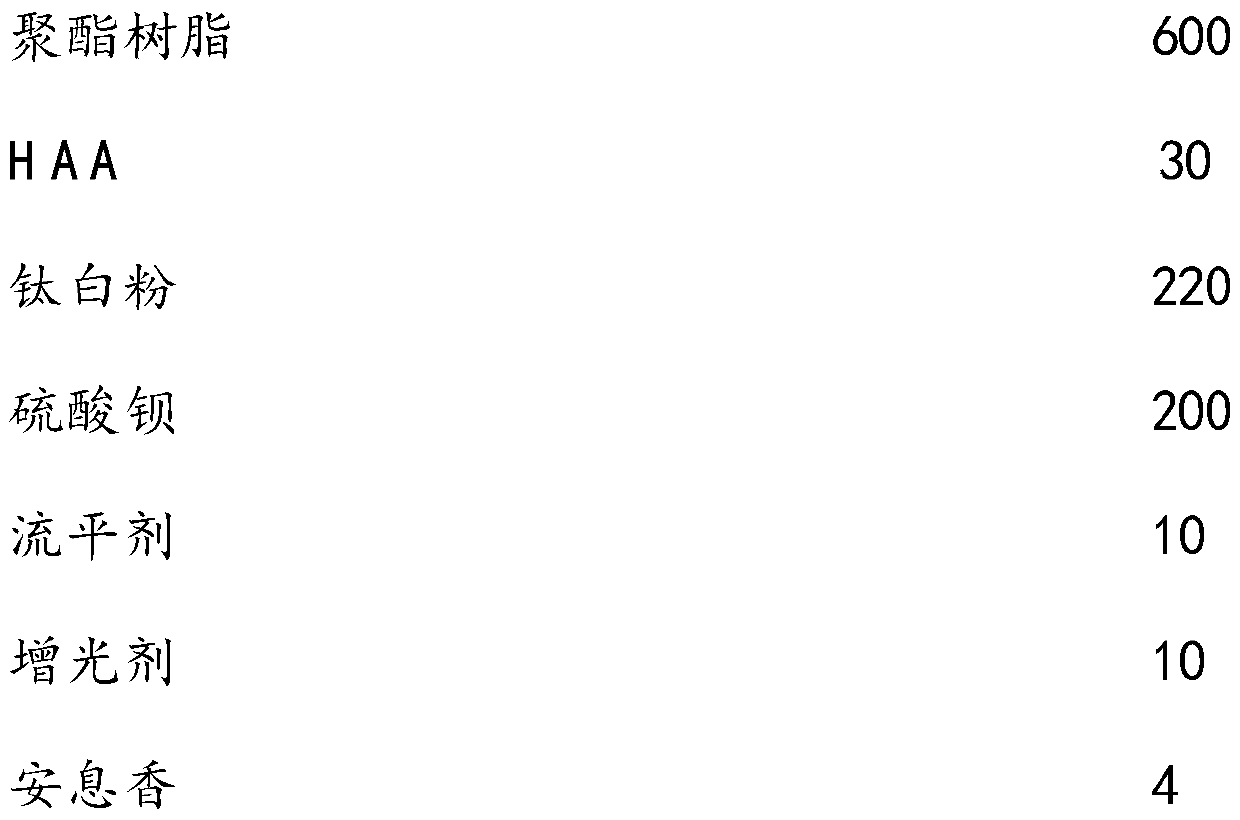

Examples

Embodiment 1

[0049] (1) Add the catalyst monobutyl tin oxide, 18 mol of neopentyl glycol, and 15 mol of pentaerythritol dioleate into the reaction kettle, and fully melt them below 140°C;

[0050] (2) Add 24mol terephthalic acid to the reaction kettle, gradually increase the temperature to 190℃ under the protection of nitrogen, control the heating rate at 5~8℃ / h, and keep the temperature for about 4h, until the acid value is reduced to 50mgKOH / g Add 12 mol lauric acid, 10 mol polypropylene glycol 400 and 3 mol 1,2-octanediol, and then increase the temperature to 240°C at a rate of 8-10°C / h and keep the temperature for the reaction until no obvious distillate is evaporated. At this time, the acid value of the reactant is less than 30mgKOH / g;

[0051] (3) Add antioxidant 1010 to the reactor, maintain a vacuum of 50-70mmHg, and react under reduced pressure at a temperature of 235-240°C for about 2 hours to promote the formation of polyester resin. When the acid value is reduced to below 15mgKOH / g,...

Embodiment 2

[0057] The difference from the embodiment is that the molar amount of each main raw material is different, and the details are as follows:

[0058] Terephthalic acid 18, tridecanedioic acid 10, neopentyl glycol 12, pentaerythritol dioleate 14, polypropylene glycol 4009, 1,2-octanediol 2, hexamethylene diisocyanate 8.

[0059] The prepared polyester resin has an isocyanate group content of 2.11% and a softening point of 94°C.

Embodiment 3

[0061] The difference from the embodiment is that the amount of each main raw material is different, as follows:

[0062] Terephthalic acid 30, tetradecanedioic acid 14, neopentyl glycol 20, pentaerythritol dioleate 18, polypropylene glycol 40012, 1,2-octanediol 4, and hexamethylene diisocyanate 12.

[0063] The prepared polyester resin has an isocyanate group content of 2.68% and a softening point of 87°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com