Coating liquid for forming ultraviolet absorbing coatings and ultraviolet absorbing glass

A technology that absorbs coatings and ultraviolet rays. It is applied in the direction of radiation-absorbing coatings, coatings, and synthetic resin layered products. Ensure consistent color and ensure weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

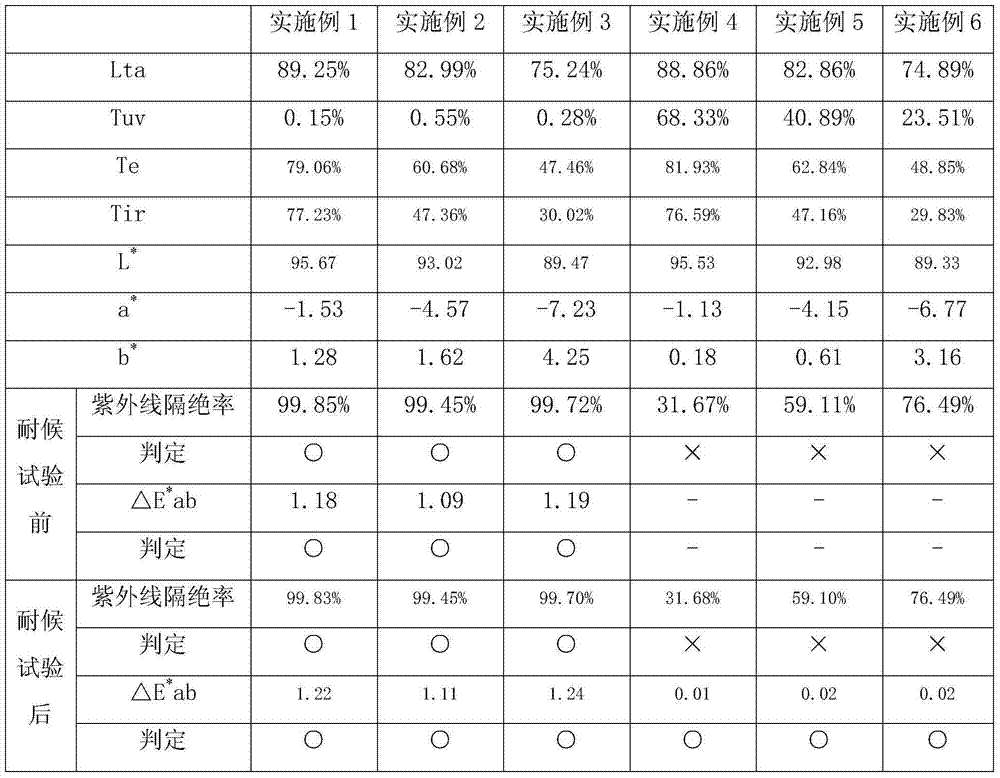

Embodiment 1

[0093] With 10g ethyl orthosilicate and 0.1g sodium tungstate (Na 2 WO 4 ) as a raw material, with ethanol, Virahol and deionized water as a solvent, stirring and ultrasonically dispersing the raw material and solvent; the raw material and solvent after stirring and ultrasonic dispersion are hydrolyzed and co-condensed to obtain a partially hydrolyzed condensate Silica sol B in the form of sol B; 2,4-dihydroxy-2',4'-dimethoxybenzophenone UV absorber 1.2g and 0.02g of KH560 (Nanjing Dawn), after stirring until the ultraviolet absorber is dissolved, continue to stir for 2 hours to obtain the coating solution C for forming the ultraviolet absorbing coating;

[0094] A thickness of 3.2mm is prepared, the color is L*=95.67, a*=-1.53, b*=1.28, and the size is 150mm×150mm float white glass (FUYAO 3.2C) as the glass substrate, the ultraviolet radiation of the glass substrate The rate is 31.67%. 2.3 g of coating solution C was evenly coated on the surface of the glass substrate, and...

Embodiment 2

[0106] Prepare a thickness of 3.2mm, color L * =93.02, a * =-4.57,b * =1.62, the float green glass (FUYAO 3.2G) with a size of 150mm×150mm is used as the glass substrate, and the ultraviolet blocking rate of the glass substrate is 59.11%. Other parameters are exactly the same as in Example 1, and a UV-absorbing glass with a UV-absorbing coating is obtained. The ultraviolet absorbing glass in Example 2 was evaluated according to the performance evaluation method in Example 1, and the evaluation results are shown in Table 1.

Embodiment 3

[0108] Prepare a thickness of 3.2mm, color L * =89.47, a * =-7.23,b * =4.25, and the float green glass (FUYAO solar 3.2SG) with a size of 150mm×150mm was used as the glass substrate, and the ultraviolet blocking rate of the glass substrate was 76.49%. Other parameters are exactly the same as in Example 1, and a UV-absorbing glass with a UV-absorbing coating is obtained. The ultraviolet absorbing glass in Example 3 was evaluated according to the performance evaluation method in Example 1, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com