EVA large hole composite foam material and preparation method

A composite foaming and coarse-pored technology, applied in applications, shoe soles, clothing, etc., can solve problems such as poor elasticity, uncomfortable wearing, and excellent texture, improve compression resistance and resilience, and improve compressive strength and tensile strength. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, the embodiment of the present invention also provides a preparation method of the EVA coarse-cell composite foam material, comprising the following steps:

[0045] Step 1: Take quantitative isotactic polybutene-1 and melt it, and add mass content of 0.05%-0.2% graphene when the melting temperature of isotactic polybutene-1 is 140-170°C, so that both Graphene-modified isotactic polybutene is obtained after mixing; the mixing time is 25-40 minutes, and the temperature is 150-180°C;

[0046] Step 2: taking each component in the material by weight fraction;

[0047] Step 3: Mix the other components weighed in step 2 except the crosslinking agent and foaming agent; the mixing time is 8-15 minutes, and the temperature is 100-110°C.

[0048] Step 4: Mix the material mixed in step 3 with the weighed crosslinking agent and foaming agent in step 2; the mixing time is 3-5 minutes, and the temperature is 110-120°C.

[0049] Step 5: The mixture obtained after knea...

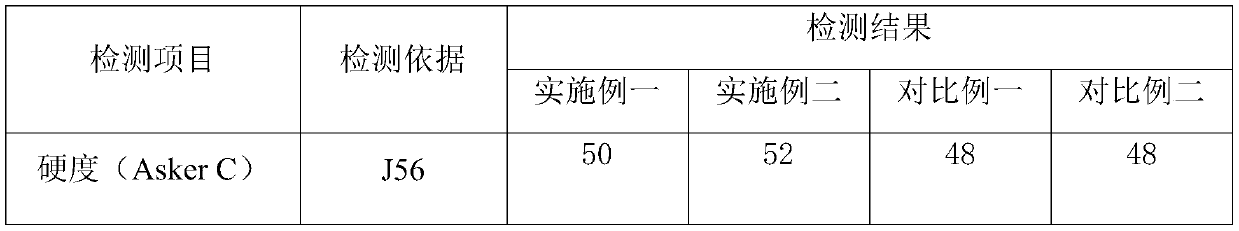

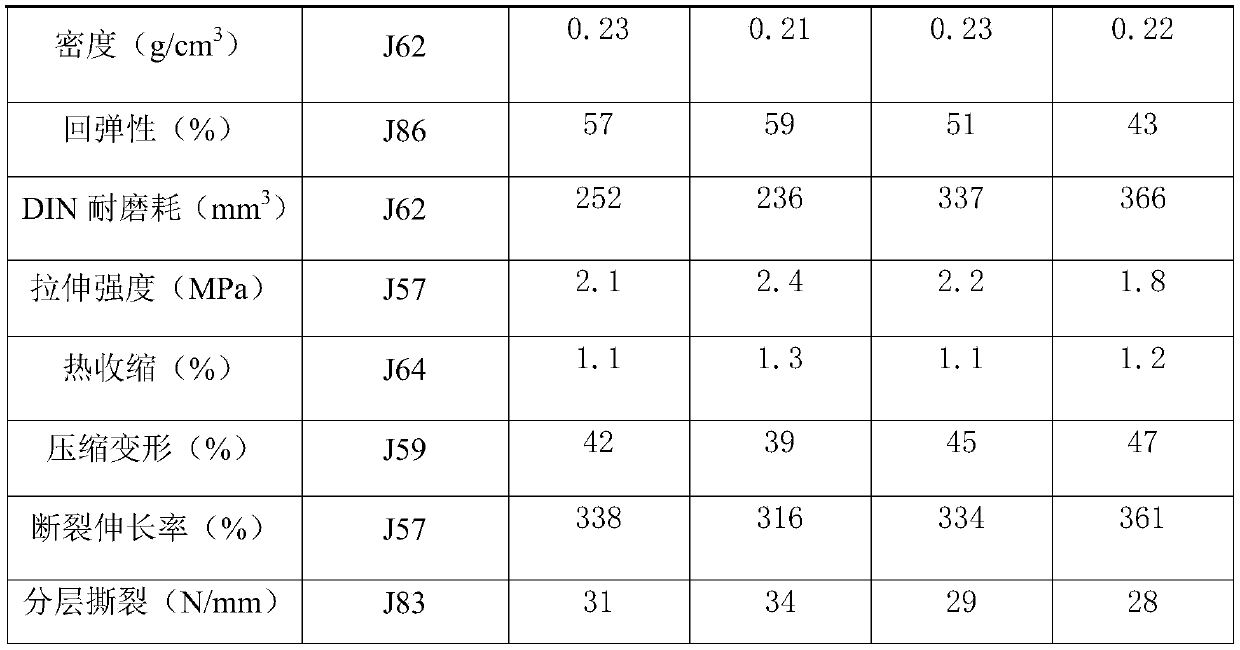

Embodiment 1

[0054] In Embodiment 1 of the present invention, the proportioning by mass of the materials contained in the EVA coarse-cell composite foaming material is as follows:

[0055] Ethylene-vinyl acetate copolymer: 45 parts by mass

[0056] Graphene modified isotactic polybutene: 15 parts by mass

[0057] Polyolefin thermoplastic elastomer: 15 parts by mass

[0058] Polyester elastomer: 15 parts by mass

[0059] Active agent: 0.6 parts by mass

[0060] Crosslinking agent: 1.2 parts by mass

[0061] Foaming agent: 3.0 parts by mass

[0062] Auxiliary: 0.3 parts by mass

[0063] Among them, the model of ethylene-vinyl acetate copolymer is 7470M, produced by Formosa Plastics Corporation; polybutene is commercially available from Shandong Dongfang Hongye Chemical Co., Ltd.; graphene is commercially available; the polyolefin thermoplastic elastomer models are Engage8180 and Engage8450, and its The ratio is 2:1, produced by DuPont; the type of polyester elastomer is DSM EL430; the ...

Embodiment 2

[0070] In the second embodiment of the present invention, the mass proportions of the materials contained in the EVA coarse-cell composite foaming material are as follows:

[0071] Ethylene-vinyl acetate copolymer: 40 parts by mass

[0072] Graphene modified isotactic polybutene: 20 parts by mass

[0073] Polyolefin thermoplastic elastomer: 10 parts by mass

[0074] Polyester elastomer: 10 parts by mass

[0075] Active agent: 0.8 parts by mass

[0076] Crosslinking agent: 1.5 parts by mass

[0077] Foaming agent: 2.8 parts by mass

[0078] Auxiliary: 0.2 parts by mass

[0079] Among them, the model of ethylene-vinyl acetate copolymer is 7470M, produced by Formosa Plastics Corporation; polybutene is commercially available from Shandong Dongfang Hongye Chemical Co., Ltd.; graphene is commercially available; the polyolefin thermoplastic elastomer models are Engage8180 and Engage8450, and its The ratio is 1:1, produced by DuPont; the type of polyester elastomer is DSM EL430 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com