Aerobic composting waste heat power generation system and working method thereof

An aerobic composting and electrical system technology, applied in general control systems, control/regulation systems, fertilization devices, etc., can solve secondary pollution and other problems, achieve the effect of ensuring composting and preventing pollution of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

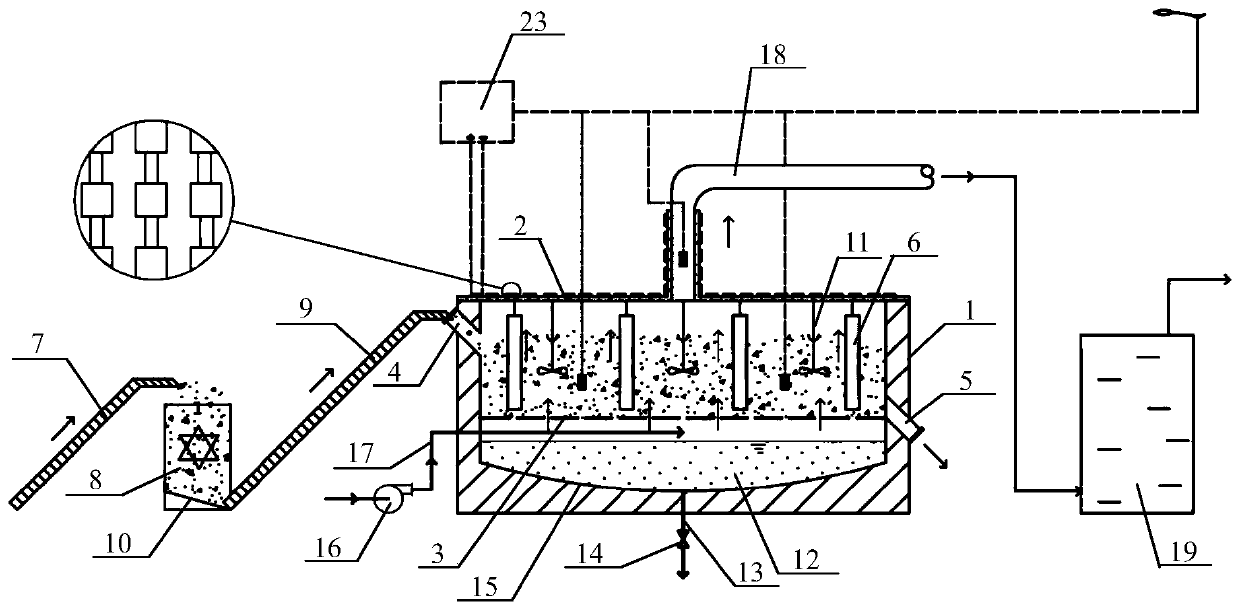

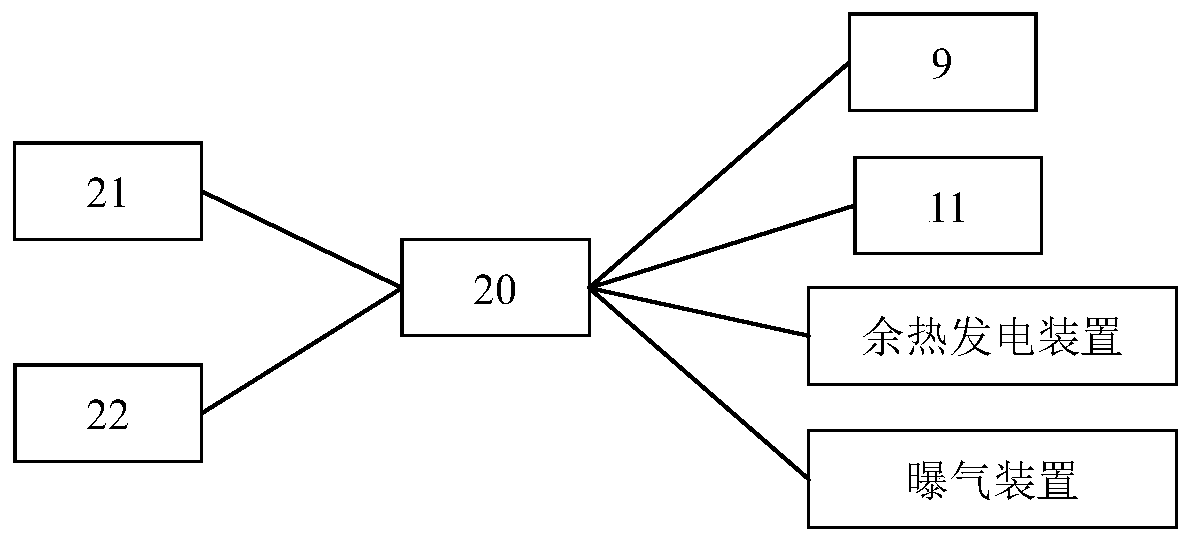

[0053] An aerobic compost waste heat power generation system, such as figure 1 As shown, it includes waste collection device, main composting reaction chamber 1, waste heat power generation device and exhaust gas collection device;

[0054] The surrounding and bottom of the main composting reaction chamber 1 are made of concrete pouring, and the top of the main composting reaction chamber 1 is provided with a heat conduction cover 2. The internal space of the main composting reaction chamber 1 includes an upper space and a lower space, and the upper space is a waste reactor. body, the lower space is a leachate collection device, a filter screen 3 is arranged between the upper space and the lower space, and a feed inlet 4 and an organic fertilizer outlet 5 are respectively arranged on the side wall of the upper space of the main composting reaction chamber 1. The composting reaction chamber 1 is also connected with an aeration device for aerating the reactor body;

[0055] The...

Embodiment 2

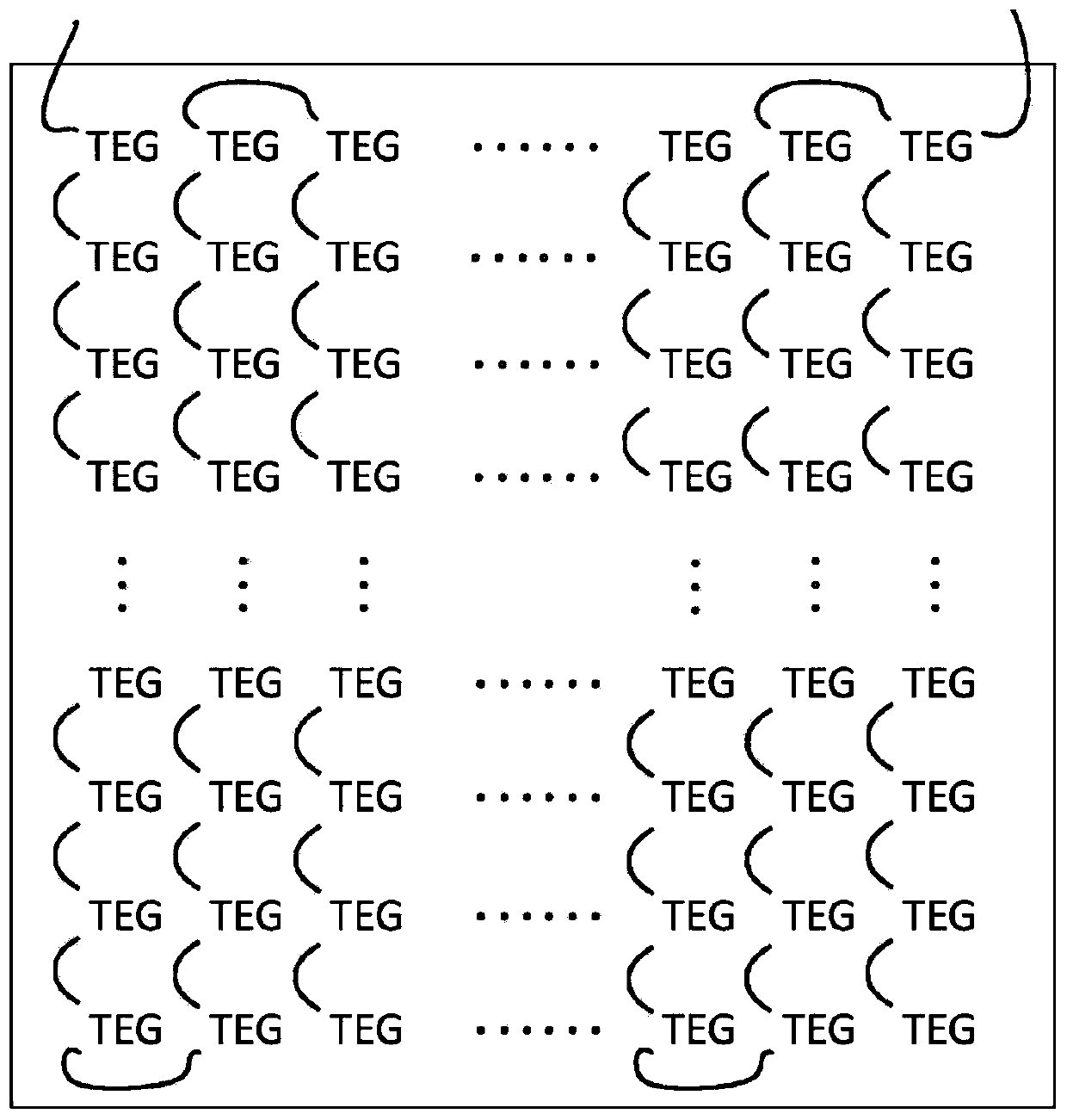

[0059] An aerobic composting waste heat power generation system, the structure of which is shown in Example 1, the difference is that the hot end side of the semiconductor thermoelectric power generation sheet is attached to the outer surface of the heat conduction cover 2, and the surface of the cold end side is installed with heat dissipation Better aluminum heat sink to ensure the temperature difference between the two sides of the temperature difference sheet.

Embodiment 3

[0061] An aerobic composting waste heat power generation system, its structure is as shown in Example 1, the difference is that the waste collection device includes a collection conveyor belt 7, a waste crushing and stirring device 8 and a feed conveyor belt 9, and the collection conveyor belt 7 adopts an inclined The upward transmission belt is realized, and its end is located directly above the waste crushing and stirring device 8. The discharge port of the waste crushing and stirring device 8 is connected to one end of the feeding conveyor belt 9, and the other end of the feeding conveyor belt 9 is connected to the main composting reaction chamber 1 The feeding port 4 is connected to transport the uniformly mixed waste to the main composting reaction chamber 1;

[0062] The bottom of the waste crushing and stirring device 8 is provided with a collection slope 10, and the collection slope 10 is inclined to the feed conveyor belt 9, that is, the lowest point of the collection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com