Patents

Literature

38results about How to "Guaranteed to be harmless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

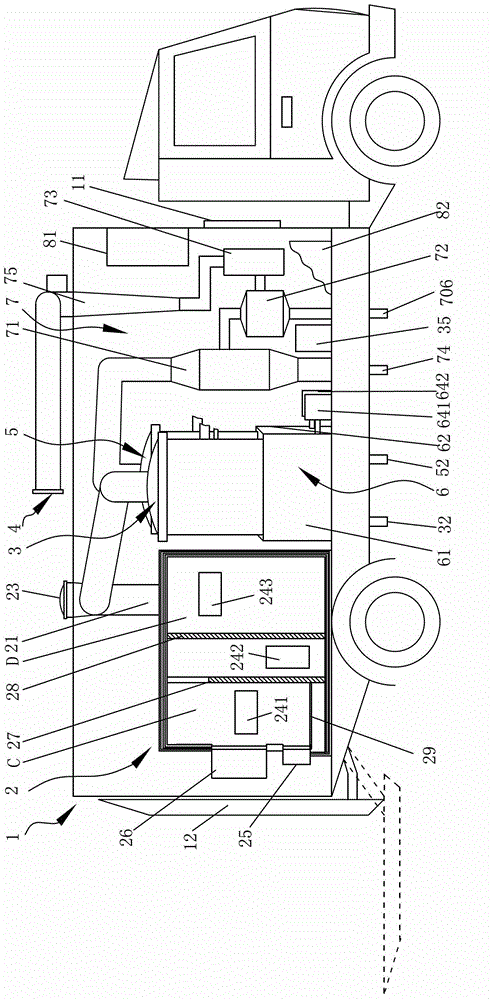

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333ALower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

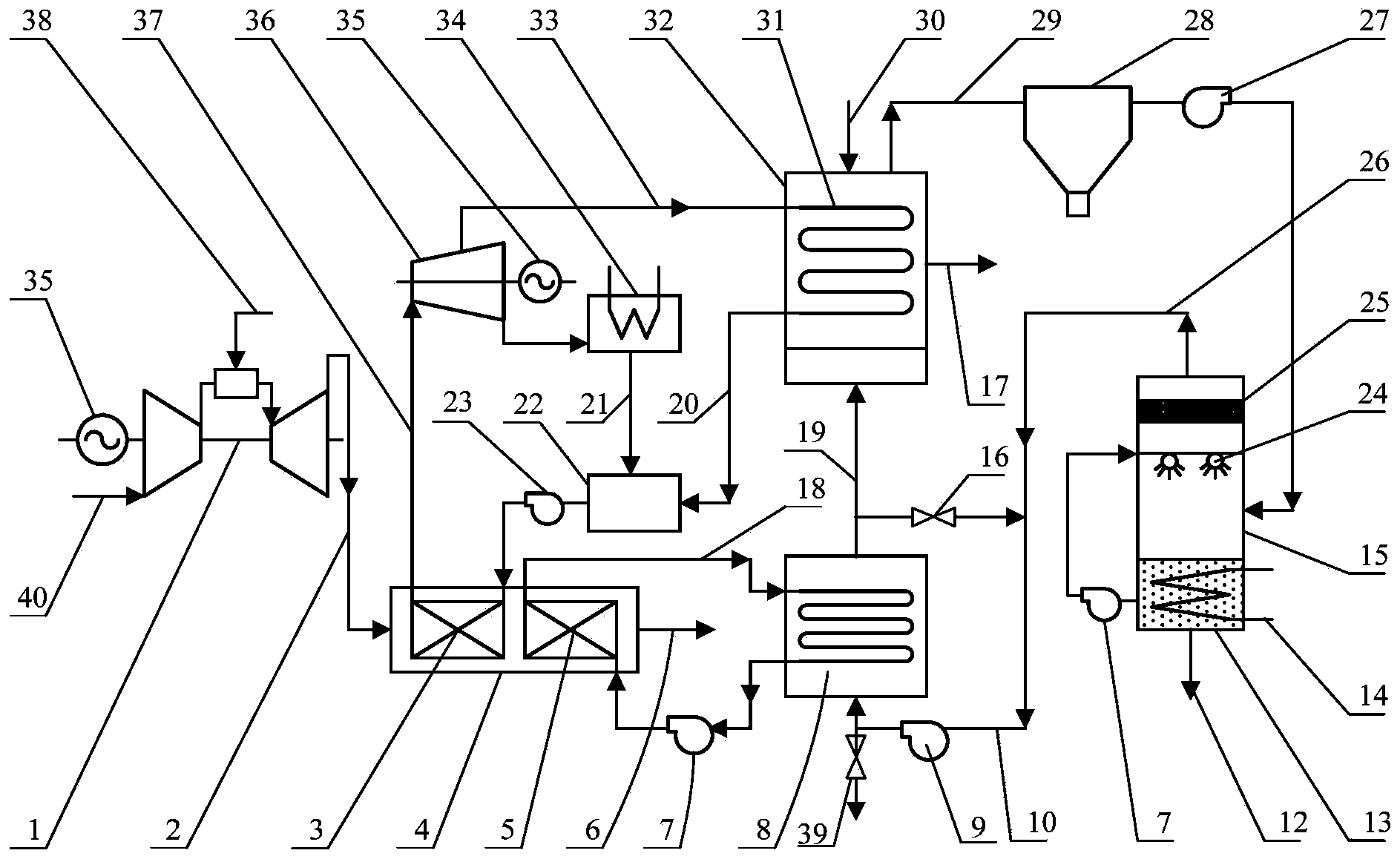

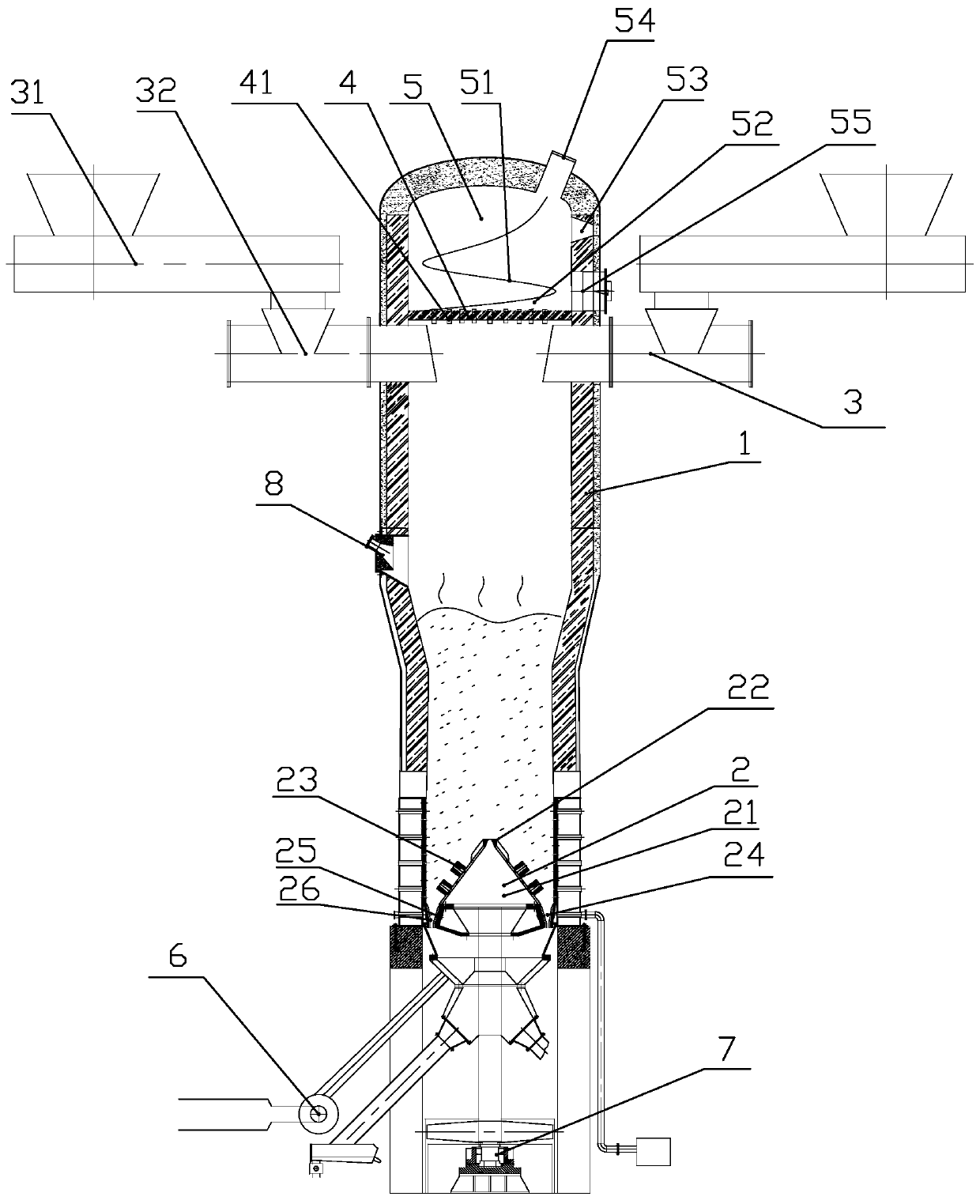

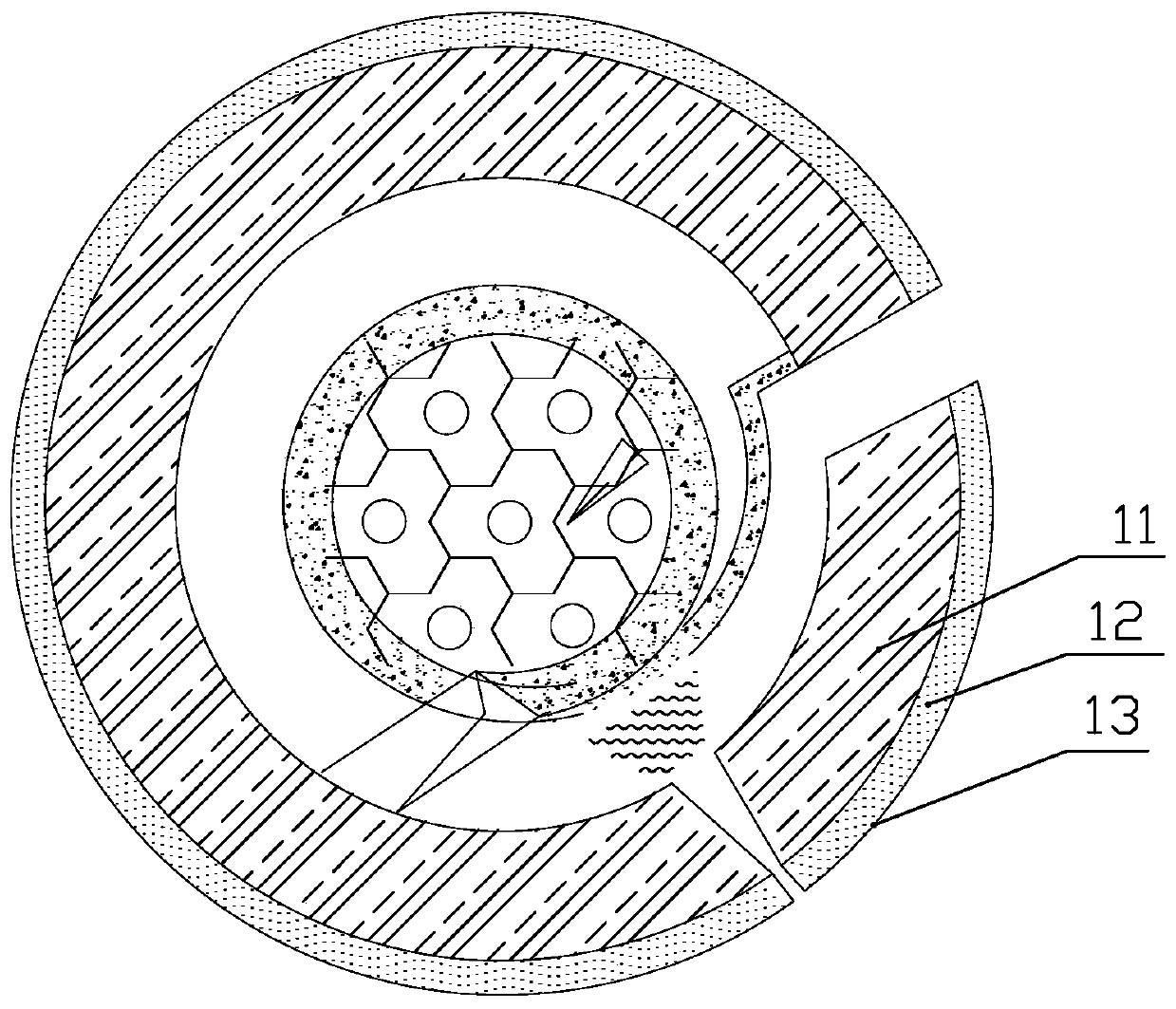

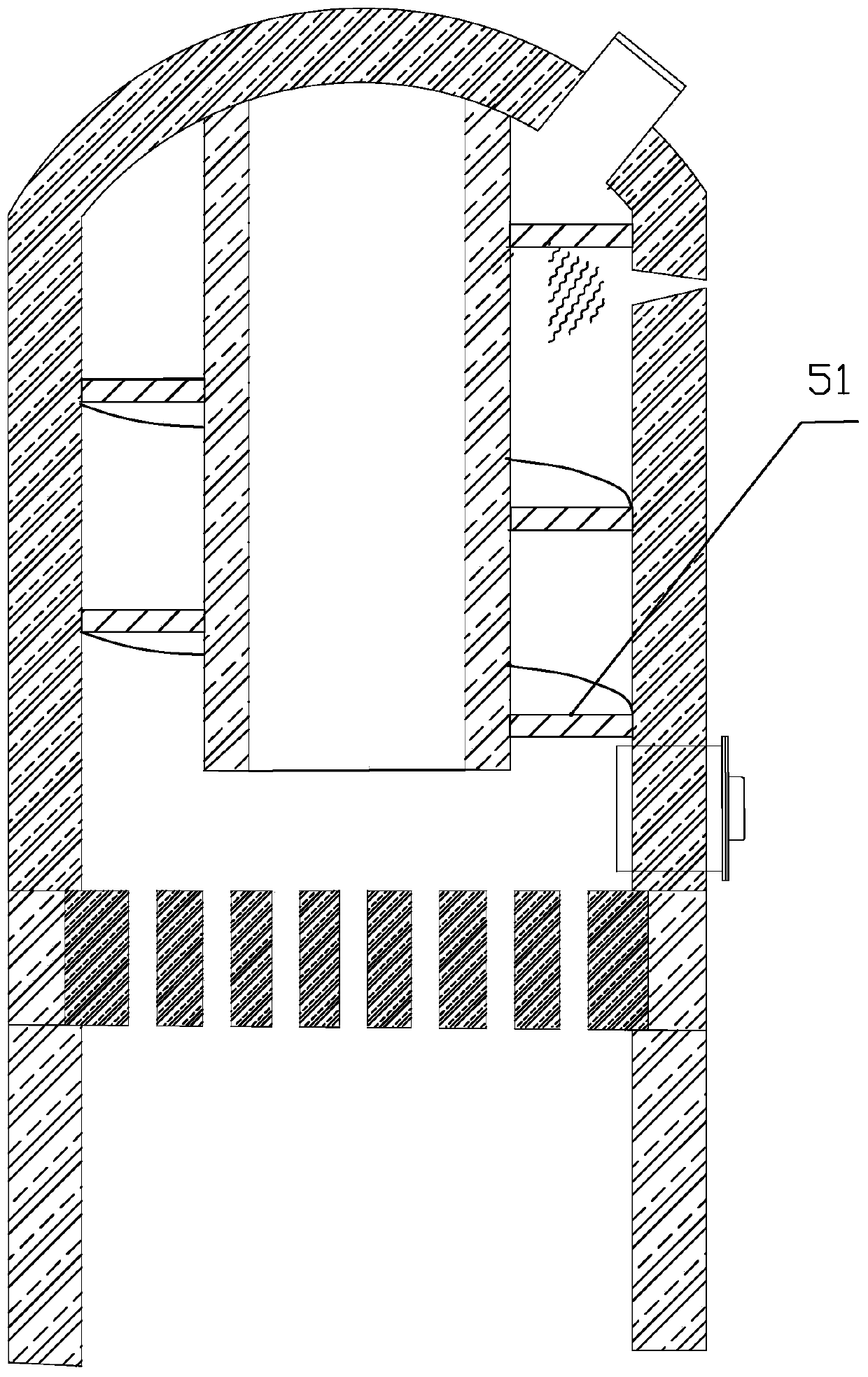

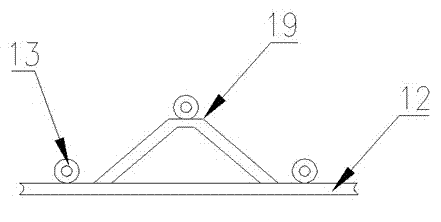

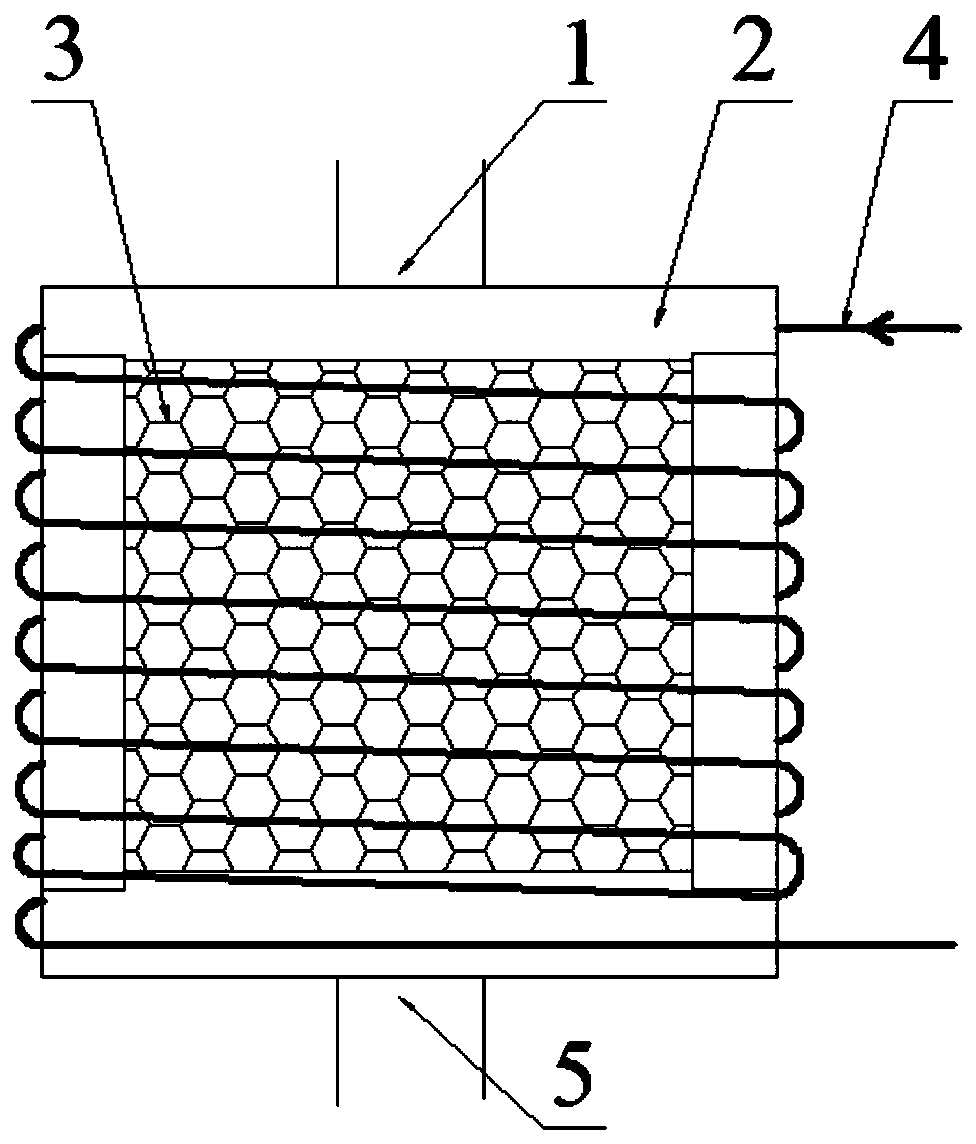

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

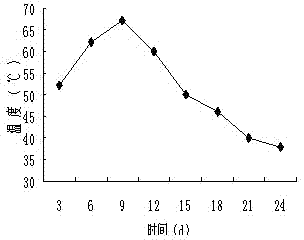

Technique for preparing biogas by high-temperature anaerobic zymosis method using animal manure as raw material

InactiveCN101358209AQuality assuranceImprove filtration efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

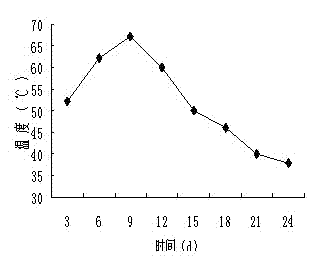

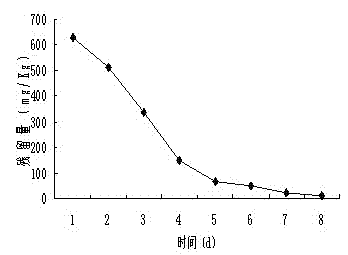

The present invention relates to a technique which utilizes animal and poultry feces as material to prepare biogas underground by anaerobic fermentation, which belongs to the technical field of environment-friendly energy. The technique utilizes the cheap animal and poultry feces as material, in which liquid dung or active sludge perennially accumulated in a farm is added when fermentation is started; high temperature can ensure good growth, thus increasing fermentation efficiency; by a high temperature of 58 DEG C plus or minus 1 DEG C and 8 to 30 grades of anaerobic fermentation, the degradation period of feces and sludge can be shortened; harmful bacteria can be thoroughly sterilized in order to ensure harmlessness; moreover, the post-fermentation biogas residue and biogas slurry can be used as high-quality organic manure; and the produced residual heat can be used for fermentation heat supply or factory heat preservation and heating.

Owner:张永军

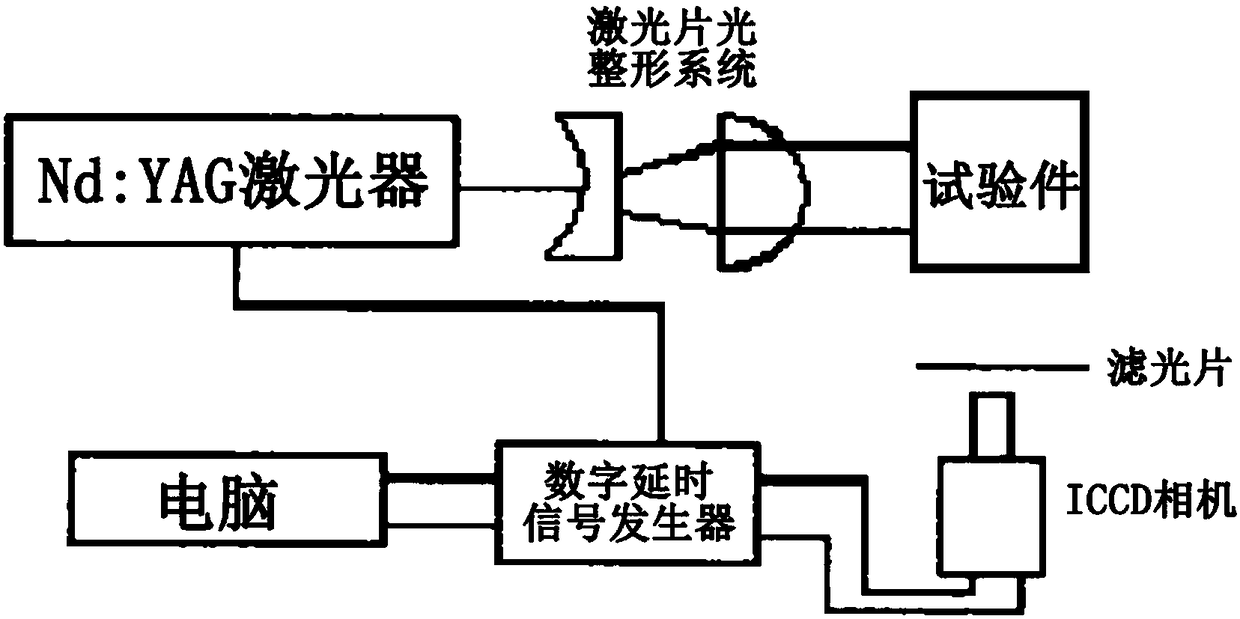

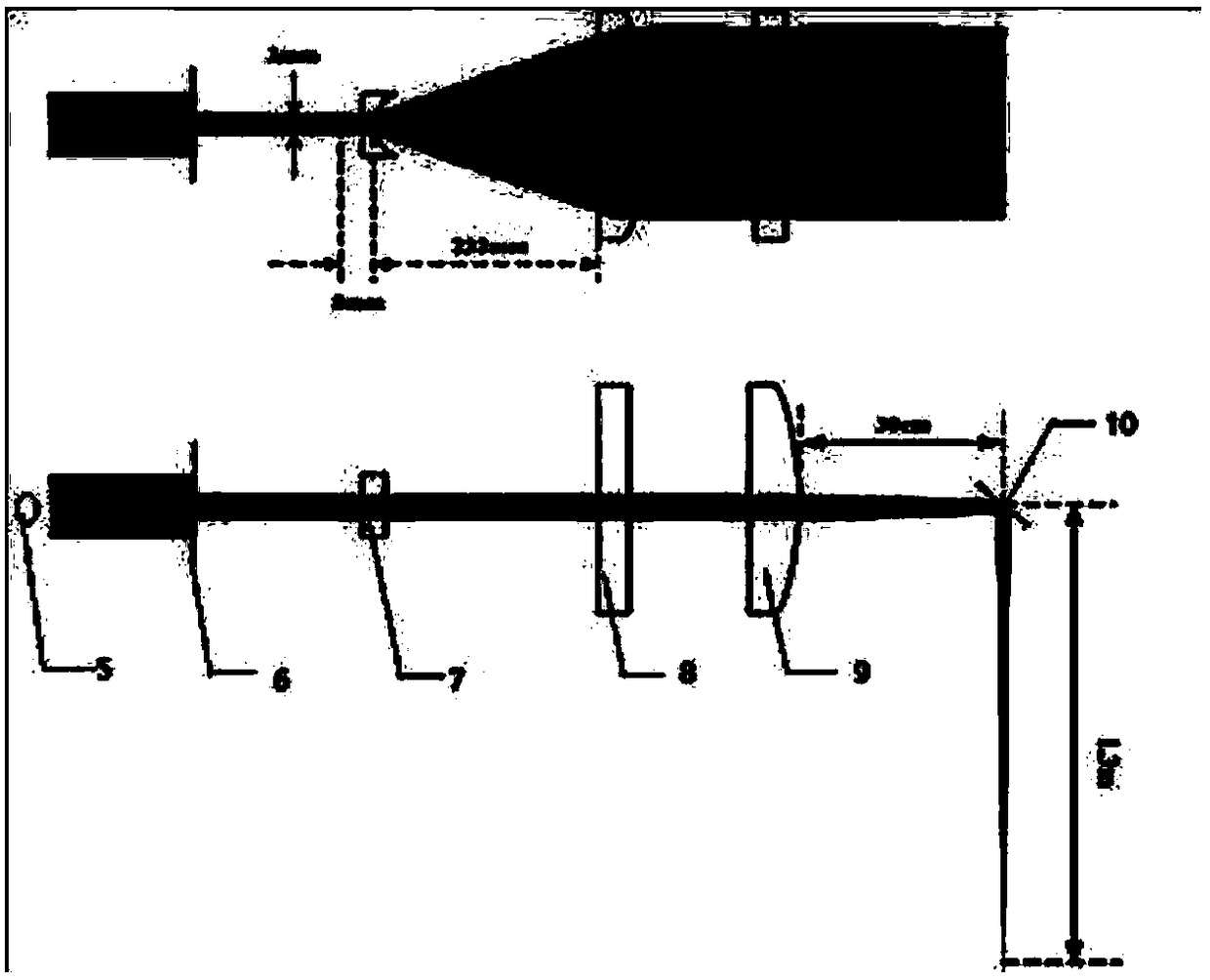

Hypersonic PLIF wind tunnel experiment method based on acetone tracer

ActiveCN107941454AImprove spatial resolutionHigh sensitivityAerodynamic testingImage diagnosisImage detection

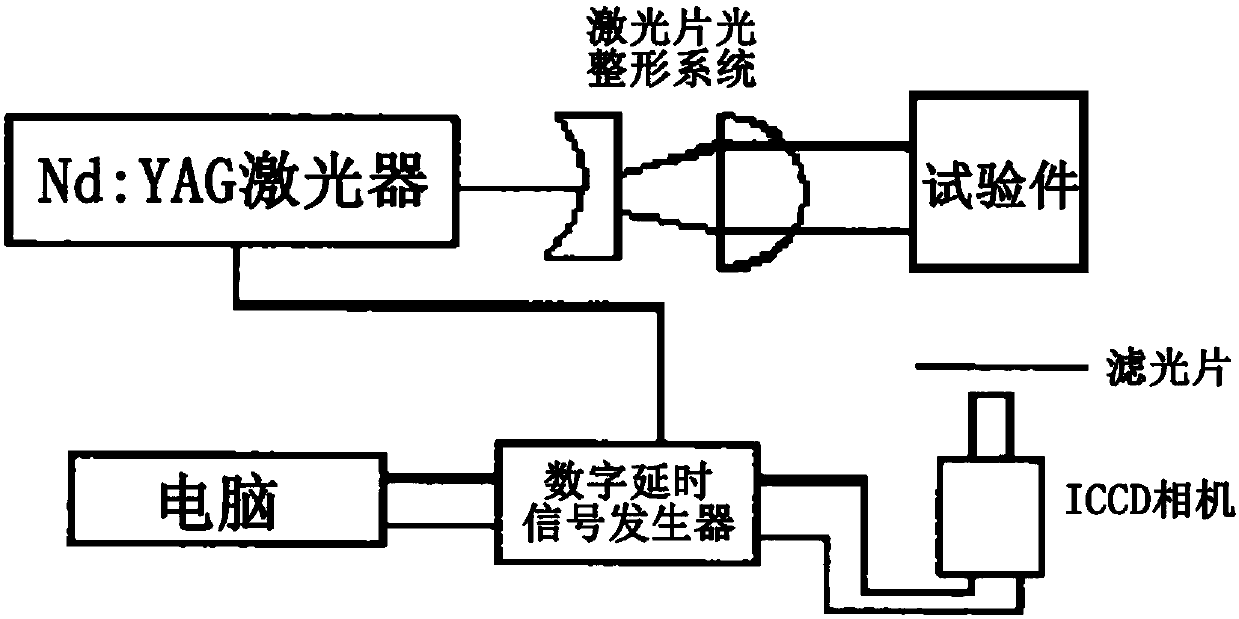

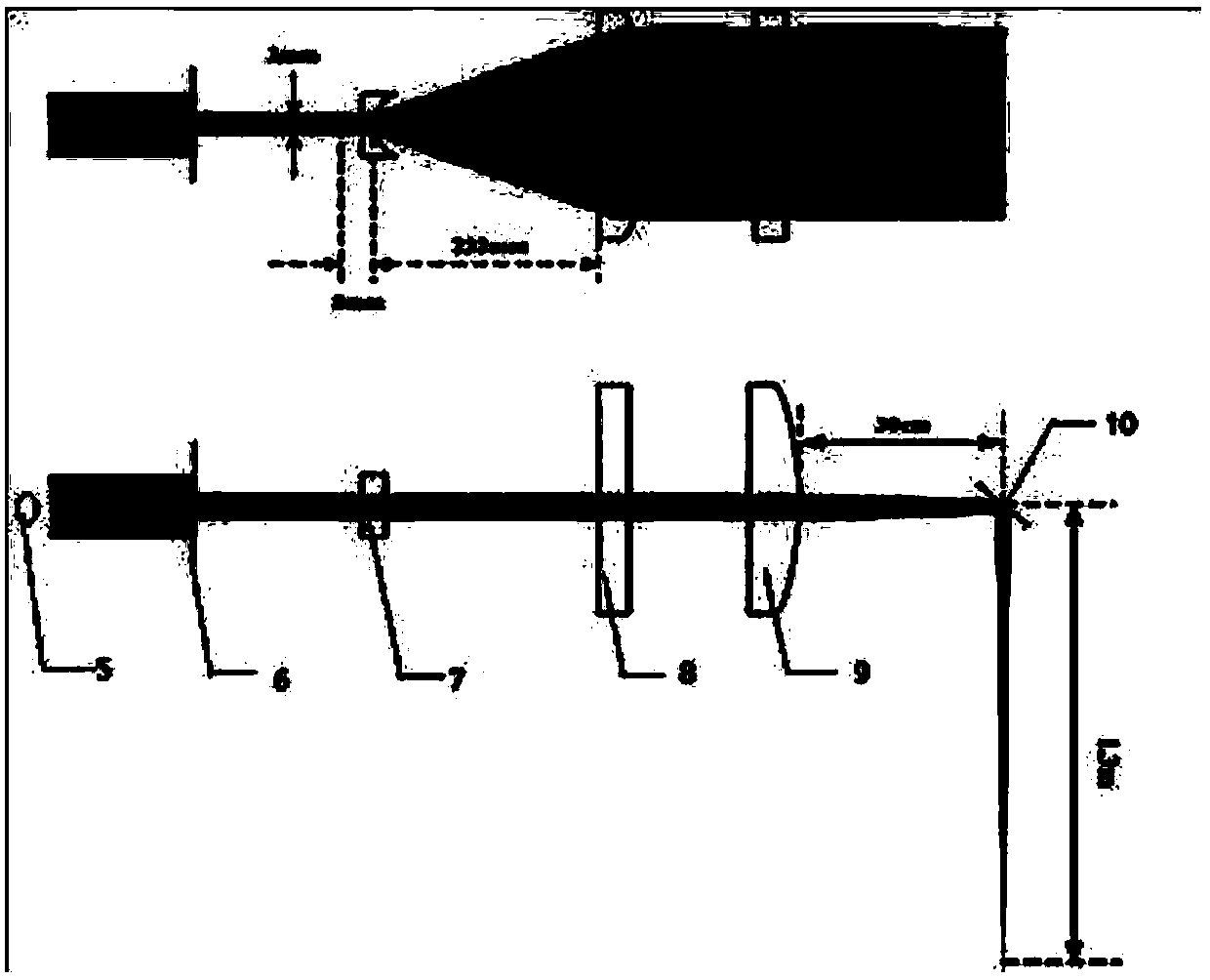

The invention relates to a hypersonic PLIF (Plane Laser Induced Fluorescence) wind tunnel experiment method based on acetone tracer. A hypersonic PLIF imaging diagnosis system based on acetone tracerincludes a laser source system, a sheet-shaped light beam shaping system, a PLIF image detection system and an acetone tracer supply system, and is characterized by taking the acetone as tracing particles, performing particle emission in the vacuum environment of a conventional hypersonic wind tunnel, obtaining a fluorescence signal of the acetone in the hypersonic flow field, applying the PLIF measurement technique to obtain a two-dimensional image of the hypersonic flow field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

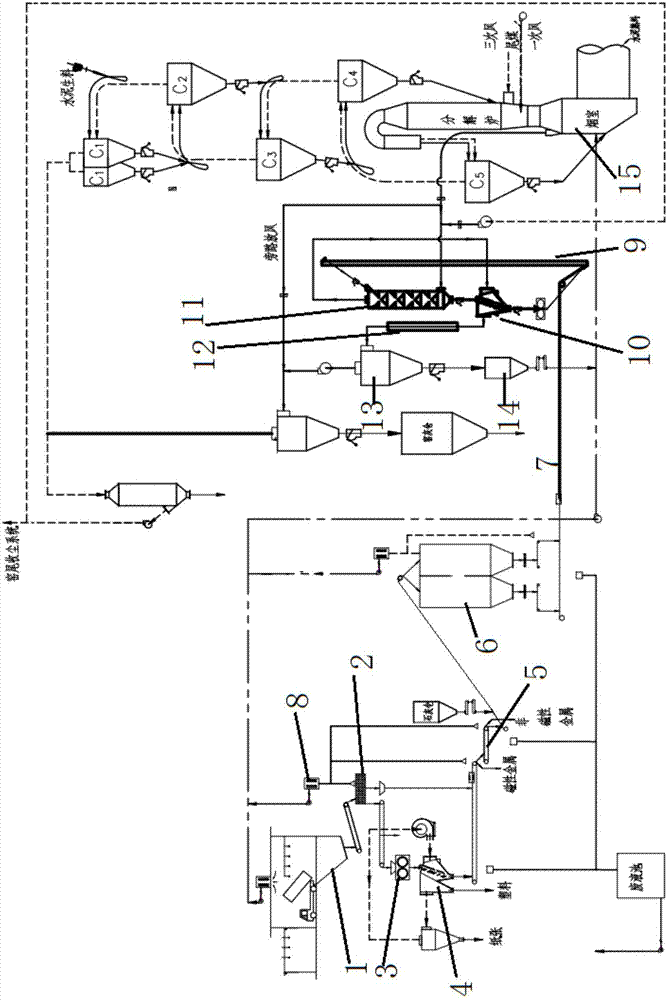

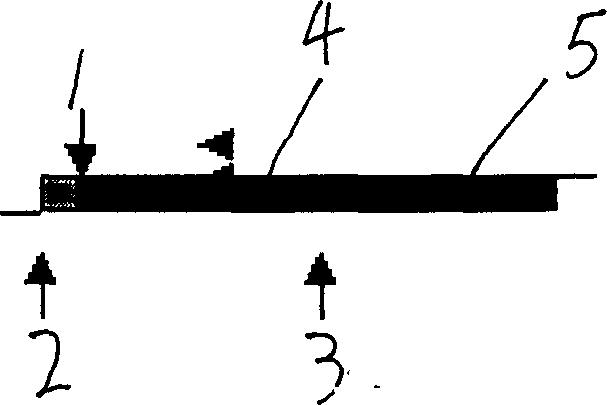

Household garbage treatment method and treatment system

The invention provides a household garbage treatment method and treatment system. According to the treatment method, household garbage is broken, recoverable garbage is sorted out, and an anti-corrosion modifier is added to be stored; the stored garbage is subject to breaking, and hot air drying and grinding of a cement kiln, powder selection is carried out, and granule matter is burnt. In the process, the garbage is subject to drying and grinding and then is burnt, the side effect of garbage water or garbage waste gas on safety operation of a cement kiln system can be reduced as far as possible, the secondary pollution is reduced, harmless, low-cost and low-investment treatment of household garbage is ensured, and the method and system meet the sustainable development circular economy direction. According to the treatment system, the special advantage of the cement kiln is sufficiently used, in combination with the garbage system, the capital investment is reduced, the garbage treatment capacity is improved, garbage applicability is improved, and the system is a harmless, recycling and low-cost treatment system.

Owner:长沙中硅环保科技有限公司

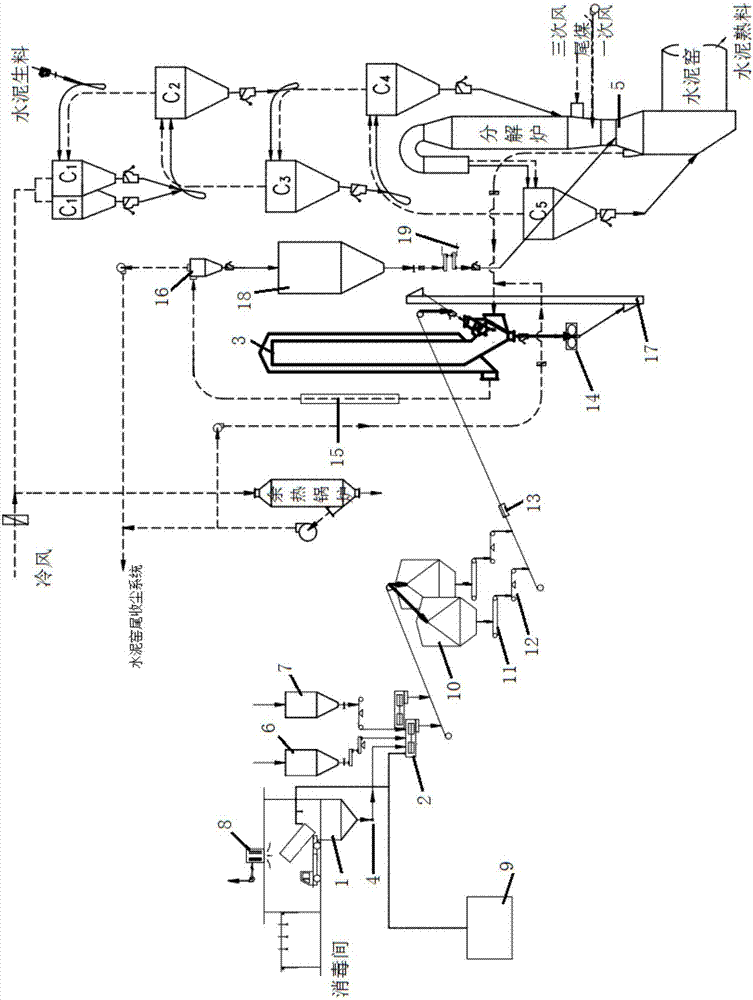

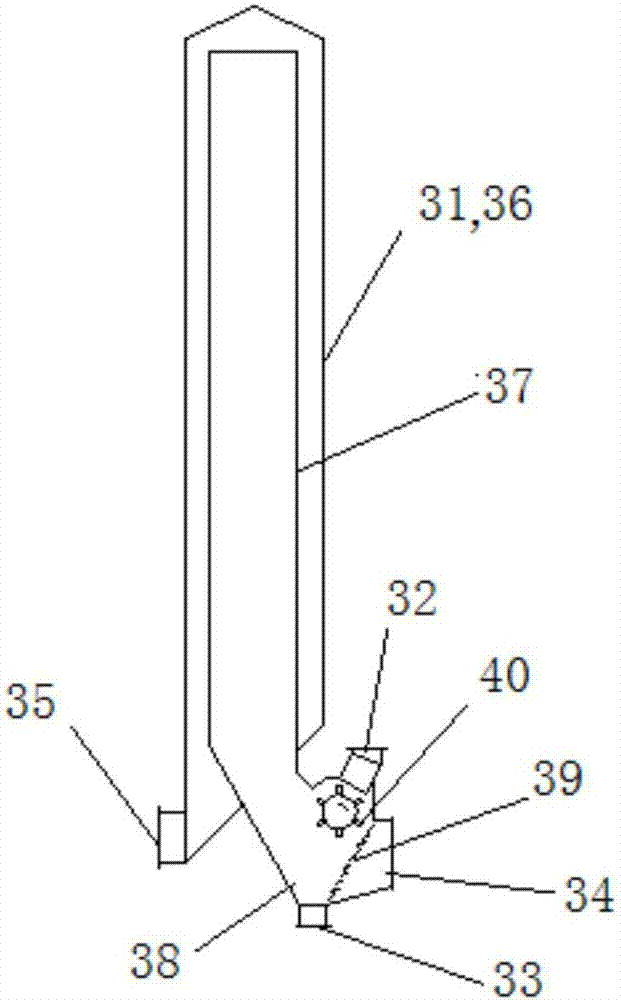

Sludge treatment method and treatment system

PendingCN107417061AEliminate adverse effectsReduce negative impactSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCo-processingCement kiln

The invention provides a sludge treatment method and treatment system. The treatment method comprises the following steps: discharging sludge into a sludge storage pond, and adding an anti-corrosion modifier and evenly mixing for storage; exporting sludge and delivering sludge into an agitator, and adding an alkaline modifier, evenly mixing and then ageing to obtain a sludge derived cement raw material; entering a vertical bushing dispersing and grading and drying furnace for dispersing, grading and drying, sorting out small-particular materials and large-particular materials, performing further grinding to the large-particular materials, then repeatedly circulating dispersing, grading, drying and grinding processes until all sludge become small--particular materials; and delivering the small-particular materials into a cement kiln tail smoke chamber for incineration. The sludge treatment method and the treatment system effectively overcome the negative influence factor during cooperative treatment of sludge during production in a cement kiln, forcibly conduct anti-corrosion modification to the sludge, reasonably treat waste gas and moisture in sludge, effectively control various effective elements of sludge carried in the cement kiln, avoid the situations influencing the cement kiln, and realizes the harmless treatment of sludge.

Owner:长沙中硅环保科技有限公司

Recombinant adenovirus capable of expressing tomour specific apoptosis peptide, and its preparing method and use

InactiveCN1775947ANo damage to physiologyGuaranteed validityViruses/bacteriophagesAntibody medical ingredientsNeoplastic tissueApoptosis

Owner:DOMINO MEDICINE INST BEIJING

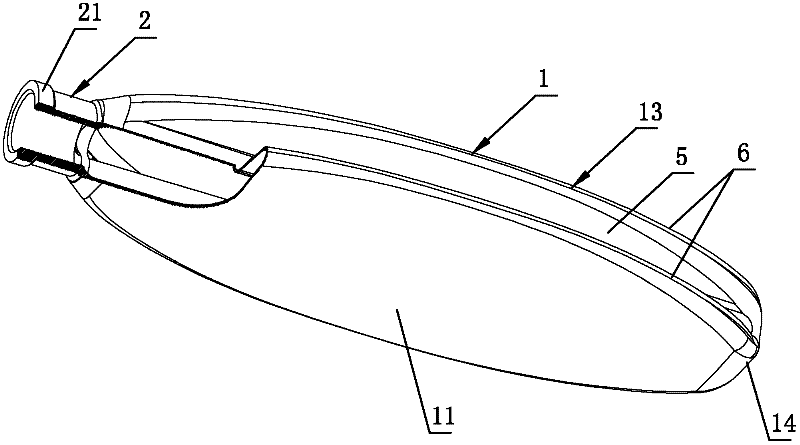

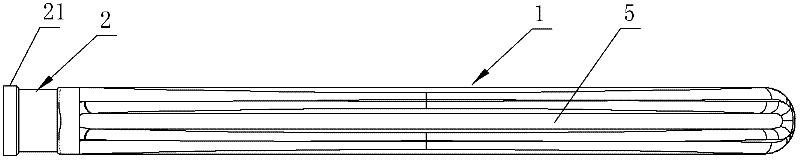

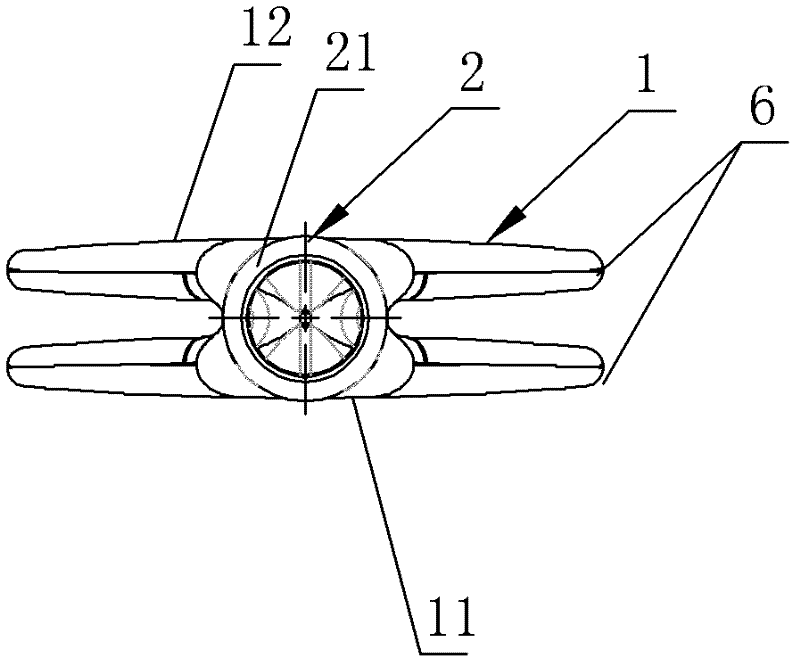

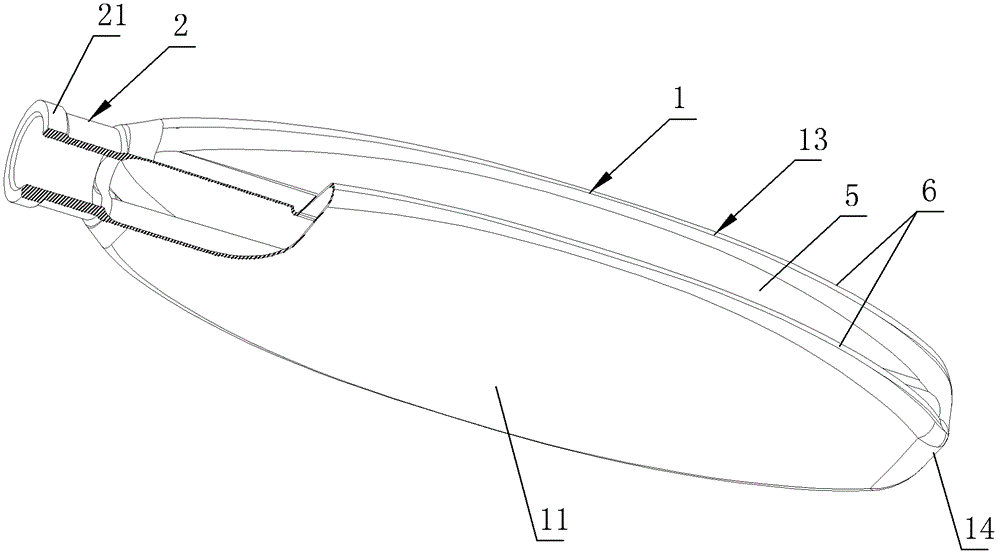

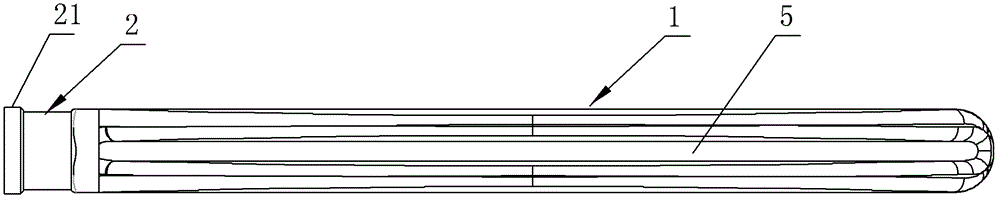

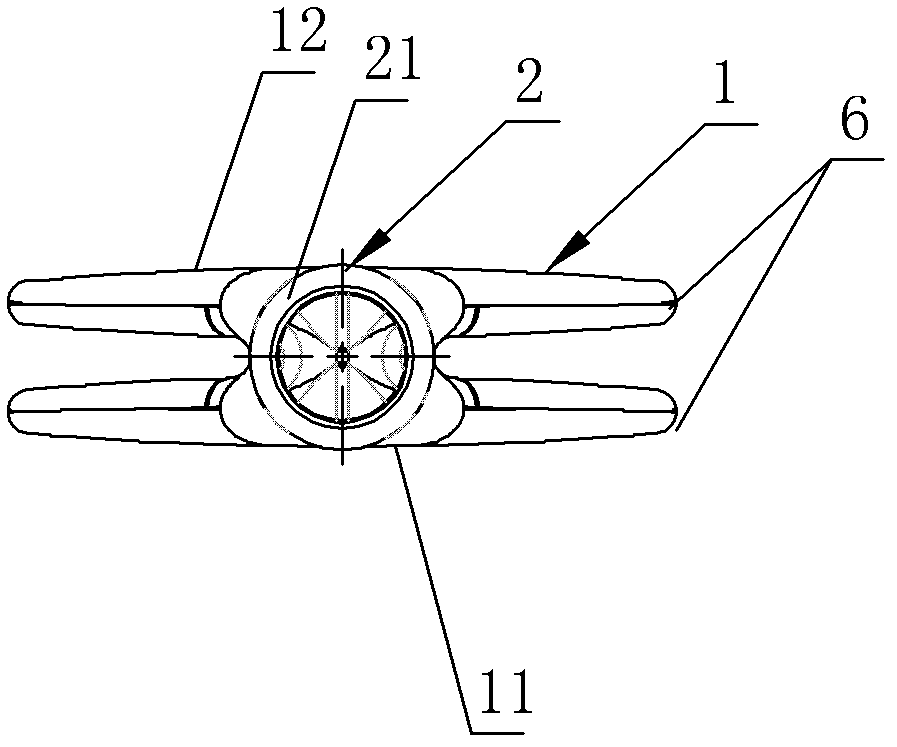

Integral type respiratory bag and manufacturing method thereof

ActiveCN102553044APrevent air leakageSimplify the manufacturing processRespiratorsCoatingsAdhesiveEngineering

The invention discloses an integral type respiratory bag, comprising a hollow bag body and a joint which is arranged on a bag body connector, wherein a through hole on the joint is communicated with the inner part of the bag body. The integral type respiratory bag is characterized in that the bag body and the joint are integrally manufactured in a mould cavity by coating glue in a vibration manner, heating and molding. The invention further discloses a manufacturing method of the integral type respiratory bag. The bag body of the respiratory bag provided by the invention is manufactured in the glue vibration manner and thicker glue can be coated on a transition part between the side face and the bottom face of the bag body, so as to prevent fisheyes from being generated after the bag body is inflated. The respiratory bag provided by the invention is integrally molded and the joint does not need to be additionally arranged, so that the manufacturing procedure is simplified and the labor cost is reduced; viscose glue or adhesive does not need to be used for sticking so that the problem that the joint drops off due to poor sticking so as to cause air leakage is solved; and therefore, materials are saved and the production cost is reduced. With the adoption of the integral type respiratory bag provided by the invention, the phenomena of causing anaphylactic reaction of a human body and diffusing a pungent smell are avoided and no harm is caused to the human body.

Owner:广州晟威医疗器械有限公司

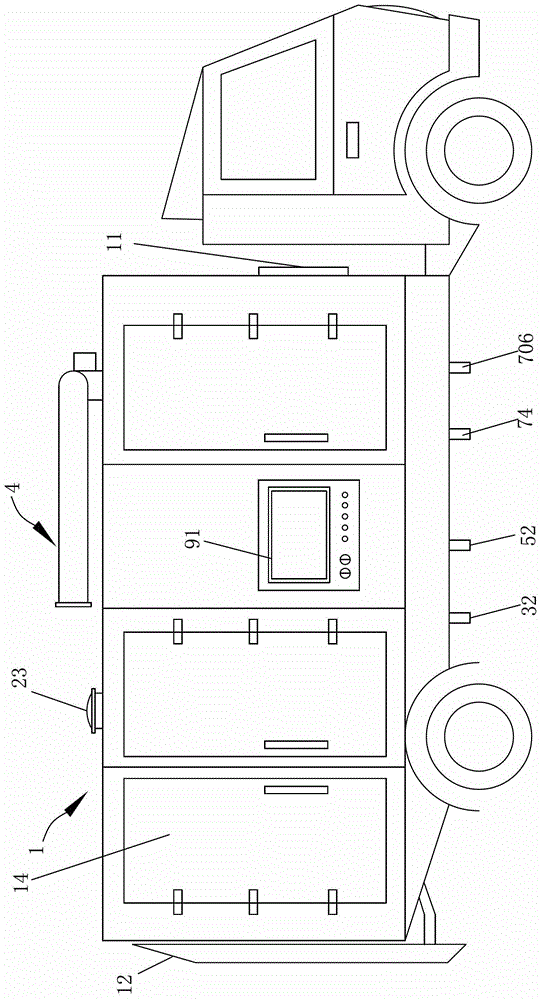

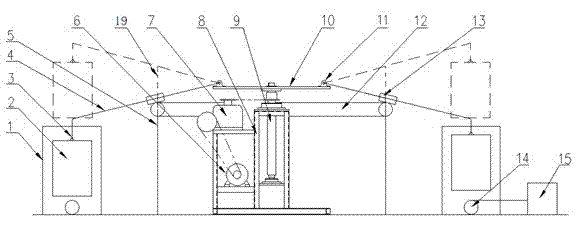

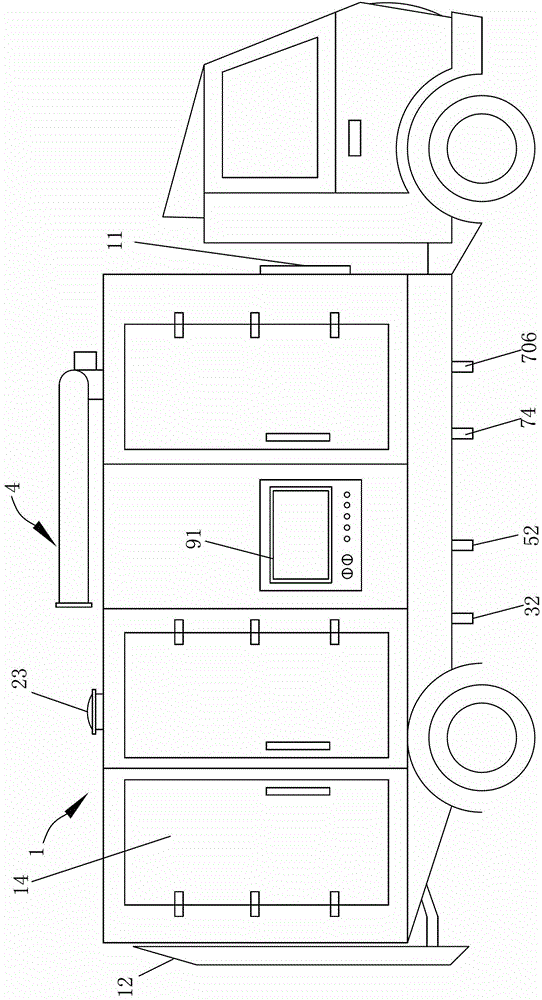

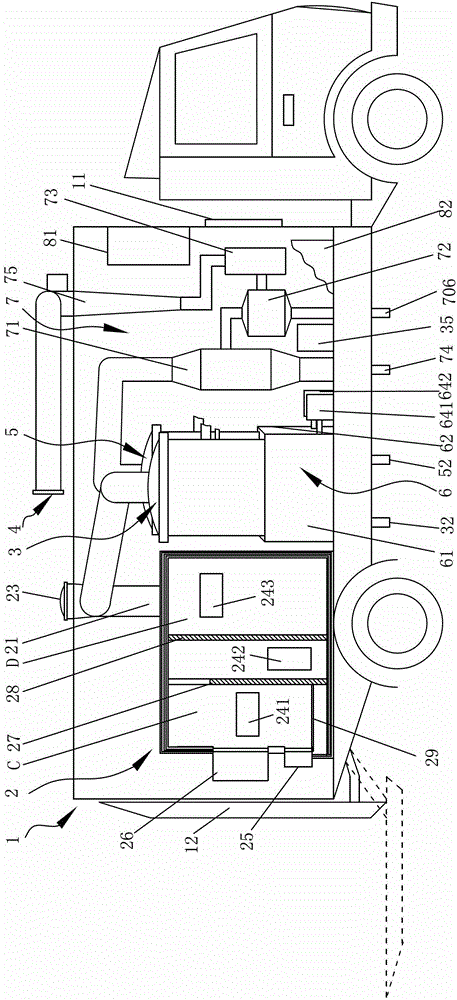

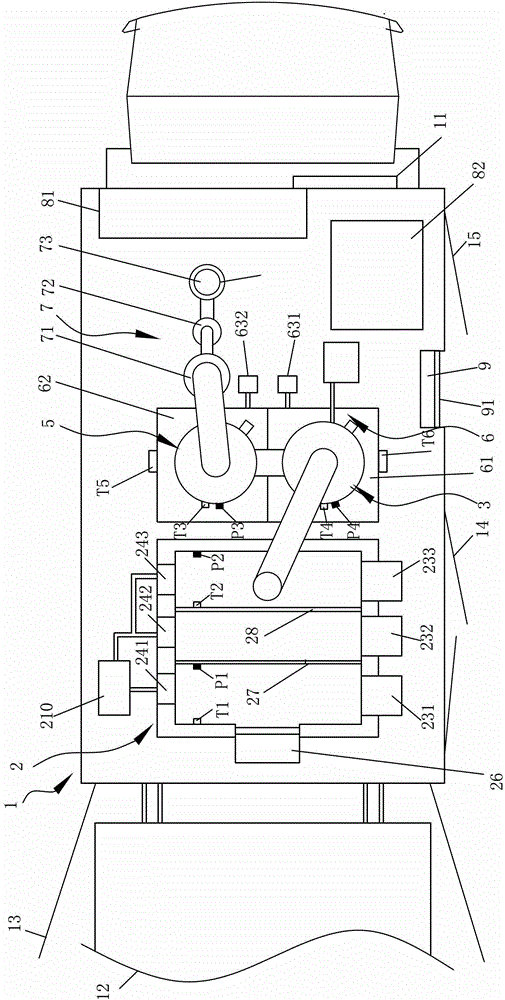

Vehicular medical waste quick ashing system

ActiveCN102873081ABurn fullyReduce weightSolid waste disposalIncinerator apparatusAshingCombustion chamber

The invention relates to a vehicular medical waste quick ashing system. The vehicular medical waste quick ashing system comprises a medical waste ashing system and is characterized by comprising a loading vehicle, and the medical waste ashing system is arranged on a vehicle body. A square incinerator body is partitioned by a vertical guide baffle with an upper right opening into a first combustion chamber and a second combustion chamber in longitudinal parallel, a vertical guide baffle with a lower left opening is parallel to the vertical guide baffle with the upper right opening and arranged in the second combustion chamber to partition the second combustion chamber into two sub-chambers in longitudinal parallel, and combustors are arranged corresponding to the two sub-chambers of the vertical guide baffle with the lower left opening and the first combustion chamber. A smoke quenching tower and a desulfurization and purification device are set as a smoke quenching, desulfurization and purification integrated device which comprises the smoke quenching tower, a spraying desulfurization and purification tower, a cooling water tank and an alkali liquor tank. An exhaust chimney is a rotary up-and-down type exhaust chimey, and the system further comprises a power generator. The vehicular medical waste quick ashing system has the advantages of easiness in movement, capability of treating medical wastes anytime anywhere, prevention of environment pollution, and protection of people's physical health.

Owner:天津环科立嘉环境修复科技有限公司

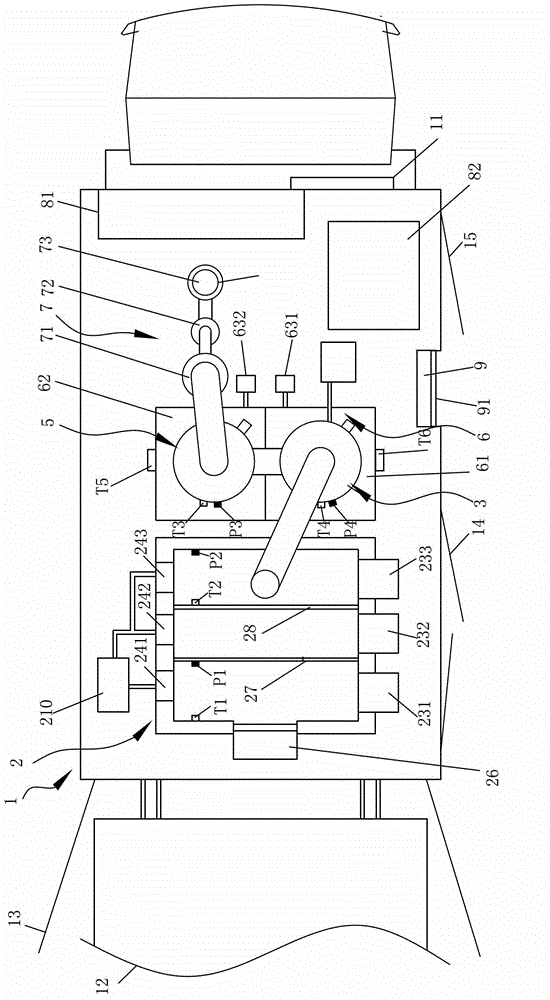

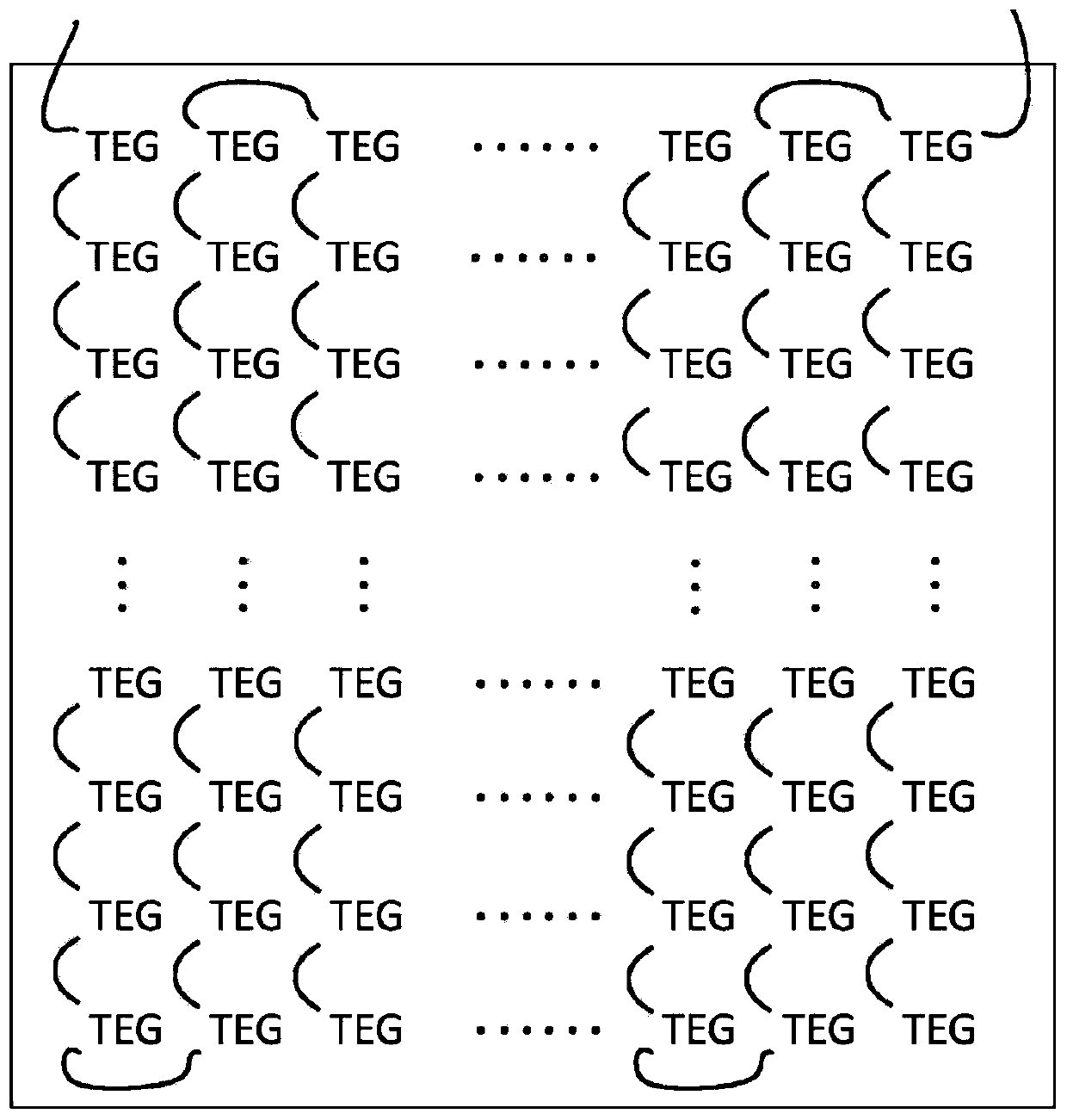

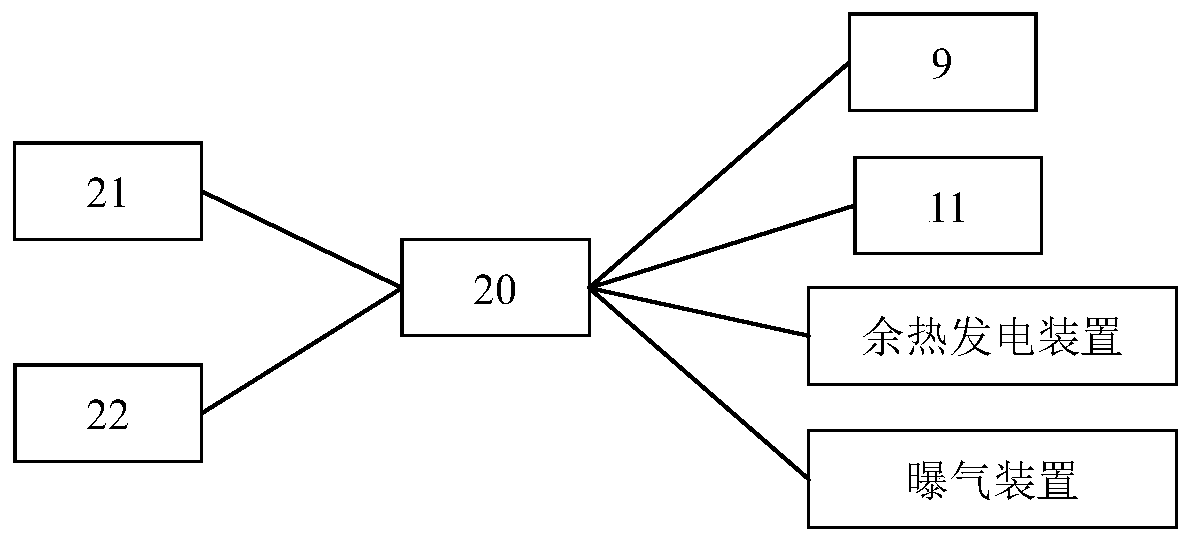

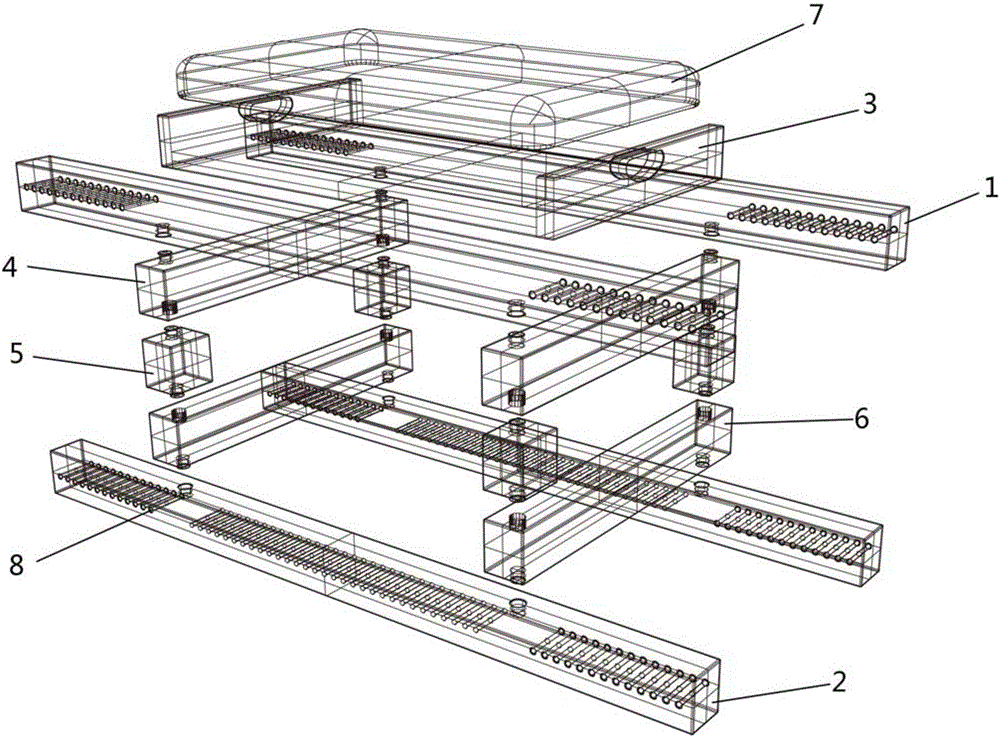

Aerobic composting waste heat power generation system and working method thereof

PendingCN110713400ARealize managementEfficient use ofBio-organic fraction processingEnergy inputCompostOrganic solid waste

The invention relates to an aerobic composting waste heat power generation system and a working method thereof, and belongs to the field of organic solid waste resource utilization. The system comprises a waste collection device, a main composting reaction chamber, a waste heat power generation device and a tail gas collection device, wherein a heat conduction cover is arranged at the top of the main composting reaction chamber, the upper space of the main composting reaction chamber is a waste reactor body, the lower space of the main composting reaction chamber is a leachate collection device, a filter screen is arranged between the upper space and the lower space, and the main composting reaction chamber is further connected with an aeration device; the bottom of the heat conduction cover is connected with the reactor body through a heat conduction rod; a waste heat power generation device is installed on the upper surface of the heat conduction cover and is formed by connecting a plurality of semiconductor thermoelectric power generation pieces in series, wherein the electric energy generated by the semiconductor thermoelectric power generation pieces is transmitted to an electricity storage and supply device. According to the invention, heat can be recovered from organic wastes while the organic wastes are treated, and the problem of secondary pollution caused by excessivewaste heat of traditional compost is solved.

Owner:SHANDONG UNIV

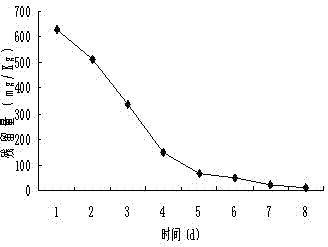

Biological organic fertilizer produced from abamectin fermentation waste residue and preparation method thereof

ActiveCN102786327ASolve the difficulty of complete fermentationSolve resource problemsBio-organic fraction processingOrganic fertiliser preparationAvermectinResource utilization

The present invention provides a method for producing a biological organic fertilizer from abamectin fermentation waste residue. A main raw material of abamectin fermentation waste residue and auxiliary blending materials of straw and chicken manure are treated with aerobic fermentation; an abamectin residue degradation microbial inoculum is added during the aerobic fermentation process to help accelerating degradation of the abamectin residue, under high temperature, ventilating and aerobic conditions. Field tests show that the biological organic fertilizer prepared by the method provided by the invention can not only substitute a conventional biological organic fertilizer to be used in agricultural production, but also has obvious yield increasing effect, so as to realize harmlessness and resource utilization of the avermectin waste residue compost.

Owner:JINAN AGRI NEW FERTILIZER +1

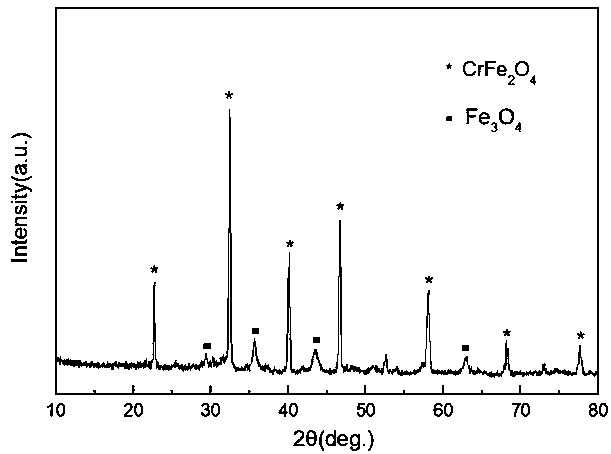

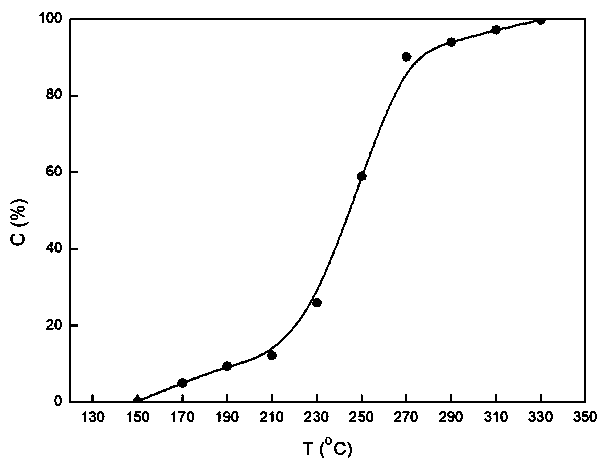

VOC catalyst characterized by ordered arrangement of composite metal oxide and ferroferric oxide, and preparation method thereof

ActiveCN110404543ASignificant process reductionReduce leaching toxicityGas treatmentSludge treatment by pyrolysisSludgeWaste treatment technologies

The invention discloses a VOC catalyst characterized by ordered arrangement of composite metal oxide and a ferroferric oxide, and a preparation method thereof. Electroplating sludge is used as a synthesis material, the temperature and the pressure are changed in an acidic environment, and the electroplating sludge is calcined in an air and nitrogen alternate-changing atmosphere to make metal elements in the electroplating sludge dissolved in a solution and fully reacted in order to form the stable composite metal oxide and ferroferric oxide orderly-arranged nanomaterial. Compared with traditional electroplating sludge treatment methods, the method of the invention has the following advantages: the reduction is obvious, and the leaching toxicity is extremely low; the calcination time is short, and the temperature is low, so much energy consumption is saved; the consumption of metal salt is reduced by nearly half; the reaction is carried out under acidic conditions, so metal ions which are easily leached and lost can be sufficiently reacted; and the process flow is simple, and the reaction conditions are mild, so the method used as a dangerous solid waste treatment technology has thecharacteristics of ensuring of harmlessness, obvious reduction, maximal utilization of the resources in the electroplating sludge, and reduction the running cost of enterprises.

Owner:SHANGHAI UNIV

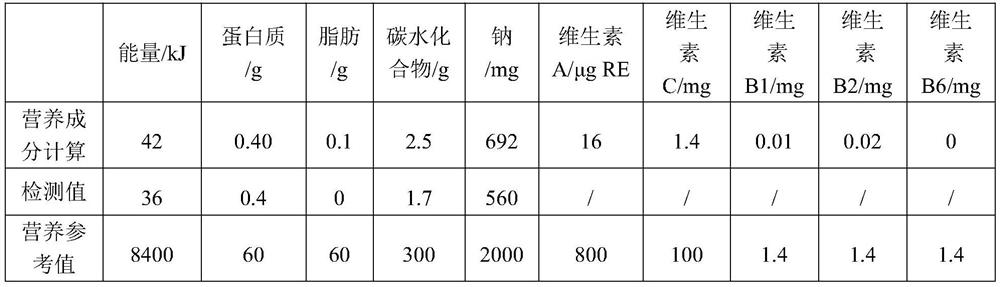

Tricholoma matsutake fresh seasoning and processing method thereof

InactiveCN112006262AImprove immunityImprove anti-cancer and anti-tumorFood ingredient functionsTricholoma matsutakeFreeze-drying

The present invention discloses a tricholoma matsutake fresh seasoning material, which comprises the following components: mushroom powder, edible salt, apple powder, corn powder, carrot powder, cabbage powder, sea sedge powder and grosvenor momordica fruit powder, and the mushroom powder comprises tricholoma matsutake powder, shiitake mushroom powder, straw mushroom powder and pleurotus eryngii powder. The processing method comprises the following steps: S1, cleaning mushrooms, apples, corns, carrots and cabbage, performing dicing, carrying out vacuum freeze drying, respectively crushing thedried raw materials, grosvenor momordica fruits and sea sedge, performing uniform mixing according to a ratio, and performing sieving; S2, adding a proper amount of water into the sieved mixture, anduniformly performing stirring; S3, granulating the uniformly stirred materials by adopting a granulator to obtain granular materials; and S4, performing hot air drying on the granular materials by using drying equipment, and then performing screening so as to obtain the uniform granular seasoning. The selected raw materials are high in nutrient content, have a health-care effect and do not have side effects on bodies, and meanwhile, a hot air-vacuum freezing combined drying technology is adopted, so that nutrient loss is reduced.

Owner:苏州松鲜鲜食品科技有限公司

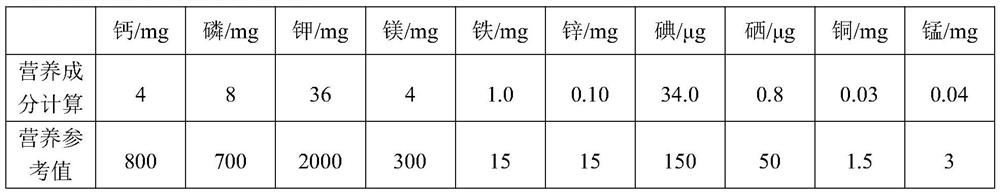

Urban sludge low-temperature hydrothermal carbonization coal production recycling system

PendingCN111875210AKill completelyHigh fuel value and environmentally friendlySludge treatment by pyrolysisChemical industryAutomatic controlProcess engineering

The invention discloses an urban sludge low-temperature hydrothermal carbonization coal production recycling system which greatly improves the combustion value of biochar and enhances the sludge incineration efficiency through a vacuum drying and squeezing system. A phosphorus recovery device is added to recover phosphorus in sewage and develop the additional value of phosphorus. The integrated system comprises a feeding system, a carbonization system, a heat exchange system, a discharging system, a dehydration system, a dosing system, a phosphorus recovery system, an automatic control systemand the like, and is characterized in that the excess sludge is converted into green fuel (charcoal), and phosphorus is recovered, so that the excess sludge is harmless, stable, reduced, recycled, economical and efficient. According to the technology, urban sludge low-temperature hydrothermal carbonization coal production recycling is provided, and sludge is pyrolyzed in an anaerobic environment to produce biochar. The biochar formed after hydrothermal carbonization and vacuum drying and squeezing is high in combustion value, environmentally friendly, high in resource utilization rate and remarkable in energy conservation.

Owner:四川欧美华环境工程有限公司

Cigarette/cigar filter tip stick prepared from natural materials

InactiveCN109363235ASolve the combustion will produce a lot of smoke,Solve the degradabilityCigarette manufactureTobacco smoke filtersFiberActivated carbon

The invention belongs to the technical field of tobaccos, and particularly relates to a cigarette / cigar filter tip stick prepared from natural materials. The cigarette / cigar filter tip stick is prepared from, by mass, 100-150 parts of active carbon granules, 60-90 parts of plant fibers, 110-140 parts of wheat, 50-80 parts of barley, 30-70 parts of corn, 40-60 parts of buckwheat, 10-40 parts of rice, 5-15 parts of sesame, 5-110 parts of a vegetable adhesive, 5-20 parts of a vegetable preservative, 30-150 parts of a plant fermentation agent and 10-25 parts of water. The problems are solved thatwhen an existing cigarette filter tip burns, a lot of smoke can be generated, and the filter tip is not easily degraded; through the cooperation of the natural materials and the active carbon, the filter tip stick is good in filter effect and high in environmental friendliness, and the cigarette / cigar filter tip stick achieves the effect of reducing the harm of the smoke to the human body.

Owner:陶祖岐

Garbage incinerator with furnace sealing combustion function

PendingCN109899804AIncreasing the thicknessLarge capacityIncinerator apparatusCombustion chamberFlue gas

The invention discloses a garbage incinerator with a furnace sealing combustion function, and belongs to the technical field of waste incineration equipment. The garbage incinerator solves the problemthat the combustion cost of the incinerator is relatively high due to the fact that the garbage incineration material layer in the existing garbage incinerator is relatively thin and does not need tobe stopped when no garbage is fed in the hearth. The equipment further comprises an isolating plate which is horizontally and fixedly arranged on the upper part of the inner side of the furnace body,the isolating plate is positioned above the spiral feeding devices, the furnace body is a vertical furnace body, the space above the isolation plate is a secondary combustion chamber, a spiral channel is arranged in the secondary combustion chamber in the vertical direction, a plurality of vent holes are vertically formed in the isolation plate, a flue gas inlet is formed in the bottom of the spiral channel, close to the flue gas inlet, of the side wall of the secondary combustion chamber, a flue gas outlet is formed in the top of the secondary combustion chamber, and the top of the spiral passage is communicated with the flue gas outlet.

Owner:上海多灵环保工程设备有限公司

Splicing type stool

InactiveCN105962671AEasy to disassembleEasy to set upDismountable chairsFoldable chairsMortise and tenonStructural engineering

The invention discloses a spliced stool, which comprises an upper stool frame, a lower stool frame, a support part and a stool surface, and the support part includes an upper support bar, a vertical insert block and a lower support bar; the upper end of the upper support bar is connected to the The upper stool frame is connected with mortise and tenon, the lower end of the upper support bar is connected with the upper end of the vertical insert block, the lower end of the vertical insert block is connected with the upper end of the lower support bar, and the lower support bar The lower end is connected with the lower stool frame by mortise and tenon; the stool surface is arranged on the upper part of the upper support bar, and the two ends of the stool surface are provided with handle holes. The overall stool surface is in the shape of a groove, and the stool surface There is a soft pad as a sitting surface on the top, a number of through holes are arranged on both ends of the upper stool frame and the lower stool frame, and there are holes between the two ends of the upper stool frame and the two ends of the lower stool frame. a hemp rope, and the hemp rope passes through the through hole. The invention has the advantages of simple structure, easy assembly, easy disassembly and assembly, convenient transportation, firm structure and beautiful appearance.

Owner:GUANGDONG UNIV OF TECH

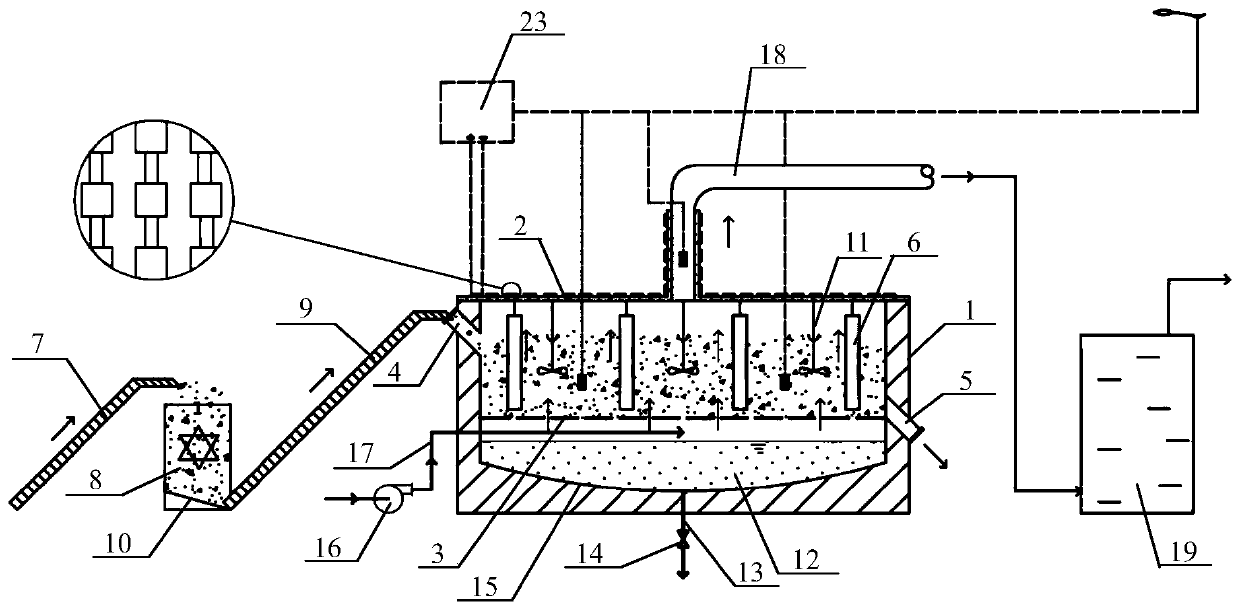

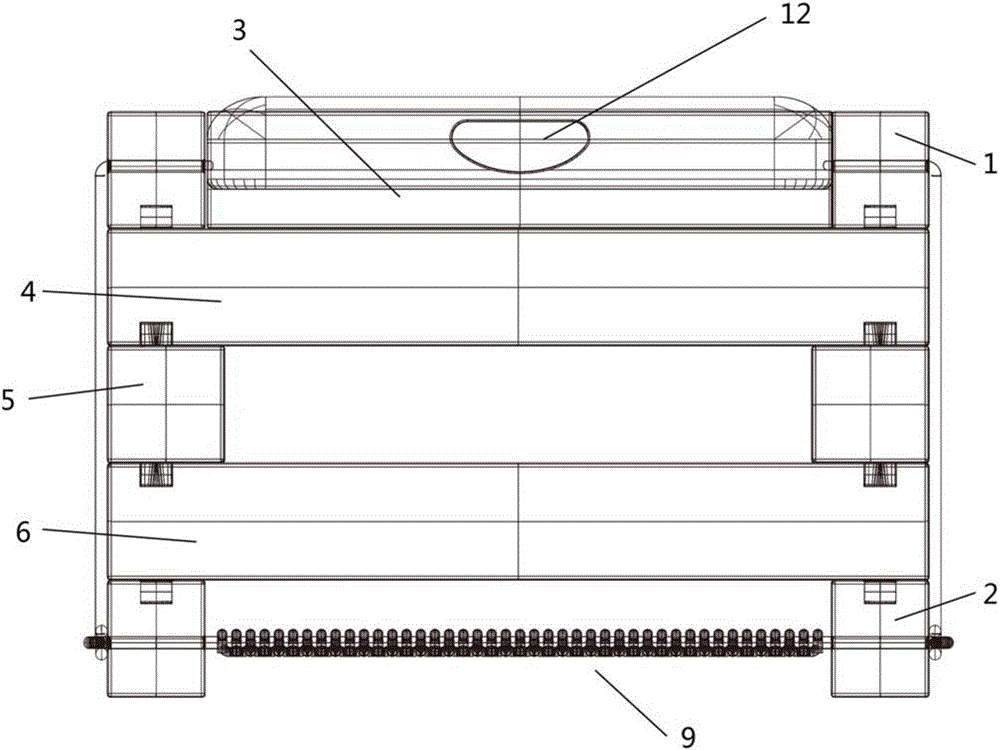

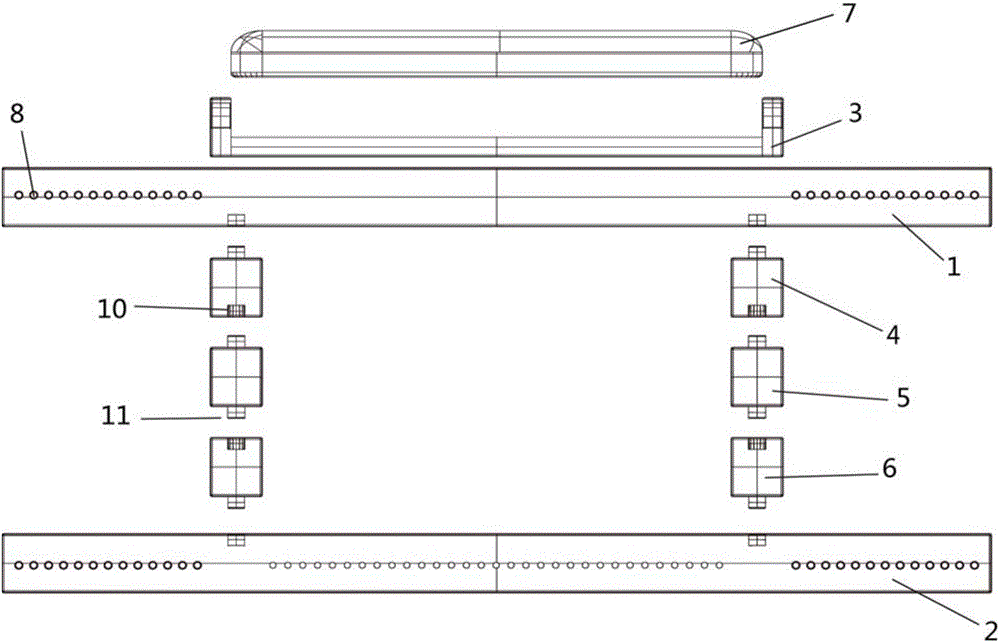

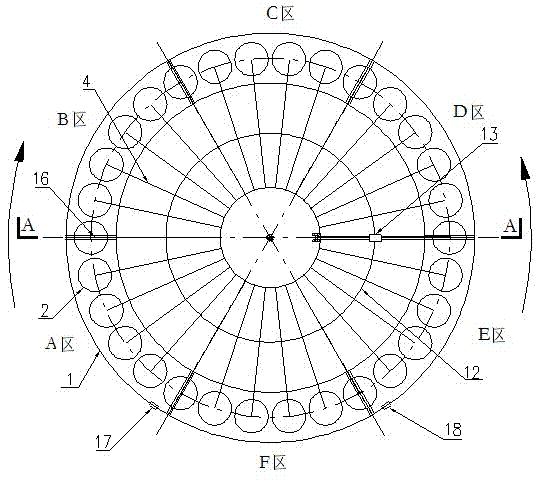

Automatic cleaning line for high-risk chemical containers

ActiveCN103191897BWash thoroughlyGuaranteed to be harmlessHollow article cleaningRotary stageAgricultural science

The invention discloses an automatic cleaning line for high-risk chemical containers and belongs to the technical field of cleaning machinery. A drive motor is used as a drive device. A hanging device comprises hangers, hanging arms, rail support rods, a rotary table, a circular rail and an ascent rail. The ascent rail and the circular rail form an integral rail. One end of each hanging arm is connected with the rotary table, and the other end of each hanging arm is connected with one hanger. The middle of each hanging arm is connected with the integral rail. The drive motor drives the hanging devices through a transmission device. A cleaning device comprises a circular cleaning tank, air mixing pipes, an air pump and more than two partitions. The partitions divide the circular cleaning tank into different areas. The air mixing pipes are mounted at the bottoms of the areas, and overflow occurs between each two areas, and the overflow is in the direction opposite to the rotation direction of the rotary table. The automatic cleaning line for high-risk chemical containers is mainly used for solving the environmental problem that the high-risk chemical containers not cleaned or not fully cleaned endanger life safety of human and livestock.

Owner:CHANGZHOU JINTAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Plasma desulfurization device and method

InactiveCN109718644AReduce manufacturing costEasy to useDispersed particle separationChemical reactionDecomposition

The invention belongs to the technical field of flue gas treatment, and particularly relates to a plasma desulfurization device and method. The plasma desulfurization device comprises an air inlet, anair outlet and a reaction container, wherein the reaction container is made of ceramic, the outer ring of the reaction container is provided with a wire, the wire is connected with a current as an alternating current, the reaction container is filled with a filler, and the filler is a mixture of sponge iron and quartz sand the plasma desulfurization method mainly comprises the following steps: agas source is introduced, the current is connected, hydrogen sulfide is removed and the gas source is discharged out, wherein when the hydrogen sulfide is removed, the hydrogen sulfide is subjected toionization decomposition under high-frequency oscillation of electromagnetic waves, and the hydrogen sulfide which is partially non-ionized into plasma reacts with the heated sponge iron to generateferric sulfide. The desulfurization device is simple in structure, is combined with a plasma desulfurization and precipitation desulfurization method for desulfurization, and is high in desulfurization efficiency, simple in equipment maintenance, long in service life and low in energy consumption.

Owner:JIANGSU HEHAI NEW ENERGY

Crusher with self-cleaning function

ActiveCN107511237ASimple materialExtended service lifeFireproof paintsAnti-corrosive paintsPulp and paper industryCrusher

The invention discloses a crusher with a self-cleaning function. The crusher is characterized in that a high pressure spray gun (with multiple nozzles) is placed on a working shaft to flush with an acid liquid or clean water, and the acid liquid or clean water and crushed materials together enter a reaction kettle directly for further treatment, so that a harmless link is guaranteed. In addition, the material of the crusher is also improved, so that the crusher is heat-resistant and corrosion-resistant and long in service life.

Owner:上海国龙生物技术集团有限公司

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333BLower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

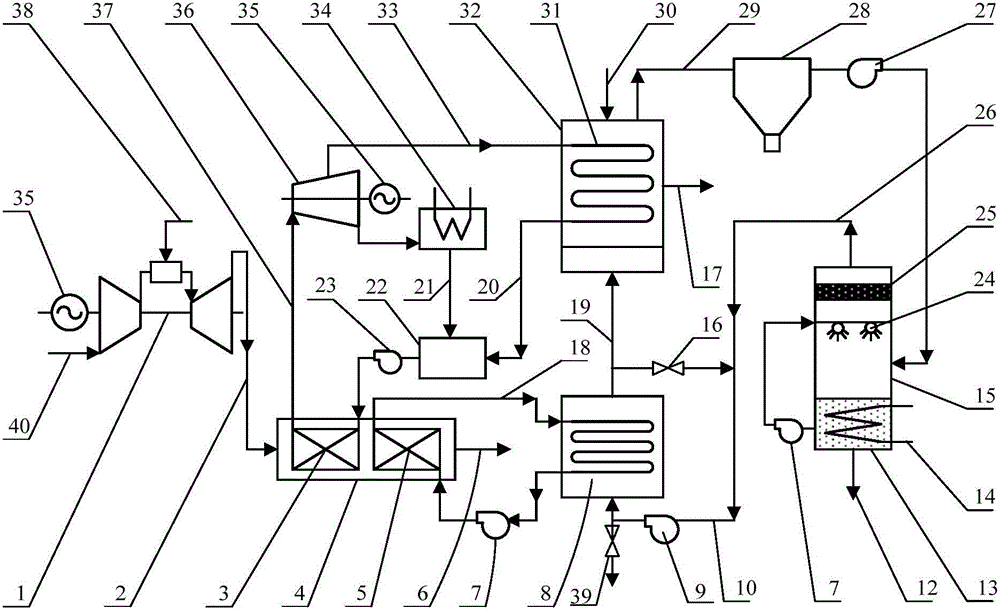

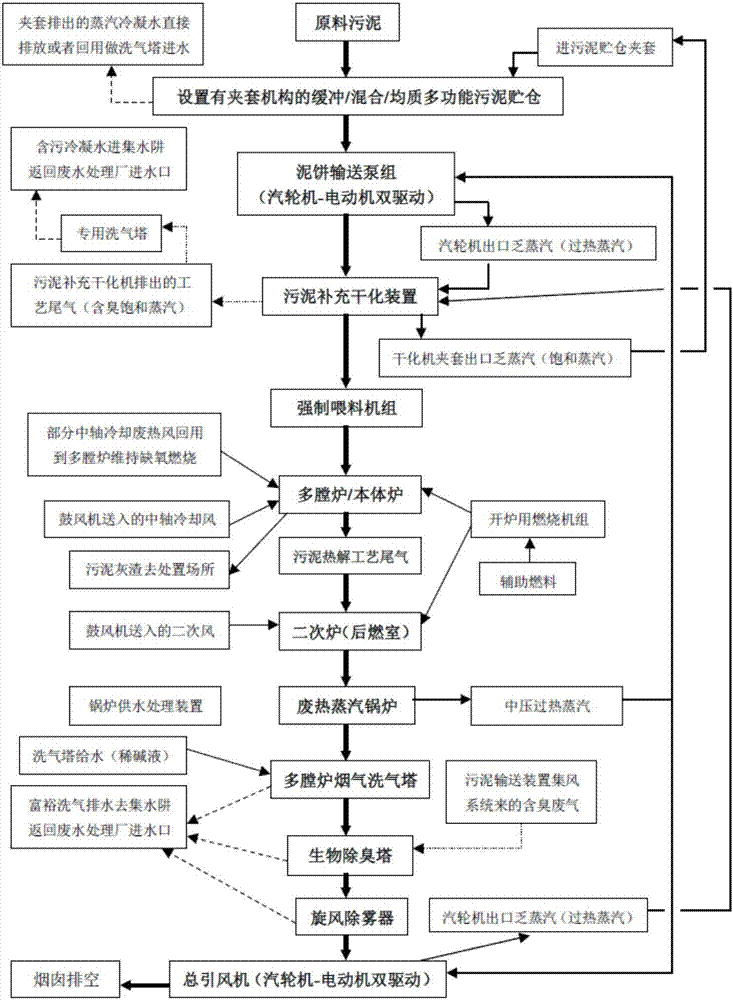

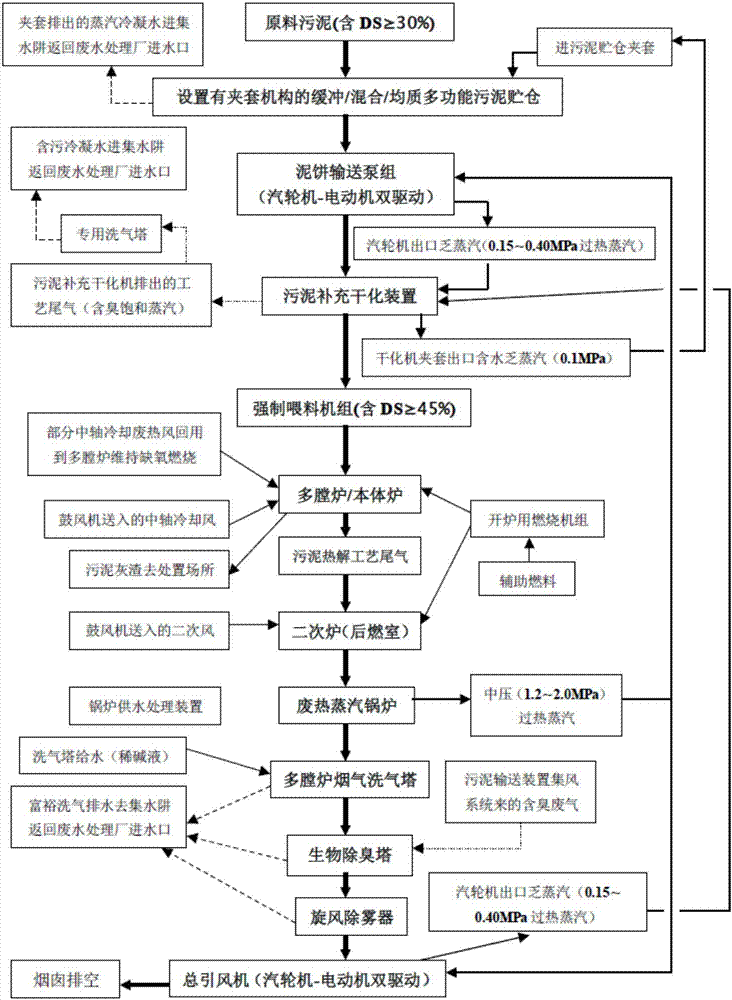

Comprehensive thermal energy utilization method for multi-hearth furnace sludge pyrolysis system

InactiveCN107473552AEnsure reductionEnsure stabilityCombination devicesSludge treatment by de-watering/drying/thickeningThermal energySludge

The invention discloses a comprehensive thermal energy utilization method for a multi-hearth furnace sludge pyrolysis system. The comprehensive thermal energy utilization method comprises the following steps: mixing and sufficiently combusting a pyrolysis process tail gas with secondary air blown by an air blower inside a secondary furnace, feeding high-temperature fume which is finally generated and comprises a small amount of dust type pollutants and trace acid gas components into a waste heat steam boiler, generating medium-pressure over-heated steam, feeding into a mud cake conveying pump group at the front end of a pyrolysis process and a main draft fan at the tail end of the pyrolysis process, and enabling the medium-pressure over-heated steam to directly drive the mud cake conveying pump group and a turbine in the main draft fan at the tail end of the process. According to the method, the thermal energy of the pyrolysis process tail gas and the high-temperature fume is recycled and utilized by using the waste heat steam boiler, the generated over-heated medium-pressure steam is applied to a turbine driving medium of a high-power electric appliance, a heat source medium of a sludge supplementing drying device, a heat-preservation / heating medium of a raw material sludge storage cabin and preparation solution / washing inlet water (hot water) of a scrubber tower in a gradient manner, and thus the comprehensive utilization efficiency of fume thermal energy is improved.

Owner:北京北宇机械设备有限公司

A pulverizer with self-cleaning function

ActiveCN107511237BGuaranteed to be harmlessSimple materialFireproof paintsAnti-corrosive paintsEngineeringCrusher

Owner:上海国龙生物技术集团有限公司

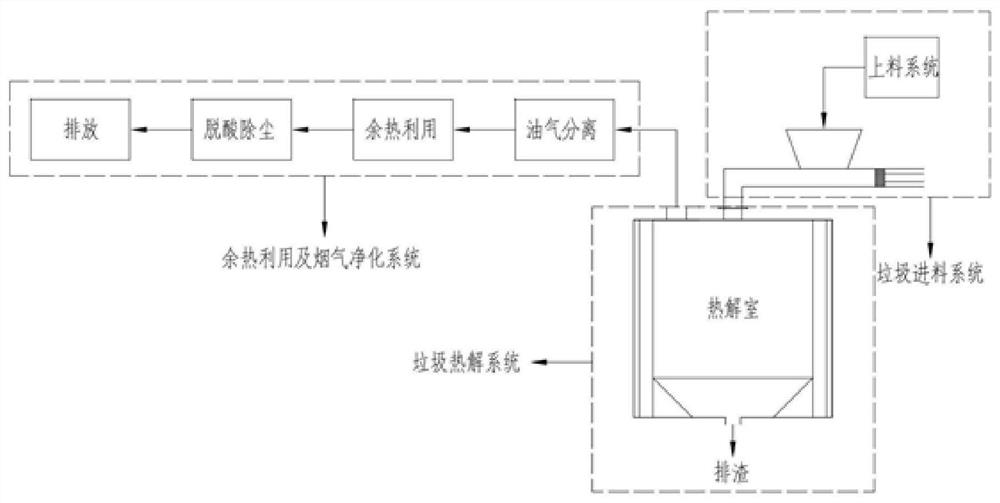

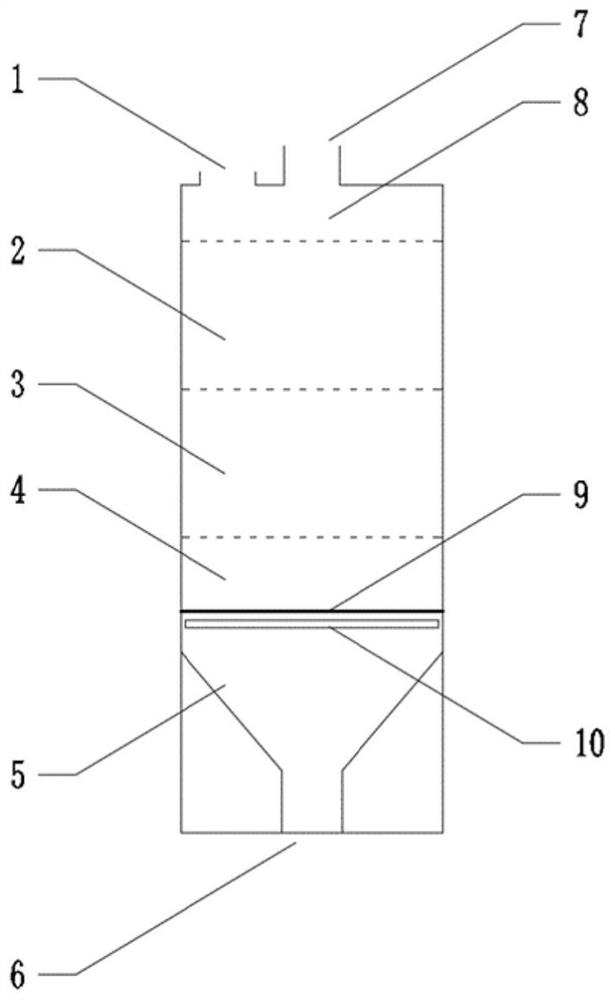

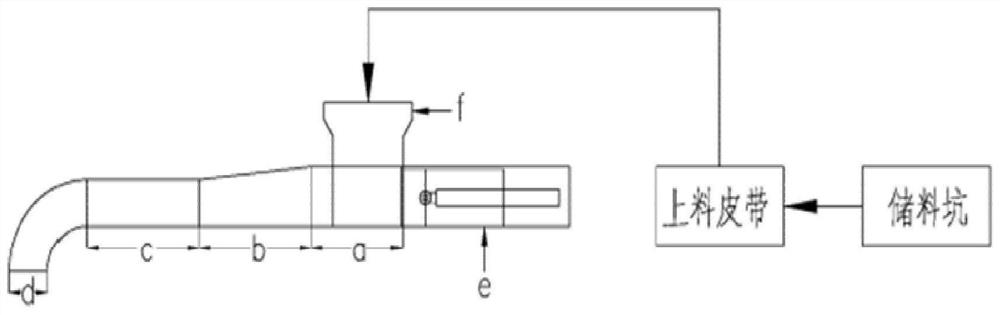

A gradient variable temperature pyrolysis system for domestic waste treatment

ActiveCN112628745BNo accumulation problemGuaranteed tightnessCombustion technology mitigationIncinerator apparatusThermodynamicsProcess engineering

The invention discloses a gradient variable temperature pyrolysis system for domestic waste treatment, which belongs to the technical field of solid waste harmless disposal, and includes a waste feeding unit, a waste pyrolysis unit, an oil-gas separation unit, a high-temperature oxidation unit, and a waste heat utilization unit , exhaust gas treatment unit and ash discharge unit, the garbage feeding unit is connected to the garbage pyrolysis unit, the main body of the garbage pyrolysis unit is a garbage pyrolysis and combustion integrated furnace, and the garbage pyrolysis and combustion integrated furnace is in the shape of a cylinder or a rectangle as a whole. The ratio of the height of the furnace cavity to the cross-sectional area is 1 to 2. The oil-gas separation unit is connected to the garbage pyrolysis unit, the high-temperature oxidation unit is connected to the oil-gas separation unit, the waste heat utilization unit is connected to the high-temperature oxidation unit, and the tail gas treatment unit is connected to the waste heat utilization unit. The slag discharge unit is connected to the slag discharge port of the garbage pyrolysis and combustion integrated furnace. The pyrolysis system of the present invention has the characteristics of being completely sealed, oxygen-free or oxygen-limited, odorless, reasonable in cloth, and automatically and rationally divided into functional areas.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD +2

Integrated breathing bag and manufacturing method thereof

ActiveCN102553044BPrevent air leakageSimplify the manufacturing processRespiratorsCoatingsAdhesiveEngineering

The invention discloses an integral type respiratory bag, comprising a hollow bag body and a joint which is arranged on a bag body connector, wherein a through hole on the joint is communicated with the inner part of the bag body. The integral type respiratory bag is characterized in that the bag body and the joint are integrally manufactured in a mould cavity by coating glue in a vibration manner, heating and molding. The invention further discloses a manufacturing method of the integral type respiratory bag. The bag body of the respiratory bag provided by the invention is manufactured in the glue vibration manner and thicker glue can be coated on a transition part between the side face and the bottom face of the bag body, so as to prevent fisheyes from being generated after the bag body is inflated. The respiratory bag provided by the invention is integrally molded and the joint does not need to be additionally arranged, so that the manufacturing procedure is simplified and the labor cost is reduced; viscose glue or adhesive does not need to be used for sticking so that the problem that the joint drops off due to poor sticking so as to cause air leakage is solved; and therefore, materials are saved and the production cost is reduced. With the adoption of the integral type respiratory bag provided by the invention, the phenomena of causing anaphylactic reaction of a human body and diffusing a pungent smell are avoided and no harm is caused to the human body.

Owner:广州晟威医疗器械有限公司

Biological organic fertilizer produced from abamectin fermentation waste residue and preparation method thereof

ActiveCN102786327BResource Utilization GuaranteeMaintain biological activityBio-organic fraction processingOrganic fertiliser preparationAbamectinField tests

The present invention provides a method for producing a biological organic fertilizer from abamectin fermentation waste residue. A main raw material of abamectin fermentation waste residue and auxiliary blending materials of straw and chicken manure are treated with aerobic fermentation; an abamectin residue degradation microbial inoculum is added during the aerobic fermentation process to help accelerating degradation of the abamectin residue, under high temperature, ventilating and aerobic conditions. Field tests show that the biological organic fertilizer prepared by the method provided by the invention can not only substitute a conventional biological organic fertilizer to be used in agricultural production, but also has obvious yield increasing effect, so as to realize harmlessness and resource utilization of the avermectin waste residue compost.

Owner:JINAN AGRI NEW FERTILIZER +1

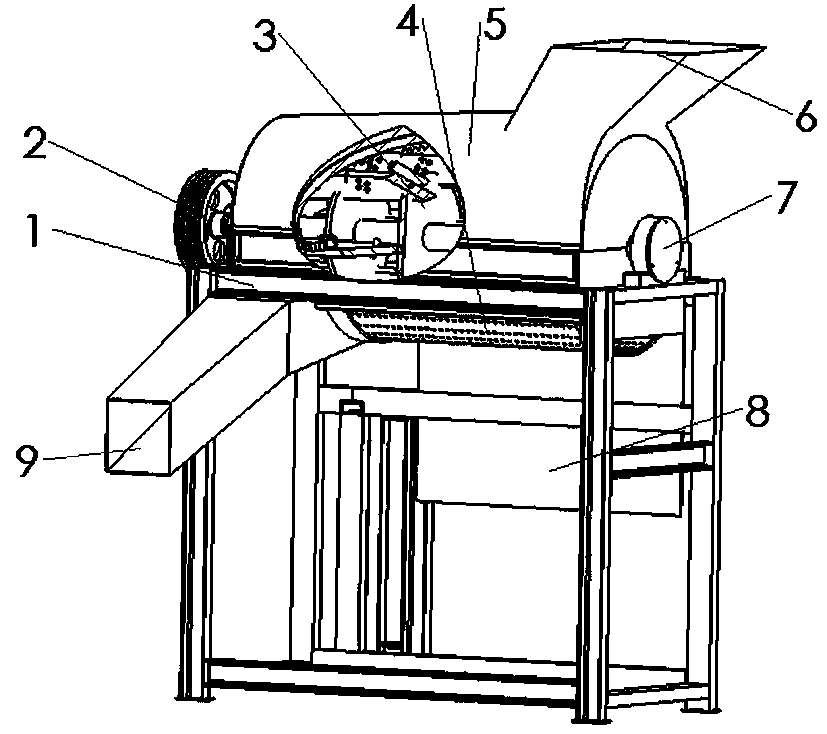

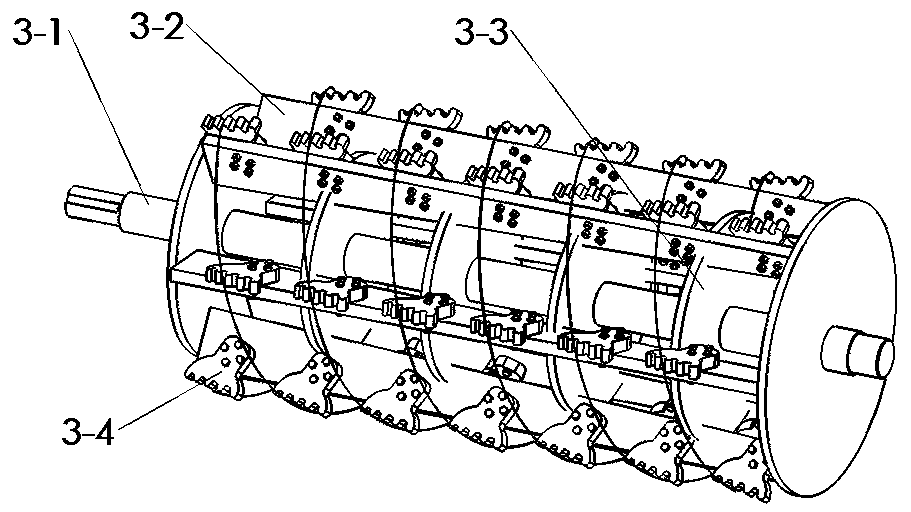

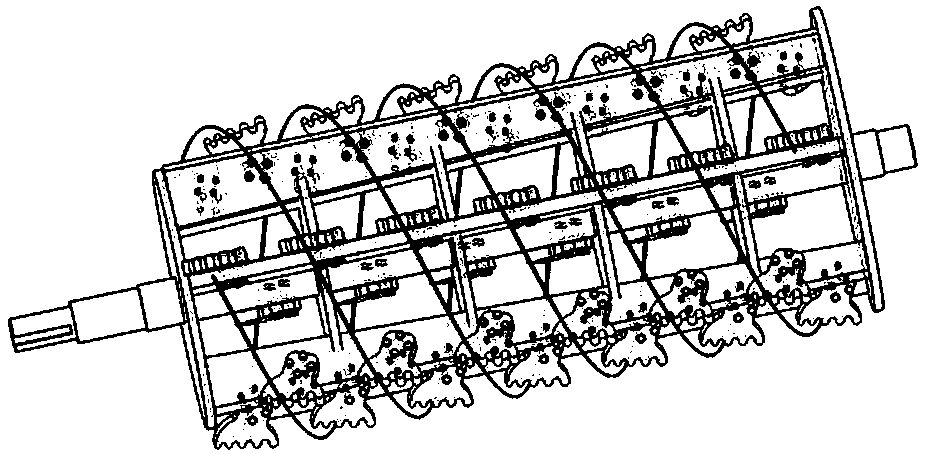

A bionic sorting machine for plastic waste

ActiveCN106696124BEfficient separationEliminates cleaning stepsPlastic recyclingEngineeringMechanical engineering

Owner:HENAN AGRICULTURAL UNIVERSITY

Hypersonic plif wind tunnel experiment method based on acetone tracer

ActiveCN107941454BImprove spatial resolutionHigh sensitivityAerodynamic testingExperimental methodsImage diagnosis

The invention relates to a hypersonic PLIF (Plane Laser Induced Fluorescence) wind tunnel experiment method based on acetone tracer. A hypersonic PLIF imaging diagnosis system based on acetone tracerincludes a laser source system, a sheet-shaped light beam shaping system, a PLIF image detection system and an acetone tracer supply system, and is characterized by taking the acetone as tracing particles, performing particle emission in the vacuum environment of a conventional hypersonic wind tunnel, obtaining a fluorescence signal of the acetone in the hypersonic flow field, applying the PLIF measurement technique to obtain a two-dimensional image of the hypersonic flow field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

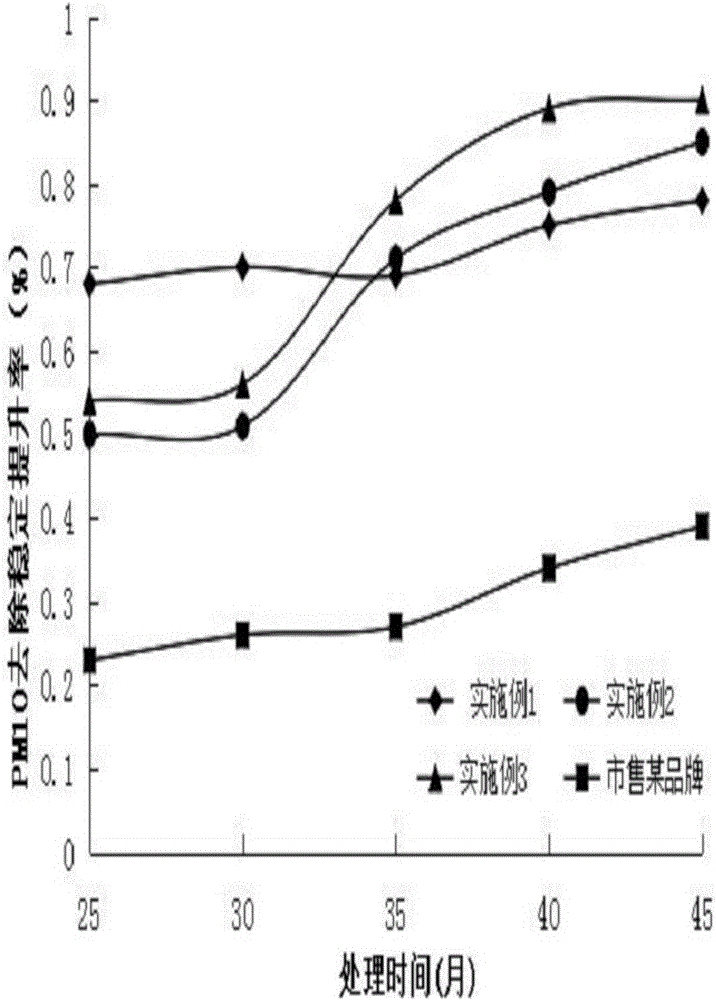

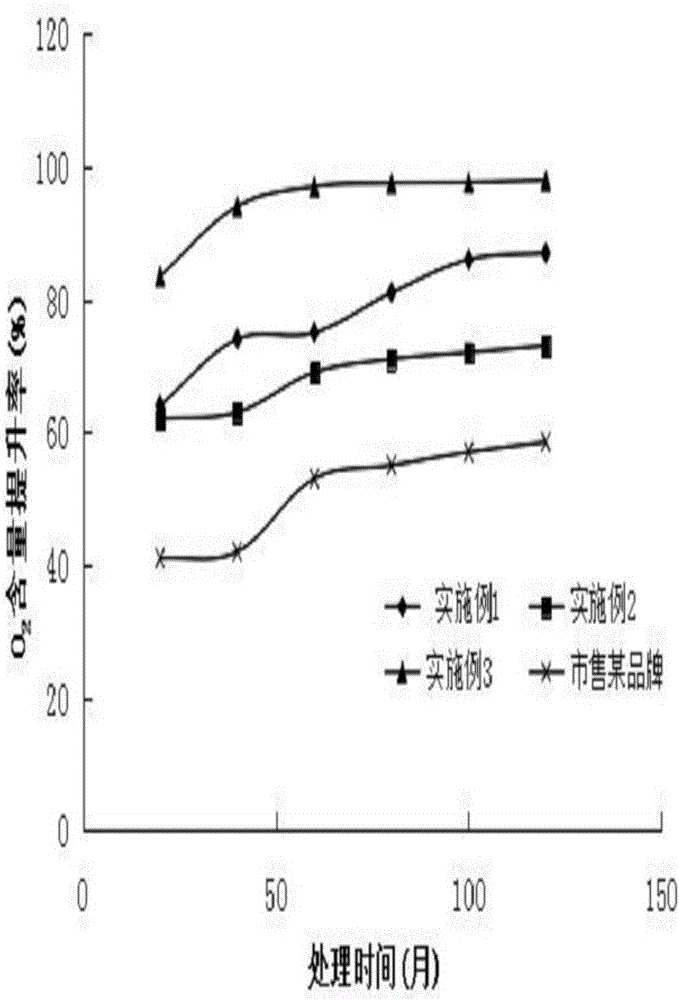

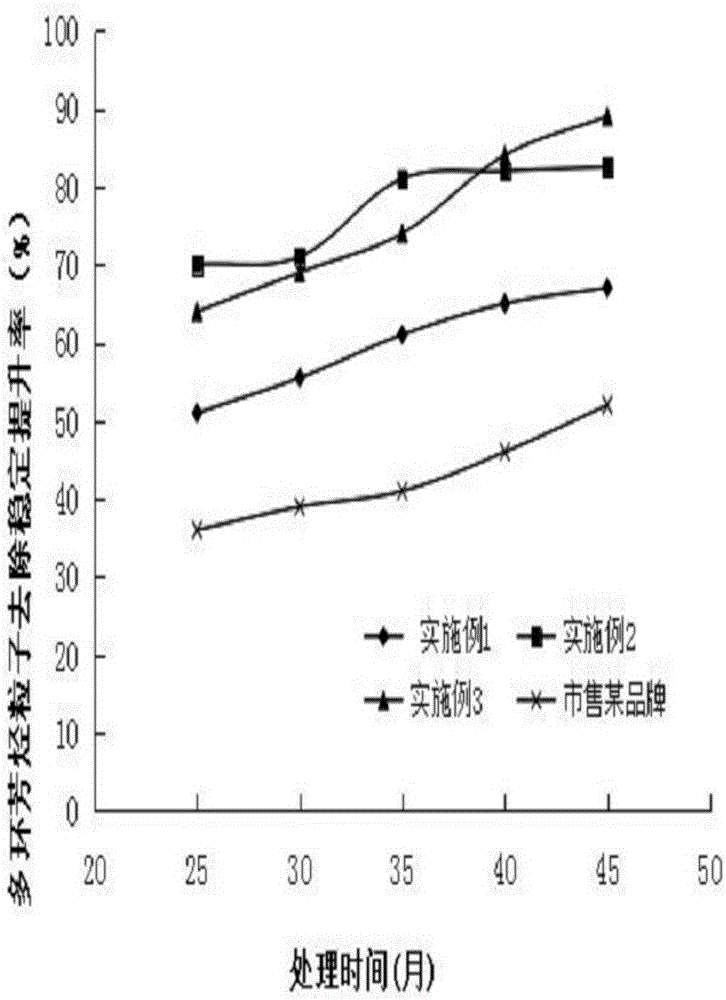

Cold cloud catalyst for spraying aerocolloid at high altitude and reducing fog and haze, and preparation method thereof

InactiveCN106824265AReduce surface tensionSimple structureOrganic-compounds/hydrides/coordination-complexes catalystsSilver iodideAutomatic control

The invention discloses a cold cloud catalyst for spraying aerocolloid at high altitude and reducing fog and haze, and a preparation method thereof. The cold cloud catalyst is prepared from the following components in parts by weight: purified lake water, silver iodide, sulfosuccinate, disodium mono(polyoxyethylene alkyl)sulfosuccinate, 3-amino-N,N-diethyl-4-methoxybenzenesulfonamide, 1-amino-4-hydroxyl-9,10-amerantrone, 1-amino-4-anilino-2-bromoanthraquinone, sodium dodecyl sulfate, copper nanoparticles, 4-bromo-1-amino anthraquinone-2-sulfonic acid, polyoxyethylene polyoxypropylene ether, 1-amino-2-anthraquinonecarboxylic acid, N-alkylbenzotriazole, 2-(6-methyl-2-benzothiazolylazo)-5-diethylamino-phenol and dialkyl sulfosuccinate. The cold cloud catalyst has the advantages that particulate pollutants are removed from the air by a new technology of performing low-tension and efficient purification on the air polluted by fog and haze, so that the particles are dispersed and absorbed; and the catalyst can reduce the surface tension, is simple in structure and convenient to operate, and can realize automatic control.

Owner:XUZHOU UNIV OF TECH

Process for producing biological bacterial fertilizer by taking domestic sewage plant dewatered sludge as raw material

InactiveCN102515886BResolve disposal issuesRich in organic nutrientsOrganic fertilisersWastewaterEngineering

The invention discloses a process for producing a biological bacterial fertilizer by taking domestic sewage plant dewatered sludge as a raw material. The process comprises the following steps of: mixing town domestic sewage plant dewatered sludge of which the sludge quality is consistent with the Disposal of Sludge from Municipal Wastewater Treatment Plant-Control Standard for Agricultural Use CJ-T309-2009 and the water content is 75-80 percent with a conditioning agent; performing high-temperature aerobic compost fermentation; screening and drying a compost finished product, and inoculating a special microbial strain; and pelletizing to obtain the biological bacterial fertilizer. The biological bacterial fertilizer produced with the process can be used for supplying a plenty of organic nutrients to crops, the nutrition absorption rates and disease resisting capabilities of crops are raised, remarkable yield increase of crops is realized, and the problem of sludge treatment of a large quantity of town domestic sewage plants is solved simultaneously.

Owner:浙江利保环境工程有限公司

Vehicular medical waste quick ashing system

ActiveCN102873081BRealize cleaner productionBurn fullySolid waste disposalIncinerator apparatusCombustion chamberCombustor

The invention relates to a vehicular medical waste quick ashing system. The vehicular medical waste quick ashing system comprises a medical waste ashing system and is characterized by comprising a loading vehicle, and the medical waste ashing system is arranged on a vehicle body. A square incinerator body is partitioned by a vertical guide baffle with an upper right opening into a first combustion chamber and a second combustion chamber in longitudinal parallel, a vertical guide baffle with a lower left opening is parallel to the vertical guide baffle with the upper right opening and arranged in the second combustion chamber to partition the second combustion chamber into two sub-chambers in longitudinal parallel, and combustors are arranged corresponding to the two sub-chambers of the vertical guide baffle with the lower left opening and the first combustion chamber. A smoke quenching tower and a desulfurization and purification device are set as a smoke quenching, desulfurization and purification integrated device which comprises the smoke quenching tower, a spraying desulfurization and purification tower, a cooling water tank and an alkali liquor tank. An exhaust chimney is a rotary up-and-down type exhaust chimey, and the system further comprises a power generator. The vehicular medical waste quick ashing system has the advantages of easiness in movement, capability of treating medical wastes anytime anywhere, prevention of environment pollution, and protection of people's physical health.

Owner:天津环科立嘉环境修复科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com