Household garbage treatment method and treatment system

A technology of domestic waste and treatment methods, applied in the field of domestic waste treatment methods and treatment systems, can solve problems such as difficult to burn garbage, difficult to refuse, reduce system temperature, etc., achieve elimination of harmful gases, reduce potential impact, and facilitate decomposition and combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

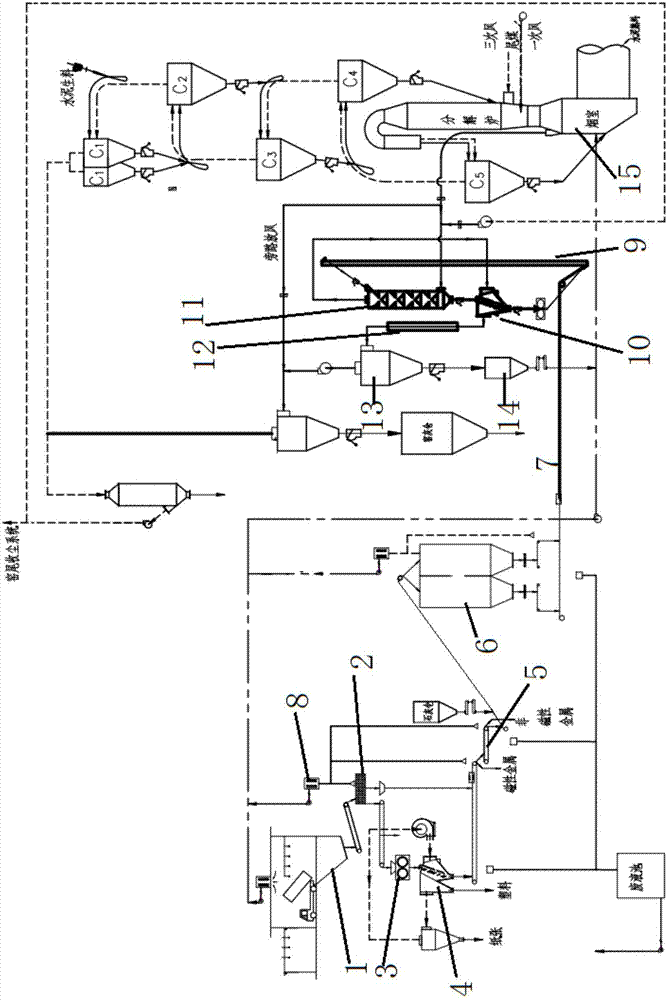

[0065] like figure 1 As shown, the present invention provides a domestic waste treatment system, including a closed pretreatment station, a drying and grinding system and a cement kiln;

[0066] The closed pretreatment station is provided with a garbage storage pit 1, a drum type bag breaking screener 2, a double-shaft shredder 3, a pneumatic separator 4, a magnetic separation and an eddy current separator 5 in sequence according to the waste treatment process. , storage 6 and conveyor 7; the discharge port of the garbage storage pit 1 is connected with the feed port of the drum type bag breaking screener 2; the discharge port of the drum type bag breaking screen machine 2 is connected to the double shaft The feed port of the shredder 3 is connected; the discharge port of the biaxial shredder 3 is connected to the feed port of the pneumatic separator 4, and the discharge port of the pneumatic separator 4 is connected to the magnetic separation and vortex separator. The feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com