VOC catalyst characterized by ordered arrangement of composite metal oxide and ferroferric oxide, and preparation method thereof

A technology of ferroferric oxide and composite metals, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problems of large space and low resource utilization , to achieve the effects of simple process flow, reduced operating costs, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

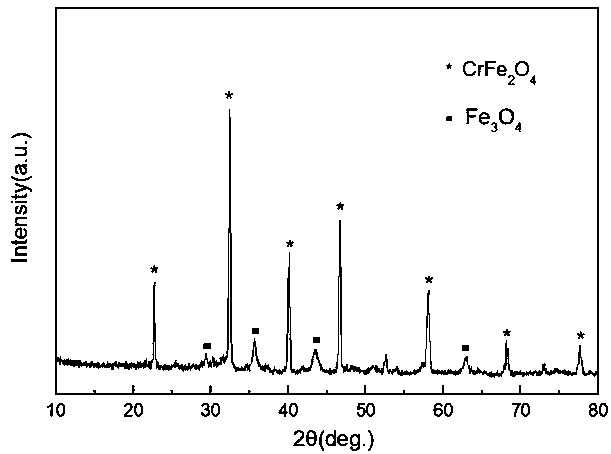

[0024] A method for synthesizing composite metal oxides using chromium-containing electroplating sludge, wherein the content of Cr element is 25.40g / 100g, and the content of iron element in iron-containing electroplating sludge is 23.16 g / 100g, comprising the following steps:

[0025] a. Prepare 0.2mol / L glacial acetic acid solution and 0.1mol / L citric acid solution, mix these two solutions 1:1, mix to make reagent a, and then prepare 0.025mol / L potassium sodium tartrate solution and 0.01mol / L The ethylenediaminetetraacetic acid solution was mixed according to the ratio of 1:2 to make reagent b, and then absolute ethanol was added to make the structure forming agent.

[0026] b. Take 5g of chromium-containing electroplating sludge and mix it with 50ml of structure-forming agent to prepare composite metal oxide embryo body.

[0027] c. Weigh 7.5g of iron-containing electroplating sludge, and prepare 0.125mol / L sodium carbonate solution, 0.05mol / L sodium sulfite solution, mix th...

Embodiment 2

[0030] A method for synthesizing composite metal oxides using nickel-containing electroplating sludge, wherein the content of Ni element is 24.18g / 100g, and the iron content of iron-containing electroplating sludge is 23.16 g / 100g, comprising the following steps:

[0031] a. Prepare 0.25mol / L glacial acetic acid solution and 0.1mol / L citric acid solution, mix these two solutions 1:1.5, mix to make reagent a, and then prepare 0.04mol / L potassium sodium tartrate solution and 0.02mol / L The ethylenediaminetetraacetic acid solution was mixed according to the ratio of 1:1 to make reagent b, and then absolute ethanol was added to make the structure forming agent.

[0032] b. Take 10g of copper-containing electroplating sludge and mix it with 100ml of structure-forming agent to prepare composite metal oxide embryo body.

[0033] c. Weigh 15g of iron-containing electroplating sludge, and prepare 0.75mol / L sodium carbonate solution, 0.05mol / L sodium sulfite solution, mix the above two s...

Embodiment 3

[0036] A method for synthesizing composite metal oxides using copper-containing electroplating sludge, wherein the content of Cu element is 39.84g / 100g, and the iron content of iron-containing electroplating sludge is 23.16 g / 100g, comprising the following steps:

[0037] a. Prepare 0.2mol / L glacial acetic acid solution and 0.1mol / L citric acid solution, mix these two solutions 1:1, mix to make reagent a, and then prepare 0.025mol / L potassium sodium tartrate solution and 0.01mol / L The ethylenediaminetetraacetic acid solution was mixed according to the ratio of 1:1 to make reagent b, and then absolute ethanol was added to make the structure forming agent.

[0038] b. Take 5g of copper-containing electroplating sludge and mix it with 50ml of structure forming agent to prepare composite metal oxide embryo body.

[0039] c. Weigh 7.5g of iron-containing electroplating sludge, and prepare 0.1mol / L sodium carbonate solution and 0.05mol / L sodium sulfite solution, and mix the above tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com