Automatic cleaning line for high-risk chemical containers

An automatic cleaning and production line technology, which is applied in the direction of chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the unsatisfactory cleaning effect of chemical packaging barrels, can not meet the needs of cleaning of packaging barrels, and the residue of chemical packaging barrels. To avoid problems such as large toxic substances, to achieve the effect of automatically overcoming obstacles, avoiding social environmental protection problems, and avoiding the safety of human and animal life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

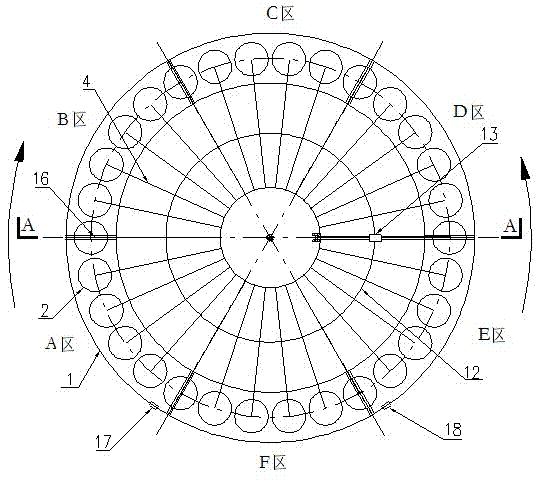

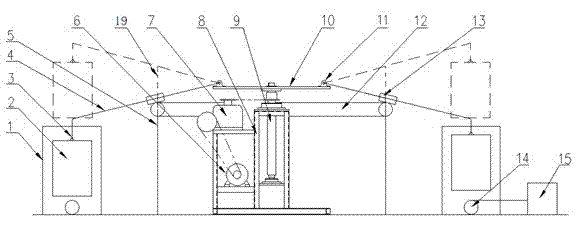

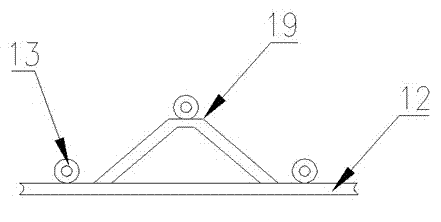

[0031] combine figure 1 , figure 2 and image 3 , a high-hazard chemical container automatic cleaning production line of the present embodiment includes a driving device, a transmission device, a suspension device and a cleaning device, wherein: the driving device includes a driving motor 6, the driving device is connected with the transmission device, and the power of the driving motor 6 is 0.75kW. Such as figure 2 As shown, the transmission device includes a speed reducer 7, a drive main shaft 9 and a rotary table 10. The transmission mode of the drive motor 6 and the speed reducer 7 is a chain drive, and the drive motor 6 drives the input shaft of the speed reducer 7 to rotate through a sprocket wheel and a chain. After the three-stage speed change of the reducer 7, the output shaft of the reducer 7 drives the drive main shaft 9 to rotate through belt transmission or gear transmission, so that the entire transmission device operates stably and reliably. Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com