Peeling-cleaning all-in-one machine for green walnuts

A green walnut and all-in-one machine technology is applied in the field of green walnut peeling and cleaning all-in-one machines, which can solve the problems that manual peeling cannot adapt to large-scale production and sales, poor working environment, and high labor intensity, and improve peeling and cleaning. Effect, good cleaning effect, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

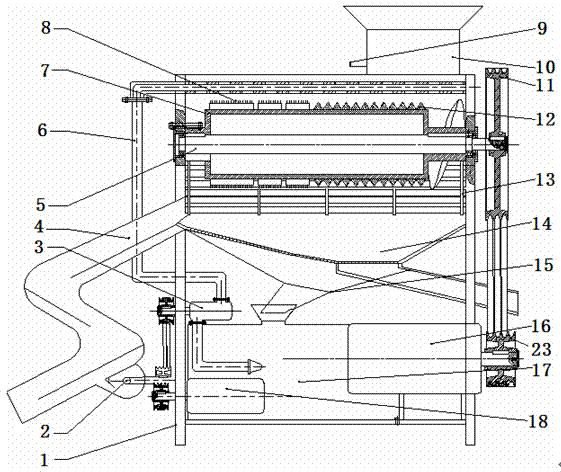

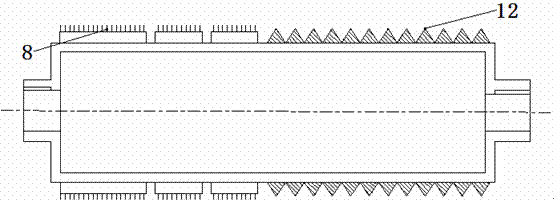

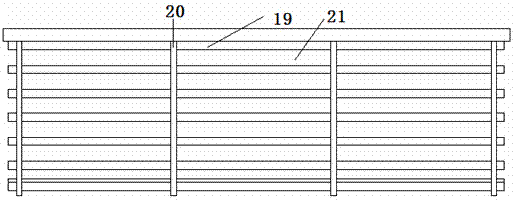

[0023] Embodiment 1: as Figure 1-4 As shown, a green walnut peeling and cleaning integrated machine includes a peeling device, a cleaning device for removing impurities, and a drying device; the peeling device includes a frame 1, a central spindle 5, a peeling cylinder 7, and a feed port 10 , concave plate sieve 13, first motor 16; the upper end of the body of the green walnut peeling and cleaning all-in-one machine is provided with a feed port 10, and the middle of the green walnut peeling and cleaning all-in-one machine body frame 1 is provided with a central main shaft 5, and a central main shaft 5 There is a peeling drum 7 on the top, on the peeling drum 7 there are conical teeth 12 and hair brushes 8, and a concave screen 13 is installed on the lower part of the peeling drum 7 to separate walnuts from green skins. It is a horizontal sieve bar 19 and a radial sieve bar 20, and a sieve hole 21 is formed between the horizontal sieve bar 19 and the radial sieve bar 20 for le...

Embodiment 2

[0026] Embodiment 2: as Figure 1-4 As shown, a green walnut peeling and cleaning integrated machine includes a peeling device, a cleaning device for removing impurities, and a drying device; the peeling device includes a frame 1, a central spindle 5, a peeling cylinder 7, and a feed port 10 , concave plate sieve 13, first motor 16; the upper end of the body of the green walnut peeling and cleaning all-in-one machine is provided with a feed port 10, and the middle of the green walnut peeling and cleaning all-in-one machine body frame 1 is provided with a central main shaft 5, and a central main shaft 5 There is a peeling drum 7 on the top, on the peeling drum 7 there are conical teeth 12 and hair brushes 8, and a concave screen 13 is installed on the lower part of the peeling drum 7 to separate walnuts from green skins. It is a horizontal sieve bar 19 and a radial sieve bar 20, and a sieve hole 21 is formed between the horizontal sieve bar 19 and the radial sieve bar 20 for le...

Embodiment 3

[0030] Embodiment 3: as Figure 1-4 As shown, a green walnut peeling and cleaning integrated machine includes a peeling device, a cleaning device for removing impurities, and a drying device; the peeling device includes a frame 1, a central spindle 5, a peeling cylinder 7, and a feed port 10 , concave plate sieve 13, first motor 16; the upper end of the body of the green walnut peeling and cleaning all-in-one machine is provided with a feed port 10, and the middle of the green walnut peeling and cleaning all-in-one machine body frame 1 is provided with a central main shaft 5, and a central main shaft 5 There is a peeling drum 7 on the top, on the peeling drum 7 there are conical teeth 12 and hair brushes 8, and a concave screen 13 is installed on the lower part of the peeling drum 7 to separate walnuts from green skins. It is a horizontal sieve bar 19 and a radial sieve bar 20, and a sieve hole 21 is formed between the horizontal sieve bar 19 and the radial sieve bar 20 for le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com