Patents

Literature

190results about How to "Does not rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

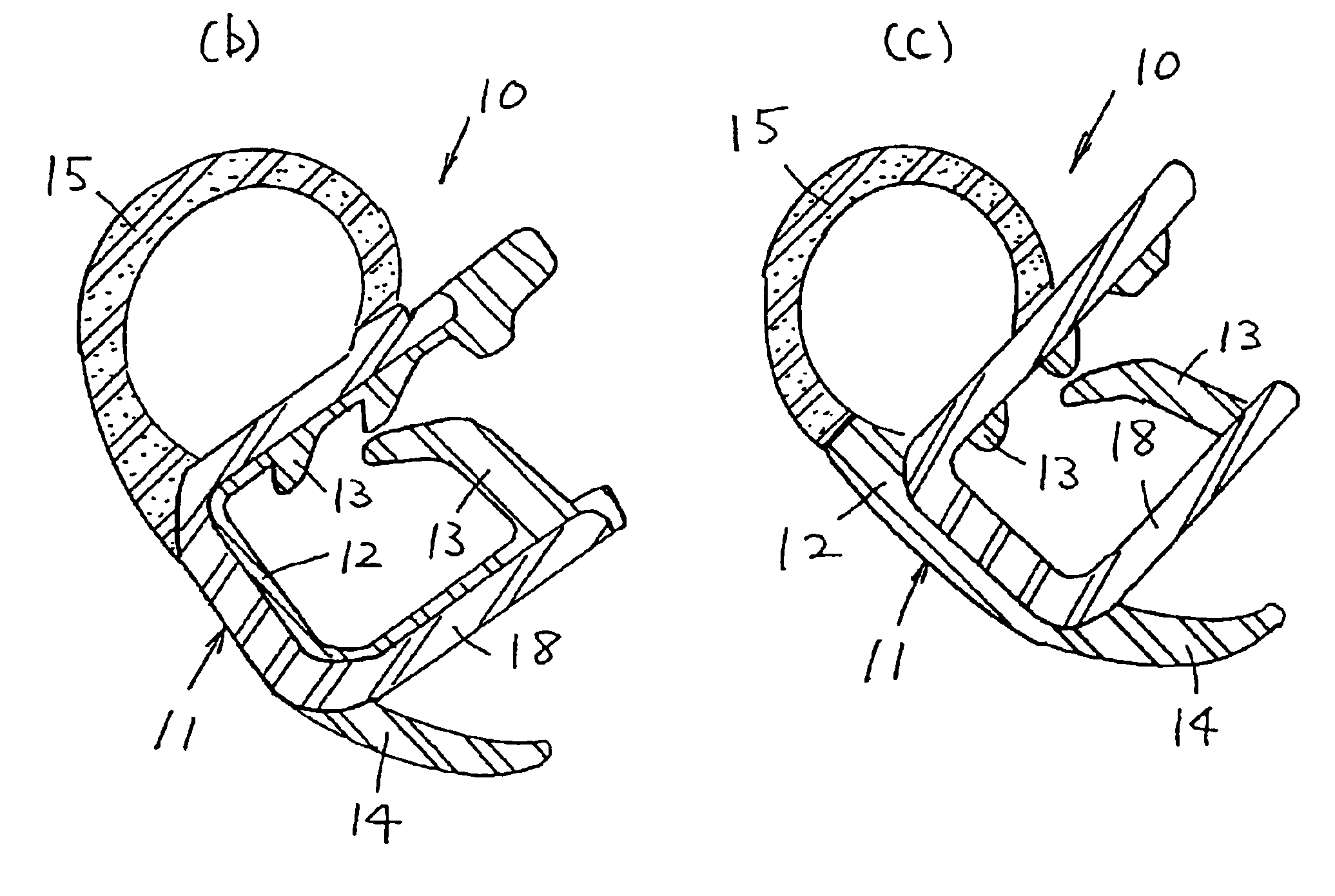

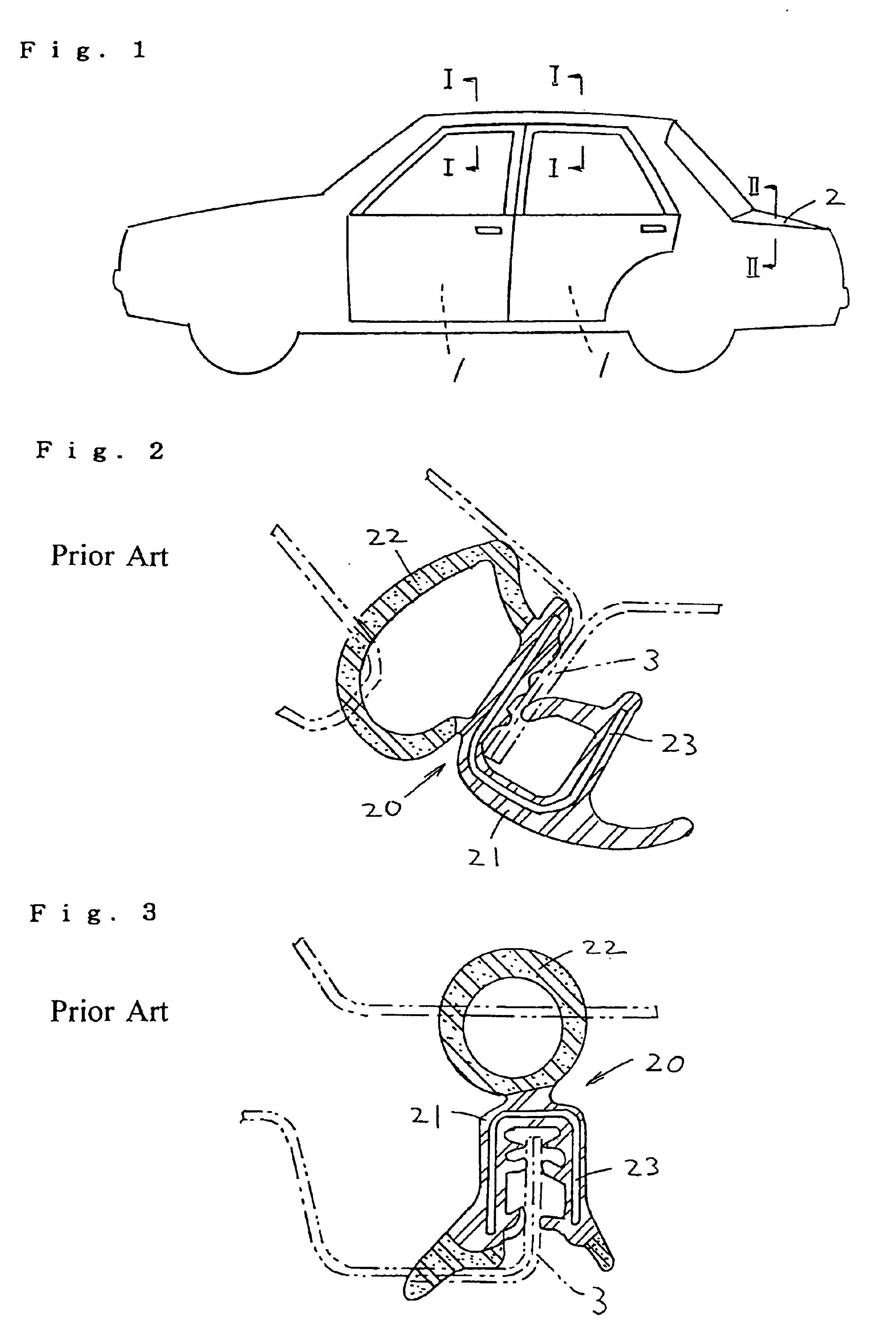

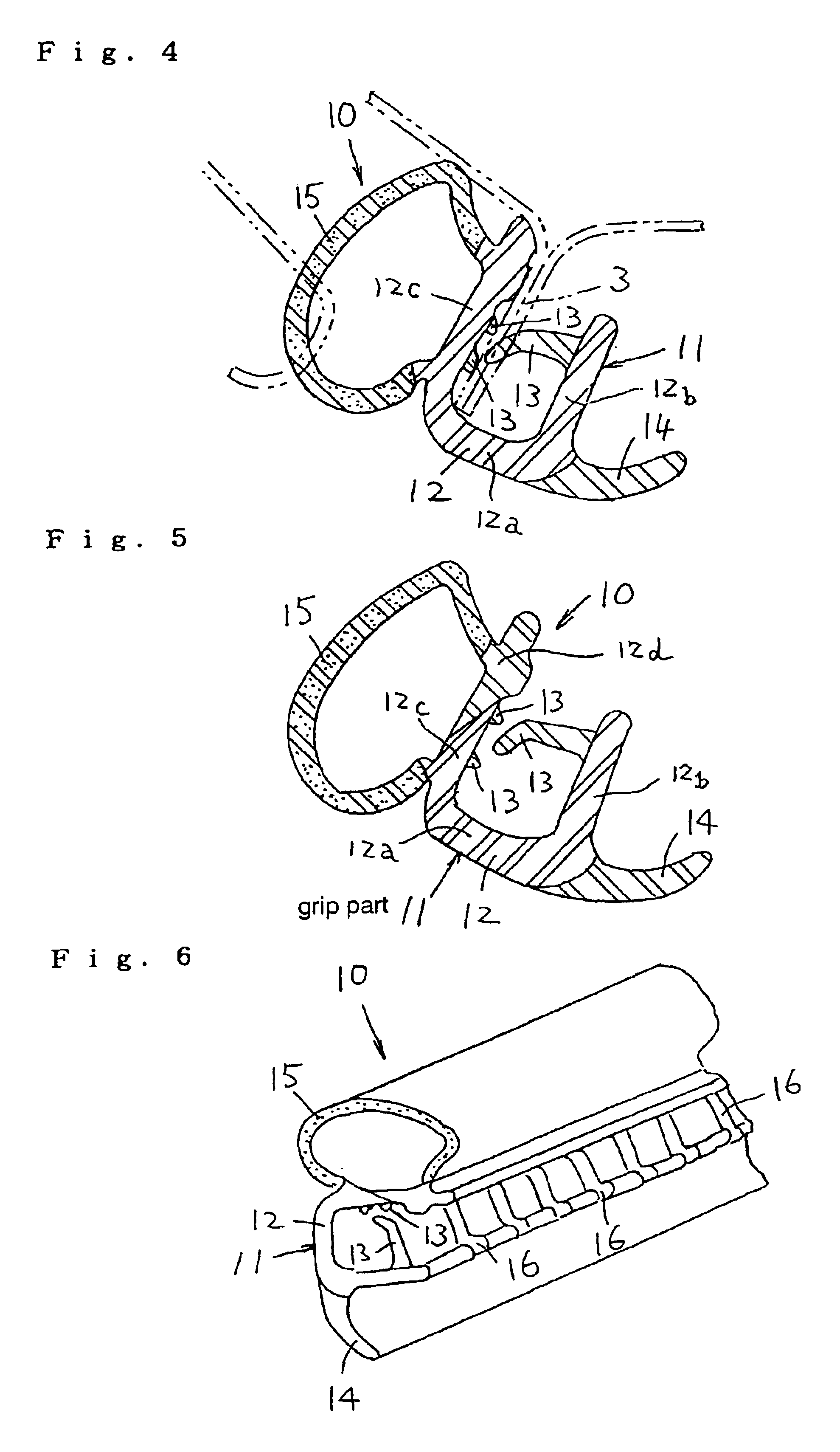

Weather strip for car without metal insert

ActiveUS6874281B2Increase production capacityImprove securityEngine sealsSuperstructure subunitsEngineeringHardness

There is provided a weather strip for a car without a metal insert which comprises a grip part having a U-shaped grip body in section and a seal part integrally molded to the outer surface of the grip part. The weather strip is installed to a flange provided to a door opening, a trunk portion and the like. The grip body is unprovided with a metal insert, and, at least, the bottom wall and the inner wall of the grip part is made of highly hardened rubber or resin having a hardness of more than Hs 90 degree.

Owner:NISHIKAWA RUBBER

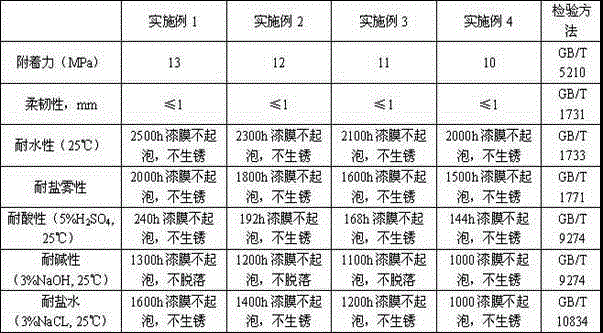

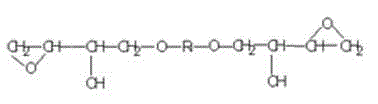

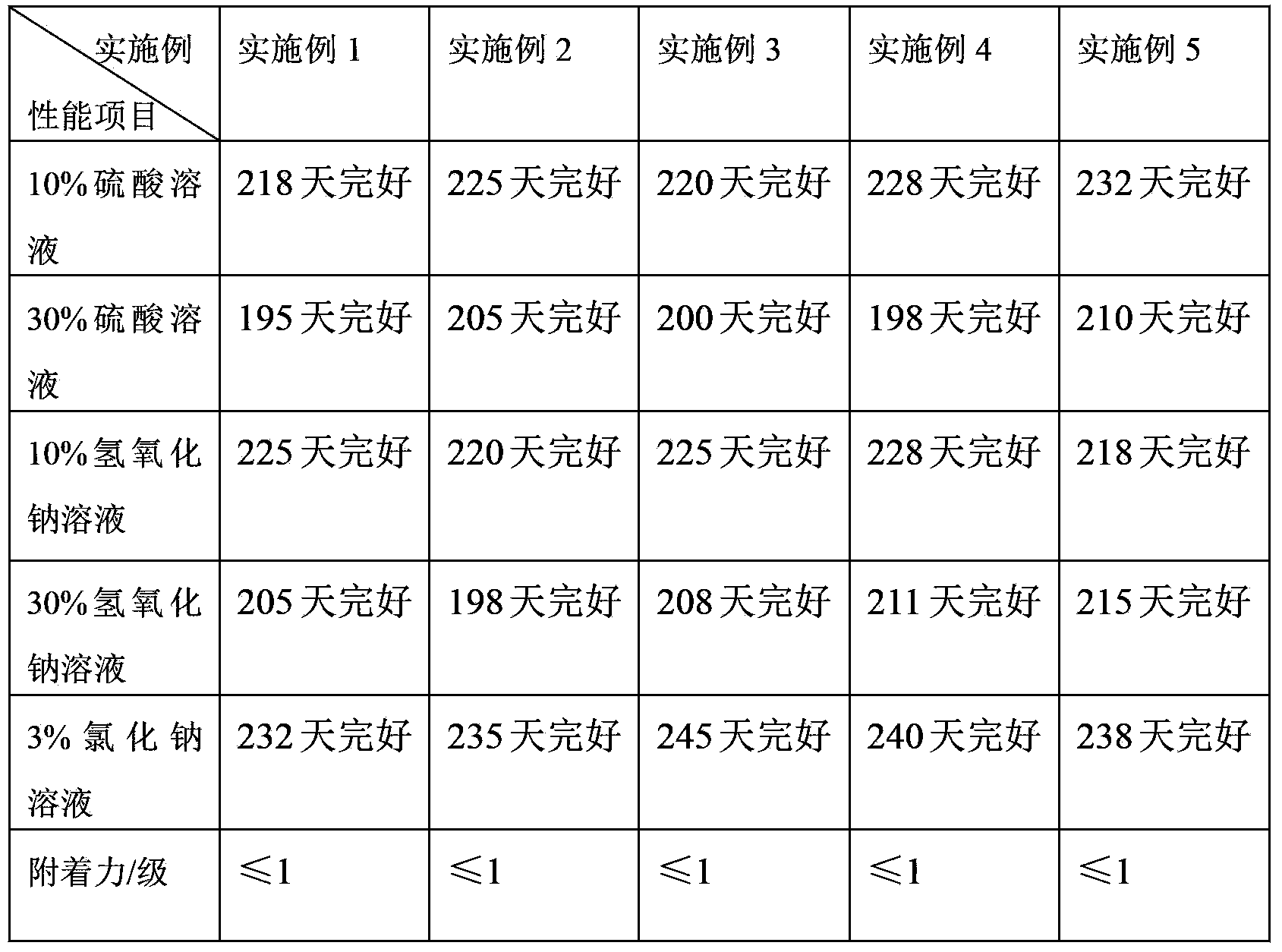

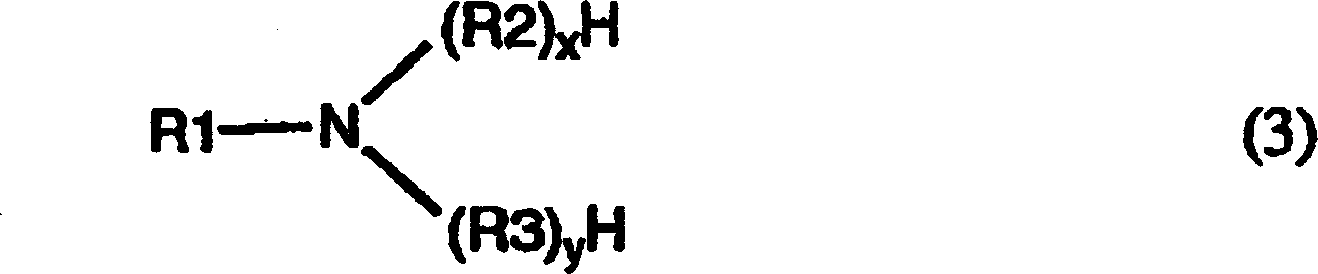

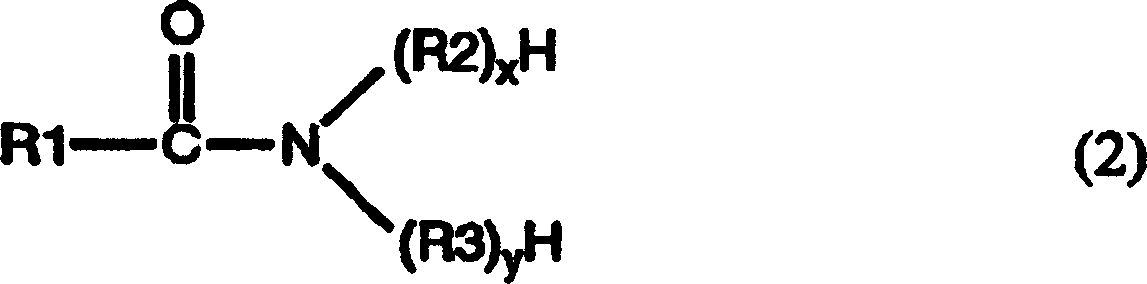

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

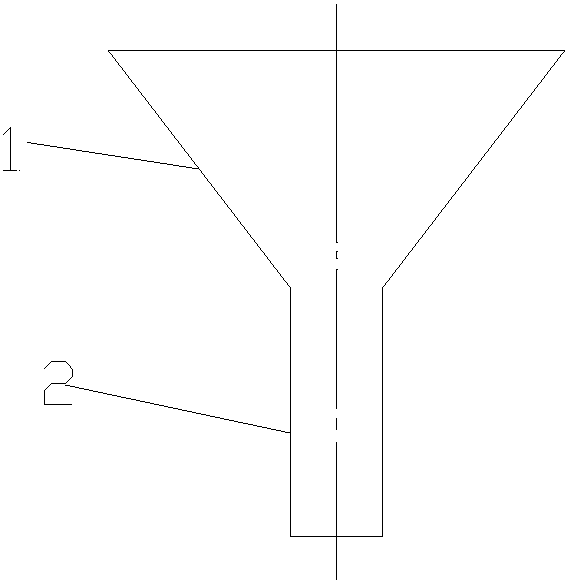

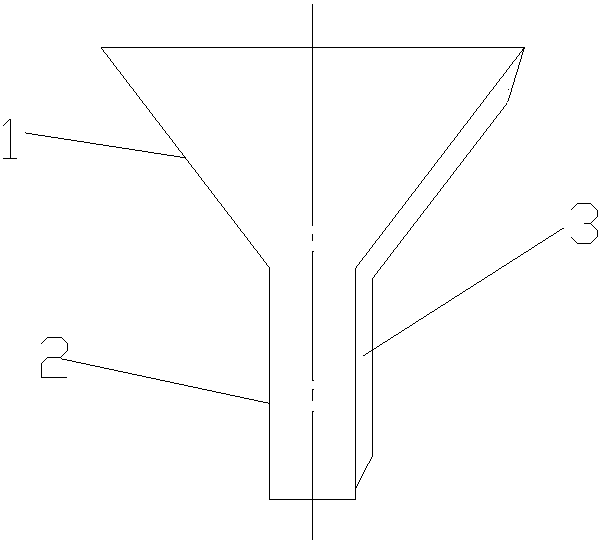

Method for producing plastic pipe fitting with insert made from polyphenylene sulfide alloy material

The invention relates to a method for making a plastic pipe with an insert made from a PPS alloy material. Materials such as PPS, nylon, etc. are treated with steps of blending, extrusion, strip stretching, cooling, pelletizing, homogenization, injection molding, etc. so as to obtain the plastic pipe with the insert made from the PPS alloy material. The making method of the invention has simple and easy technique; the alloy material has the advantages of small specific weight, good heat and corrosion resistance as well as good dimensional stability; in addition, the obtained pipe has good sealing, high notched impact strength, etc. The plastic pipe provided by the invention has wide range of application and can be applicable to water supply and drainage systems and drinking water pipe systems, gas transmission systems and industrial pipe systems, heating systems and agricultural pipe systems.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

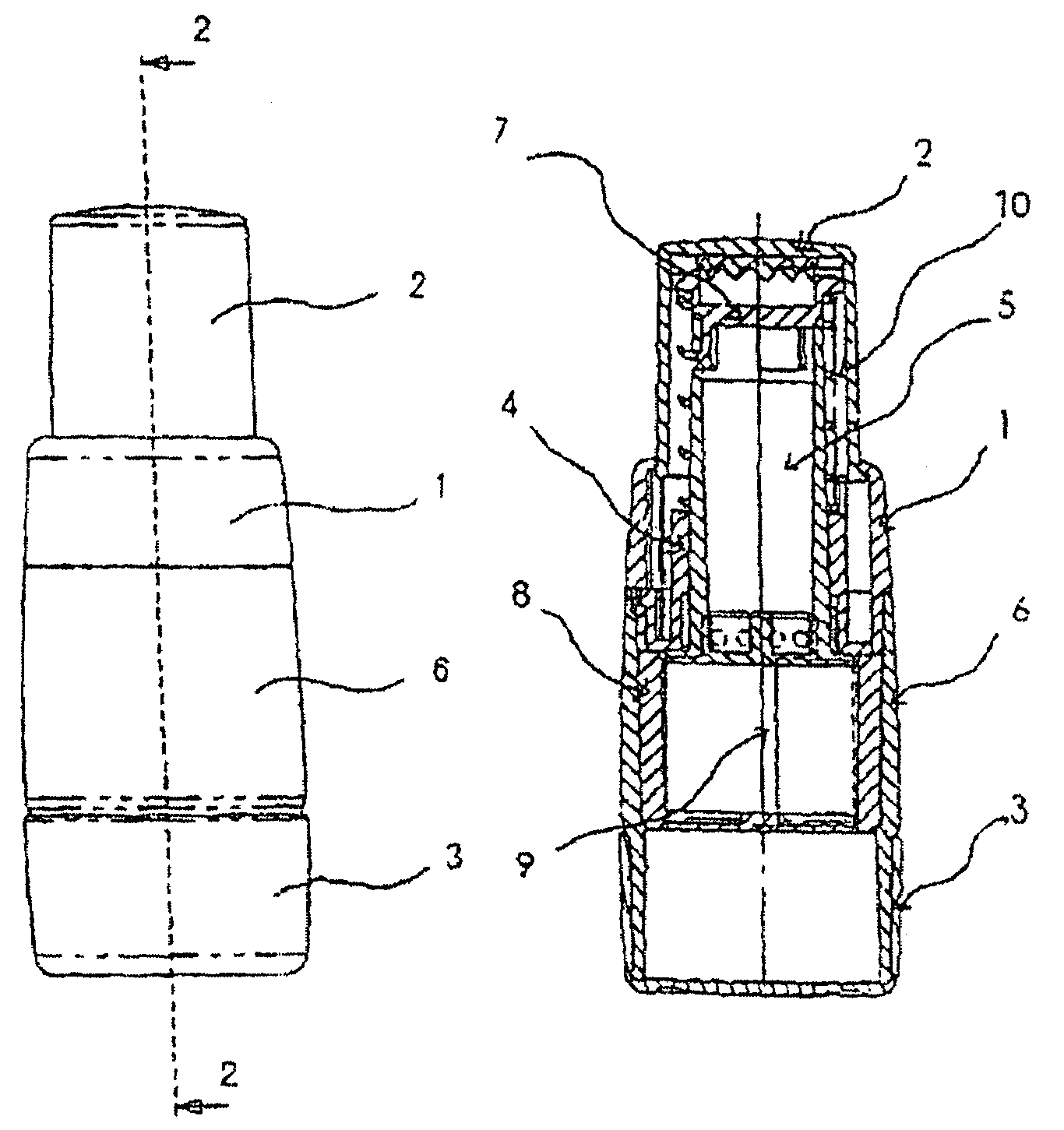

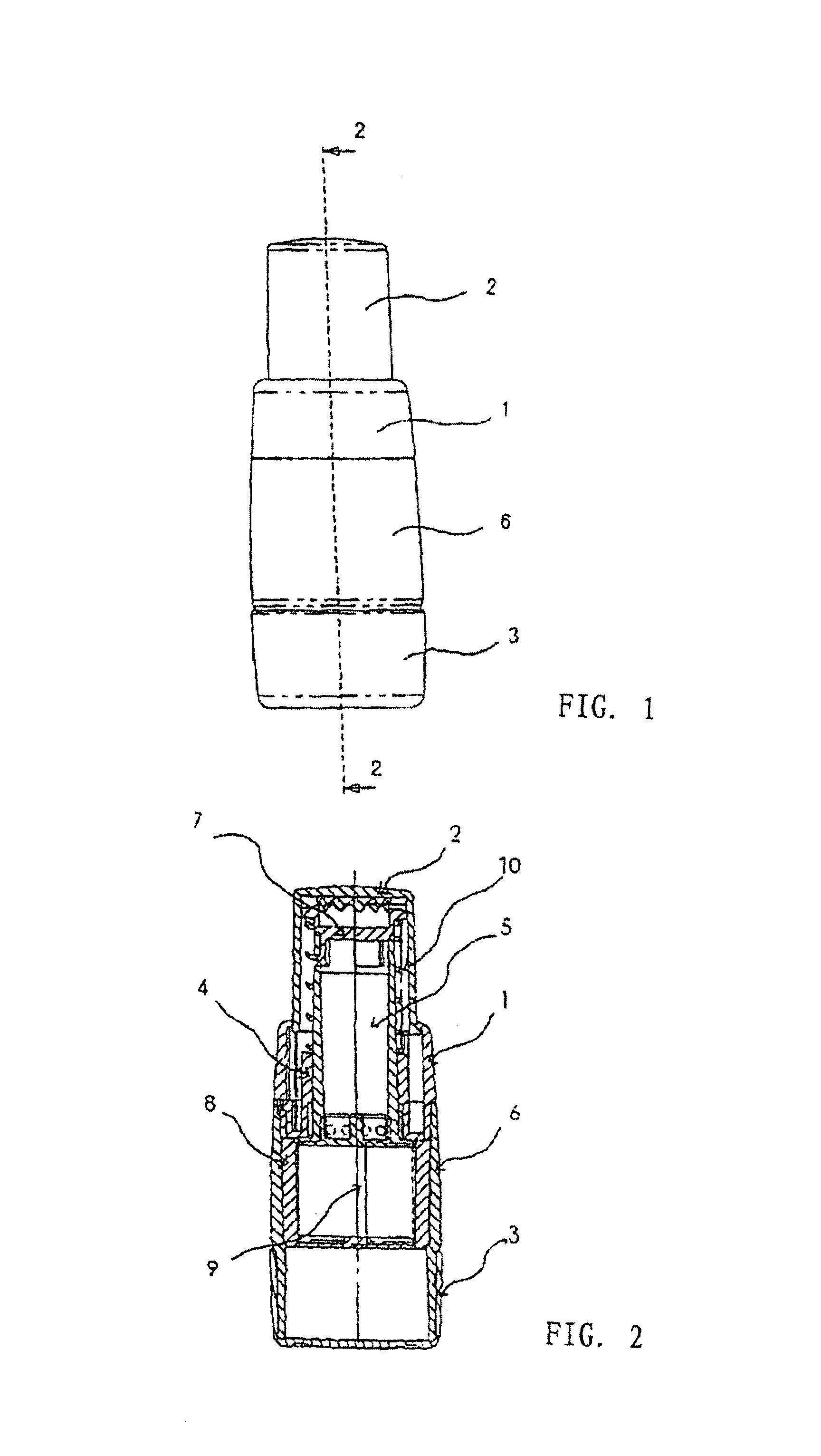

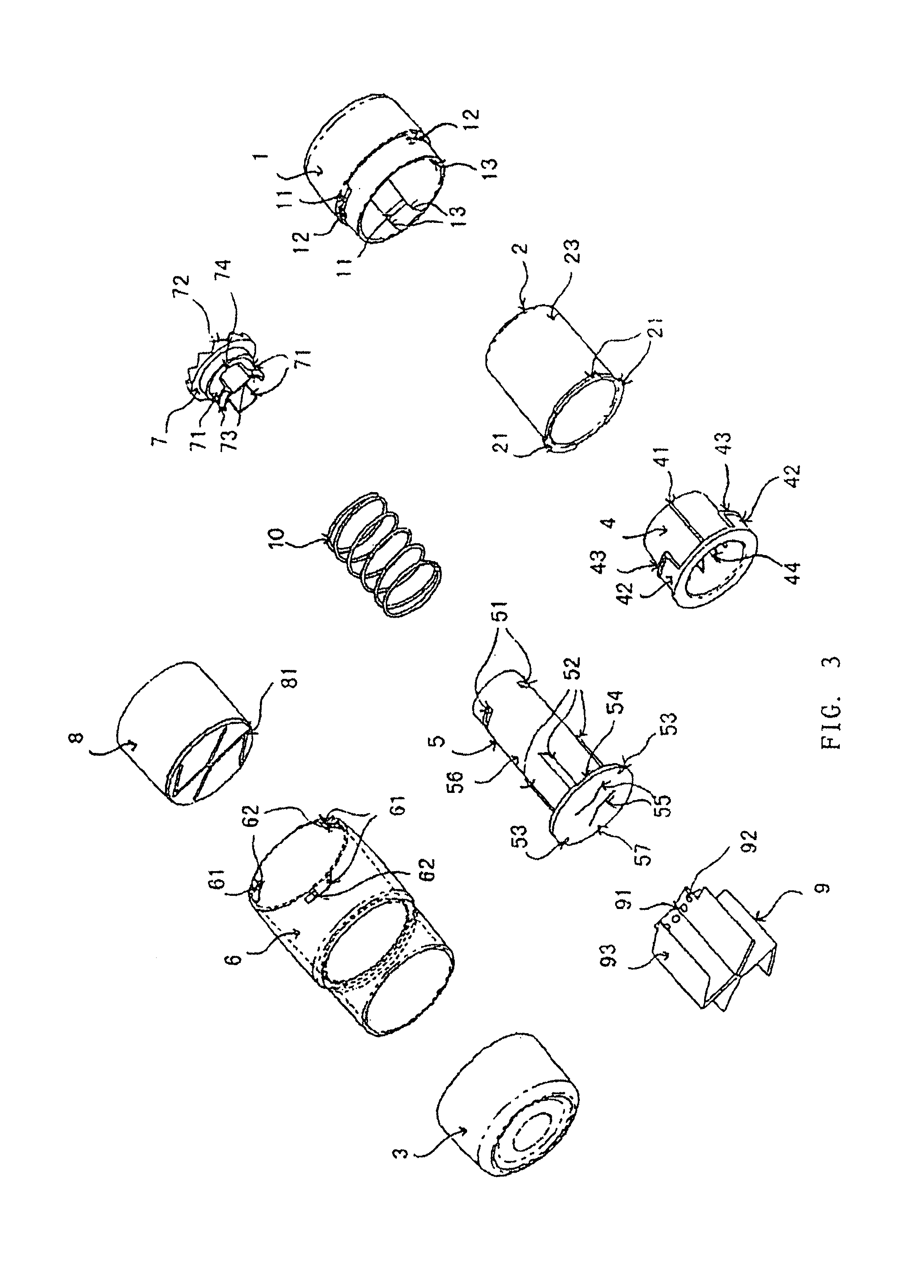

Mini-type food chopper

InactiveUS7258292B2Easy to operateDoes not rustGrain treatmentsMetal working apparatusElectrical and Electronics engineering

A small-sized food chopper for chopping up foodstuffs, includes an outer case including a lower casing removably connected with an upper casing and a button mounted on the upper casing; a blade connection holder installed inside the outer case, the blade connection holder can move axially up and down in the outer case; a plurality of blades installed on the lower end of the blade connection holder; a reset spring sheathed on the blade connection holder which restores the blade connection holder axially up; a mechanism which makes the blade connection holder rotate a predetermined angle circumferential each time the blade connection holder operates axially; the button is configured such that it can slide up and down axially, and the button acts on the upper end of the blade connection holder to make the blade connection holder move axially downwardly.

Owner:CHEUNG YIU JOE

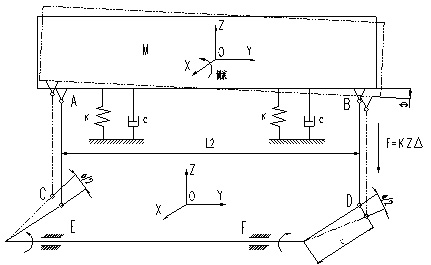

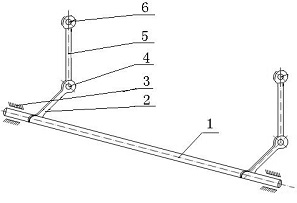

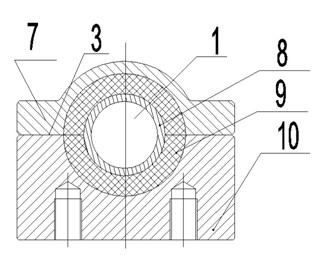

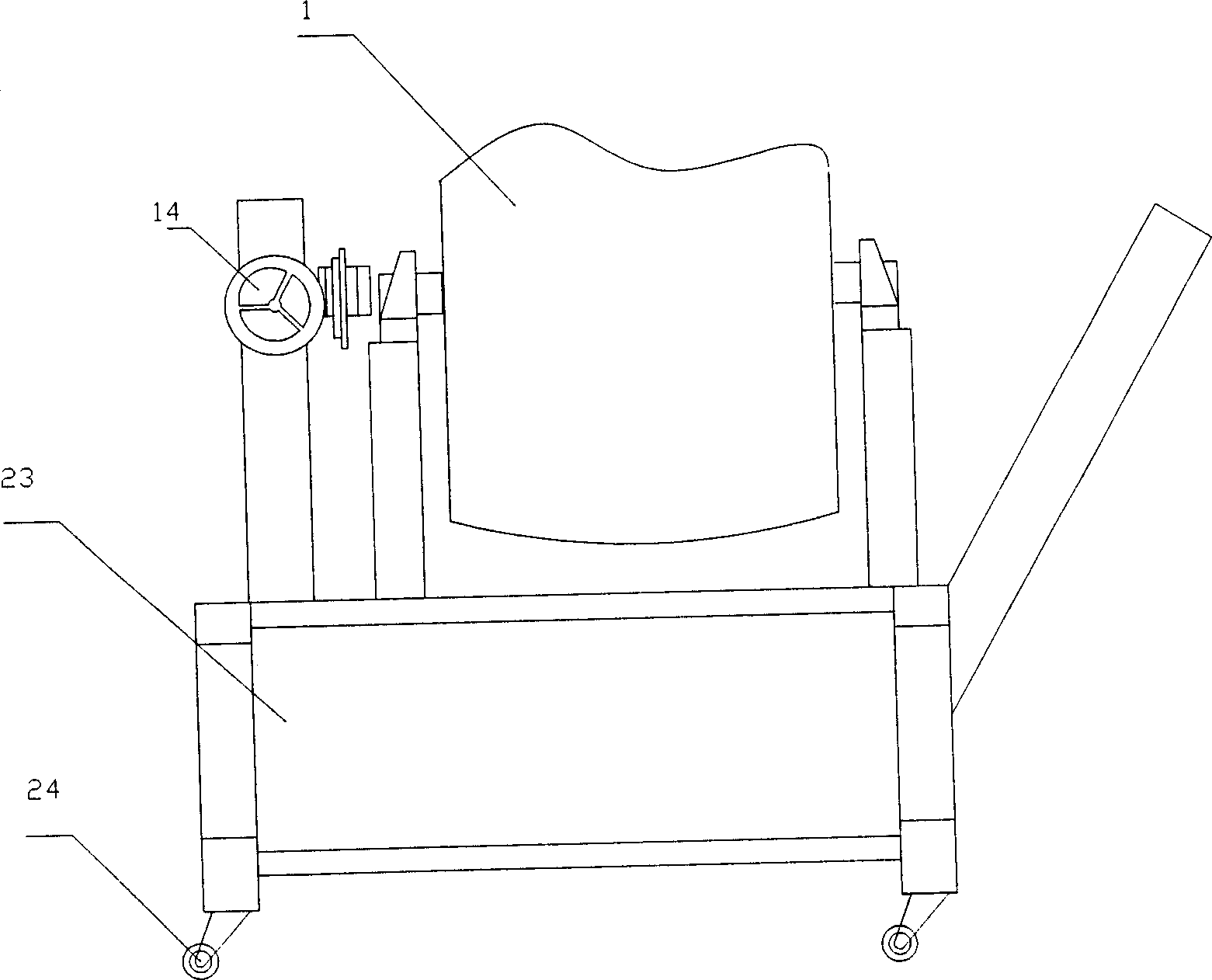

Method and device for supporting side-roll torsion bar system of railway vehicle

ActiveCN102009662AThe torsion function is successfully realizedEasy loading and unloadingBogie-underframe connectionsEngineeringHardness

The invention provides a method and device for supporting a side-roll torsion bar system of a railway vehicle. A multi-layer composite sleeve support method is used for supporting an anti-rolling torsion bar system of the railway vehicle. The multi-layer composite sleeve support method is as follows: a layer of steel bushing the hardness of which is lower than that of a torsion bar shaft material is sleeved on the torsion bar shaft by means of interference fit; the steel bushing is used for bearing torsional friction generated in the use process; the steel bushing is made of a material the hardness of which is relatively low, so that the torsion bar shaft can be effectively protected (because the hardness of the torsion bar shaft is high and the torsion bar shaft is sensitive to surface defects, the torsion bar shaft is easy to rapidly expand to be damaged if the torsion bar shaft is scratched in the use process); and a layer of friction resisting sleeve is sleeved outside the steel bushing, the outer diameter of the friction resisting sleeve and a support seat are in an interference fit structure, and the inner diameter of the friction resisting sleeve and the torsion rod shaft are in interference fit, thus ensuing that radial bearing can be provided and the torsional function of the torsion bar shaft can be successfully realized in the use process.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Preparation method for high-performance water-based environmentally-friendly anticorrosive paint used for metal base material

ActiveCN104530911AImprove adhesionNon-foamingAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

A preparation method for high-performance water-based environmentally-friendly anticorrosive paint used for a metal base material comprises the step that a component A and a component B are blended with the ratio being 1: (0.3-1.2), and then the high-performance water-based environmentally-friendly anticorrosive paint can be prepared, wherein the component A comprises, by weight, 30-45 parts of waterborne epoxy curing agents, 10-15 parts of non-heavy-metal antirust paint, 11-28 parts of de-ionized water, 15-30 parts of packing, 2-7 parts of thickening agents, 0.3-1.3 parts of dispersing agents, 0.1-0.5 part of flatting agent, 0.1-0.4 part of de-foaming agent, 0.1-0.8 part of PH conditioning agent and 1-4 parts of film coalescing aid; the component B comprises, by weight, 85-95 parts of water-borne epoxy resin and 5-15 parts of mussel adhesive proteins. The mussel adhesive proteins in the paint are utilized to perform a strong coordination complexation effect with ions in the non-heavy-metal antirust paint, and the adhesive force of a coating to the metal base material is increased to 10 MPa; at the temperature of 25 DEG C, the water resistance reaches 1,400 h, the salt fog resistance reaches 2,000 h, and coated films do not foam or rust.

Owner:XIAMEN SUNRUI SHIP COATING

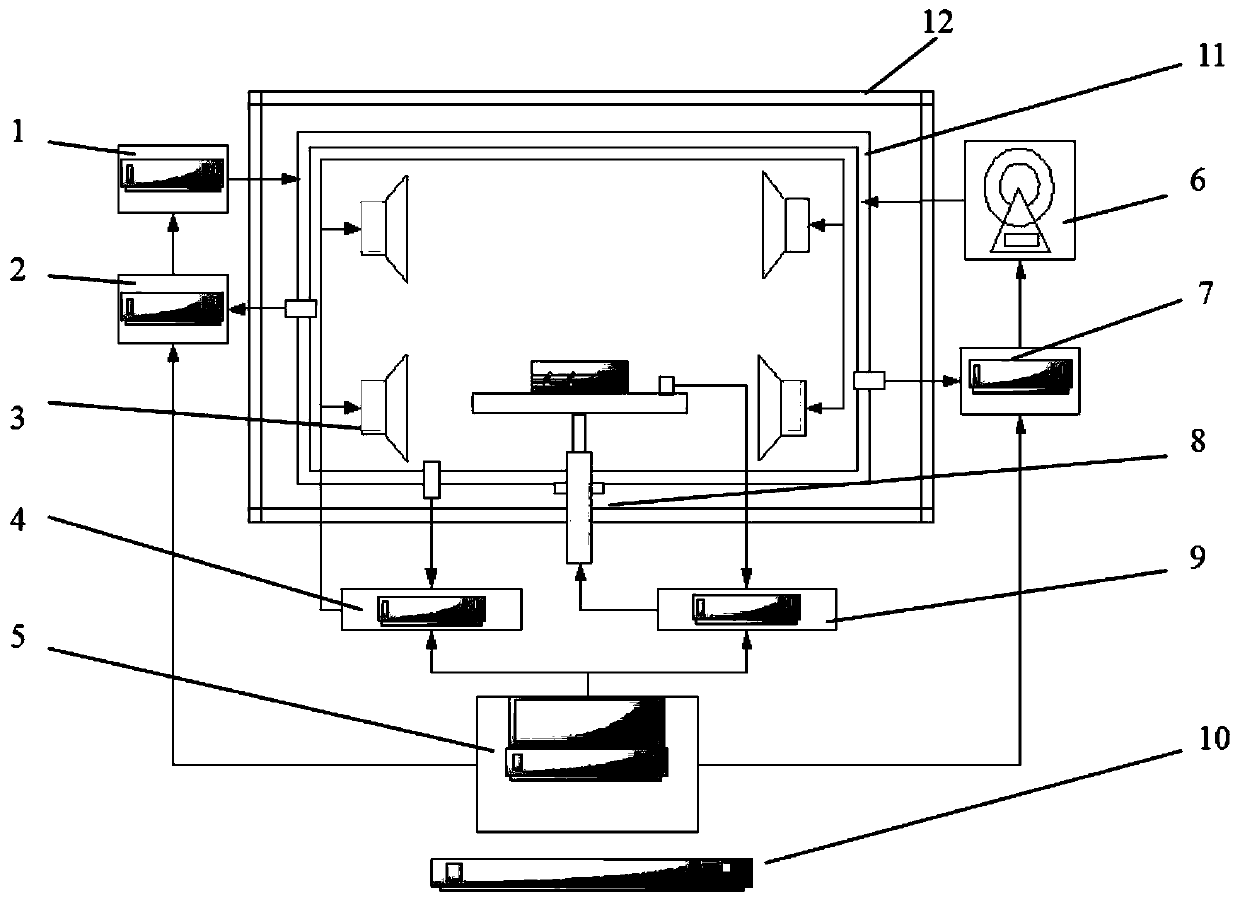

Comprehensive environment simulation device

InactiveCN110243617AIncrease authenticityImprove effectivenessStructural/machines measurementNoise controlVibration control

The invention provides a comprehensive environment simulation device. The comprehensive environment simulation device comprises a temperature and humidity applying system, a temperature and humidity control system, a loudspeaker, a noise control system, a comprehensive environment display and control system, a vacuum pump, a low air pressure control system, a hydraulic vibration table, a vibration control system, a protection system and a box body. The comprehensive environment simulation device can coordinate and control five environment factors consisting of the temperature, the humidity, the height, the vibration and the noise at the same time to form comprehensive environment simulation, can truly simulate the air-based equipment war preparation on-duty comprehensive environment, and improves the authenticity and effectiveness of the air-based equipment environment adaptability test verification.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

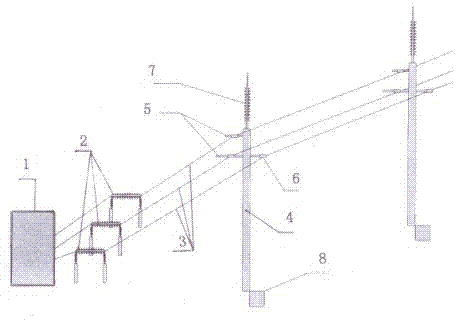

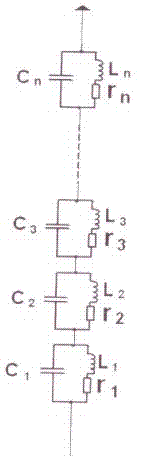

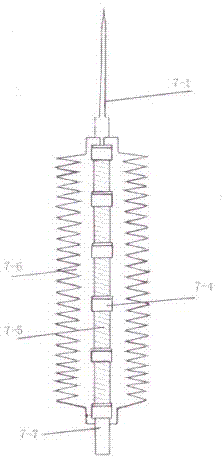

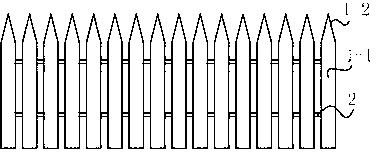

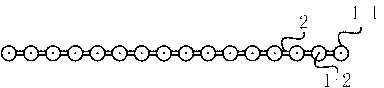

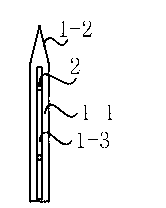

Distribution network integrated lightning protection system

ActiveCN104518475ASmooth shockReduce shockInstallation of lighting conductorsCorona dischargeOvervoltageTelecommunications

The invention discloses a distribution network integrated lightning protection system comprising a transformer substation, and output lines led out of three phases of outlet ports of a transformer substation transformer. Each phase of line is connected in series with an overvoltage isolator. Overhead wires are formed through lead-out of the output ends of the voltage isolators to a pole tower. Pole tower insulating cross arms support the overhead wires, and power transmission wires are fixed via multifunctional wire clamps arranged on the insulating cross arms. A wave-resistant lightning rod is installed at the top end of the pole tower. A simple and rapid grounding device is embedded in the ground of the bottom part of the pole tower so that integrated lightning protection performed on the distribution network lines and the transformer substation is realized with pole tower protection acting as the center and prevention of distribution network lightning tripping and disconnection acting as the key points. Distribution network line dedicated lightning equipment like the wave-resistant lightning rod, the insulating cross arms, the multifunctional wire clamps and the simple grounding device are organically integrated by the system so that the multilayer and three-dimensional integrated lightning protection system is constructed and realized, lightning trip-out rate and disconnection rate can be substantially reduced, and maximum matching of distribution network lightning economical efficiency and effectiveness is realized.

Owner:成都星河科技产业有限公司

Environment-friendly anticorrosive coating and preparation method thereof

The invention belongs to the field of preparation of coatings and particularly relates to an environment-friendly anticorrosive coating and a preparation method thereof. The coating is prepared by mixing an oil paint component and a curing agent component in a weight ratio of 100 to (20-30). The oil paint component is prepared from the following components in percentage by weight: 55-70wt% of acrylic resin, 5-15wt% of tea stem powder, 10-15wt% of organic pigments, 3-5wt% of rosin, 10-15wt% of solvent and 2-5wt% of surfactant. The curing agent component is prepared from the following components in percentage by weight: 60-69wt% of curing agent, 30-39wt% of solvent and 0.05-1wt% of dehydrating agent, wherein the dehydrating agent is one or two of butyl ester, cyclohexanone and butyl cellosolve. The added tea stem powder can react with harmful gases such as formaldehyde and dimethylbenzene to form non-volatile harmless macromolecular chain substances, so as to effectively eliminate harmful gases in the atmosphere, so that the prepared coating is relatively environmentally friendly and pollution-free. Due to the design of a stepwise feeding device, the raw materials are fully and uniformly mixed, thereby improving the performance of the coating. Due to adoption of a discharging spill-proof hopper, the packaging process is simple, convenient and efficient.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

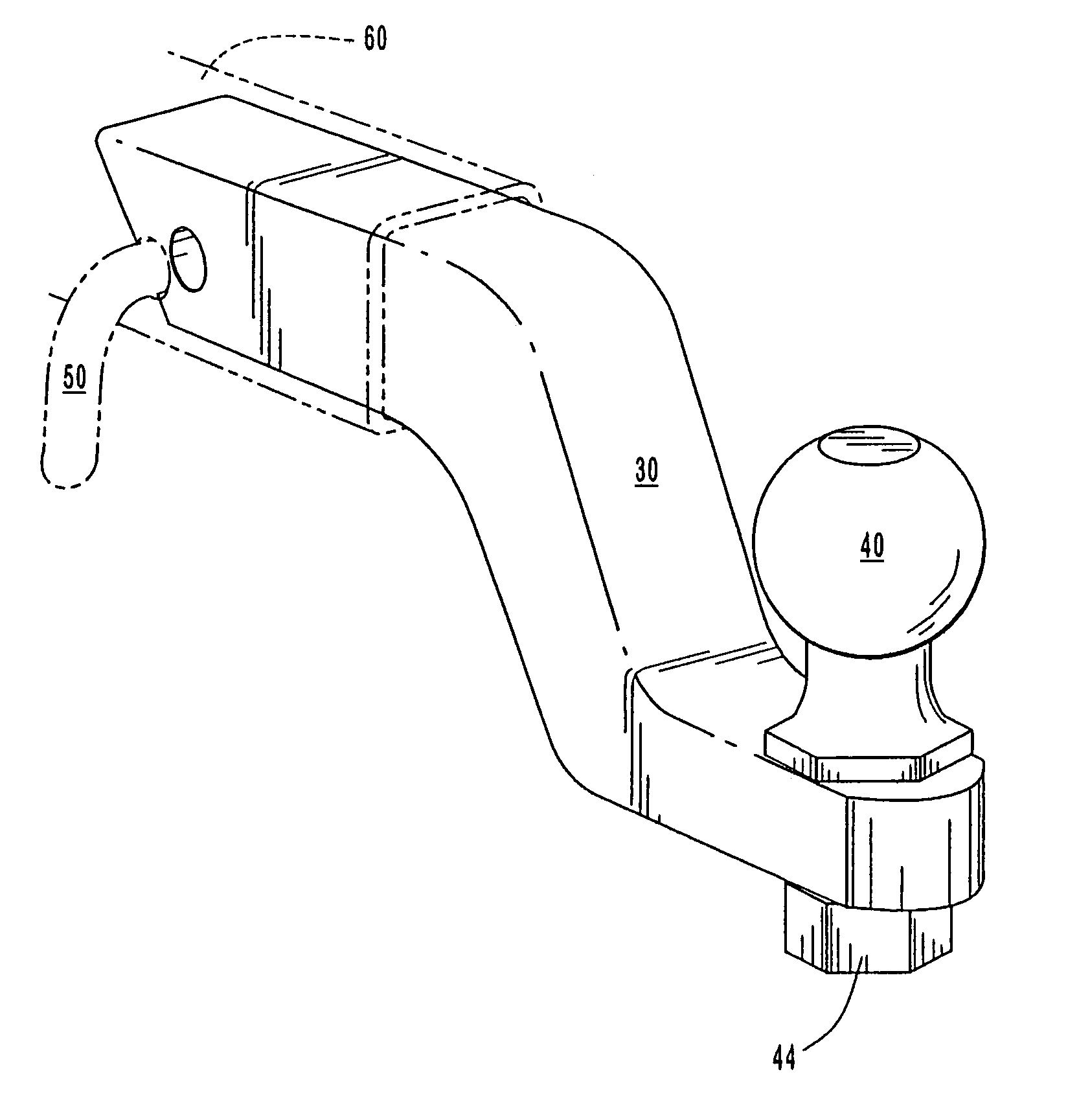

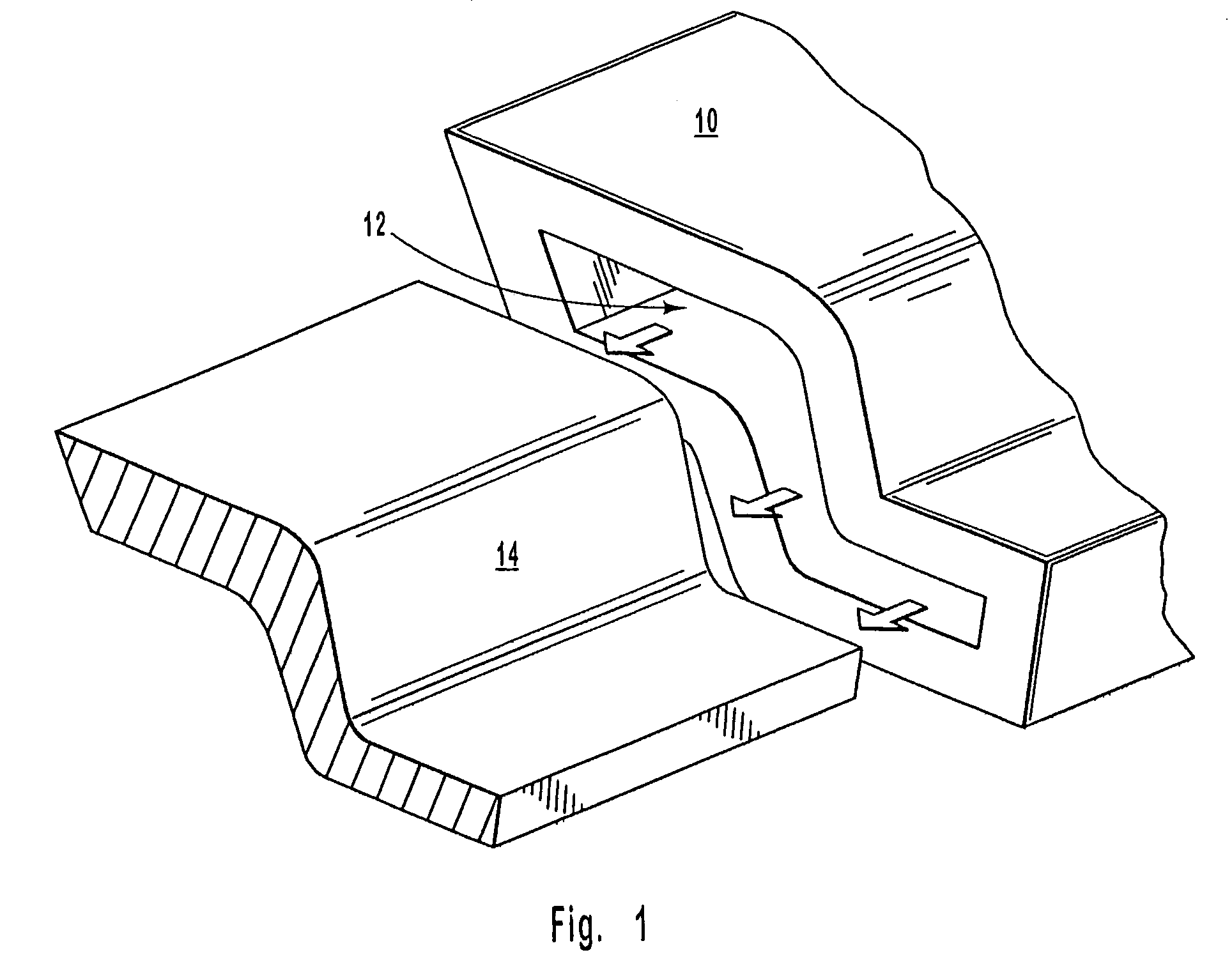

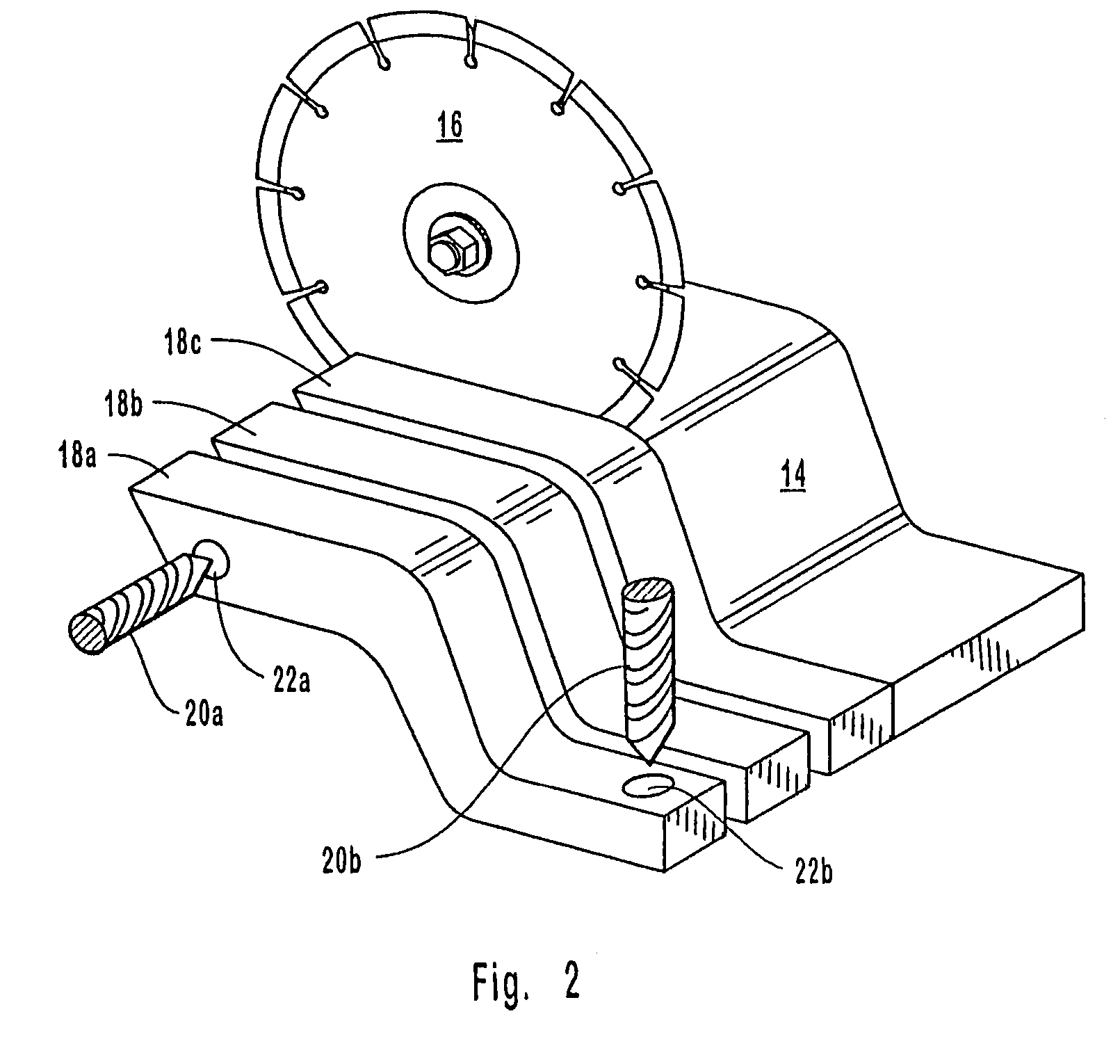

Systems and methods for providing an aluminum bar for towing

InactiveUS7156412B2High strengthAppealing to consumerEngine componentsTowing devicesUltimate tensile strengthMachining process

Systems and methods for using an extrusion, forging, casting and / or machining process to provide an aluminum hitch component with increased strength that eliminates encumbrances, such as rusting and fusing, associated with traditional hitch components. Accordingly, an extruded hitch is provided that includes increased tensile strength, does not rust, is lighter, and is more appealing to consumers.

Owner:ANDERSEN JOHN I

High-temperature-resistant water-borne coating and preparation method thereof

InactiveCN105176386ALow toxicityReduce surface tensionAnti-corrosive paintsEpoxy resin coatingsAcrylic resinKaolin clay

The invention discloses a high-temperature-resistant water-borne coating and a preparation method thereof. The high-temperature-resistant water-borne coating consists of the following materials in parts by weight: 82 to 85 parts of epoxy-modified organic silicone resin, 30 to 38 parts of bisphenol-A epoxy resin, 11 to 13 parts of water-based acrylic resin, 18 to 24 parts of graphite powder, 10 to 13 parts of polydimethylsiloxane, 5 to 8 parts of calcium carbonate, 8 to 10 parts of titanic oxide, 60 to 65 parts of deionized water, 10 to 12 parts of peal powder, 5 to 8 parts of titanium dioxide, 8 to 12 parts of kaolin, 5 to 8 parts of Rhine powder as release agent, 3 to 5 parts of thermal carbon black MT and 3 to 5 parts of toluene. Not only is the corrosion resistance of the water-borne coating good, but also the adhesion is good, so the water-borne coating cannot easily shed; moreover, colors are diversified; the service life is long, and problems, such as blistering, cracking, whitening and even leafing, cannot take place after the water-borne coating is used for a long time.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

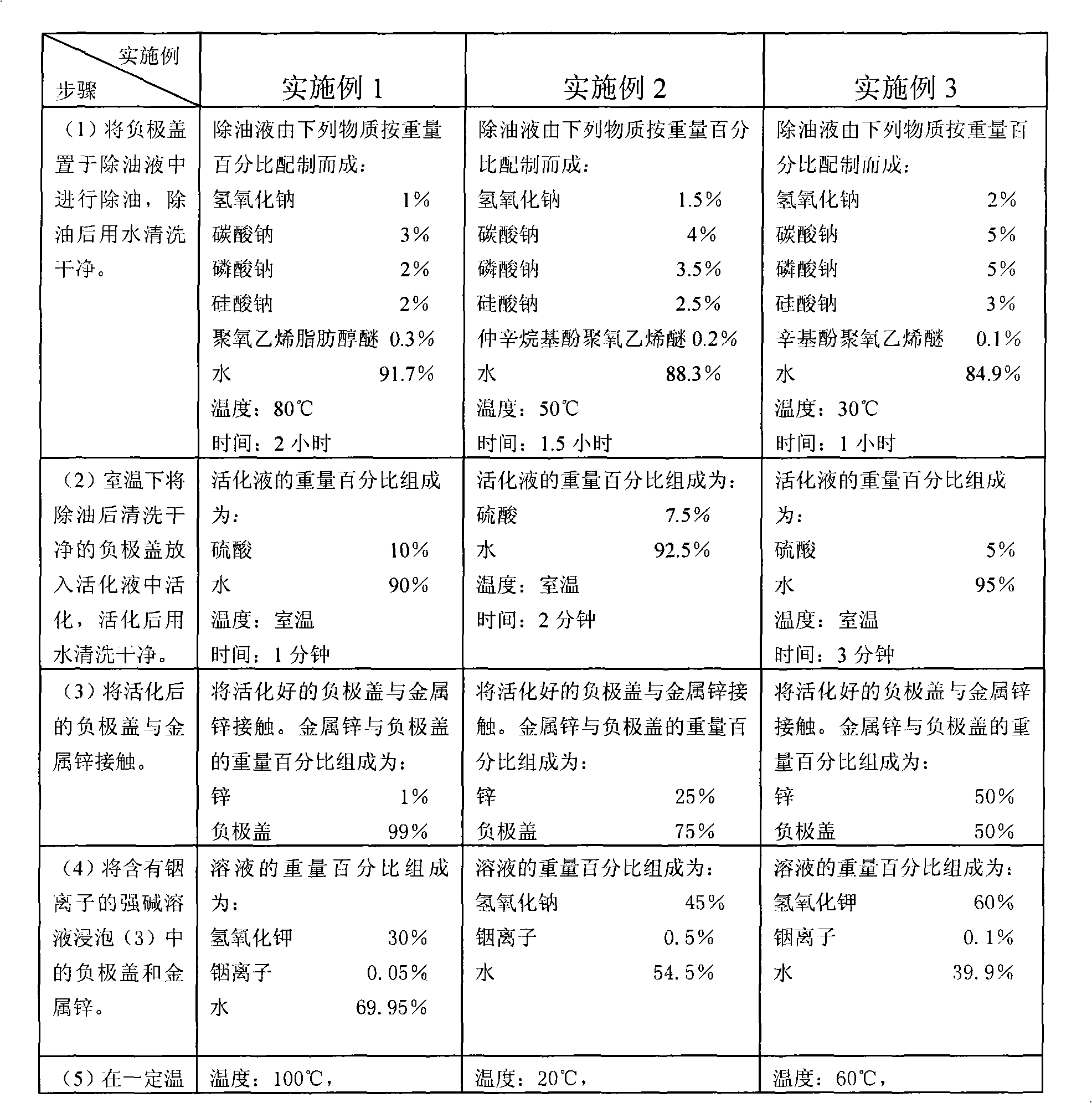

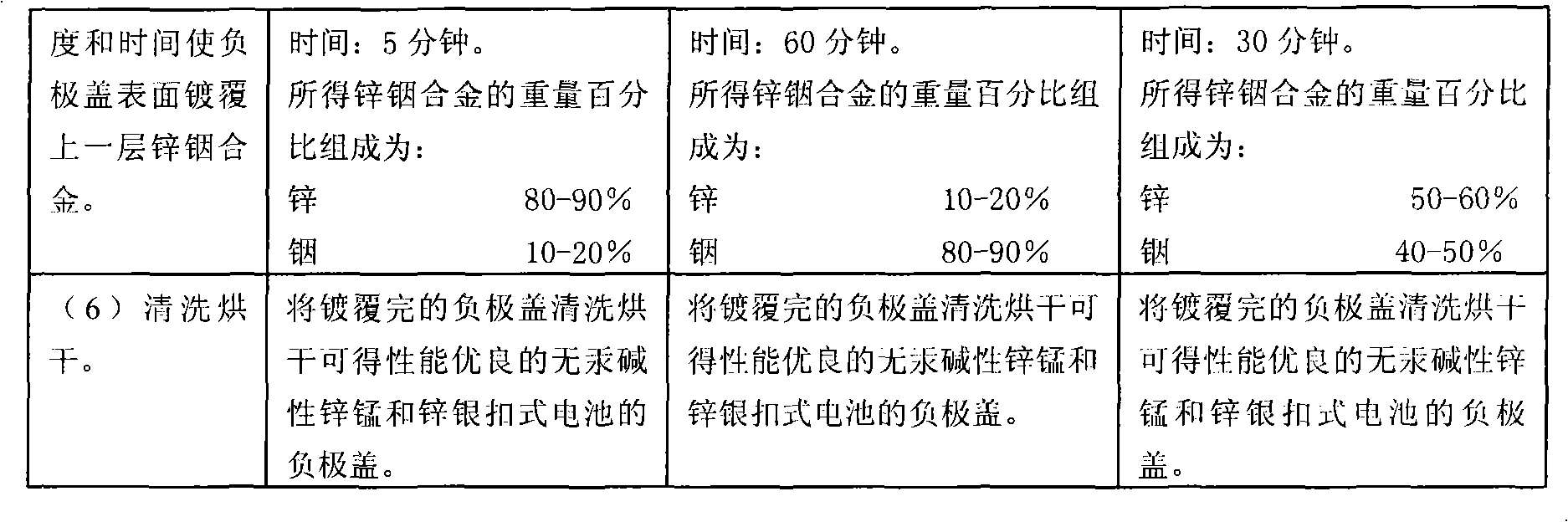

Method for processing surface of non quicksilver basicity zincium manganese and zincium silver button cell cathode cover

ActiveCN101299457ASave resourcesReduce pollutionElectrode manufacturing processesPrimary cell electrodesIonIndium

The invention provides a cathode cover surface treatment method of the Hg-free alkaline zinc manganese and the zinc silver button cell, including the following steps: 1. deoiling the cathode cover of the commodity and cleaning by water; 2. putting the cleaned cathode cover into the activate fluids for activation, then cleaning by water after activation; 3. contacting the metallic zinc with the activated cathode cover; 4. putting the cathode cover and the metallic zinc in the strongly alkaline solution soaking step (3) containing the indium ion; 5. coating a layer of zinc indium alloy on the surface of the cathode cover under certain temperature and time; 6. cleaning and drying the coated cathode cover. The invention uses the contact coating theory and the replacement coating theory to directly prepare the zinc indium alloy of the hydrogen-eduction overpotential with good property on the cathode cover without the DC source and the reducer, which saves the resource and reduces the pollution, the metallic zinc with lower cost is adopted to partially replace indium with higher expensive, and the reclaimed bath and the metallic zinc can be used again to reduce the production cost.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Graphene thermal spraying enamel paint and use method thereof

ActiveCN107629493ADoes not rustDoes not fall offMolten spray coatingAntifouling/underwater paintsCvd grapheneSurface strength

The invention discloses a graphene thermal spraying enamel paint and a use method thereof. The graphene thermal spraying enamel paint comprises the following raw materials by weight percentage: 80-98%of a first raw material, 0.2-2% of graphene powder, 0.5-1% of borax and 1-3% of a pigment. The first raw material is one of or a mixture of several of enamel powder, ceramic slurry / ceramic powder andquartz powder. The graphene thermal spraying enamel paint provided by the invention is prepared from graphene and one of or a mixture of several of enamel powder, ceramic slurry, ceramic powder and quartz powder, not only is environment-friendly, but also can withstand high temperature construction, thermal spraying equipment is employed to form a coating, and the coating does not rust or fall off, has good corrosion resistance and excellent bactericidal and algal inhibiting effects, at the same time strengthens the surface strength, prolongs the maintenance period, is easy for maintenance, and reduces the maintenance cost.

Owner:高登科学(深圳)有限公司

Paint for high-class woodenware artwork and preparation thereof

InactiveCN101343498AGood weather resistanceImprove anti-corrosion performanceLiquid surface applicatorsEpoxy resin coatingsPolyesterChemistry

The invention relates to high-grade wooden artwork coating, which is composed of host crystal and solidifying agent, wherein according to the weight parts: the host crystal and solidifying agent are 100:20 to 100:40. The high-grade wooden artwork coating of the invention is characterized in that the coating is made through utilizing that polyester modified epoxy resin is mixed with materials such as high color pigment, dispersing agent, leveling agent, anti-sagging auxiliary agent, anti-scratching auxiliary agent, filler and the like, and additionally matched with polyamide and aliphatic amine solidifying agent. Under the high temperature and high humidity conditions the coating can be coated on the surfaces of various wooden artworks, when the thickness of one-time coating paint film is within 120 um to 150 um, the high-grade wooden artwork coating can not generate sagging phenomenon, and the paint film is bright and flat and has good physical chemical properties. The coating has the protecting and decorating effects to the wooden artwork, which can be widely used for the coating of the wood sculpture, the long high table, the noble furniture and the wooden artwork products.

Owner:TIANJIN COLOROAD COATING & CHEM

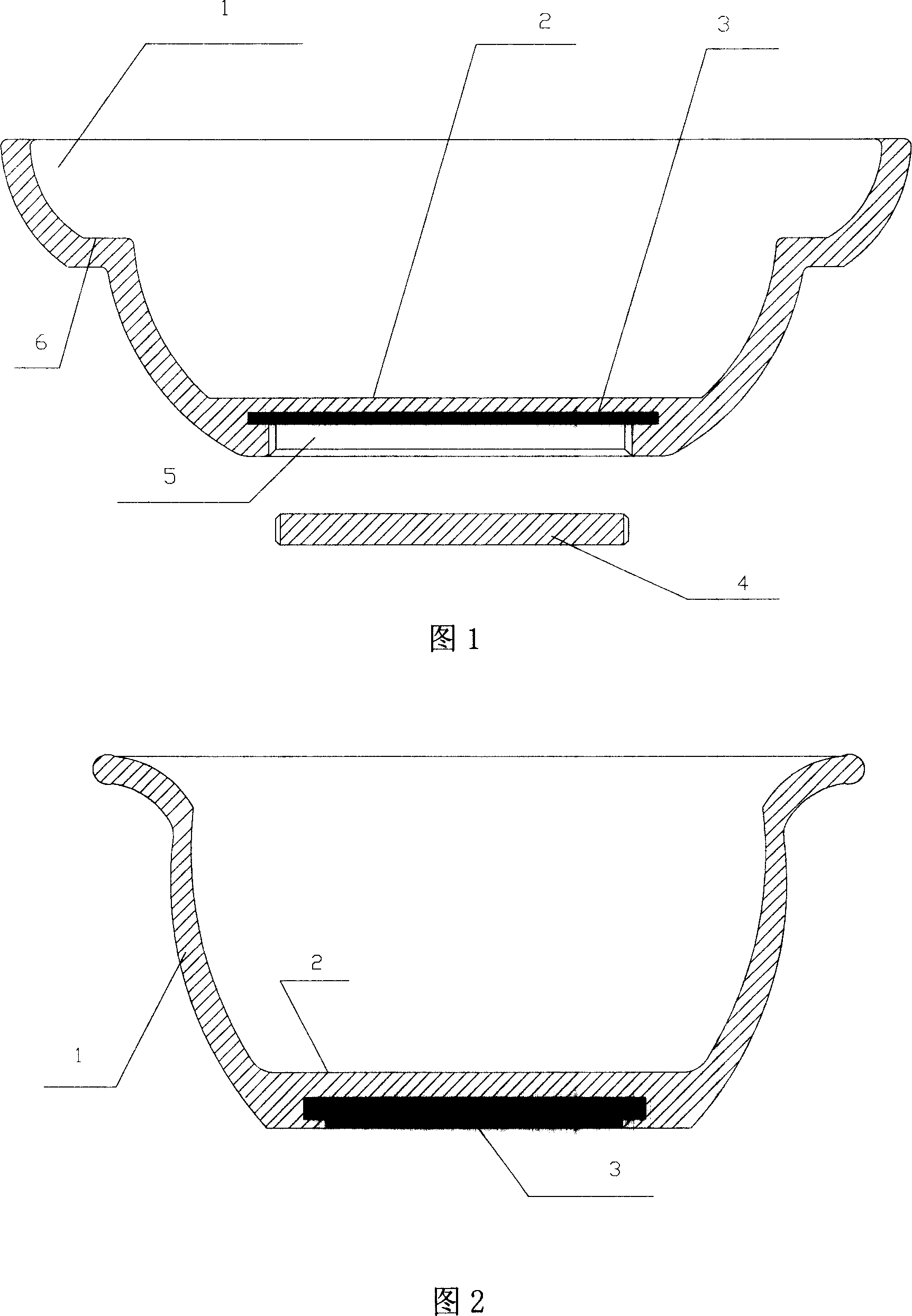

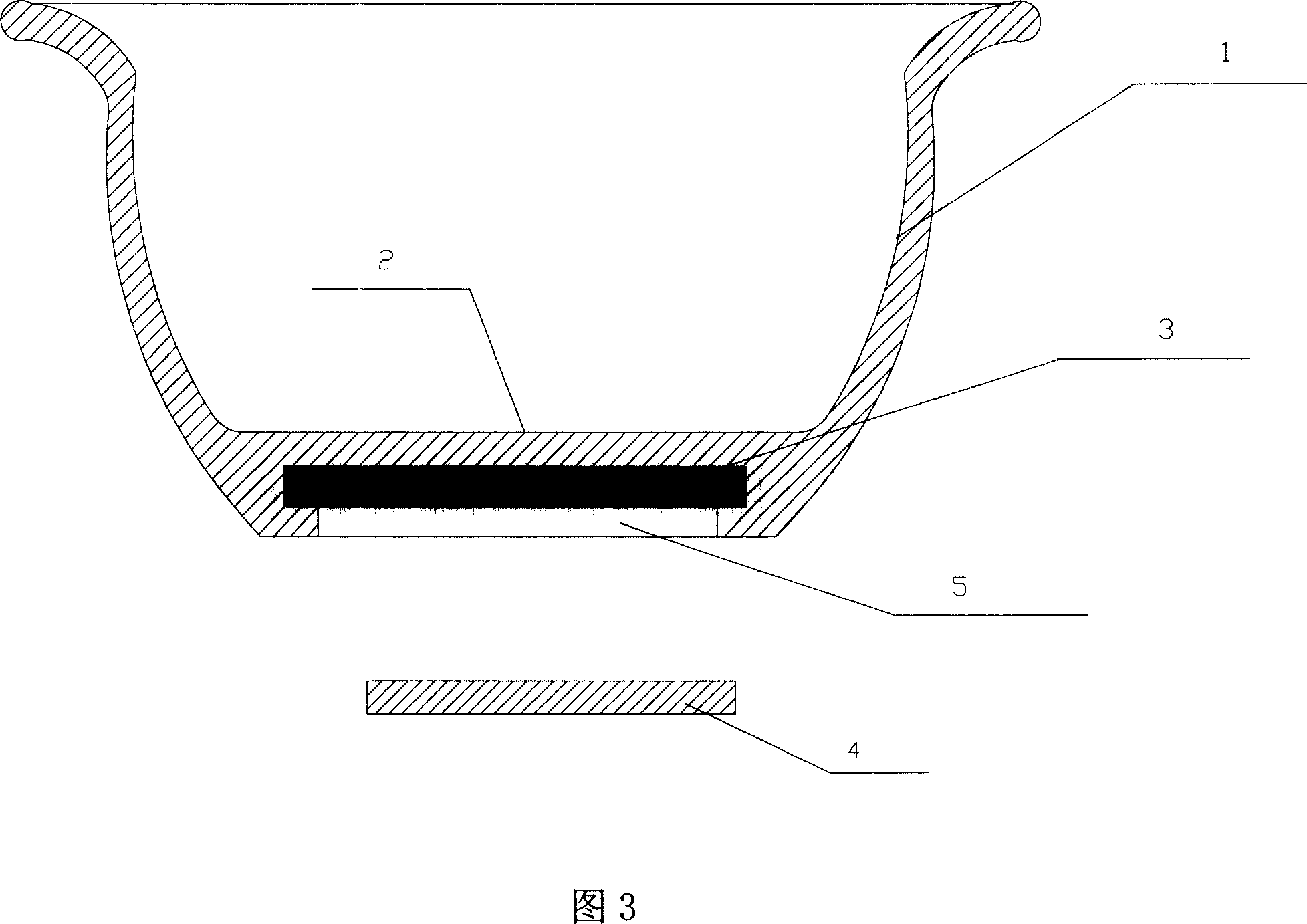

Health-care stone pan

The invention discloses a stove made of stone for electromagnetic oven or heated by open fire, which consists of integral stove bottom and stove bulk, wherein the bottom of stove possesses flute inserted by a layer of magnetic conductive material; the magnetic conductive layer is fixed through casting, adhering, screwing or other patterns, which can adsorb electromagnetic wave to produce energy to heat food in the stove bottom.

Owner:岳泉

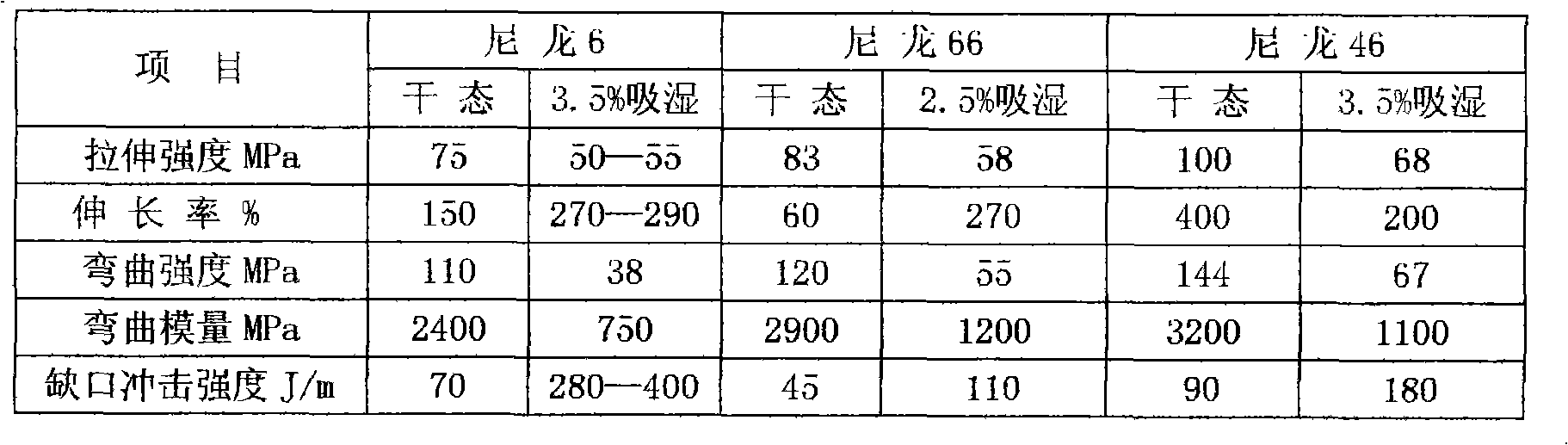

Super-antiwear cast form nylon pulley and processing method thereof

InactiveCN101063482AHigh crystallinityLow densityPortable liftingGearing elementsCorrosionCushioning

A super abrasion-proof nylon block and the manufacturing method relates to the high molecular material-nylon 6 and the manufacturing method of the material. The technical scheme is that the proportion by weight of aminocaprolactam, accelerant and curative is 1000:1. 2-1. 6:3-4. The invention is characterized in that 1, small density and inertia, light quantity and stable operation, 2, superior mechanic property, high intensity and rigidity, good tenacity and creep resistance, antihunt with high shape stability and completely exchangeable with cast-steel block, 3, abrasion-proof function with good self-lubricating property, 4, grease-proof and corrosion-proof without rustiness, 5, good cushioning capacity without noise.

Owner:扬州赛尔达尼龙制造有限公司

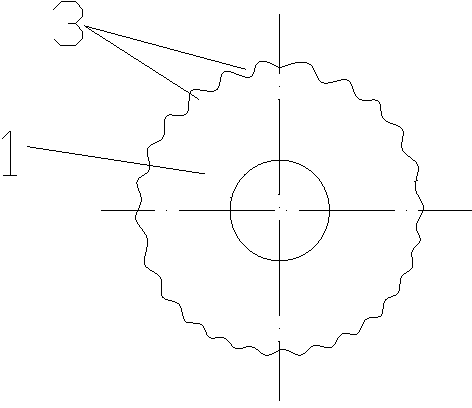

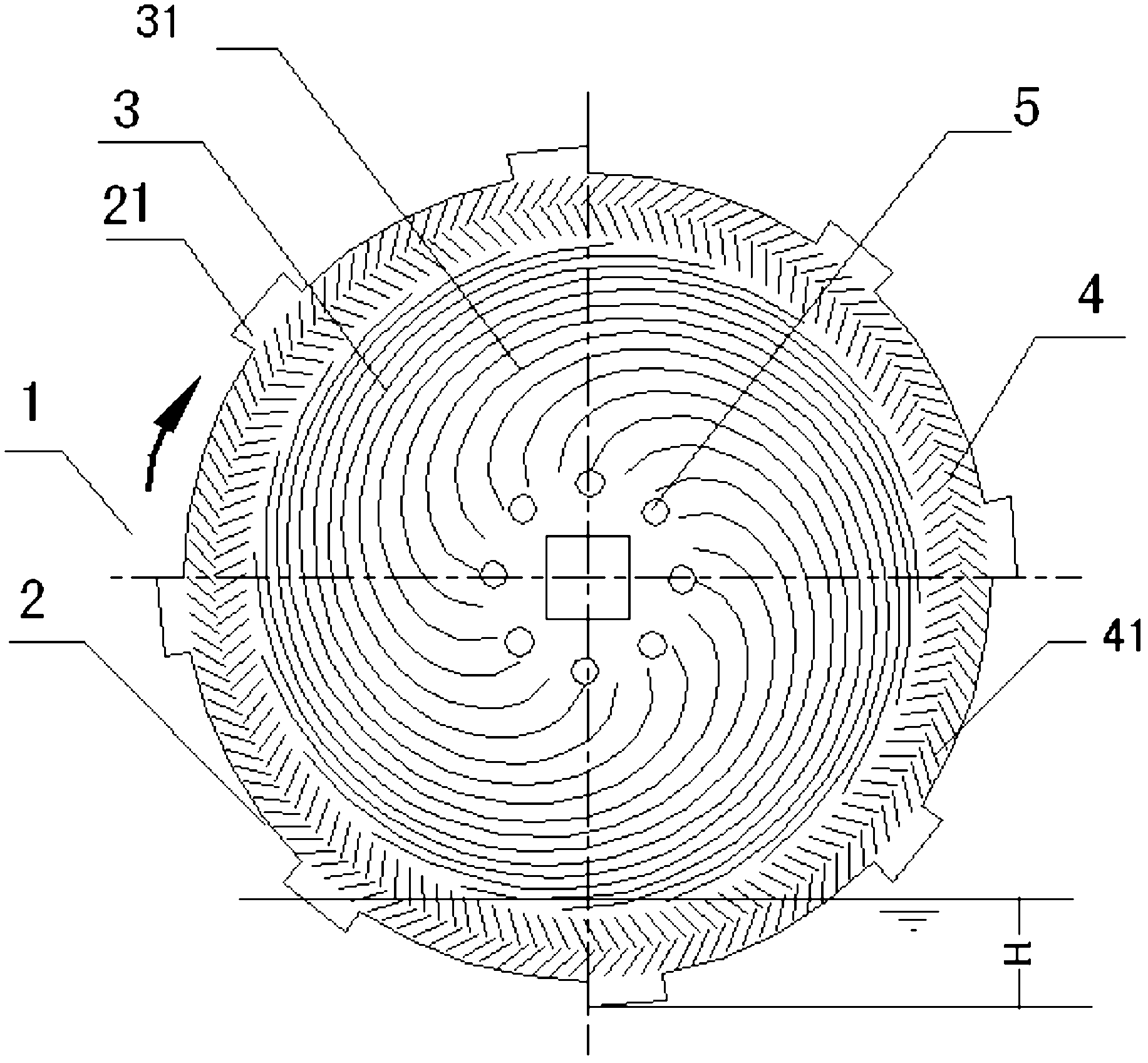

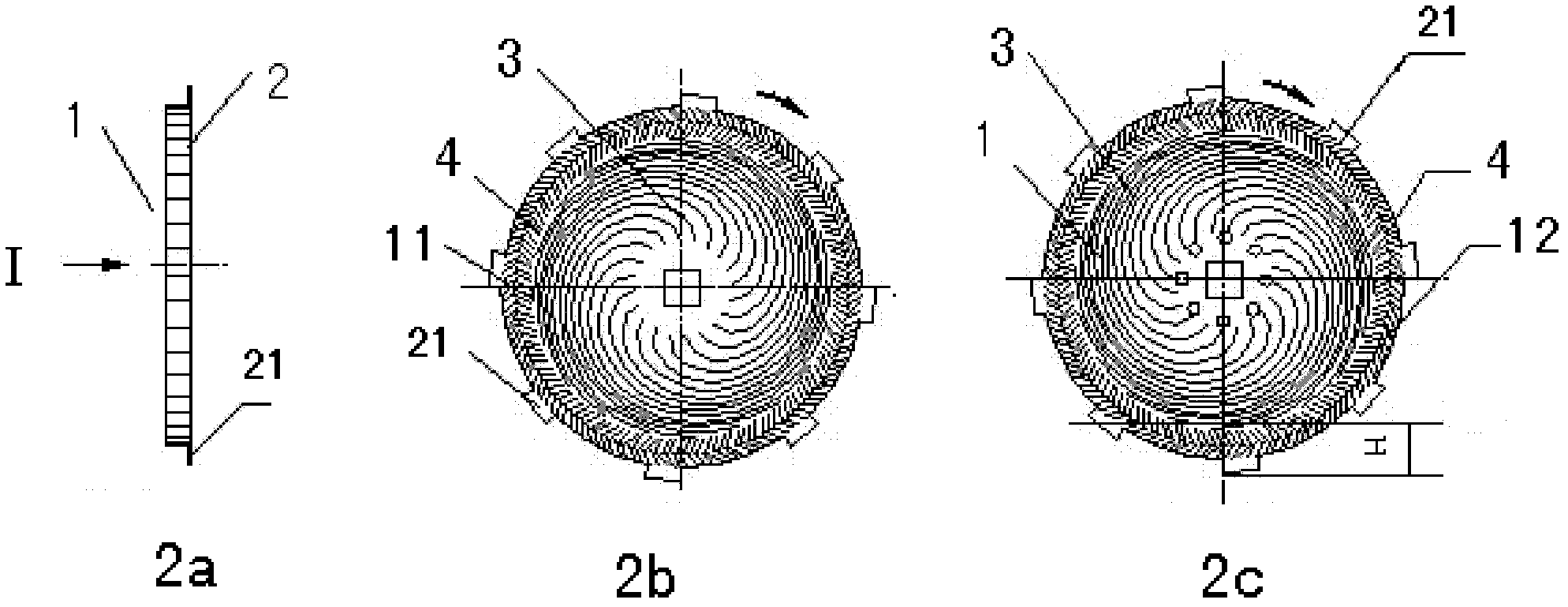

Biological disk, biological revolving drum and integrated revolving drum type domestic sewage treater

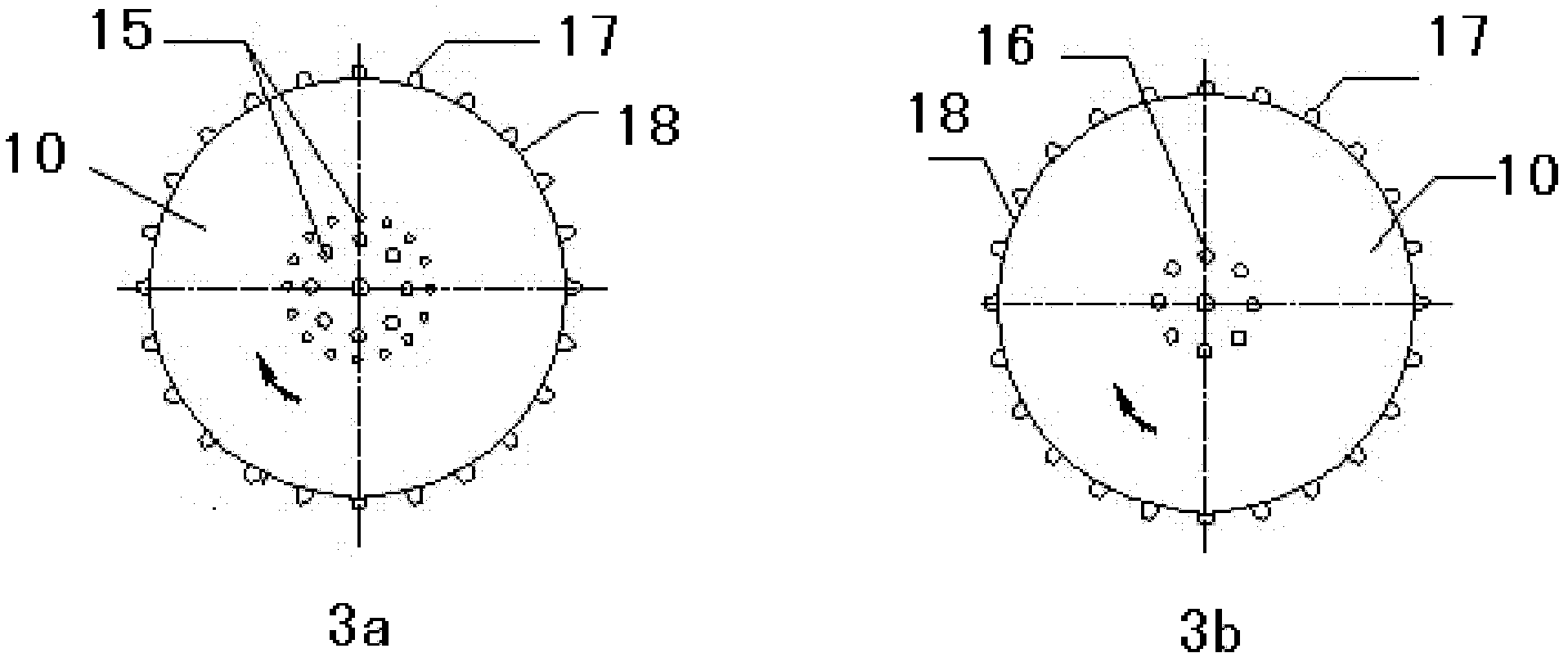

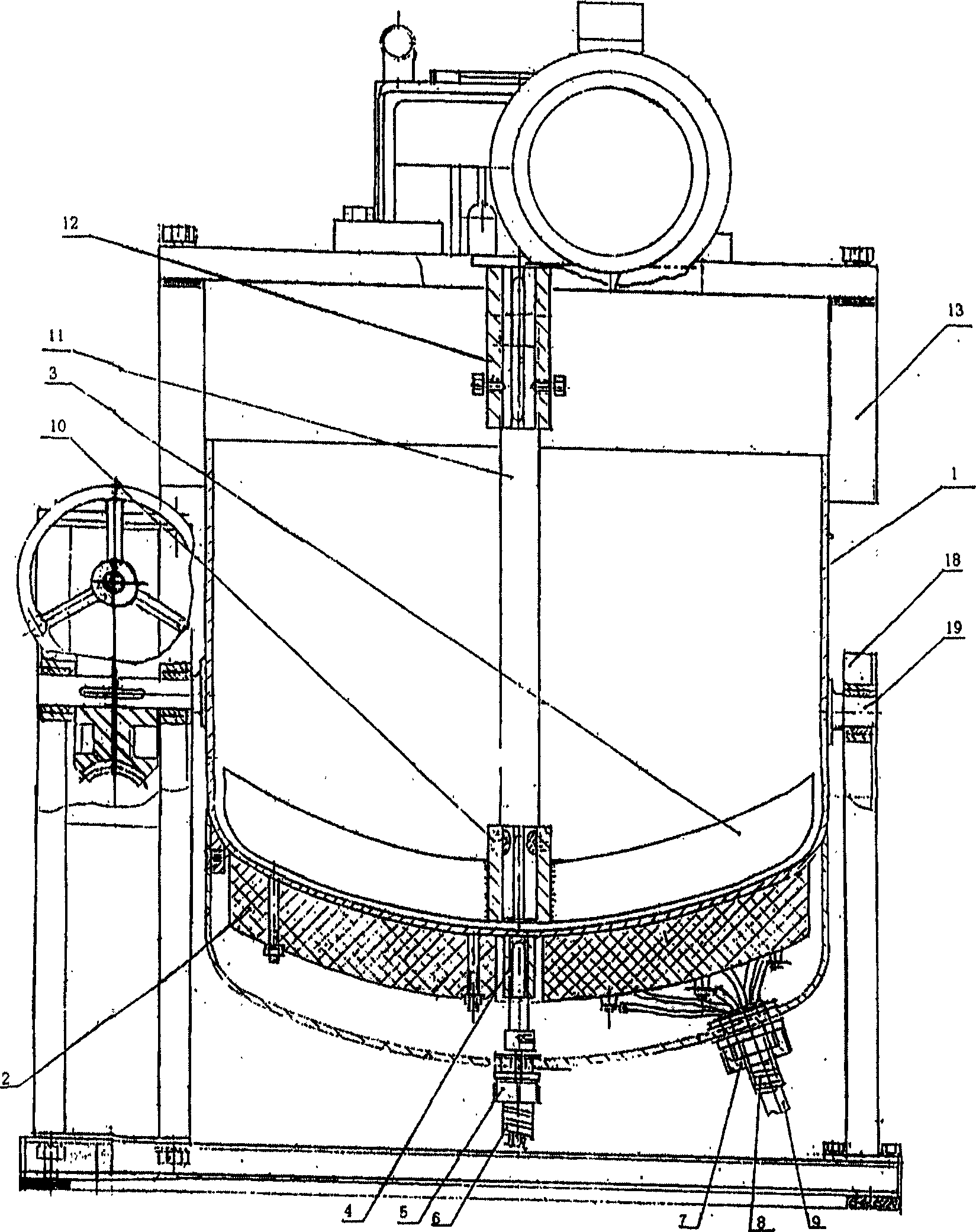

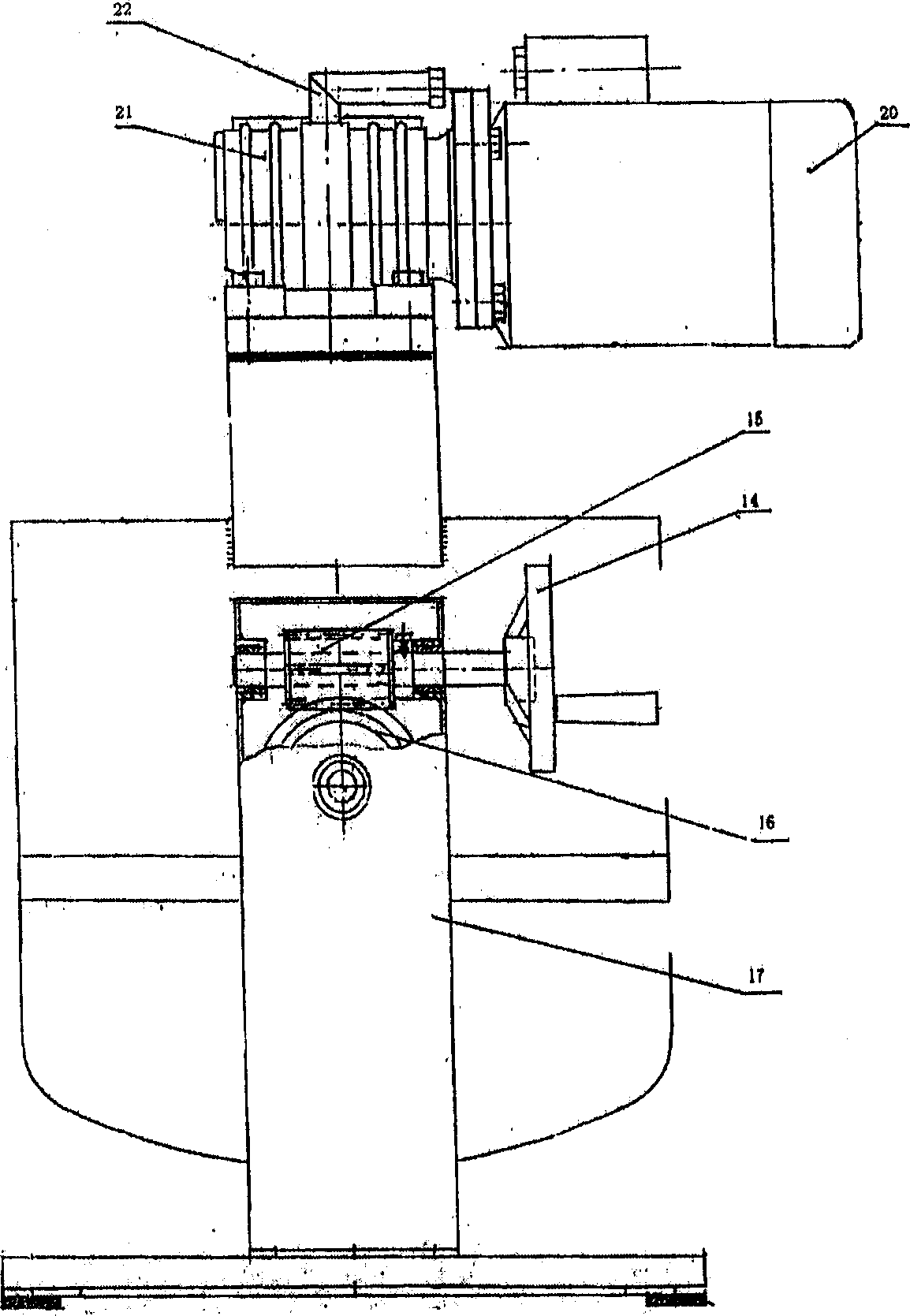

ActiveCN102633355AAvoid cloggingLifting special structuresTreatment using aerobic processesMultistage water/sewage treatmentWater flowSewage

The invention provides a biological disk, a biological revolving drum and an integrated revolving drum type domestic sewage treater. The biological disk comprises a circular support disk and blades fixed on the support disk; the blades are vertical to the support disk; an axial hole is formed in the centre of the support disk; the blades comprise lifting blades which are in a plurality of spiral structures in the same direction starting from the axial centre of the support disk; and the distance between every two spiral structures at the position close to a circle centre is more than that at the position far away from the circle centre. According to the invention, because the biological disk is provided with the lifting blades and aeration blades, the area of a turntable is greatly increased; furthermore, in the event of passing through the biological revolving drum disclosed by the invention, the water flow must flow through each disk; therefore, the superficial area contacted with sewage is greatly increased; the sewage treatment capability is greatly increased; the integrated revolving drum type domestic sewage treater is convenient for maintenance and low in intensity; and main body equipment is rustless and corrosion resistant.

Owner:苏州克莱茵环境发展有限公司

Preservative resin coating

InactiveCN103360936AQuality improvementEasy to useAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention discloses a preservative resin coating. The preservative resin coating comprises the following components in percentage by weight: 60-80% of component A and 20-40% of component B, wherein the component A comprises the following components in parts by weight: 40-50 parts of polyester resin, 14-19 parts of epoxy resin, 8-12 parts of coloring pigments, 5-10 parts of rust-proof pigments, 5-7 parts of filler, 0.5-2 parts of auxiliary agents and 0.5-2 parts of a mixed solvent, the mixed solvent comprises xylene and butyl acetate, and the auxiliary agents include a defoaming agent, an anti-settling agent and a thixotropic agent; and the component B the following components in parts by weight: 0.5-1 part of plasticizer, 3-8 parts of tricarboxymethyl propane, 8-15 parts of butyl acetate, 15-25 parts of toluene diisocynate, 6-15 parts of xylene, 1-3 parts of cyclohexanone and 0.5-2 parts of polyurethane dehydrant. According to the preservative resin coating disclosed by the invention, the quality is stable, the polyester resin and the epoxy resin are taken as base materials to form an interpenetrating polymer network to endow the coating with compactness, the preservative property and the adhesive force are greatly improved, and the preservative resin coating cannot blister, rust, fade and fall in a long time.

Owner:南京市荣达树脂有限公司

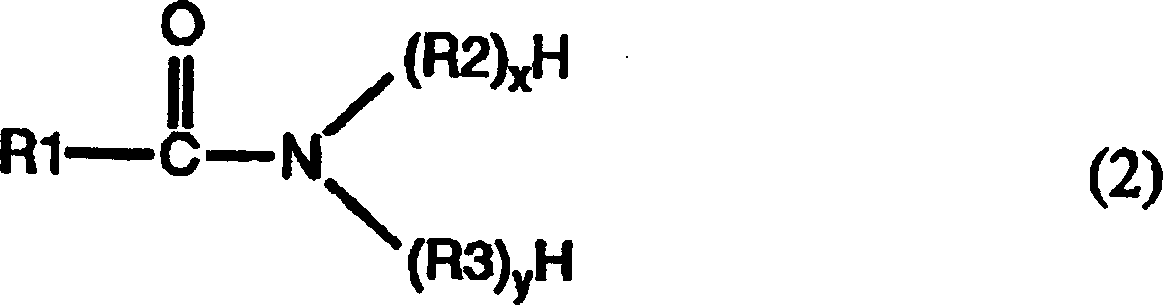

Water-based double-component corrosion-resistant industrial paint and production method thereof

The invention discloses a water-based double-component corrosion-resistant industrial paint which is prepared from a component A and a component B. The component A is an acrylic acid epoxy hybrid emulsion prepared by grafting an epoxy group with reaction activity on the acrylic acid main chain, and is 100 parts by weight. The component B is composed of the following components in parts by weight: 20-25 parts of water, 0.1-1.0 part of wetting and dispersing agent, 0.1-0.5 part of defoaming agent, 10-15 parts of antirust pigment, 2-4 parts of functional antirust pigment, 15-25 parts of tinting pigment, 30-35 parts of filler, 8-12 parts of fatty amine curing agent, 1-2 parts of preservative, 0.5-1.0 part of thickener and 0.2-0.5 part of leveling agent. The invention also discloses a production method of the water-based double-component corrosion-resistant industrial paint. The solid content of the water-based double-component corrosion-resistant paint reaches 65% or above, the hardness reaches H, and the adhesion reaches Grade 0. The water-based double-component corrosion-resistant paint can resist water and brine for 7 days, and has favorable solvent resistance and salt spray resistance. The VOC (volatile organic compound) content is less than 50g / l.

Owner:福建百花化学股份有限公司

Stainless steel and electric heating type cooker chestnuts roasted in sand with brown sugar

An electrically heating stainless steel cooker for chestnuts roasted in sand with brawn sugar is composed of electric drive system, pot-body, heating assemblage consisting of electric heater and heater unit, and stirrer assemblage with paddles. Its advantages are uniform heating, saving electricity, low service life and no environmental pollution.

Owner:王金波

Anti-static composition and method for production thereof

InactiveCN1834171AImprove anti-static effectImprove antistatic performanceLayered productsPolyurea/polyurethane coatingsAlkaline earth metalHeat stability

An anti-static composition comprising a resin and a specific alkali metal salt or alkaline earth metal salt; and a method for producing the composition. The anti-static composition is excellent in heat stability, is free from the problem of bleeding out, exhibits its effect independently of humidity, has fast-acting nature, and also exhibits excellent and durable anti-static property.

Owner:SANKO CHEM CO LTD

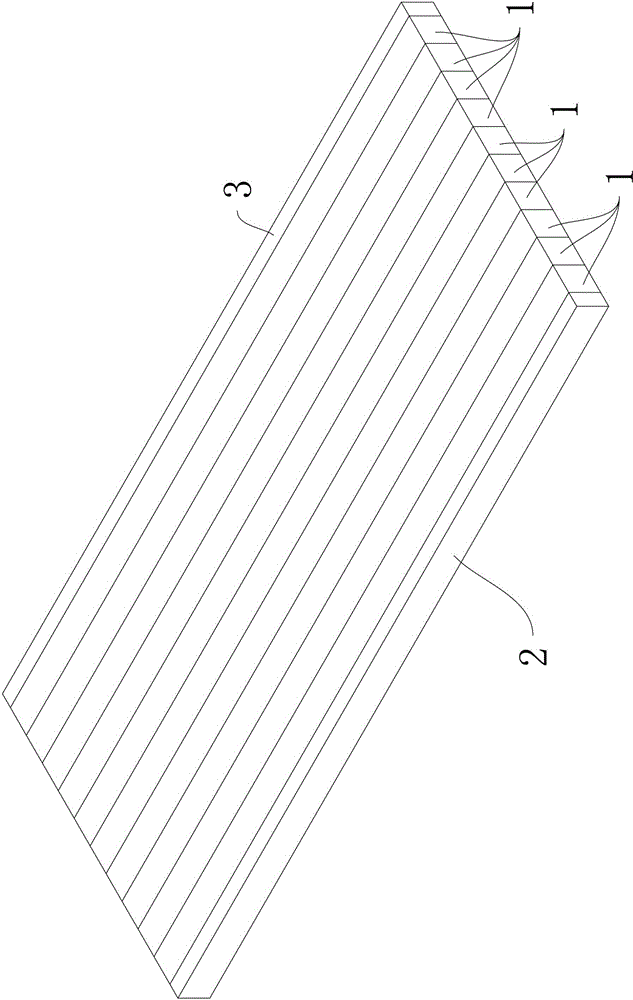

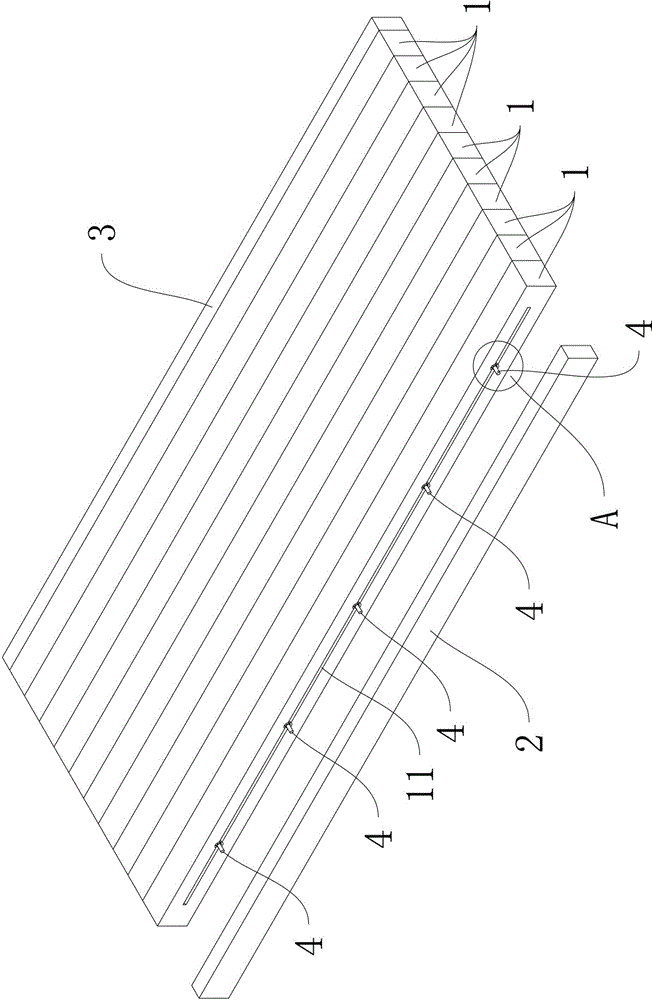

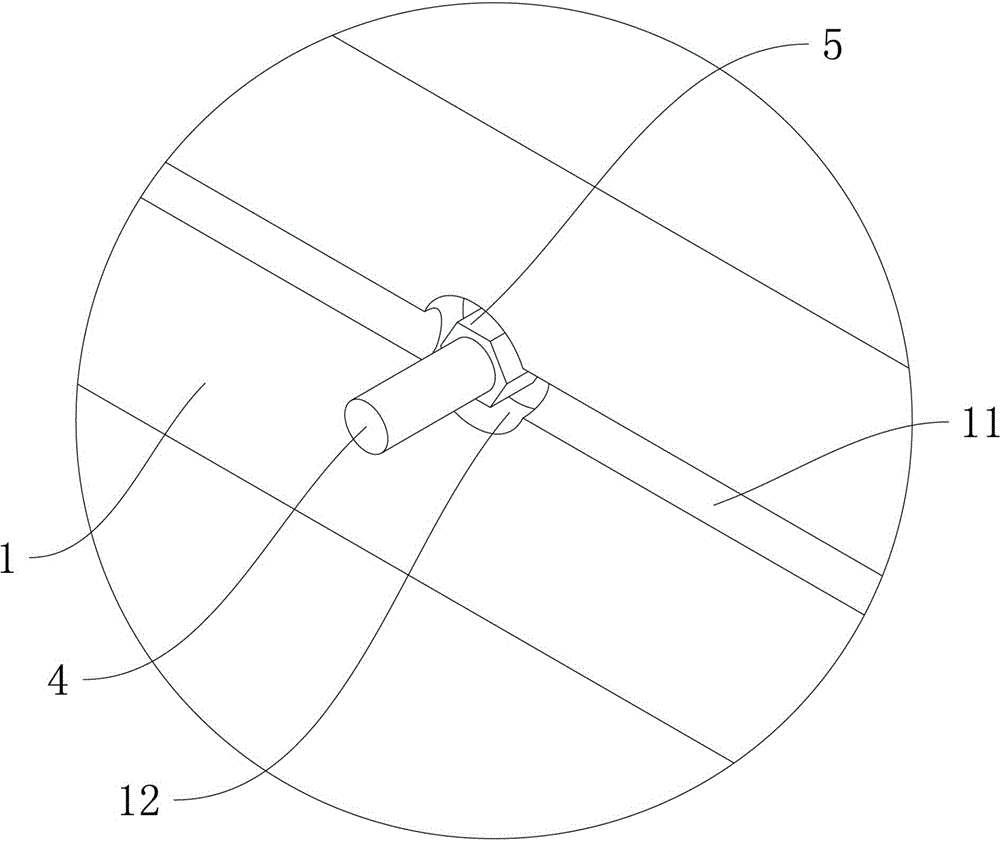

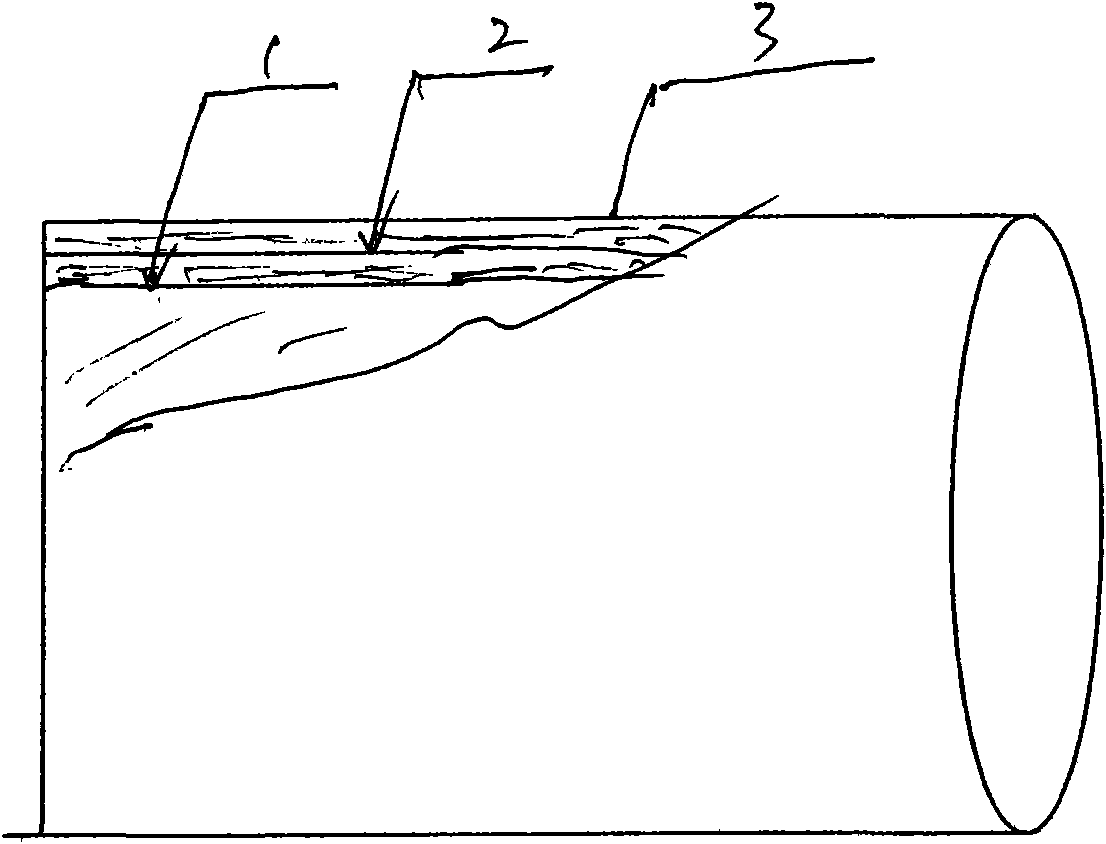

Pure log spliced board and aluminum-wood composited spliced board device using same

InactiveCN105113702AWon't swellWon't archConstruction materialCovering/liningsAdhesiveMechanical engineering

The invention relates to a pure log spliced board and an aluminum-wood composited spliced board device using the same. The pure log spliced board comprises a plurality of pure log boards, a first pure log side board, a second pure log side board, a plurality of screws and a plurality of nuts, each pure log board is made to have a splicing lateral side, an extensible groove slit and multiple screw holes are formed in each splicing lateral side, an adhesive is coated on each splicing lateral side, the pure log boards are arranged, spliced and pressed to form an integrated pure log spliced board body, each screw is penetratingly nested in the corresponding screw hole of the corresponding pure log board, two ends of each screw are tightened and locked by using the nuts, and the pure log side boards are arranged on the splicing lateral sides on two sides of the pure log spliced board body respectively to hide the ends of the screws and the nuts in the spliced board. The pure log spliced board is simple in structure, convenient to assemble and easy to realize, unfavorable factors like material cracking and deforming caused by thermal expansion and cold contraction of pure log are prevented effectively, and a log product is more attractive, more environment friendly and longer in service life.

Owner:彭志军

Method for manufacturing paper water pipe

InactiveCN101879791ADoes not rustExtended service lifeSpecial paperPaper/cardboard wound articlesRolling paperAdhesive

The invention relates to a method for manufacturing a paper water pipe. The paper water pipe comprises the following raw materials in percentage by weight: 85 to 90 percent of wood pulp paper, 8 to 10 percent of paper tube adhesive, 0.08 to 1 percent of film (PE), 1 to 1.2 percent of aluminum plating film (VMPEP) and 0.05 to 0.08 percent of film (OPE). The method comprises the following steps of: 1, slitting paper strips for later use; 2, arranging the paper strips in order; 3, sizing; 4, thermally sealing a device; and 5, rolling paper tubes. The paper water pipe has the advantages of environmental protection, corrosion resistance, rust resistance, cracking resistance in winter, long service life, light weight, convenient construction, thermal seal connection at a joint, low cost and the like.

Owner:任立群

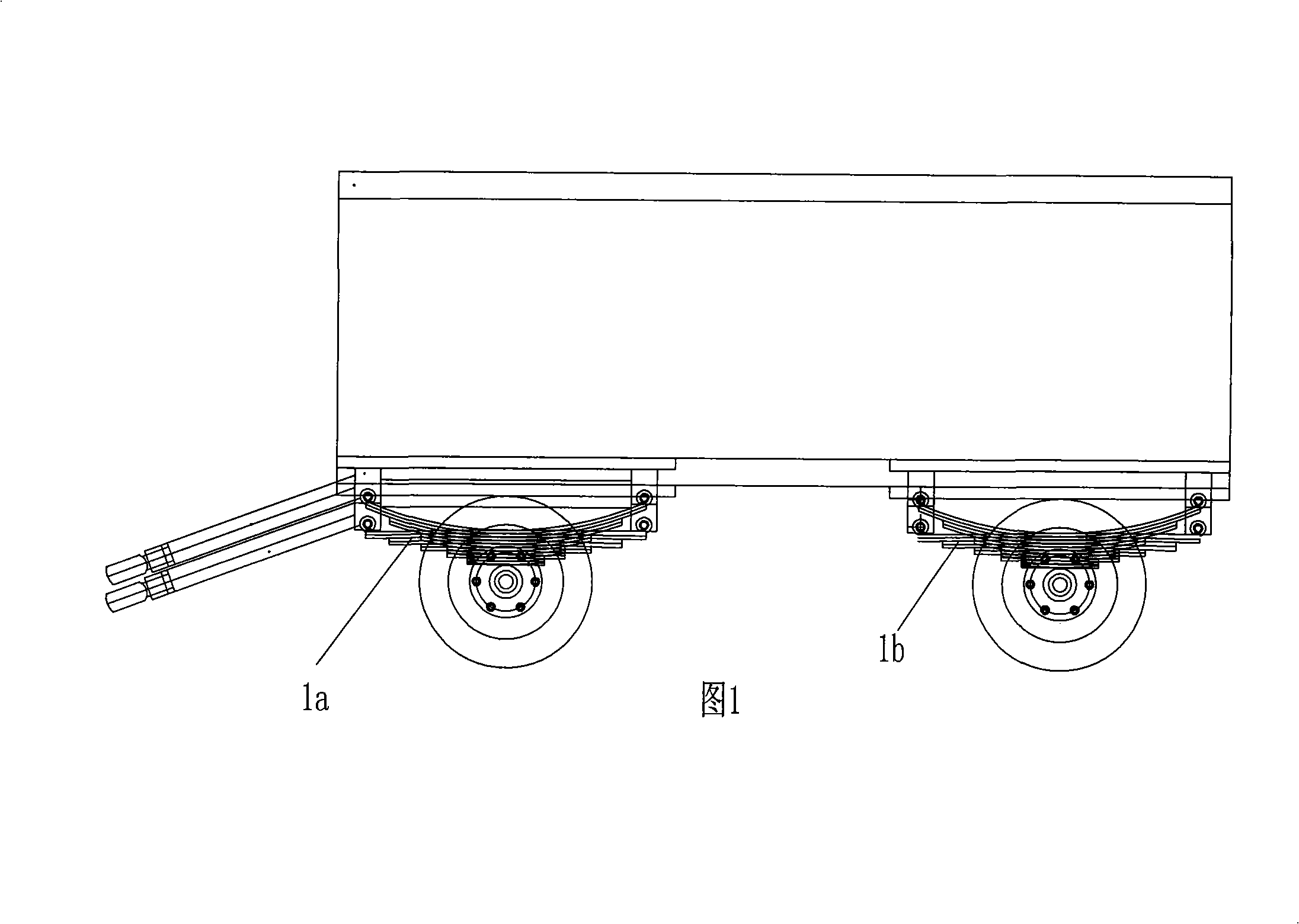

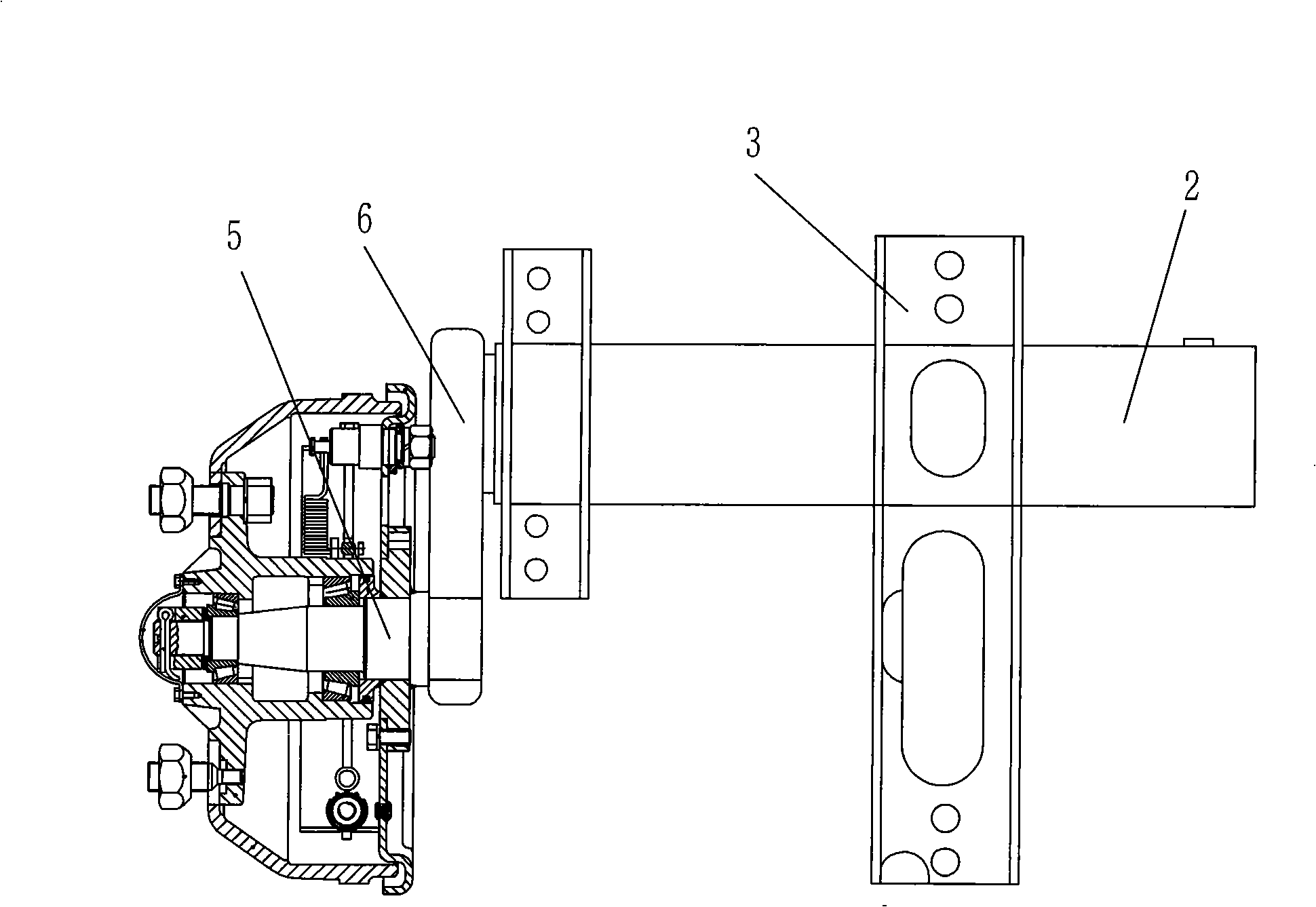

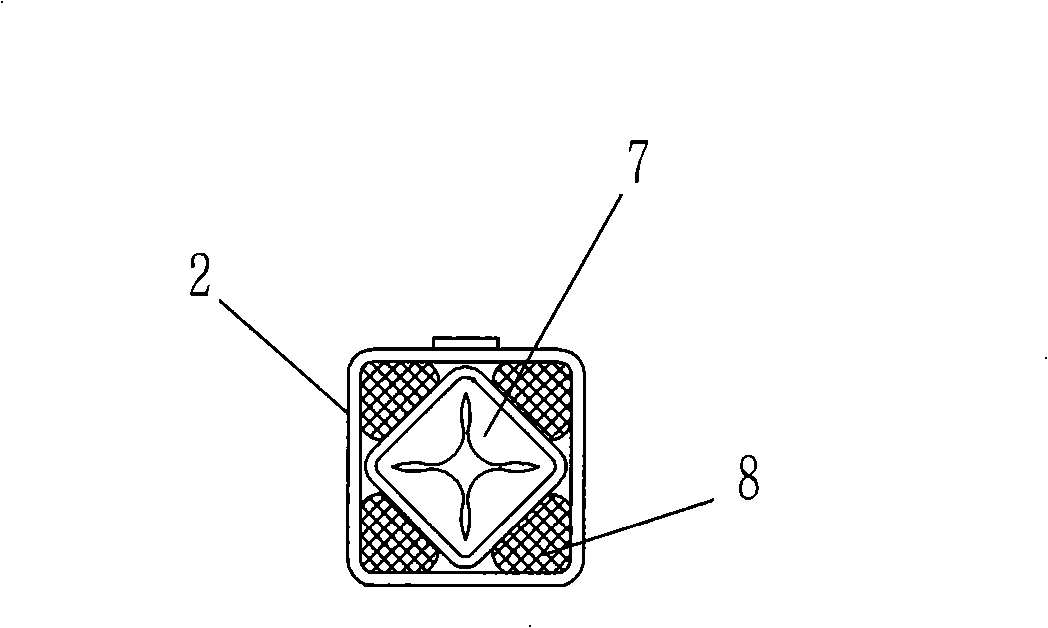

Shock-absorbing axle of special-shaped rubber stick

InactiveCN101293469ASimple structureStrong bearing capacityResilient suspensionsTorsion springEngineering

A deformed rubber stick damping axle is characterized by being provided with an outer axle tube; an inner bushing is sheathed in the outer axle tube; the inner bushing and the outer axle tube can form mutual rotation and an empty cavity is formed between the inner bushing and the outer axle tube; an elastomer which forms obstruction to the mutual rotation between the outer axle tube and the inner bushing is pressed and arranged in the empty cavity to form a torsion spring; the outside of the outer axle tube is fixedly provided with a bracket fixedly connected with a carriage or a device; the two ends of the outer axle tube are empty sleeves; the two ends of the inner bushing are respectively and fixedly connected with a torsion arm along the radial direction; the other end of the torsion arm is fixedly connected with a shaft head; the torsion arm and the axes of the shaft head are arranged in 'L' shape; the axle of the invention has the advantages of simple structure and high bearing capacity, which can greatly reduce the elastic distance between empty load and heavy load by the torsion spring, reduces the gravity center of the car body and improves the moving stability of the car body.

Owner:涡阳县康达车桥有限公司

Anti-static composition and method for production thereof

InactiveCN1509316AImprove antistatic performanceDoes not rustPolyurea/polyurethane coatingsThin material handlingAlkaline earth metalHeat stability

An anti-static composition comprising a resin and a specific alkali metal salt or alkaline earth metal salt; and a method for producing the composition. The anti-static composition is excellent in heat stability, is free from the problem of bleeding out, exhibits its effect independently of humidity, has fast-acting nature, and also exhibits excellent and durable anti-static property.

Owner:SANKO CHEM CO LTD

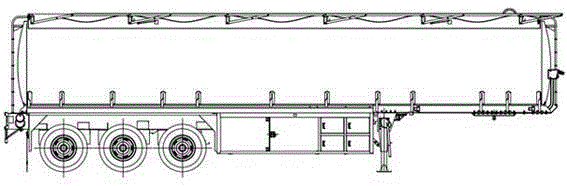

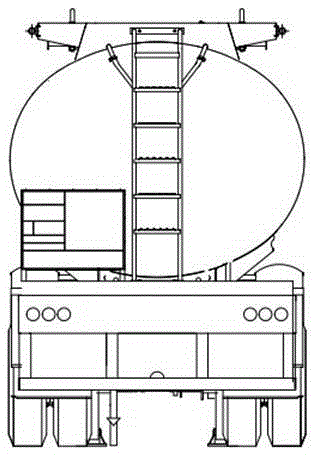

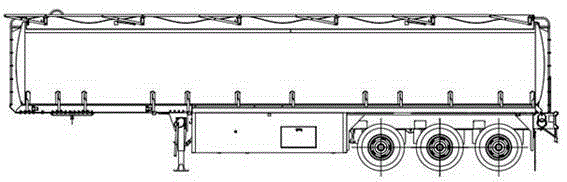

Semi-trailer oil tank truck with aluminum alloy structure

InactiveCN105383361AReduce fuel consumptionLight curb weightTank vehiclesItem transportation vehiclesSemi-trailerTruck

The invention discloses a semi-trailer oil tank truck with an aluminum alloy structure. The semi-trailer oil tank truck comprises an aluminum alloy tank body, an aluminum alloy supporting seat and an aluminum alloy frame, wherein the aluminum alloy tank body and the aluminum alloy supporting seat are welded; the aluminum alloy frame is fixedly connected to the aluminum alloy tank body; axles and tires are mounted on the aluminum alloy frame; an oil feeding and discharging pipeline is mounted at the right side of the aluminum alloy tank body. The semi-trailer oil tank truck is light in mass, high in loading mass, small in oil consumption, safe, clean, and environmentally friendly.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

Preparation method of high-molecular composite material strip nail

InactiveCN103254615AHigh strengthReduce weightStaplesNailsInjection molding machineInjection moulding

The invention relates to a preparation method of high-molecular composite material strip nail. Strength and toughness of plastic nails prepared by present methods are not high enough. The method provided by the invention comprises the following steps: firstly uniformly mixing nylon resin, glass fibre, a toughening modifier, a filler, a coupling agent, an anti-oxidant and a lubricant in proportion, and carrying out melt extrusion for pelleting; drying pellets, and forming by injection moulding in an injection machine to form a strip nail structure which comprises a plurality of individual nail bodies which are arranged in parallel, wherein two adjacent individual nail bodies are connected with each other through a connecting rod and a sidewall of each nail body part is provided with an elongated groove; and dipping and drying the injection-moulded material by the use of a silicone oil acetone solution, so as to obtain the high-molecular composite material strip nail. The high-molecular composite material strip nail prepared by the method has characteristics of high strength, light weight, rust resistance, corrosion resistance, antistatic performance, colorable performance and stable performance, and is convenient for secondary processing.

Owner:HANGZHOU HAIXUE TECH

Slow-release dry-type aqueous inorganic zinc-rich coating and preparation method thereof

ActiveCN102775828AStrong chemical bondSolve the problem of corrosionAlkali metal silicate coatingsAnti-corrosive paintsSand blastingFirming agent

The invention relates to a slow-release dry-type aqueous inorganic zinc-rich coating. The slow-release dry-type aqueous inorganic zinc-rich coating mainly comprises a host agent and a curing agent, wherein the part by weight of the host agent to the curing agent is 100:30-100:50. The slow-release dry-type aqueous inorganic zinc-rich coating is prepared from a slow-release dry-type modifier which is matched with zinc powder and functional fillers, overcomes the rigorous condition restriction that when the conventional aqueous inorganic zinc-rich coating is applied to outdoor construction, wind force cannot be higher than the 3rd grade, and the temperature of base materials cannot be higher than 30 DEG C, can be coated on the surface of steel base materials subjected to sand blasting under the conditions that the outdoor wind force is at the 5th grade, and the temperature is 50 DEG C, can avoid the paint film defects of film cracking, film rolling in recoating and dry coating when the film thickness is 50-100 mu m, and plays an excellent role of anticorrosion on steel board workpieces. The slow-release dry-type aqueous inorganic zinc-rich coating is used for surface coating of steel boards and steel structure workpieces (such as oil tanks, air tanks and steel structure buildings) which are subjected to sand blasting.

Owner:TIANJIN COLOROAD COATING & CHEM

Preparation method for anticorrosion resin emulsion paint

InactiveCN103382355AQuality improvementEasy to useAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneEpoxy

The invention discloses a preparation method for an anticorrosion resin emulsion paint. The preparation method comprises the following steps: adding a polyester resin and an epoxy resin into a reaction vessel, then adding an antirust pigment, a coloring pigment and a filling material, carrying out mixing for 0.5 to 1 h with stirring, adding an auxiliary agent and a mixed solvent after uniform dispersion and then carrying out grinding, filtering, barreling and packaging so as to prepare a component A; adding tricarboxymethyl propane, a polyurethane dehydrating agent and cyclohexanone into the reaction vessel together, starting stirring, then stopping stirring when a temperature rises to 80 DEG C through heating, continuing heating to a temperature of 140 DEG C, allowing a mixture of the dehydrating agent and water to be evaporated, adding a plasticizer and toluene diisocyanate into the reaction vessel and allowing a reaction temperature to be maintained at 40 to 50 DEG C so as to prepare a component B in 2 h; and blending 60 to 80% of the component A and 20 to 40% of the component B so as to obtain a finished paint. The anticorrosion paint provided by the invention has stable quality; through usage of the polyester resin and the epoxy resin as base materials and formation of an interpenetrating polymer network, a coating is endowed with compactness, and anticorrosion performance and adhesion of the coating are substantially improved.

Owner:南京市荣达树脂有限公司

6000-series high-performance aluminum alloy plate for automobile panel and manufacturing method thereof

The invention relates to a 6000-series high-performance aluminum alloy plate for an automobile panel and a manufacturing method thereof. The 6000-series high-performance aluminum alloy plate contains Si, Fe, Cu, Mn and Mg and comprises a 6016 high-performance aluminum alloy plate, a 6022 high-performance aluminum alloy plate and a 6111 high-performance aluminum alloy plate. The manufacturing method comprises the following steps: adding an alloy, determining a metallographical refinement level, casting an aluminum plate ingot of a certain thickness, carrying out mechanical cold working to a certain process dimension, determining gate arrangements, rolling reductions and front and back tensile forces for hot rolling and cold rolling, carrying out recrystallization annealing at 370-390 DEG C for 10-20 minutes, thereby manufacturing the 6000-series high-performance aluminum alloy plate for an automobile panel. Thus, the invention achieves the purposes of automobile weight reduction, energy conservation and emission reduction.

Owner:JIANGSU CAIFA ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com