Method for producing plastic pipe fitting with insert made from polyphenylene sulfide alloy material

A technology for polyphenylene sulfide and plastic pipe fittings, which is applied in the field of building materials, can solve the problems of layered water leakage, large difference in expansion coefficient, complicated processing technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a plastic pipe fitting with a polyphenylene sulfide alloy material insert, which can be manufactured by the following method:

[0031] A: The production method of polyphenylene sulfide composite material, which consists of the following components, by weight percentage:

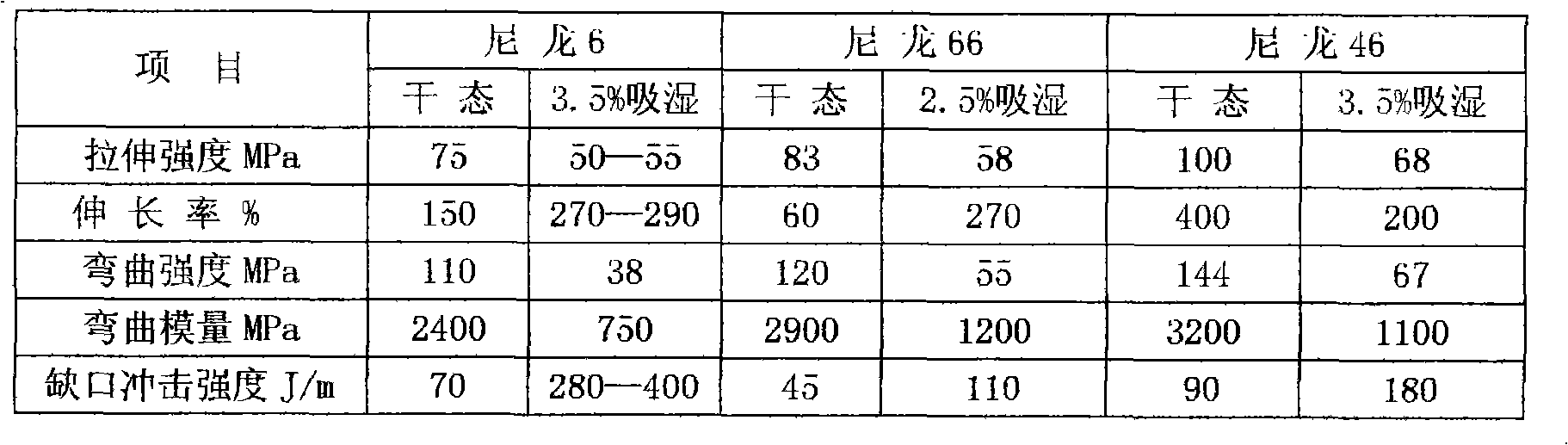

[0032] Polyphenylene sulfide 60%; polypropylene graft 8%; polypropylene 5%; nylon 10%; filler 15%; coupling agent 1%; antioxidant 1%;

[0033] Dry polyphenylene sulfide at 140°C for 5 hours; dry nylon at 90°C for 6 hours, add and mix polypropylene grafts, polypropylene, fillers, coupling agents, and antioxidants accurately After mixing in the machine for 20 minutes, add the twin-screw extrusion granulator; through the twin-screw extrusion granulator, add glass fiber into the glass fiber port to fully melt and plasticize extrusion, stranding, cooling, pelletizing, and homogenization Made of polyphenylene sulfide composite material;

[0034] B: Inject the polyphenylene sulfid...

Embodiment 2

[0045] A method for manufacturing a plastic pipe fitting with a polyphenylene sulfide alloy material insert, which can be manufactured by the following method:

[0046] A: The production method of polyphenylene sulfide composite material, which consists of the following components, by weight percentage:

[0047] Polyphenylene sulfide 50%; polypropylene graft 5%; polypropylene 5%; nylon 15%; filler 22%; coupling agent 2%; antioxidant 1%;

[0048] Dry polyphenylene sulfide at 140°C for 3 hours; dry nylon at 85°C for 5 hours, add and mix polypropylene grafts, polypropylene, fillers, coupling agents, and antioxidants accurately After mixing in the machine for 10 minutes, add the twin-screw extrusion granulator; through the twin-screw extrusion granulator, add glass fiber into the glass fiber port to fully melt and plasticize extrusion, stranding, cooling, pelletizing, and homogenization Made of polyphenylene sulfide composite material;

[0049] B: Inject the polyphenylene sulfid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com