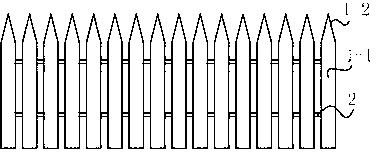

Preparation method of high-molecular composite material strip nail

A composite material and polymer technology, applied in the field of polymer composite materials, can solve the problems of insufficient strength, toughness and strength reduction of plastic nails, and achieve the effect of light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

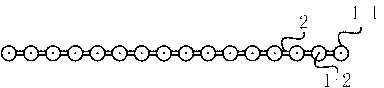

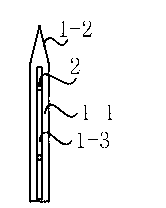

Method used

Image

Examples

Embodiment 1

[0025] Step (1). 40Kg nylon-6, 40Kg glass fiber, 1Kg grafted POE, 1Kg nanoscale talcum powder, 2Kg nanoscale calcium carbonate, 2Kg nanoscale silicon dioxide, 0.1Kg coupling agent KH-560, 0.2Kg Antioxidant 1098 and 0.1Kg calcium stearate were mixed uniformly, put into a twin-screw extruder, and granulated through melt extrusion. The technological parameters of the melt extrusion granulation are as follows: the barrel temperature of the twin-screw extruder is 250° C., the nozzle temperature is 260° C., and the screw speed is 200 rpm.

[0026] Step (2). The obtained pellets were dried at 100° C. for 8 hours, and then injection molded in an injection molding machine. The injection molding process parameters are: the mold temperature is 120°C, the injection molding temperature is 250°C, and the injection molding pressure is 45Mpa.

[0027] Step (3). After impregnating the injection-molded material with a silicone oil-acetone solution with a mass content of 1% silicone oil, dry it...

Embodiment 2

[0029] Step (1). With 45Kg nylon-66, 30Kg glass fiber, 2Kg grafted EPDM, 2Kg nano-scale calcium carbonate, 2Kg nano-scale silicon dioxide, 0.2Kg coupling agent KH-570, 0.3Kg antioxidant 1010, 0.5Kg The silicone powder is mixed evenly, put into a twin-screw extruder, and granulated through melt extrusion. The technological parameters of the melt extrusion granulation are as follows: the barrel temperature of the twin-screw extruder is 255° C., the nozzle temperature is 265° C., and the screw speed is 250 rpm.

[0030] Step (2). The obtained pellets were dried at 105° C. for 7 hours, and then injection molded in an injection molding machine. The injection molding process parameters are: the mold temperature is 125°C, the injection molding temperature is 260°C, and the injection molding pressure is 40Mpa.

[0031] Step (3). After impregnating the injection-molded material with a silicone oil-acetone solution with a mass content of 1.5% of silicone oil, dry it at 135°C for 1 hour...

Embodiment 3

[0033] Step (1). With 60Kg nylon-610, 20Kg glass fiber, 4Kg grafted POE, 3Kg nanometer silicon dioxide, 0.25Kg coupling agent KH-560, 0.25Kg coupling agent KH-570, 0.1Kg antioxidant 1098 , 1Kg calcium stearate, and 1Kg silicone powder are mixed evenly, put into a twin-screw extruder, and granulate through melt extrusion. The technological parameters of the melt extrusion granulation are as follows: the barrel temperature of the twin-screw extruder is 260° C., the nozzle temperature is 270° C., and the screw speed is 240 rpm.

[0034] Step (2). The obtained pellets were dried at 110° C. for 6 hours, and then injection molded in an injection molding machine. The injection molding process parameters are: the mold temperature is 130°C, the injection molding temperature is 265°C, and the injection molding pressure is 38Mpa.

[0035] Step (3). After impregnating the injection-molded material with a silicone oil-acetone solution with a mass content of 2% silicone oil, dry it at 140°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com