Patents

Literature

233results about How to "Convenient secondary processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing technique for moisture-proof middle, high-density pressed-fibre board

InactiveCN101269508APrevent deformation and thickeningResistance to intrusionAldehyde/ketone condensation polymer adhesivesDomestic articlesFiberSteam pressure

The invention relates to a production technology of a moistureproof medium and high density fibre panel in the fibre panel production technology. The production technology comprises the working procedures of wood chip screening and washing, stewing, hot grinding, glue blending and spreading, drying, paving and molding, heat pressing, and cooling. The steam pressure for wood chip stewing after water-washing ranges from 0.70 to 0.80MPa, and the stewing time is 3 to 5 minutes; when the wood chip is processed through hot grinding defibrination, a water repellent substance is added in, and the pressure in a grinding chamber is lower than the pressure in a stewing cylinder, wherein, the weight of the water repellent substance is 1 to 1.5 percent of the dry fibre, and the pressure of the stewing cylinder is 0.01 to 0.02MPa; in the working procedure of glue blending and spreading, MDI modified urea formaldehyde resin adhesive and firming agents are added in, wherein, the weight of the MDI modified urea formaldehyde resin adhesive is 9 to 11 percent of the dry fibre, and the weight of the firming agents is 2 to 4 percent of the dry fibre; in the drying working procedure, the water ratio is 8 to 12 percent; parting medium of 1 to 2ml / m<2> is sprayed onto the upper surface and the lower surface of a plate blank before entering into the working procedure of heat pressing; then the heat pressing is acted to form the fibre panel. Moistureproof plank stuffs which are produced by the invention can prevent the moisture in air from intruding, the various indexes satisfy the national standards, the surface is smooth and regular, the secondary process is facilitated, and the production cost is lowered.

Owner:DONGYING ZHENGHE WOOD IND

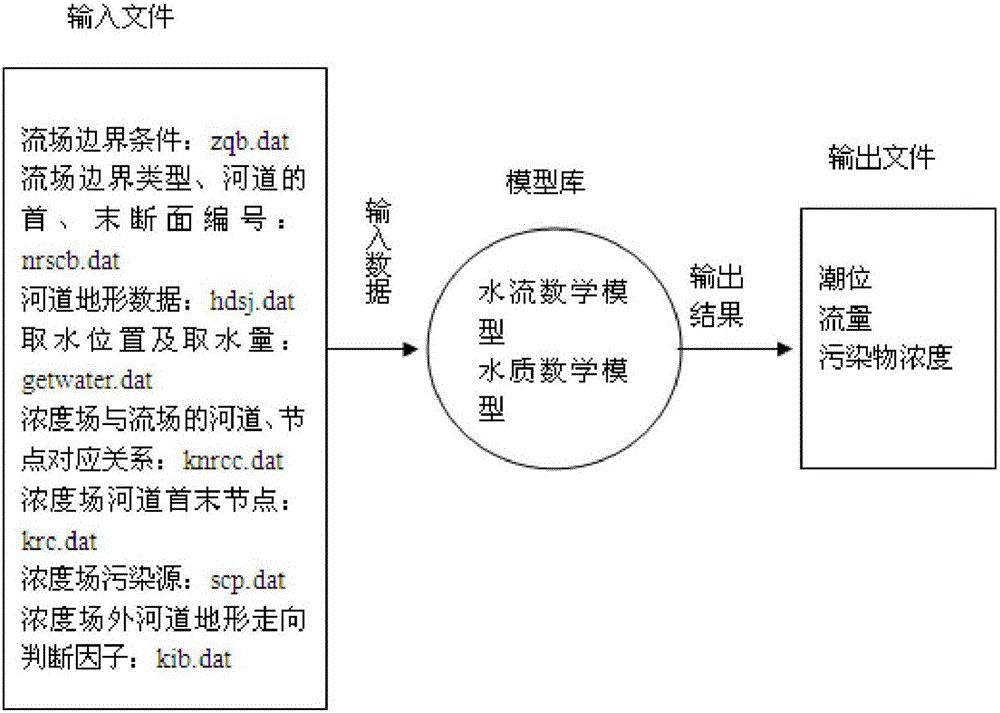

High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

The invention provides a high-plasticity aluminum-based composite material containing TiB2 particles and a preparation method thereof, and relates to an aluminum-based composite material and a preparation method thereof. The invention solves the problems of the prior art, such as poor plasticity and toughness and difficulty in secondary processing. The composite material contains (by volume) titanium diboride reinforcement particles 10-25 percent, aluminum particles 25-35 percent, and aluminum alloy matrix in balance. The preparation method comprises: (1) weighing titanium diboride reinforcement particles, aluminum particles and aluminum alloy matrix; (2) mixing by mechanical dry method to obtain a reinforcement powder; (3) placing the reinforcement powder in a die and compression-molding; (4) heating the die; (5) melting aluminum alloy and casting in the die; (6) applying a pressure on the die with molten aluminum and maintaining the pressure for a period of time and cooling; (7) demoulding and taking the cast ingot, that is reinforced aluminum-based composite material. The inventive aluminum-based composite material has high plasticity and good wear resistance and is adapted to secondary processing and machining.

Owner:HARBIN INST OF TECH

Electron radiation cross-linked polyolefin pearl foam and preparation method thereof

ActiveCN103849004AMeet the requirements of beautiful appearancePlay pearlescent anti-counterfeiting effectSynthetic resin layered productsPolymer sciencePolyolefin

The invention relates to polyolefin pearl foam and a preparation method thereof. The method comprises the following steps: (1) preparing foaming master batch; (2) preparing flame retardant master batch; (3) preparing calcium carbonate filler master batch; (4) adding raw materials into a high-speed mixer to prepare an ingredient 1; (5) adding raw materials into the high-speed mixer to prepare an ingredient 2; (6) performing double-layer composite extruding: adding the ingredient 1 and the ingredient 2 into a hopper of a double-layer composite sheet extruder to extrude into double-layer composite sheets; (7) performing radiation crosslinking of the composite sheets; (8) foaming the composite sheets; (9) cutting the composite sheets to obtain a finished product. The polyolefin pearl foam prepared by using the method has the advantages of good luminescence effect, easily available raw materials and low preparation cost.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

High specific weight soundproof composite material

InactiveCN1424350AConvenient secondary processingImprove applicabilitySound proofingFlooring insulationsHigh resistanceMachinability

A sound-isolating composition with high specific weight contains PVC (5-35 wt.%), tungsten powder (40-90), coupling agent (1-10) and assistant (4-15). Its advantages are high softeness and effect on reducing noise by 20-25 db, high resistance to fire and chemical corrosion, no poison and high machinability.

Owner:SHANGHAI JIAO TONG UNIV

Production process of fire-retardant particleboard

InactiveCN105965660AProcess stabilityMoisture-proofVeneer manufactureDomestic articlesFire retardantEnvironmentally friendly

The invention relates to a production process of a fire-retardant particleboard. The process comprises the following steps: cutting into pieces; flaking; drying; sieving; winnowing; making and applying glue; paving; pre-pressing to form; thermally pressing; cooling a plain board, and stacking; then intermediately storing and transporting; sanding; sawing; and finally packaging and warehousing. The fire-retardant particleboard produced by the process has the characteristics of being stable in process, stable in internal performances, damp-proof, hard to break, environmentally friendly, and easy to secondarily process.

Owner:鸿伟木业(仁化)有限公司

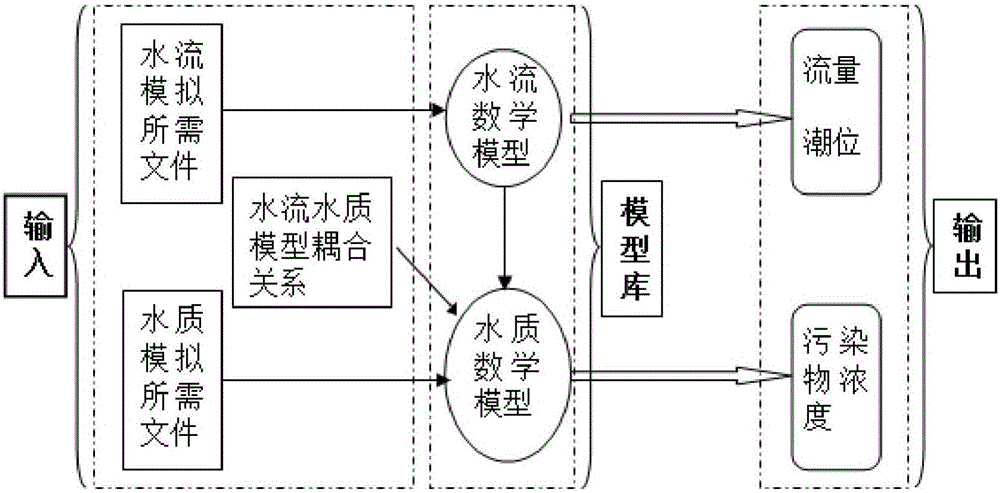

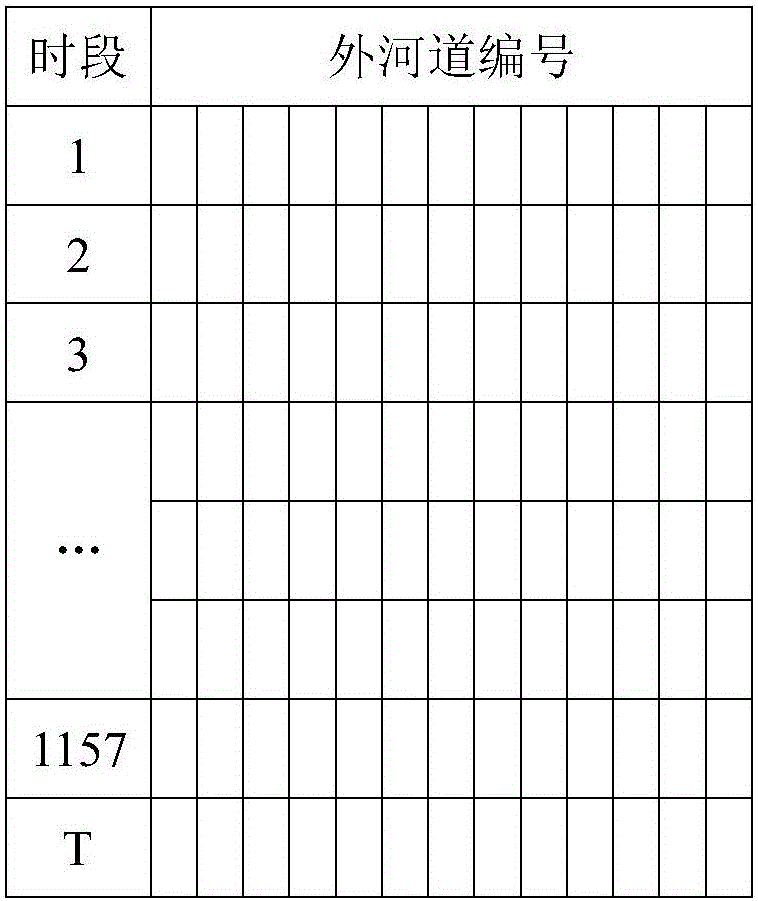

South tidal river network area water flow and water quality coupling simulation system

ActiveCN105893763AEnsure efficient operation and stabilityImproved applicability and portabilityGeneral water supply conservationInformaticsTerrainRiver water

The invention provides a south tidal river network area water flow and water quality coupling simulation system, which comprises three modules: a data input module, a model base and a data output module, wherein the model base comprises a water flow mathematical model and a water quality mathematical model. The water flow mathematical model can be used as a separate module, carries out analysis calculation on input terrain, water intake engineering data, hydrologic data and the like, adopts a flexible user interface so as to conveniently carry out secondary processing, required by a user, on the data, and provides a basic data support for the water quality mathematical model. The water quality mathematical model is organically combined with the water flow mathematical model, so that simulation on river water quantity of a large-range river network area on the basis of the water flow mathematical model is implemented; moreover, a gate dam, water intake and drainage and the like can be flexibly set, so that practicality and applicability of the system are reinforced.

Owner:SUN YAT SEN UNIV

Metal wire mesh reinforced heat-conducting plastic with high strength, high corrosion resistance and high heat conductivity

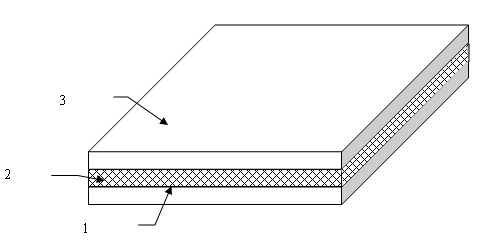

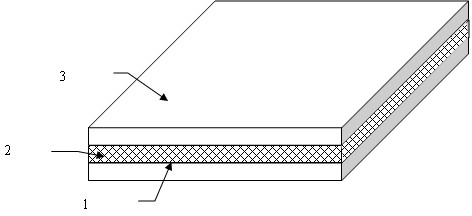

InactiveCN102649328AImprove mechanical propertiesFast heat conductionSynthetic resin layered productsMetal layered productsWire meshCorrosion resistant

The invention discloses a metal wire mesh reinforced heat-conducting plastic with high strength, high corrosion resistance and high heat conductivity. The metal wire mesh reinforced heat-conducting plastic is obtained by compounding a heat-conducting plastic lower layer, a metal wire mesh reinforced layer and a heat-conducting plastic upper layer in sequence from bottom to top; the heat-conducting plastic lower layer is 0.1-5 mm thick; the metal wire mesh reinforced layer is 0.1-5 mm thick; and the heat-conducting plastic upper layer is 0.1-5 mm thick; and the metal wire mesh reinforced heat-conducting plastic with high strength, high corrosion resistance and high heat conductivity, disclosed by the invention, has the advantages of good mechanical property, high corrosion resistance, high heat conduction coefficient and easiness for secondary machining. The bending strength can be more than 70 MPa and the heat conduction coefficient is more than 1.5 W / m.oC; the bending strength of a pure heat-conducting plastic is only 25-50 MPa and the heat conduction coefficient is about 0.4-1.0 W / m.oC; and the metal wire mesh reinforced heat-conducting plastic disclosed by the invention is very suitable for preparing heat radiators and heat exchangers.

Owner:陈建伟

Hydrogen sulfide leakage emergency removing dry powder, and preparation method thereof

InactiveCN103949140AGood dispersionConvenient secondary processingDispersed particle separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a hydrogen sulfide leakage emergency removing dry powder, and a preparation method thereof. The hydrogen sulfide leakage emergency removing dry powder is mainly used for solving problems of existing technology that environmental pollution is caused, and removing efficiency is low. The hydrogen sulfide leakage emergency removing dry powder mainly comprises, by mass, 65 to 99% of a removing agent, 0.5 to 15% of a moisture-proof agent, and 0.5 to 20% of an additive; the additive is at least one selected from polyethylene glycol dimetyl ether, N-methylpyrrolidinone, propylene carbonate, tributyl phosphate, N-methylcaprolactam, methyl alcohol, alkyl alkylol amine, sulfolane, bentonite, carboxymethyl cellulose, and sodium carboxymethylcellulose. The hydrogen sulfide leakage emergency removing dry powder is capable of solving the above problems preferably, and can be used for hydrogen sulfide leakage emergency removing.

Owner:CHINA PETROLEUM & CHEM CORP +1

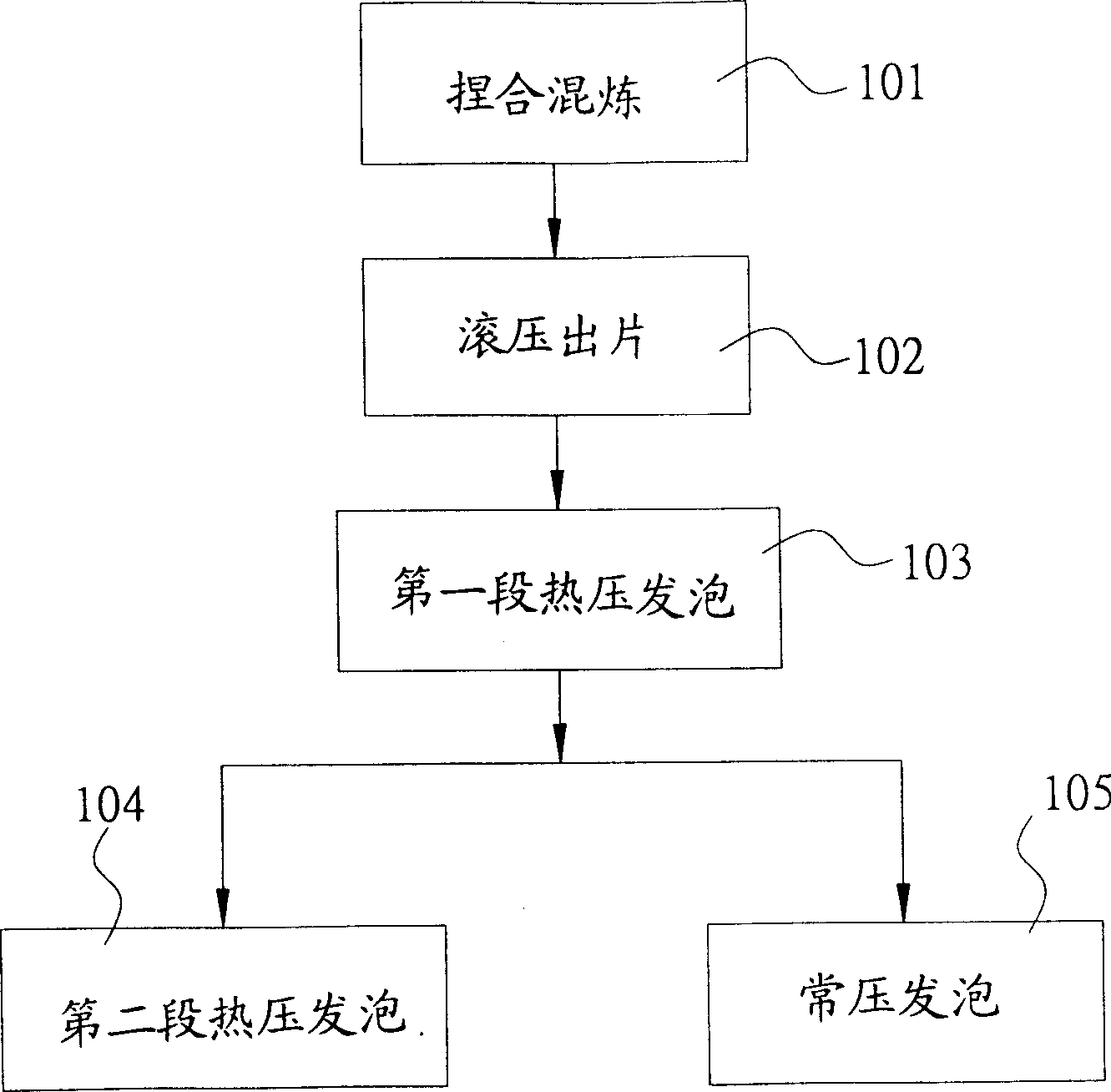

High-power foaming production of thermoplastic elastomer composite material

A process for preparing thermoplastic elastic composition by high-multiple foaming includes such steps as mixing the thermoplastic elastomer with foaming agent and bridging agent, kneading, making sheets, stacking, hot die pressing while foaming, and secondary hot die pressing or baking in long oven while foaming again.

Owner:MICROCELL COMPOSITE CO LTD

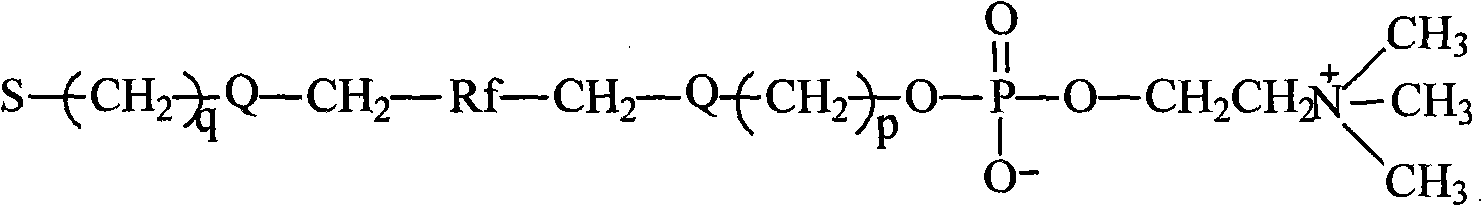

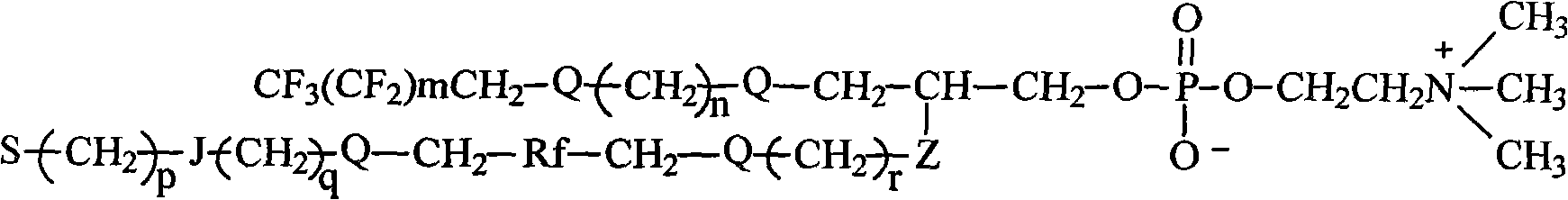

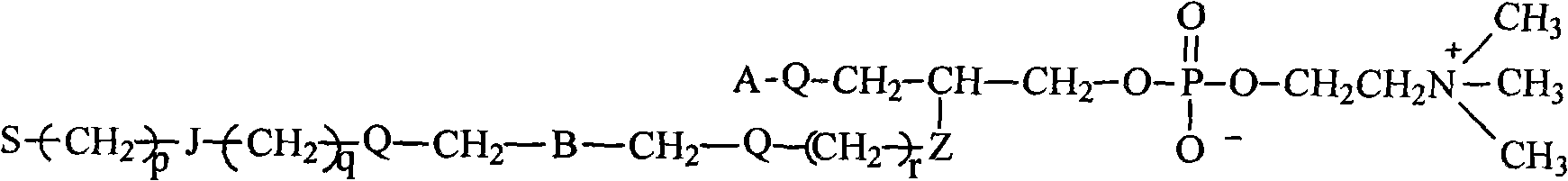

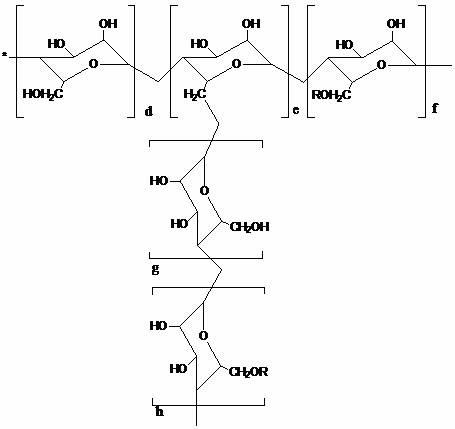

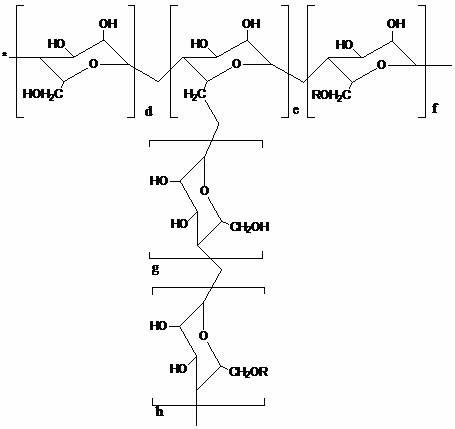

Fluorocarbon chain or/and hydrocarbon chain containing phosphatidylcholine blocking agent with hydroxyl or amino at tail end and polyurethane material for blocking same

ActiveCN101787047AGood biocompatibilityMolecular weight does not affectPhosphorus organic compoundsBiocompatibility TestingHigh activity

The invention discloses fluorocarbon chain or / and hydrocarbon chain containing phosphatidylcholine blocking agent with hydroxyl or amino at the tail end, fluorocarbon single-chain containing phosphatidylcholine with hydroxyl or amino at the tail end, fluorocarbon double-chain containing phosphatidylcholine with hydroxyl or amino at the tail end, fluorocarbon and hydrocarbon mixed double-chain containing phosphatidylcholine with hydroxyl or amino at the tail end, or hydrocarbon double-chain containing phosphatidylcholine with hydroxyl or amino at the tail end. The invention also discloses a polyurethane material for blocking the blocking agents respectively. Because the blocking agent provided by the invention enables a phosphatidylcholine group to be positioned at the polyurethane tail end with high activity, the phosphatidylcholine group easily moves to the surface of the material so as to obtain phosphatide surface polyurethane; therefore, the blocking agent can endow the material with good biocompatibility and keep excellent physical and mechanical properties of the material, and the material has low cost and can be secondarily processed conveniently for manufacturing artificial blood vessels, artificial cardiac pacemaker leads, artificial heart valves, interposed catheters and the like.

Owner:SICHUAN UNIV

Radiation-resistant liquid organic glass

ActiveCN104262527AEfficient radiation protectionConvenient secondary processingShieldingMethacrylateCyclohexanone

The invention provides radiation-resistant liquid organic glass. Lead methacrylate and samarium methacrylate are used for preparing the radiation-resistant liquid organic glass as radiation-resistant components by the following steps: dissolving the lead methacrylate in cyclohexanone, dissolving the samarium methacrylate in caprylic acid and propylene glycol, weighing methyl methacrylate, dioctyl phthalate, cyclohexane and butanol, feeding the raw materials into a reaction kettle, stirring and heating the raw materials to 78 DEG C, dropwise adding a cyclohexanone solution of benzoyl peroxide, and keeping the temperature constant for 1 to 4 hours to obtain the liquid organic glass. The organic glass has the characteristics of high radiation resistance and good convenience in secondary processing.

Owner:砀山县纳方包装材料有限公司

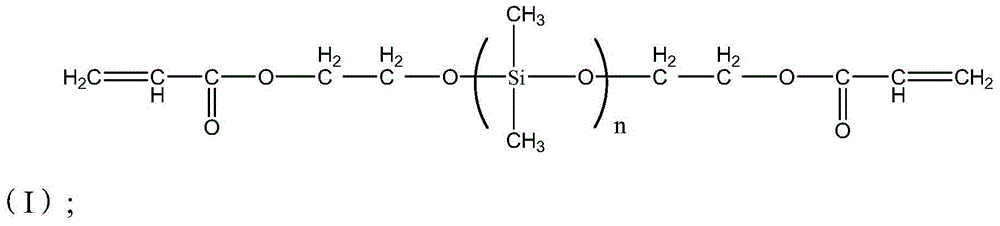

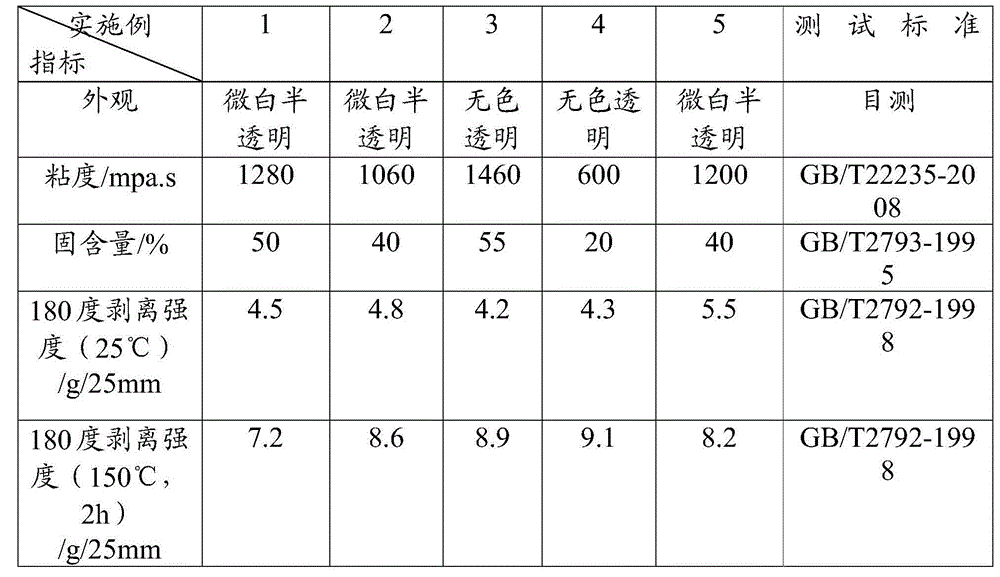

High temperature-resistant low viscosity pressure-sensitive adhesive used for protection films, and preparation method and application thereof

InactiveCN104152084ALow peel strengthConvenient secondary processingEster polymer adhesivesOrganic solventUltimate tensile strength

The invention discloses a high temperature-resistant low viscosity pressure-sensitive adhesive used for protection films, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, providing a basic monomer and a modifying monomer, and mixing the basic monomer with the modifying monomer in proportion to form a mixed solution; 2, preparing an initiator organic solution; 3, preparing an organic solvent; and 4, adding the mixed solution, the initiator organic solution and the organic solvent into a reactor, reacting, adding the residual mixed solution and the residual initiator organic solution into the reactor in a dropwise manner, carrying out heat insulation, adding the residual organic solvent into the reactor if the organic solvent is still residual, cooling after the dropwise addition, and filtering the obtained discharged material to obtain a target product. The pressure-sensitive adhesive has a wide application. The pressure-sensitive adhesive has a very small peeling strength increase in high temperature environment, can be used at a high temperature of 150DEG C, and is convenient for secondary processing. The pressure-sensitive adhesive has low viscosity, and does not stay on a protected surface after peeling.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

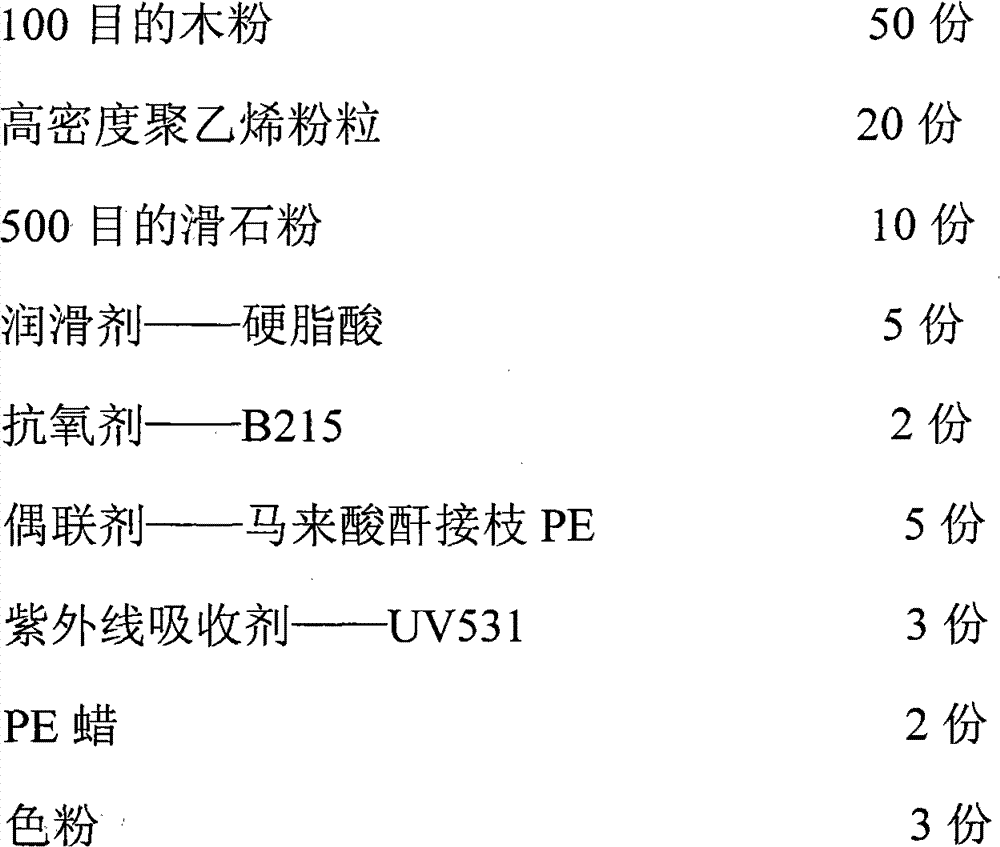

Wood-plastic tile

The invention provides a wood-plastic tile which is processes by subjecting, by weight, 47.5-52.5 parts of wood powder, 19-21 parts of high-density polyethylene powder, 9.5-10.5 parts of talcum powder, 4.75-5.25 parts of lubricant, 4.75-5.25 parts of coupler, 1.9-2.1 parts of PE (polyethylene) wax, 2.85-3.15 parts of ultraviolet light absorber, 1.9-2.1 parts of antioxidant and 2.85-3.15 parts of toner to mixing, heating, extrusion forming and paint spraying. The wood-plastic tile is light in weight, high in strength, less prone to damage, convenient for transport and secondary processing and wide in utilization range.

Owner:刘光群

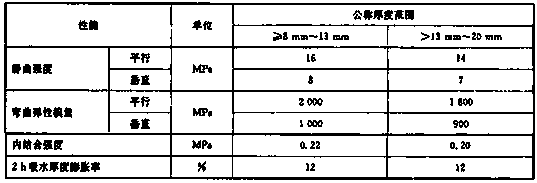

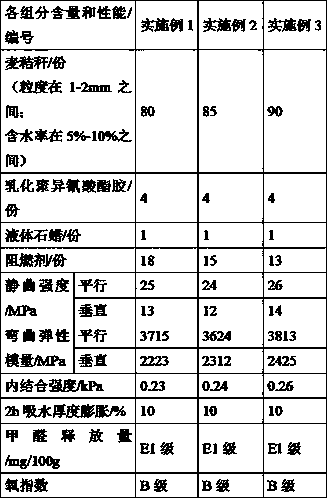

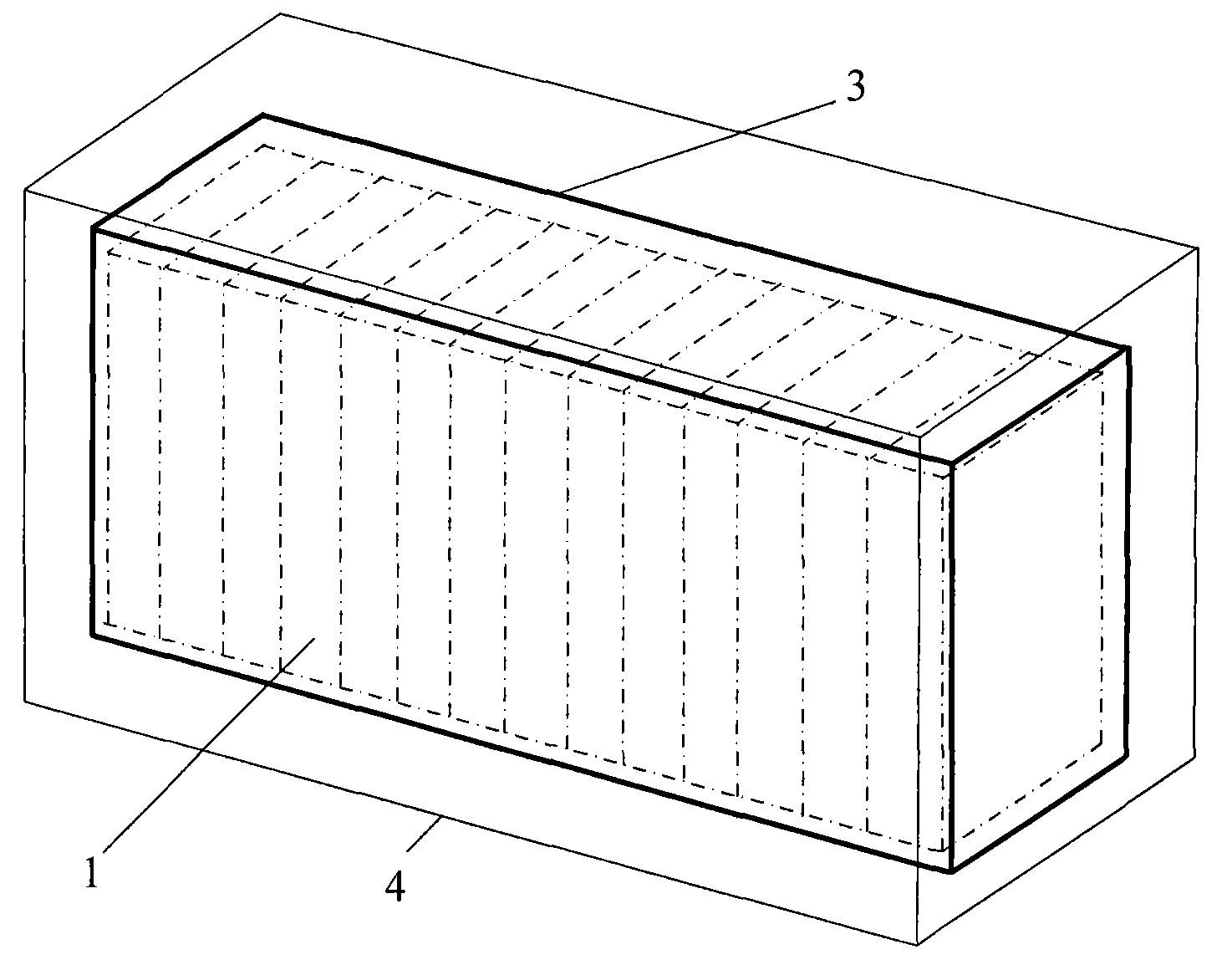

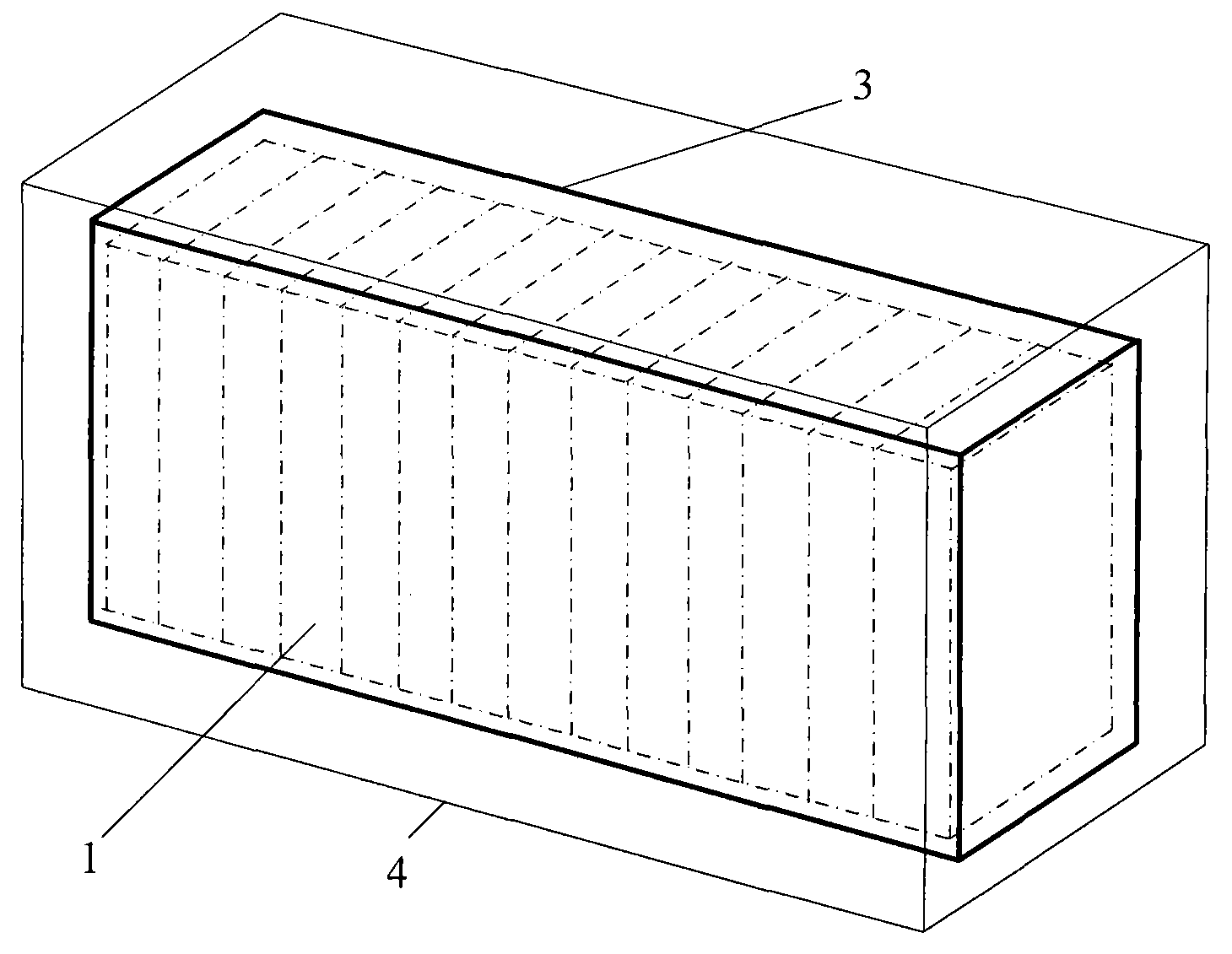

Lightweight and high-strength wheat straw board of oriented structure

InactiveCN107775747AHigh strengthImprove mechanical propertiesWood veneer joiningDomestic articlesAdhesiveMoisture

The invention belongs to the technical field of building boards, and relates to a light-weight, high-strength directional-structure wheat straw board. The oriented structure wheat straw board of the present invention is prepared from the following raw materials in parts by weight: 80-90 parts of wheat straw (particle size between 1-2mm; moisture content between 5%-10%), adhesive 3 ‑5 parts, 1‑2 parts of liquid paraffin and 10‑20 parts of flame retardant. The invention has the advantages of high strength, good dimensional stability, light weight, good machinability, and good water resistance; the invention uses a halogen-free added flame retardant liquid to carry out fire and flame retardant treatment on the wheat straw board, and the fire resistance reaches the national GB8624‑2006 ‑B level standard; polyisocyanate is used as the adhesive of wheat straw board, so that the wheat straw board does not contain free formaldehyde, meets the requirements of green environmental protection, and meets the national GB18580‑2001‑E1 standard; the present invention weaves wheat straw in a criss-cross pattern Permanent pavement, fully improve the strength and toughness of the formed wheat straw board, enhance the waterproof performance, greatly increase the section density, high mechanical properties, and good appearance flatness.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

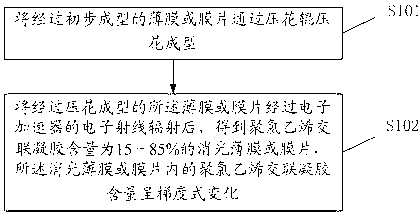

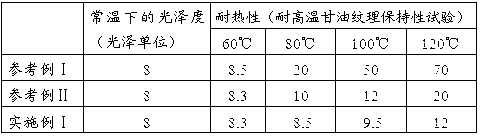

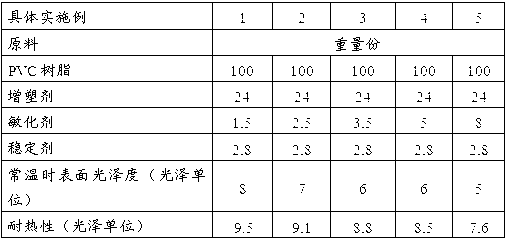

Extinction film or diaphragm and preparation method for same

The invention discloses an extinction film or diaphragm. The extinction film or diaphragm is formed by a framework agent and a sensitizer, and the content of a polyvinyl chloride cross-linked gel in the extinction film or diaphragm is controlled to be 15-85% after electron ray irradiation; the content of the polyvinyl chloride cross-linked gel in the extinction film or diaphragm presents a gradient change; and the framework agent is polyvinyl chloride resin having a polymerization degree of 500-2800, and the sensitizer is a polyfunctional unsaturated monomer. Correspondingly, the invention further discloses a preparation method for the extinction film or diaphragm. The preparation method comprises the following steps of: performing embossing forming on the primarily-formed film or diaphragm via an embossing roll; and then performing the electron ray irradiation of an electron accelerator. With the adoption of the preparation method disclosed by the invention, the extinction film or diaphragm is excellent in extinction property, low in glossiness, high in haze, good in diffuse reflection extinction effect, excellent in texture heat-resistant retainability, simple in processing technique, low in energy consumption, high in yield, pollution-free, and wider in industrial application prospect.

Owner:GUANGDONG TIANAN NEW MATERIAL

Bean curd block making method method for processing thin sheet of bean curd stuffed with filling

A stuffed bean curd is prepared through preparing stuffing, preparing dries bean-curd sheet from water, soybean protein powder, magnesium, defoaming agent, soybean oil, calcium sulfate, starch and yellow pigment, wapping the stuffing by said dried soybean-curd sheets, thermoprinting characters or pattern, cooking and cold storage.

Owner:山东龙藤食品有限公司

Method for preparing mature bee products by using bee

InactiveCN102106320AConvenient secondary processingImprove natural qualityBeehivesMelenaBee products

The invention discloses a method for preparing mature bee products by using bee. The method comprises the following steps that: an area isolated from the outside is enclosed by a separation net, and bees cannot pass the separation net via meshes of the separation net; and the bees are raised in the area in the common way, and the boxes storing immature honey are arranged inside / outside the beehives. In order to ensure the honey-making effect, the boxes storing the immature honey can be honey-storing cans and honey-storing tubes, pressure pumps and control valves are arranged on the pipelines, by which the honey-storing cans and honey-storing tubes are communicated, and the tube walls of the honey-storing tubes are provided with a plurality of honey-discharging holes. The method has the advantages that: by adopting simple facilities and using natural quality of bees, the immature honey is processed into the natural high-concentration honey, the investment on concentrating equipment is saved, and the natural quality of the finished product of honey is improved. Because no mechanical equipment or other human factors are involved in the whole processing flow, the finished product of honey prepared by the method passes the whole natural processing flow, and the product quality is guaranteed.

Owner:赵文明

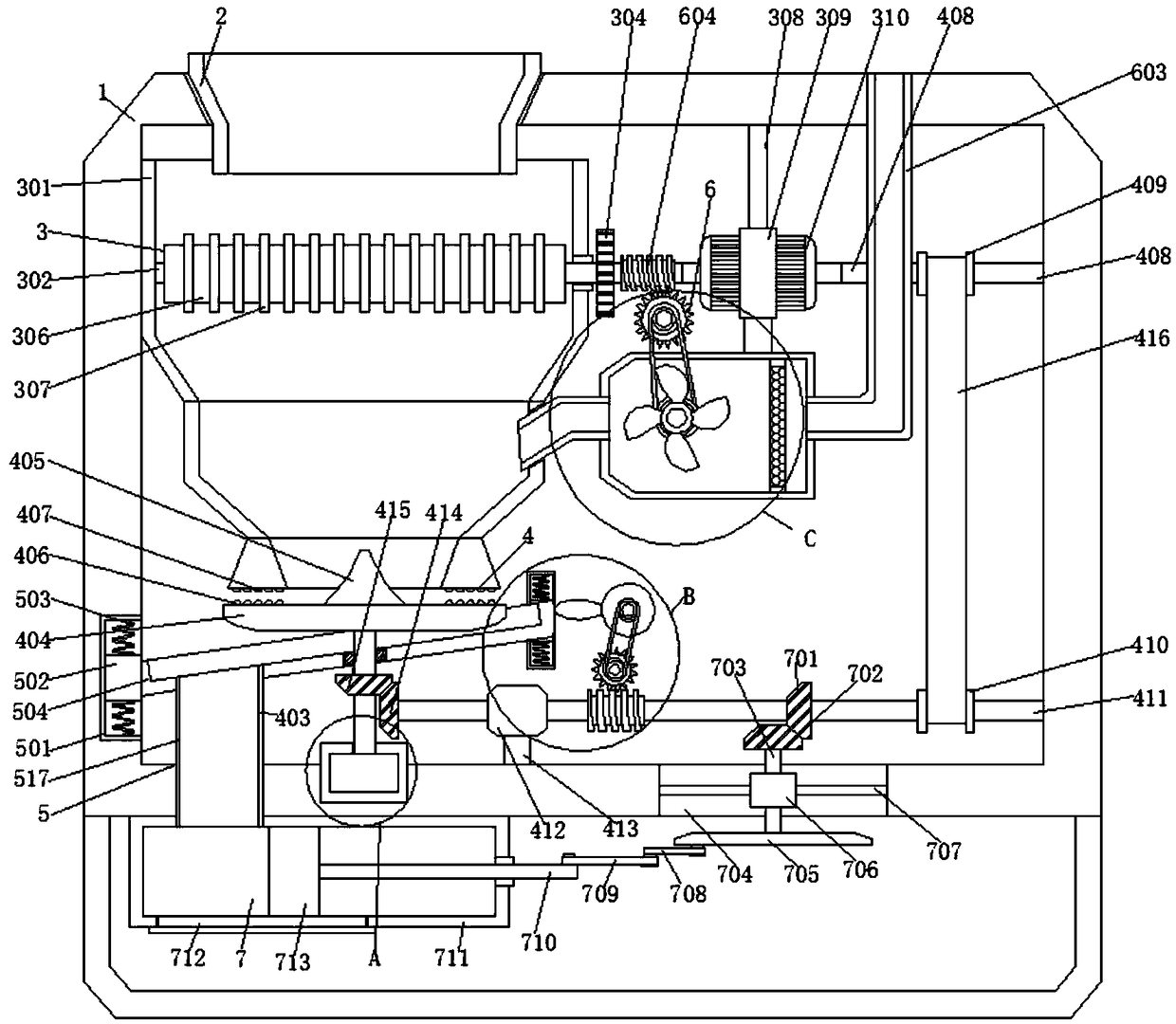

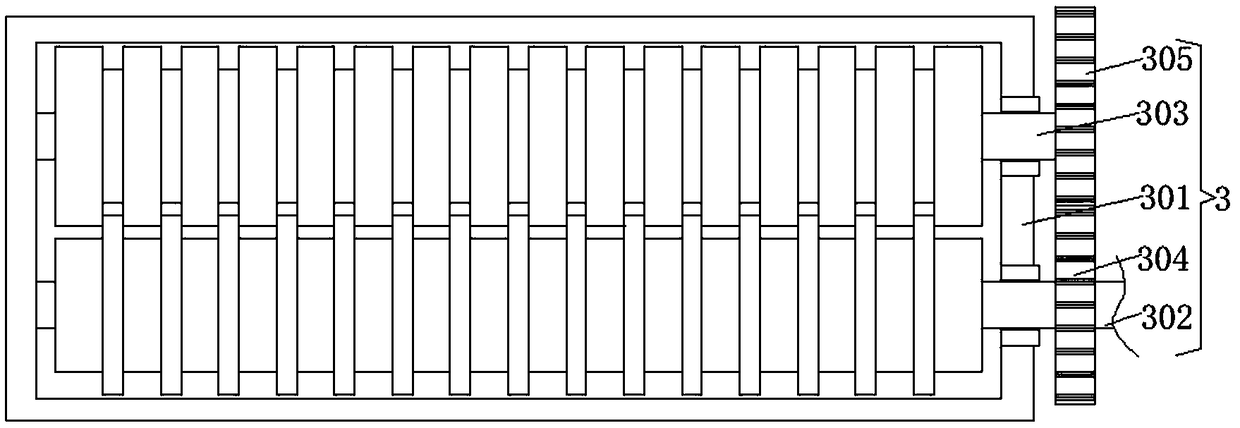

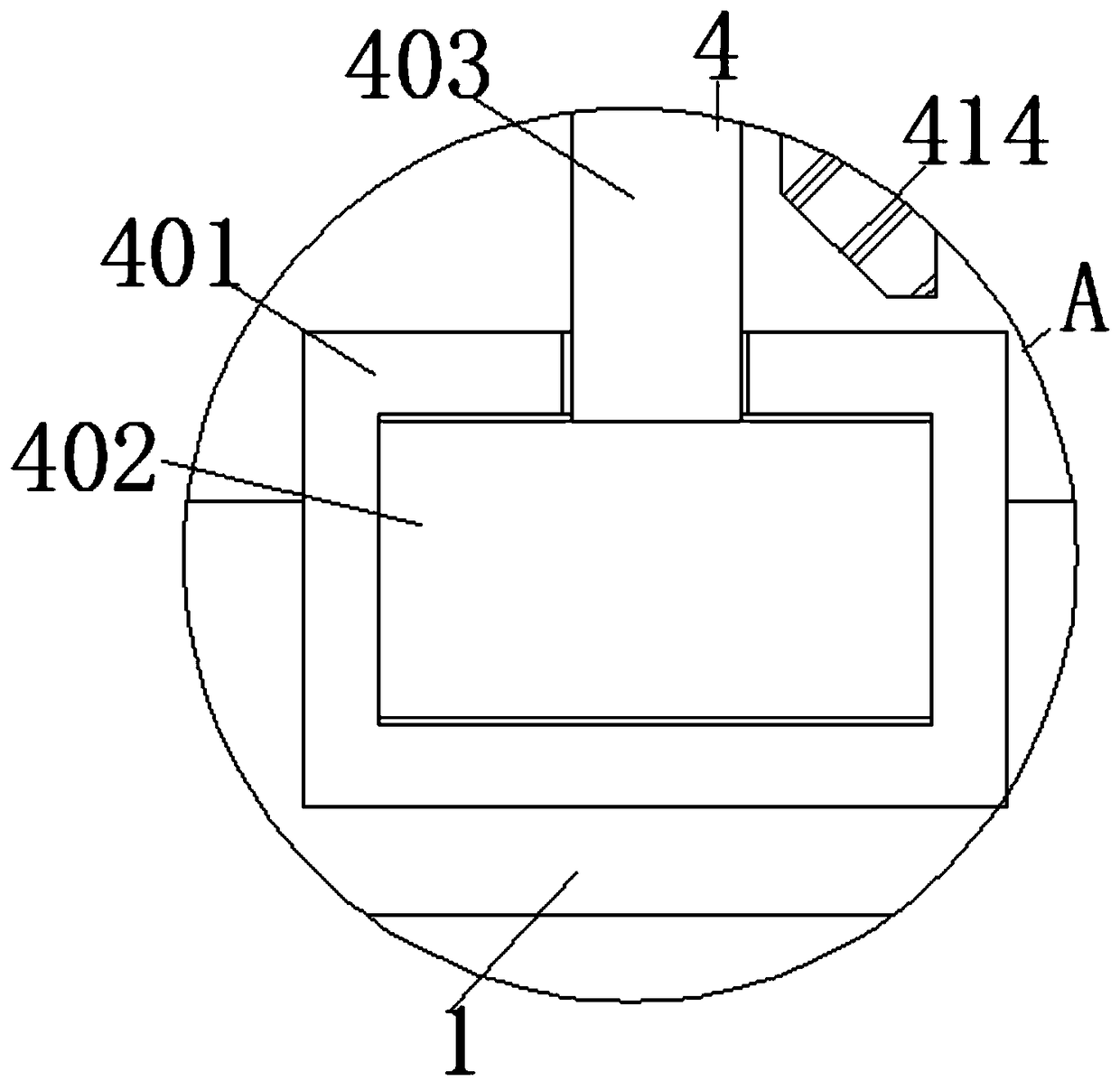

Processing mechanism for preliminary secondary machining of waste PVC (polyvinyl chloride) plastic water pipes

The invention relates to the technical field of environmental protection equipment, in particular to a processing mechanism for preliminary secondary machining of waste PVC (polyvinyl chloride) plastic water pipes. A technical problem to be solved by the invention is that PVC plastic is not convenient for discharging, briquetting and packing. In order to solve the technical problem, the inventionprovides a processing mechanism for preliminary secondary machining of waste PVC plastic water pipes, which comprises a box, wherein a feeding pipe is plugged inside the opening of the top of the box,a preliminary strip cutting mechanism is fixedly connected to one side of the inside wall of the box, a granulating mechanism is arranged on the bottom of the inside wall of the box, the output end of the granulating mechanism is in driving connection with the output end of the preliminary strip cutting mechanism, and a material spreading mechanism is in bell and spigot joint with the granulatingmechanism. In case of rotation, a lower granulating bulge on the granulating mechanism disclosed by the invention rotates, with use of an upper granulating bulge, segmented plastic strips can be granulated, and a dispersion cone block arranged on the top of a rotary table can facilitate diffusion of falling plastic strips to four sides, so as to facilitate discharging and enable the plastic to enter granulating step smoothly.

Owner:博兴兴业智能新材料有限公司

Multi-effect power module for electric vehicle

InactiveCN101830181AReduce weightFlame retardantSecondary cells servicing/maintenanceVehicular energy storageHeat conductingMetallic materials

The invention relates to a multi-effect power module for an electric vehicle, comprising a power module, a heat-insulation flame-retardant module and a shell anti-collision module, wherein the power module as a power source provides stable voltage and power for the electric vehicle; the heat-insulation flame-retardant module consists of a functional foaming body with an integral sealing profiling structure, and the functional foaming body is made of foam material and has the effects of water and moisture prevention, heat preservation and insulation, flame retardance, fire resistance, shock and collision avoidance and electromagnetic radiation prevention; and the shell anti-collision module consists of metal or nonmetal materials which have mechanical strength and heat conductivity. The invention ensures that the components have optimal environment-friendly ecological conditions by using environment-friendly nontoxic materials and components and partial materials can be recycled; and besides, functional parts, such as a heat conducting system and the like, can be conveniently added on the structure because the functional foaming body has the characteristic of convenient secondary processing.

Owner:李光明 +1

Method for recycling coal ashes in power plant

InactiveCN102530966AHigh in ironConvenient secondary processingSilicaSolid waste disposalMagnetiteCarbon dust

The invention discloses a method for recycling coal ashes in a power plant, wherein the coal ashes in the power plant are crushed, ball-milled and sieved by a 24-mesh sieve; the method is characterized in that carbon dust is separated by floatation, reducing agent is added into a floated raw material, particles containing iron are reduced into magnetite particles, and an iron-containing product is obtained by magnetic separation. According to the method for recycling the coal ashes in the power plant, the carbon dust is firstly separated by floatation, then the coal ashes are reduced to reduce iron oxide into magnetite, the magnetite is then separated by magnetic separation, the iron oxide is effectively separated, and the product obtained by separation can be sold as an iron-making raw material. Excess materials subjected to magnetic separation are then finely grinded again, so that silica, calcium oxide and aluminum oxide are then separated by floatation. The silica and the calcium oxide can be used as building materials, and the aluminum oxide can be sold to an electrolytic aluminium factory. According to the method for recycling the coal ashes in the power plant, after main constituents of the coal ashes are separated, various materials can be conveniently processed for a second time, so that the value of the product is greatly improved.

Owner:贵州绿水青山环保科技有限公司

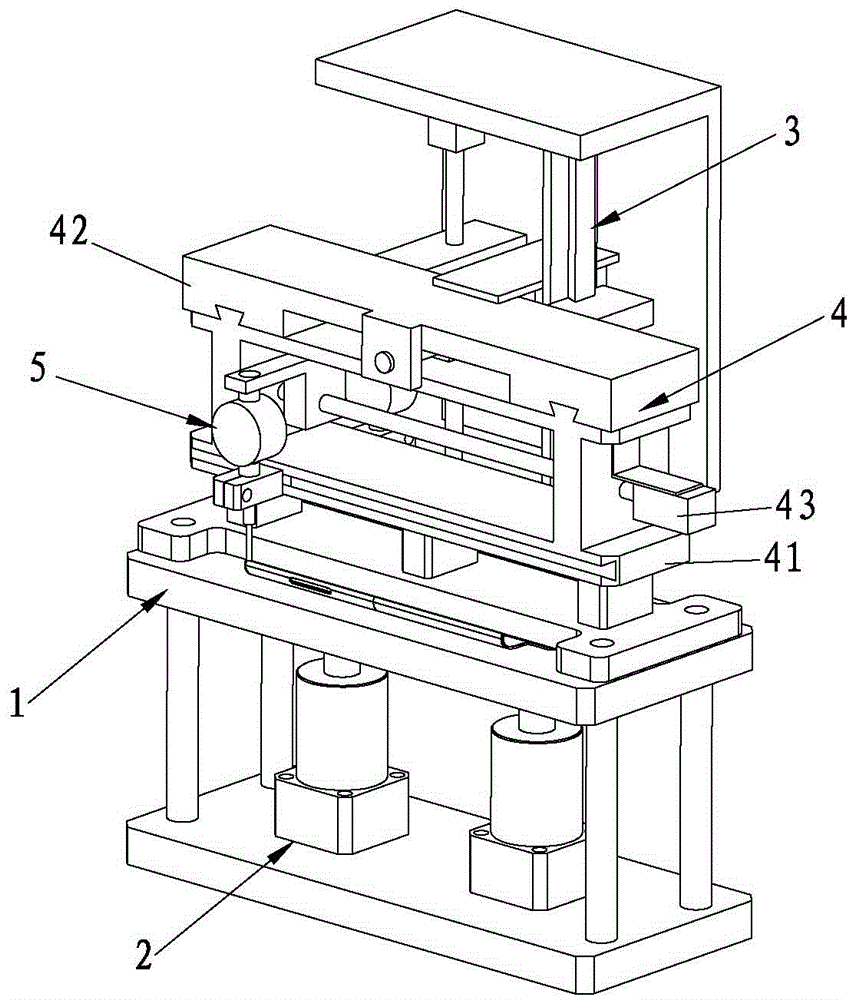

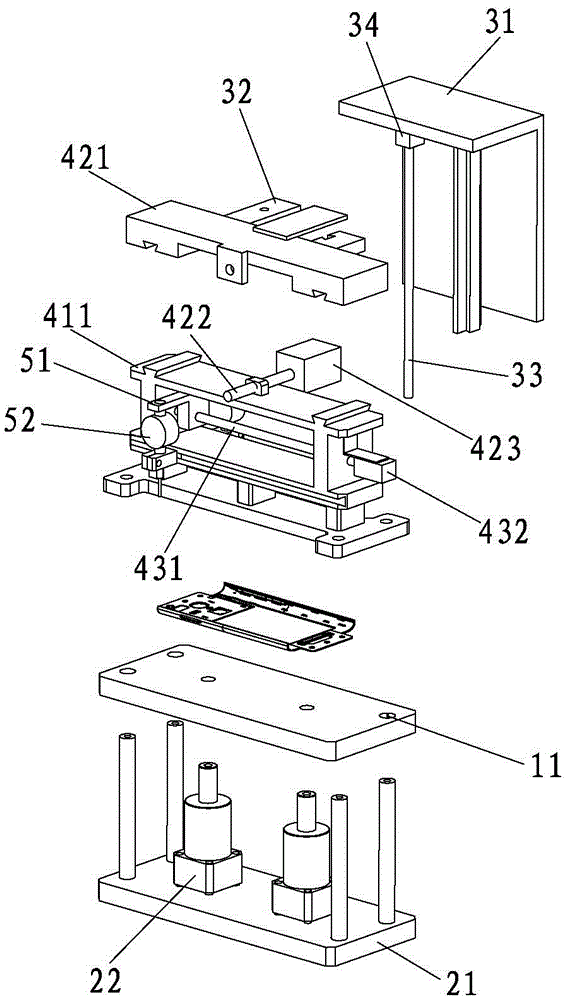

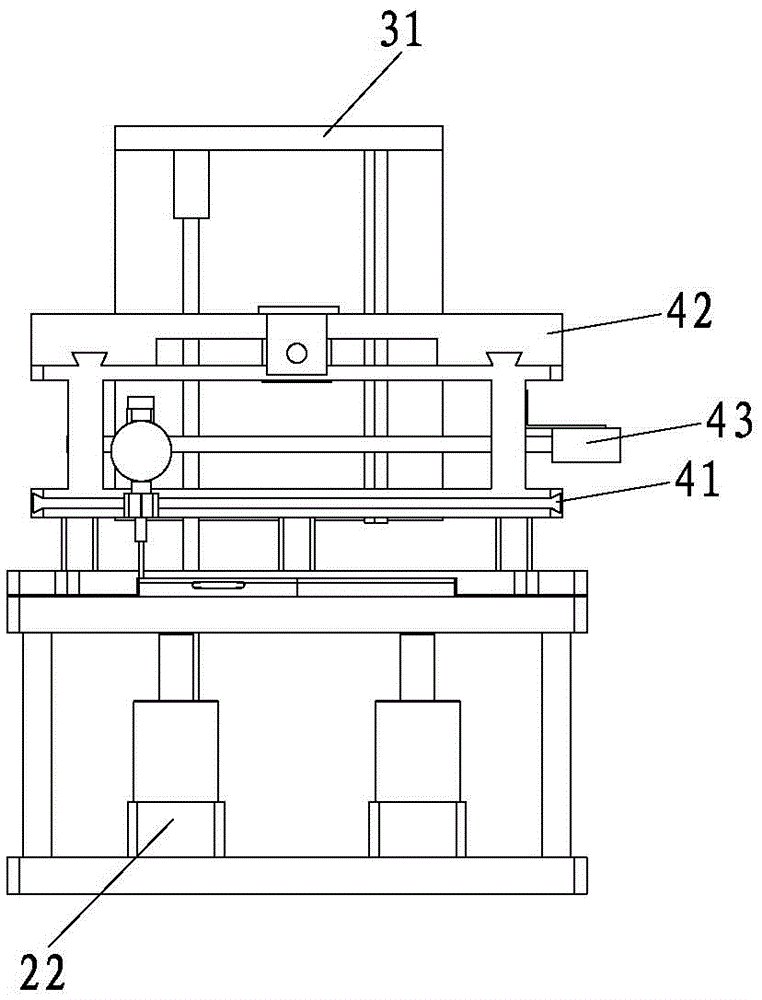

Automatic flatness detection device and test method

InactiveCN105526858ADetection speedSimple structureElectric/magnetic roughness/irregularity measurementsUsing optical meansTesting equipmentAutomation

The invention relates to the detection device technology field and discloses an automatic flatness detection device. The automatic flatness detection comprises a fixed table for installing a test member and an elevation mechanism for driving the fixed to move up and down; a vertical micro-adjustment device is connected to the part above the fixed table and a horizontal displacement device is connected to the vertical micro-adjustment device; and the horizontal device is connected to at least one plane detection device. The detection device is fast in detection speed, simple in structure and high in automation degree. Besides the invention also provides test method of a flatness detection device. The detection method performs segmentation on the detection plane, performs marking so as to accurately identify a corresponding recording segment of the preset tolerance value and provides secondary processing on the test member.

Owner:DONGGUAN SIXIANG PRECISION METAL CO LTD

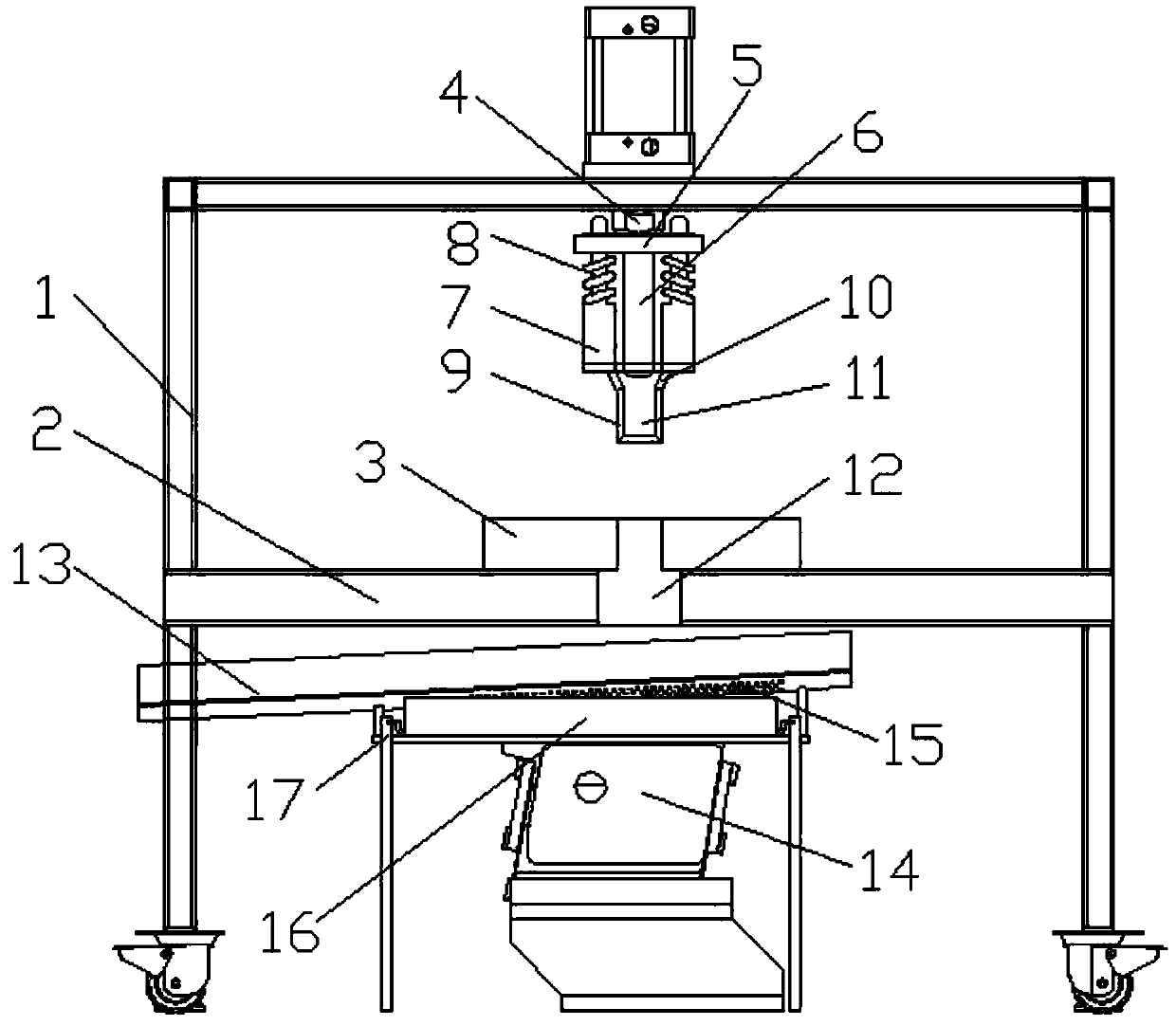

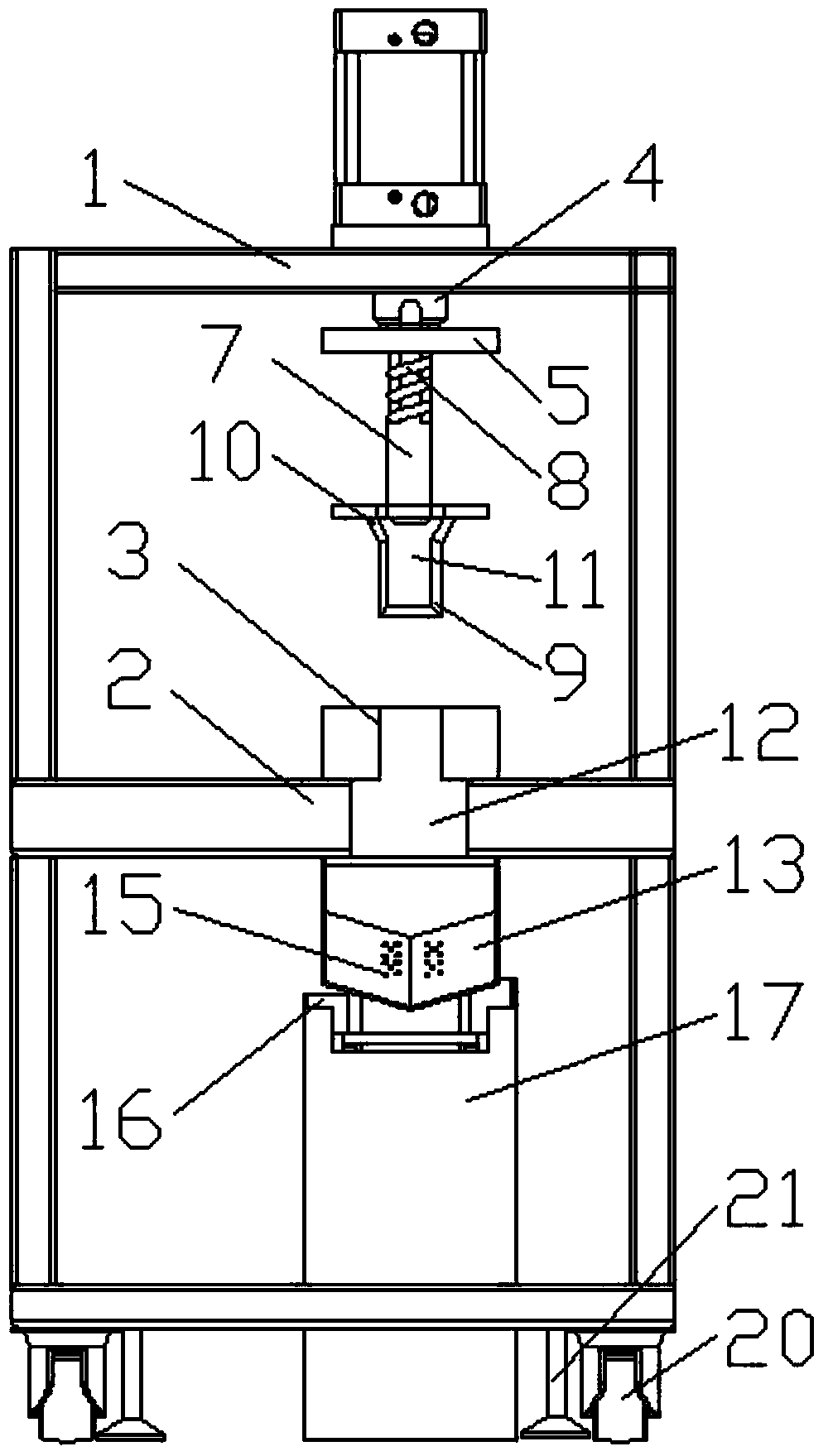

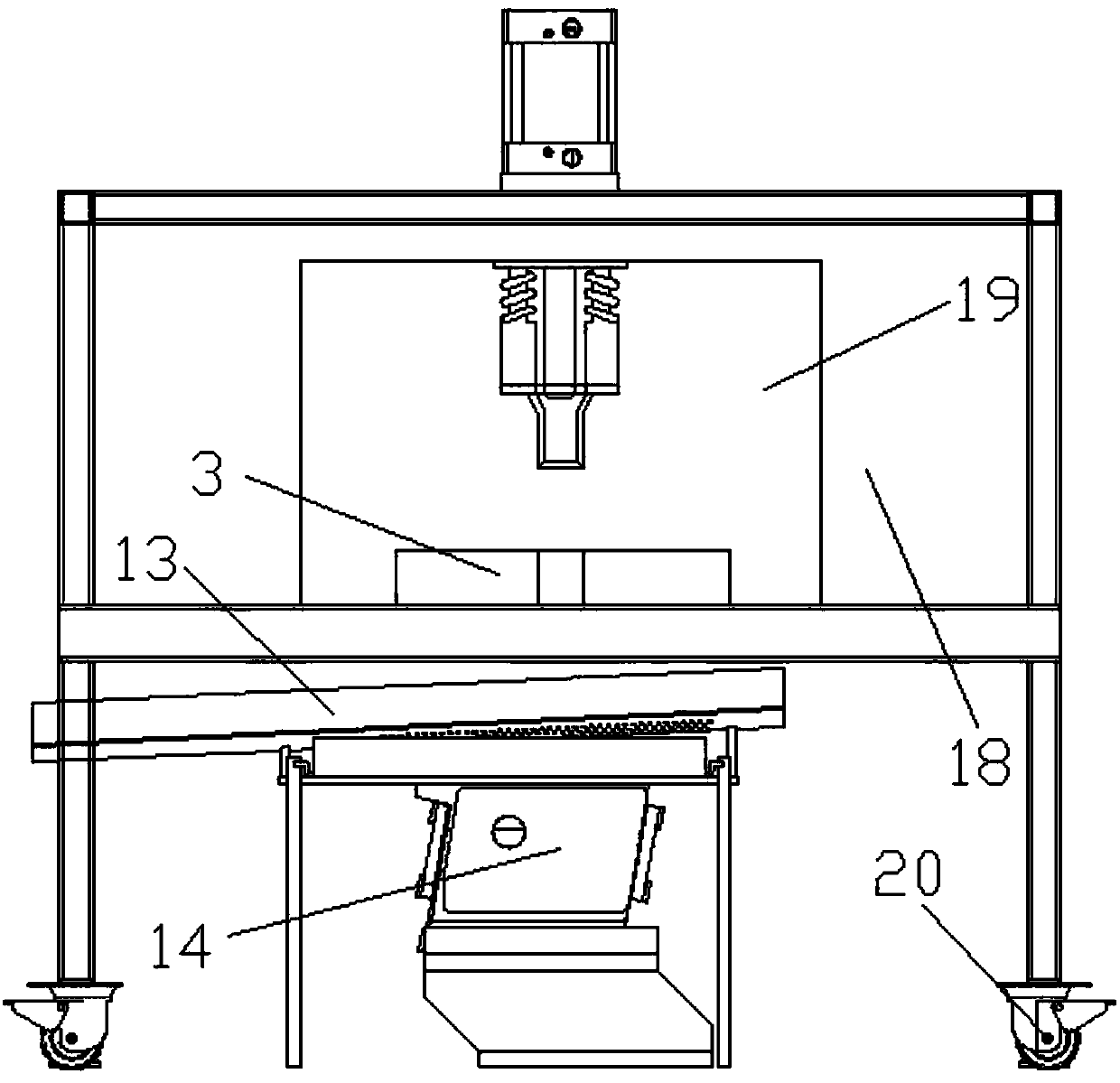

Novel punching machine

InactiveCN107838266AEffective protectionPlay a cleaning effectMetal-working feeding devicesShaping safety devicesPunchingPulp and paper industry

The invention discloses a novel punching machine. The novel punching machine comprises a frame, below which a working platform is arranged. A punching rod is arranged at the upper part of the frame. The end part, opposite to the working platform, of the punching rod is equipped with a punching board. A fixing rod is connected at the bottom of the punching board. Two sides of the fixing rod are provided with guide arms. Outsides of the guide arms are equipped with damping springs. Lower ends of the guide arms are connected with a punching tool. The interior of the punching tool is equipped witha cavity. A machining through hole is arranged in a position, corresponding to the punching tool, of the working platform. A waste material classifying device is arranged in the frame below the machining through hole and comprises a material separating groove and a vibrator located below the material separating groove. The bottom plane of the material separating groove is equipped with a materialfalling hole, below which a collection box is arranged. The damping springs can help effectively buffer impact of the punching tool to a machine body so that the machine body is protected. Meanwhile,waste material remaining in the cavity is pushed out of the cavity by the fixing rod so that waste material is completely cleaned. Cooperation between the vibrator and the material separating groovehelps separate chunks of waste material from metal chippings. Therefore, secondary machining is convenient.

Owner:苏州特精模具有限公司

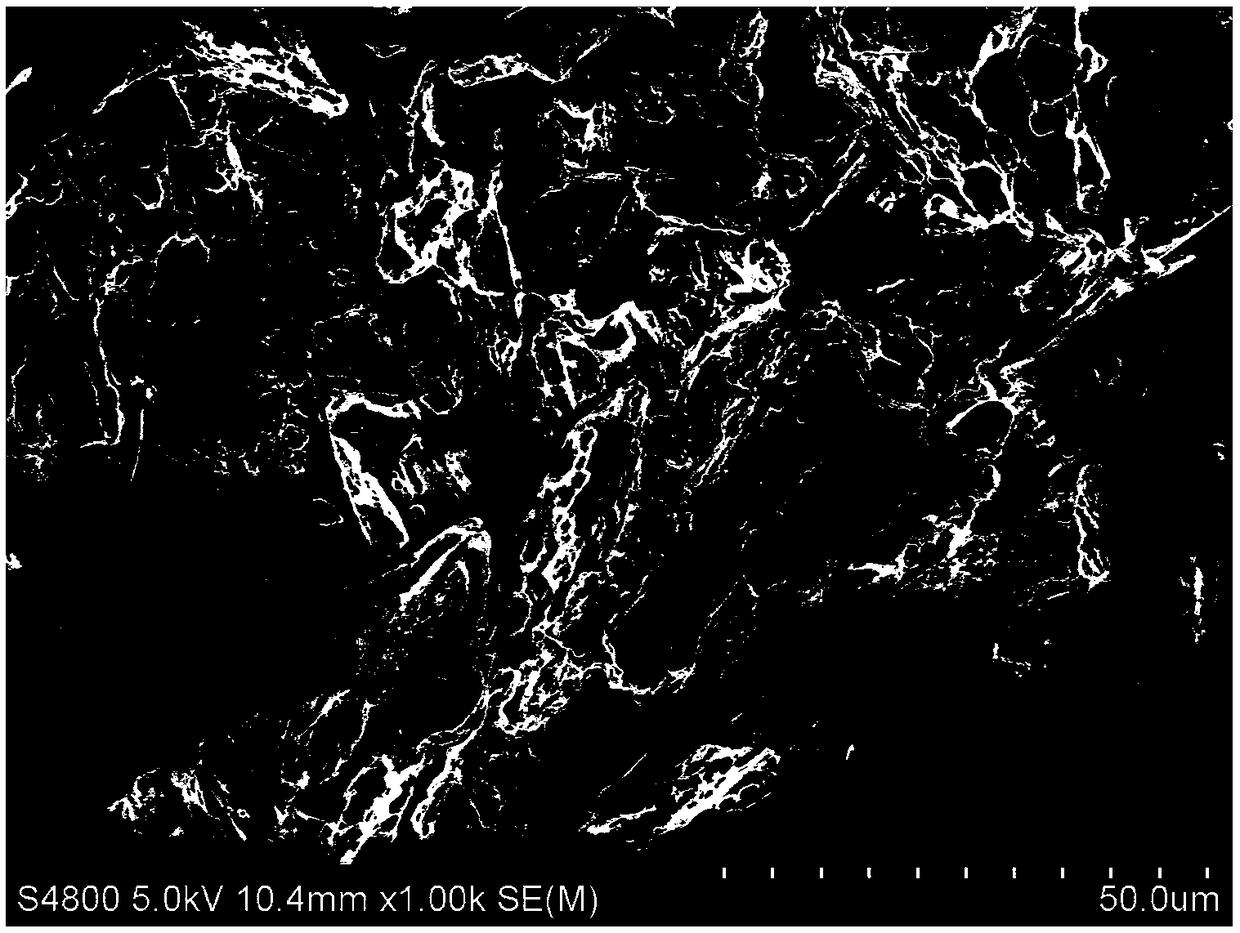

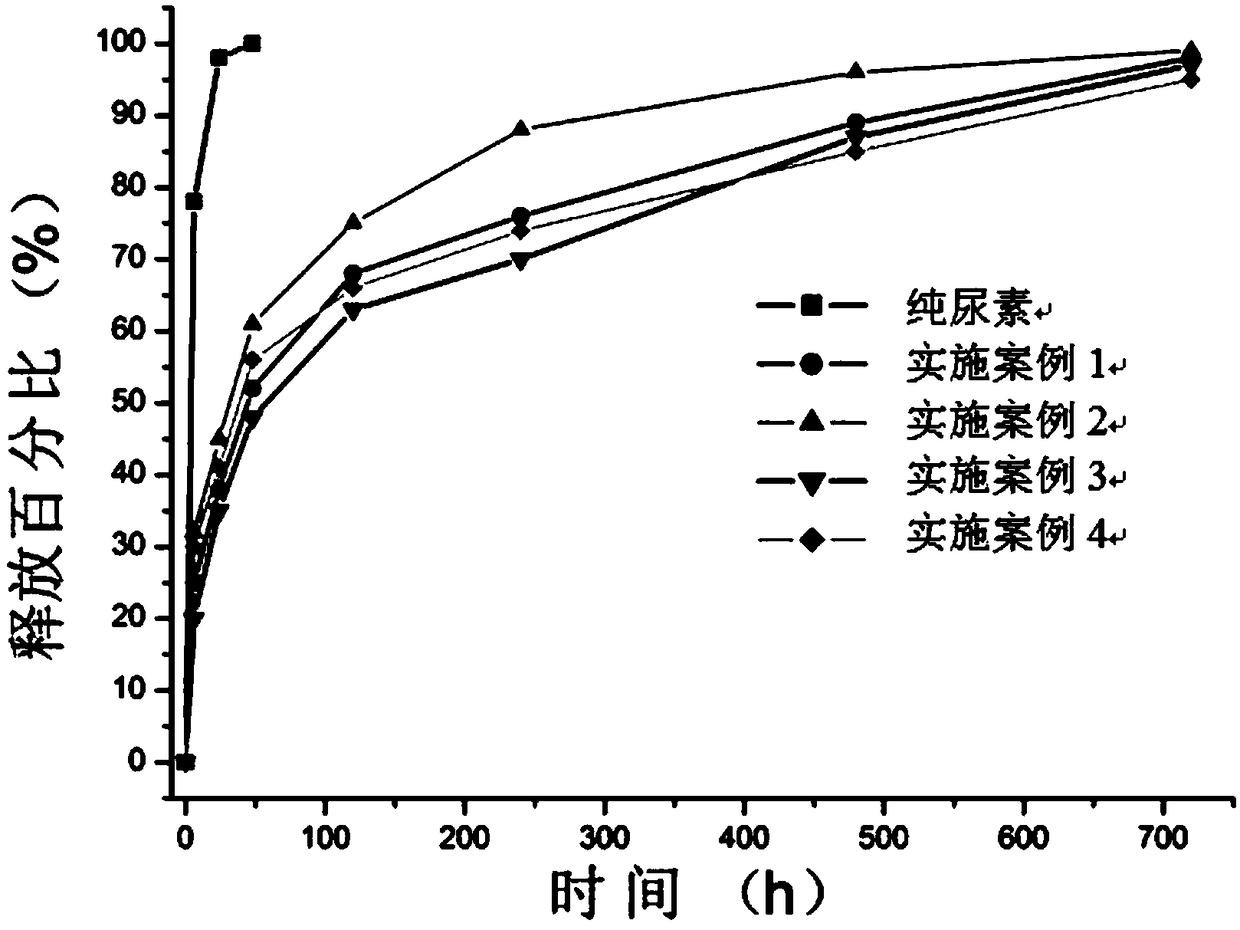

Biocharcoal-based slow release fertilizer and preparation method thereof

ActiveCN108314591AHigh specific surface areaHigh porosityUrea compound fertilisersFertilizer mixturesWear resistantIon exchange

The invention discloses biocharcoal-based slow release fertilizer. The biocharcoal-based slow release fertilizer is prepared from biocharcoal and chemical fertilizer with the mass ratio being 20:(5 to10). The biocharcoal-based slow release fertilizer disclosed by the invention has the beneficial effects that agricultural and forest wastes such as straws with wide distribution, large yield and lowcost are adopted as biomass, has rich pore channels, is easily decomposed, is not deteriorated after being absorbed, is wear-resistant, and also has excellent adsorbing and ion-exchange properties, the fertility, the structure and microorganisms and the like of soil can be effectively improved, and the soil quality can be improved; shown from the cumulative released amount of nitrogen of the biocharcoal-based slow release fertilizer in water, the cumulative released amount of the nitrogen in 480 hours is about 80%, i.e., the cumulative released amount of nitrogen nutrients in 20 days is 80%.The invention also discloses a preparation method of the biocharcoal-based slow release fertilizer. The preparation method adopts a hydrothermal method to prepare the biocharcoal-based slow release fertilizer, the technology is manure, the operation is convenient, simple and easy, low cost, less investment and low energy consumption are achieved, and an economic and feasible technical means is provided for large-scale application of the biocharcoal-based slow release fertilizer.

Owner:HUNAN AGRICULTURAL UNIV +1

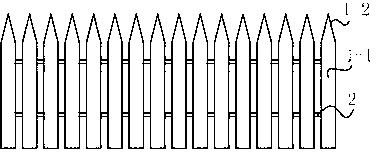

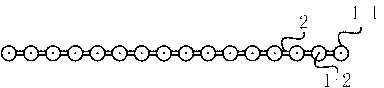

Preparation method of high-molecular composite material strip nail

InactiveCN103254615AHigh strengthReduce weightStaplesNailsInjection molding machineInjection moulding

The invention relates to a preparation method of high-molecular composite material strip nail. Strength and toughness of plastic nails prepared by present methods are not high enough. The method provided by the invention comprises the following steps: firstly uniformly mixing nylon resin, glass fibre, a toughening modifier, a filler, a coupling agent, an anti-oxidant and a lubricant in proportion, and carrying out melt extrusion for pelleting; drying pellets, and forming by injection moulding in an injection machine to form a strip nail structure which comprises a plurality of individual nail bodies which are arranged in parallel, wherein two adjacent individual nail bodies are connected with each other through a connecting rod and a sidewall of each nail body part is provided with an elongated groove; and dipping and drying the injection-moulded material by the use of a silicone oil acetone solution, so as to obtain the high-molecular composite material strip nail. The high-molecular composite material strip nail prepared by the method has characteristics of high strength, light weight, rust resistance, corrosion resistance, antistatic performance, colorable performance and stable performance, and is convenient for secondary processing.

Owner:HANGZHOU HAIXUE TECH

Method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive

ActiveCN105563571AStress reliefUniform thicknessLaminationLamination apparatusAfter treatmentAdhesive

The invention discloses a method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive, belongs to the technical field of wood processing, and solves such problems as large back surface cracks, moreburrs, high thickness deviation and easiness in deformation and bending. The production method comprises wood block pretreatment, rotary cutting, drying, plasma treatment, veneer surface scratch treatment, gluing, prepressing, hot pressing and after-treatment. The method is suitable for producing the aldehyde-free thick-core plywood, largely reduces the production cost, and improves the production efficiency.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

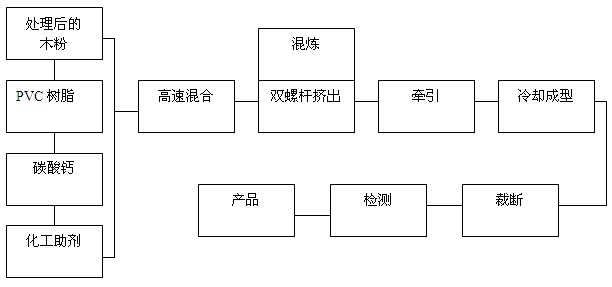

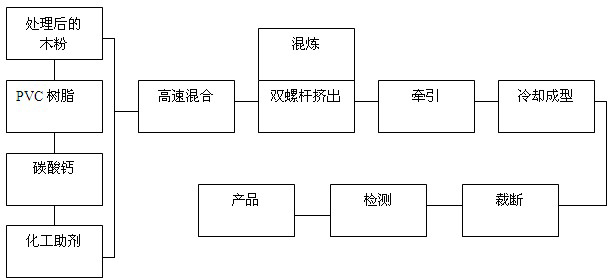

Wood and calcium plastic mixed and co-extruded material

The invention relates to a wood and calcium plastic mixed and co-extruded material. The material is prepared by mixing and co-extruding the following raw materials by weight: 25kg of polyvinyl chloride (PVC) resin, 45 to 50kg of wood powder or rice bran powder of 50 to 80 meshes, 35 to 40kg of calcium powder of more than 800 meshes, 2.5kg of maleic anhydride graft polymer, 1.8kg of polypropylene / polyethylene (PP / PE) wood plastic extruded lubricating, dispersing and coupling agent, 0.1kg of phenyl salicylate, 0.1kg of tertiary butyl hydroquinone, 3 to 3.5kg of hot compounding lead salt stabilizer, 2 to 3kg of PVC processing aid ACR 401, 2kg of dibutyl phthalate, 0.8kg of paraffin, 0.5kg of polyethylene wax and 0.3kg of stearic acid 1801. The wood and calcium plastic mixed product has the advantages of water resistance, fire resistance, flame retardance, insect resistance, health, environment friendliness and the like, the cost of the product is reduced by 1 / 3 compared with that of a pure wood plastic product, and the performance and application range of the product are far superior to those of the pure wood plastic product and a pure calcium plastic product.

Owner:林仕华

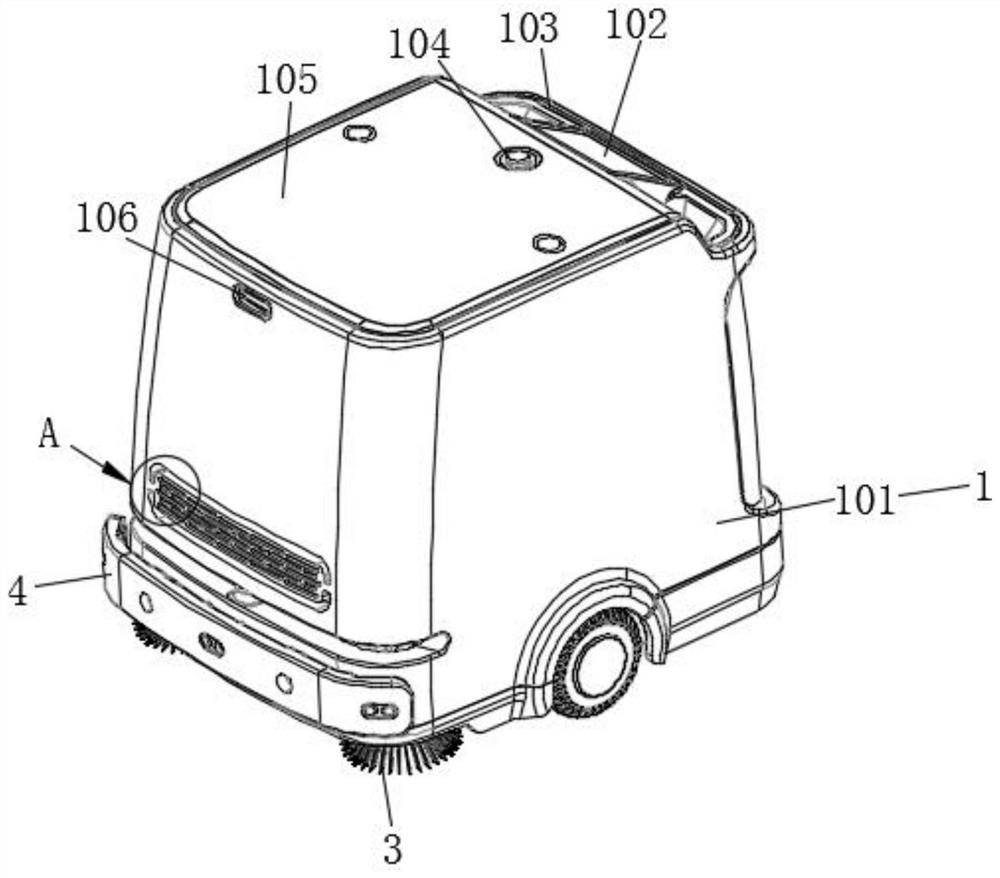

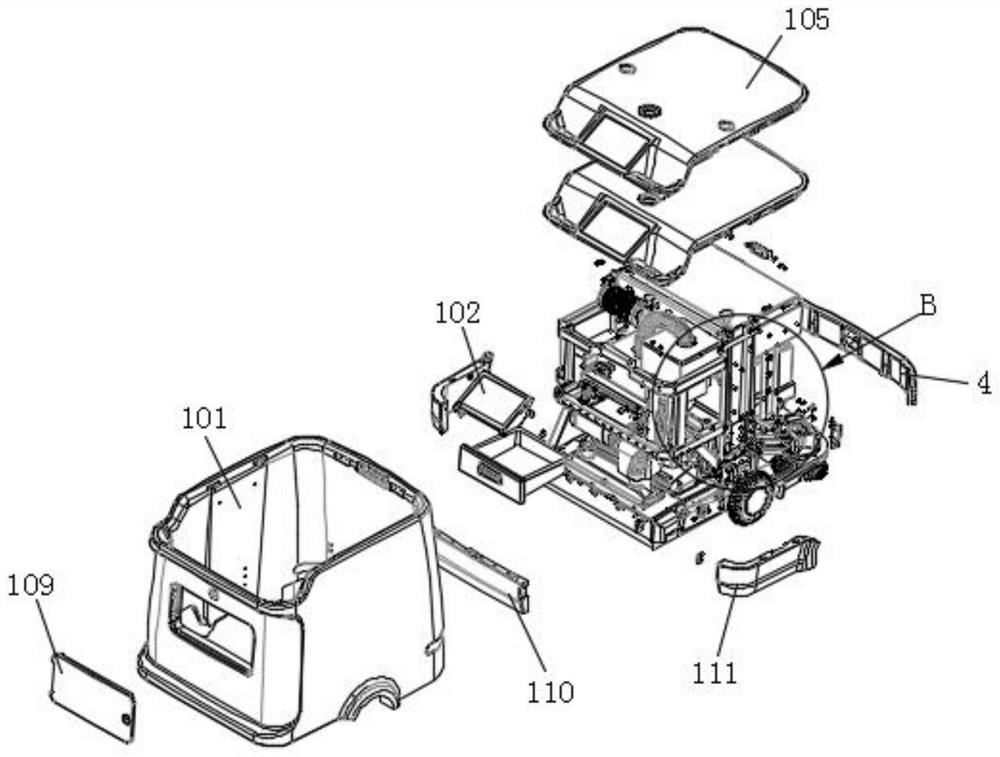

Sweeping robot

The invention discloses a sweeping robot which comprises a main brush assembly, a rack assembly and a side brush assembly. The side brush assembly and the main brush assembly are connected to the front end and the rear end of the rack assembly respectively. The main brush assembly comprises a main brush lifting assembly and a main brush roller. The main brush lifting assembly comprises a main brush steel wire rope and a main brush air cylinder. The main brush roller is connected to the output end of the main brush air cylinder through a flexible main brush steel wire rope. The side brush assembly comprises a side brush lifting structure and a side brush connecting piece. The side brush lifting structure comprises a side brush steel wire rope and a side brush cylinder; one end of the side brush connecting piece is rotationally connected to the rack assembly. The other end of the side brush connecting piece is connected to the output end of the side brush air cylinder through the flexible side brush steel wire rope. According to the invention, when the main brush assembly and the side brush assembly sweep bumpy ground, the robot is lifted, and the main brush steel wire rope becomes loose, so that damage to parts is reduced.

Owner:合肥哈工澳汀智能科技有限公司

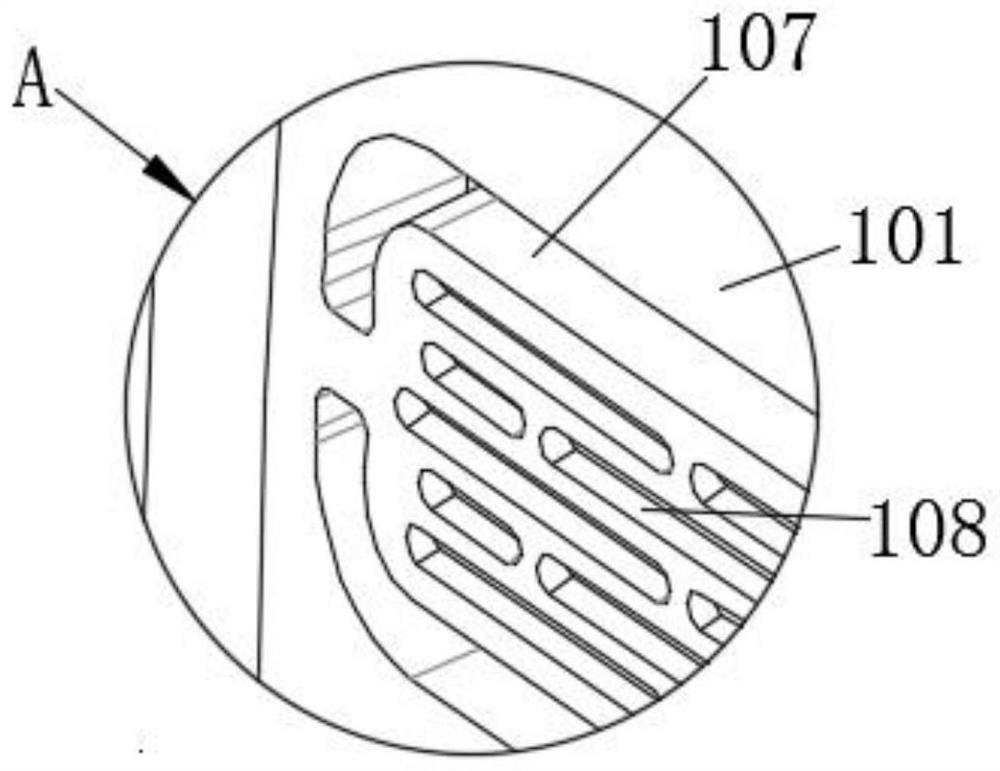

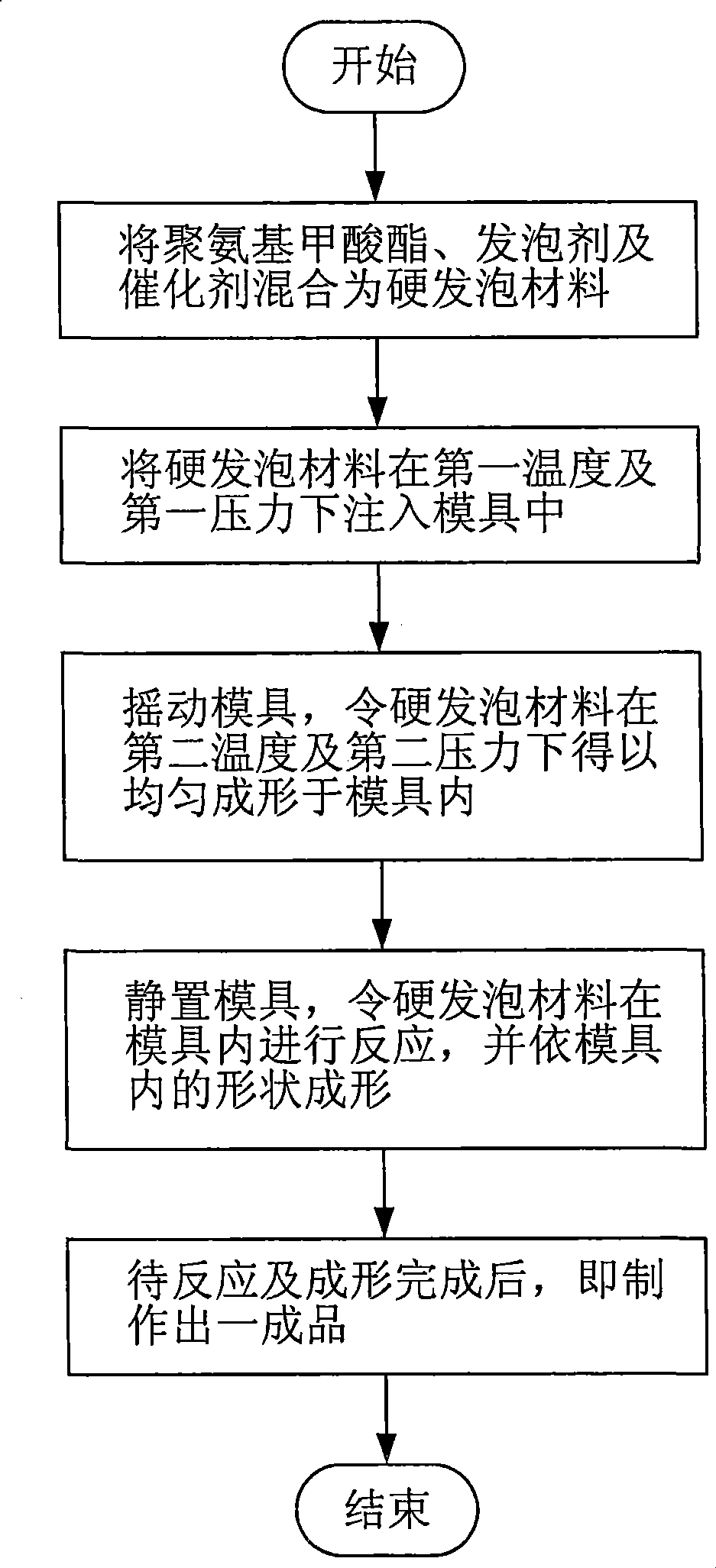

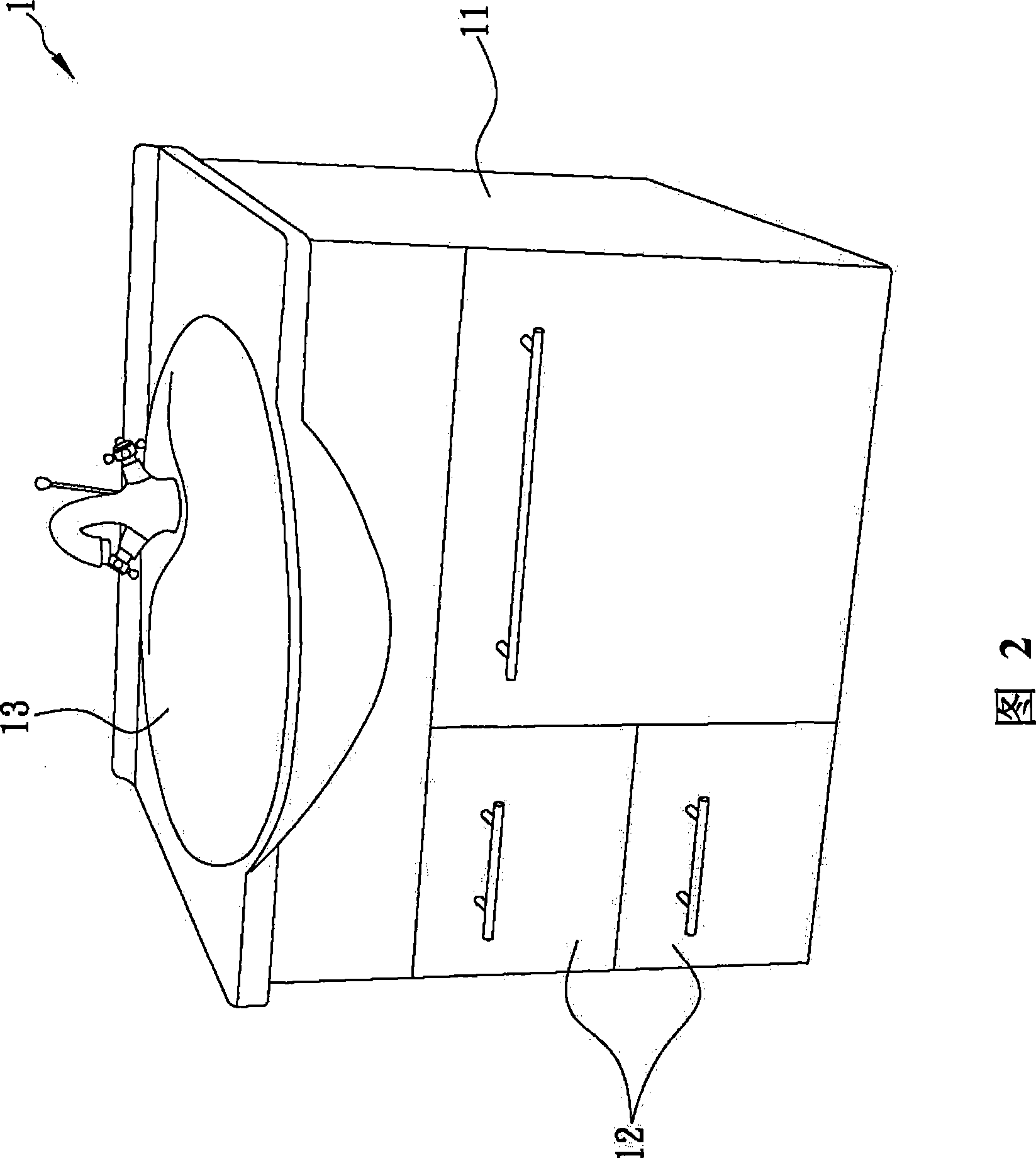

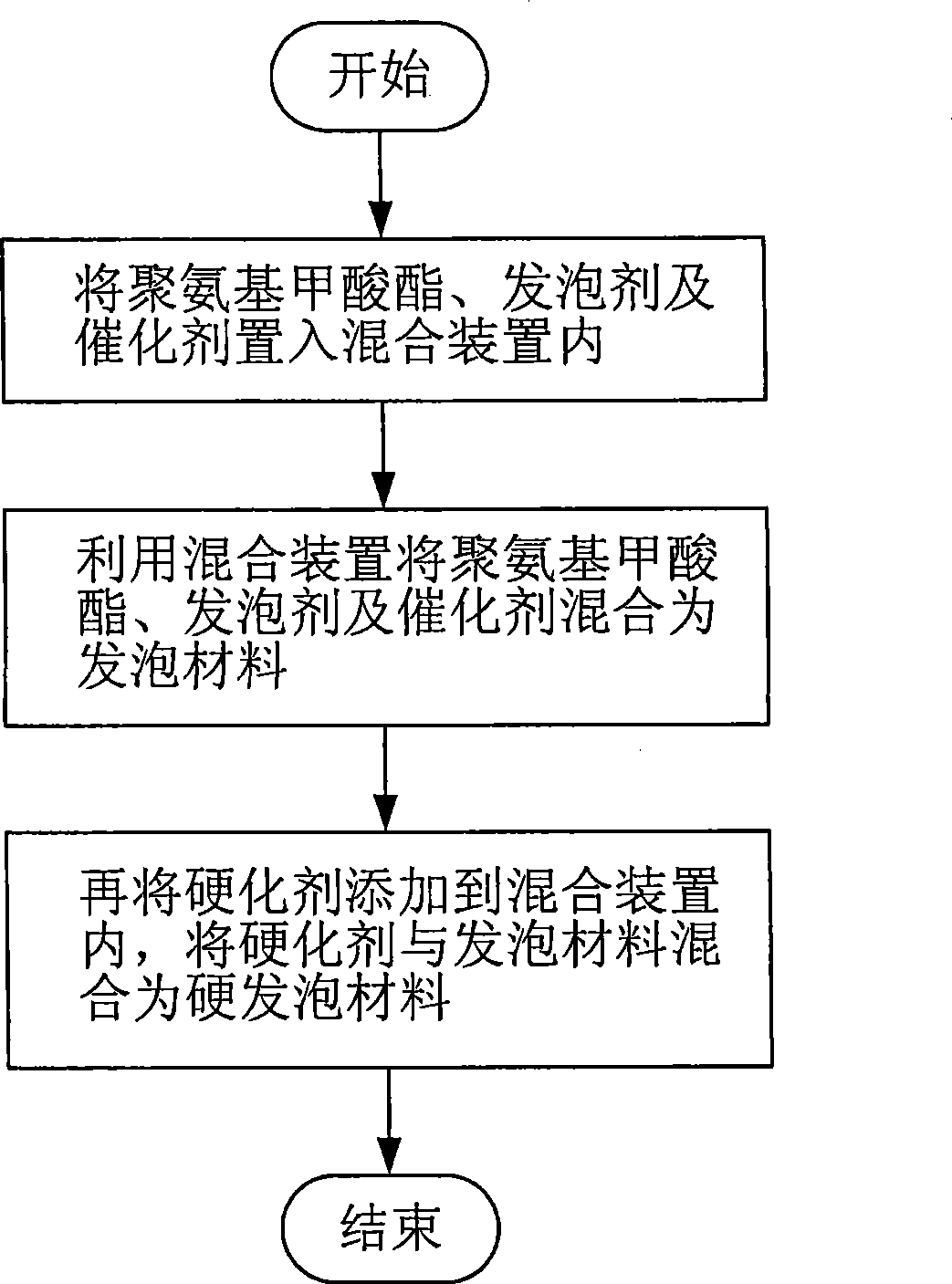

Method of preparing thermoplastic hard foam

The invention relates to a method for manufacturing a thermoplastic hard foaming body. The method comprises the following steps: mixing polyurethane, a foaming agent and a catalyst by a mixing device to produce a hard foaming material; injecting the hard foaming material in a mould; shaking the mould to make the hard foaming material evenly shaped in the mould; keeping the mould on standing to cause the hard foaming material to react in the mould and be shaped according to the shape in the mould; and producing a finished product without a joint close after reacting and shaping. The manufacture method not only has the characteristics of simple formulation and easy coloration and the like, but also can easily control fire resistance, humidity resistance, hardness and corrosion resistance of the manufactured finished product without joint seam.

Owner:许育乾

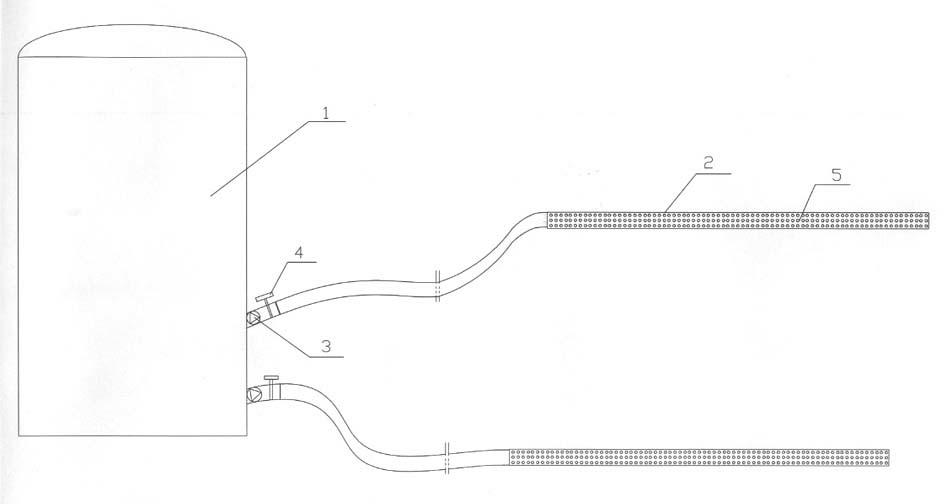

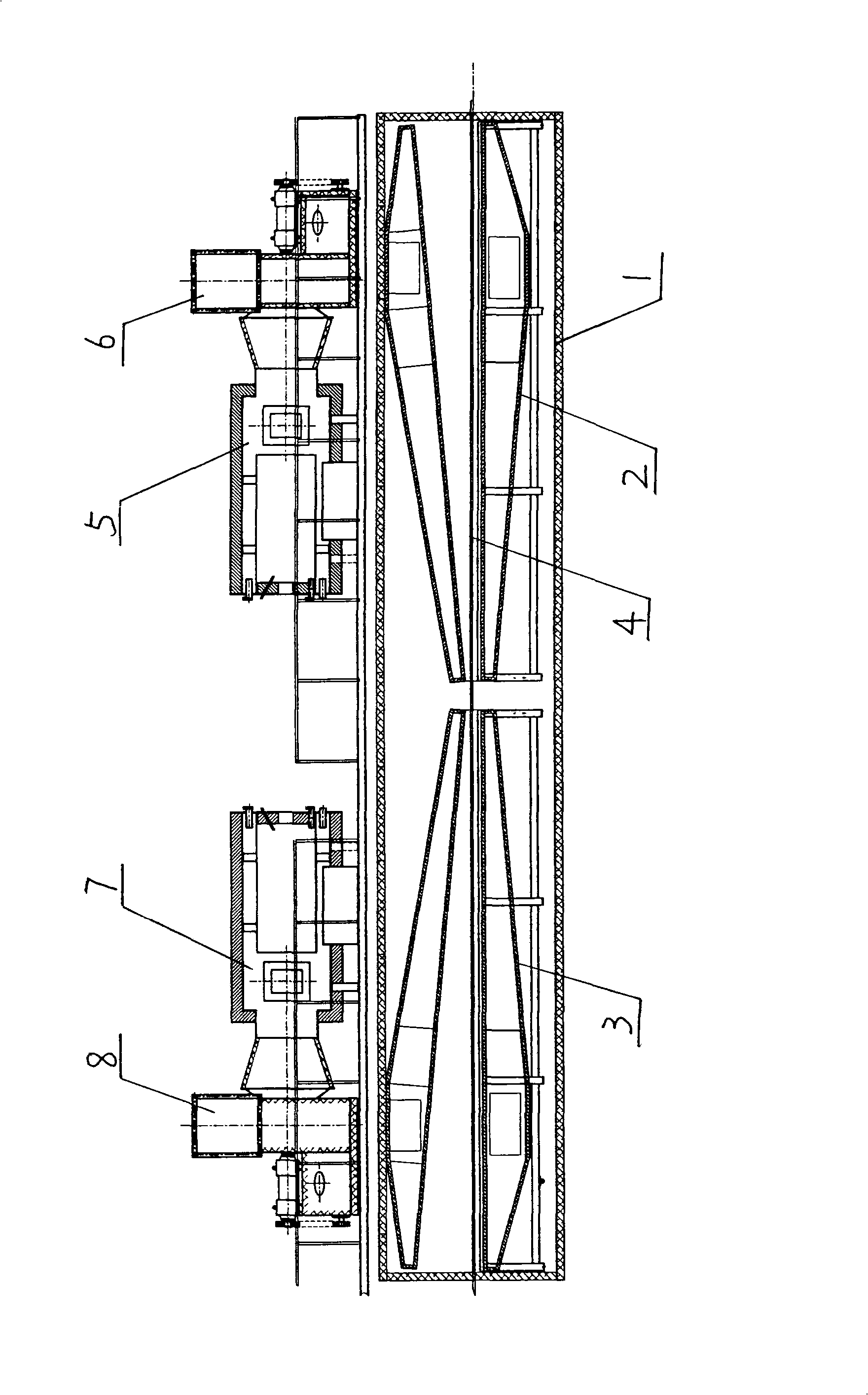

Crosslinked foaming heating stove

The invention belongs to the technical field of PE chemical cross-linking foaming, in particular relate to a cross-linking foaming furnace, which is characterized in that a cross-linking box body and a foaming box body are arranged in a heat-preservation box body and a stainless steel conveyor belt is arranged in the cross-linking box body and the foaming box body; a heating device is arranged on the heat-preservation box body and the heating device is separately communicated with the cross-linking box body and the foaming box body through pipelines. The cross-linking foaming furnace has the advantages of high foaming ratio, low density of the produced products, small thickness, smooth surface, high elasticity, good flexibility and easy secondary processing.

Owner:程志

Biodegradation composition, and preparation method and application thereof

ActiveCN102070795AThermoplasticMolecular weight controllableConjugated synthetic polymer artificial filamentsBlow moldingPolymer science

The invention discloses a biodegradation composition, and a preparation method and application thereof. The biodegradation composition consists of a biodegradation resin, dextrin and a plasticizer, wherein the mass ratio of the biodegradation resin to the dextrin is 1:9 to 9:1; the content of the plasticizer is 1 to 30 percent based on the total weight of the biodegradation composition; and the dextrin is prepared from the mixture of dried natural starch and acid solution in melting and mixing equipment. The biodegradation composition is prepared from the mixture of the components in the smelting and mixing equipment. The biodegradation composition provided by the invention has relatively higher physical properties and processability, relatively higher water resistance and medium biodegradation speed, well satisfies the needs of practical application, and can be prepared into various products by universal processing methods such as blowing molding, extrusion molding, injection molding, spinning molding and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com