Crosslinked foaming heating stove

A heating furnace and Lianfa's technology, applied in the field of cross-linked foaming heating furnace, can solve the problems of poor heat insulation, formability, sound absorption and cushioning, and not suitable for high-end packaging needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

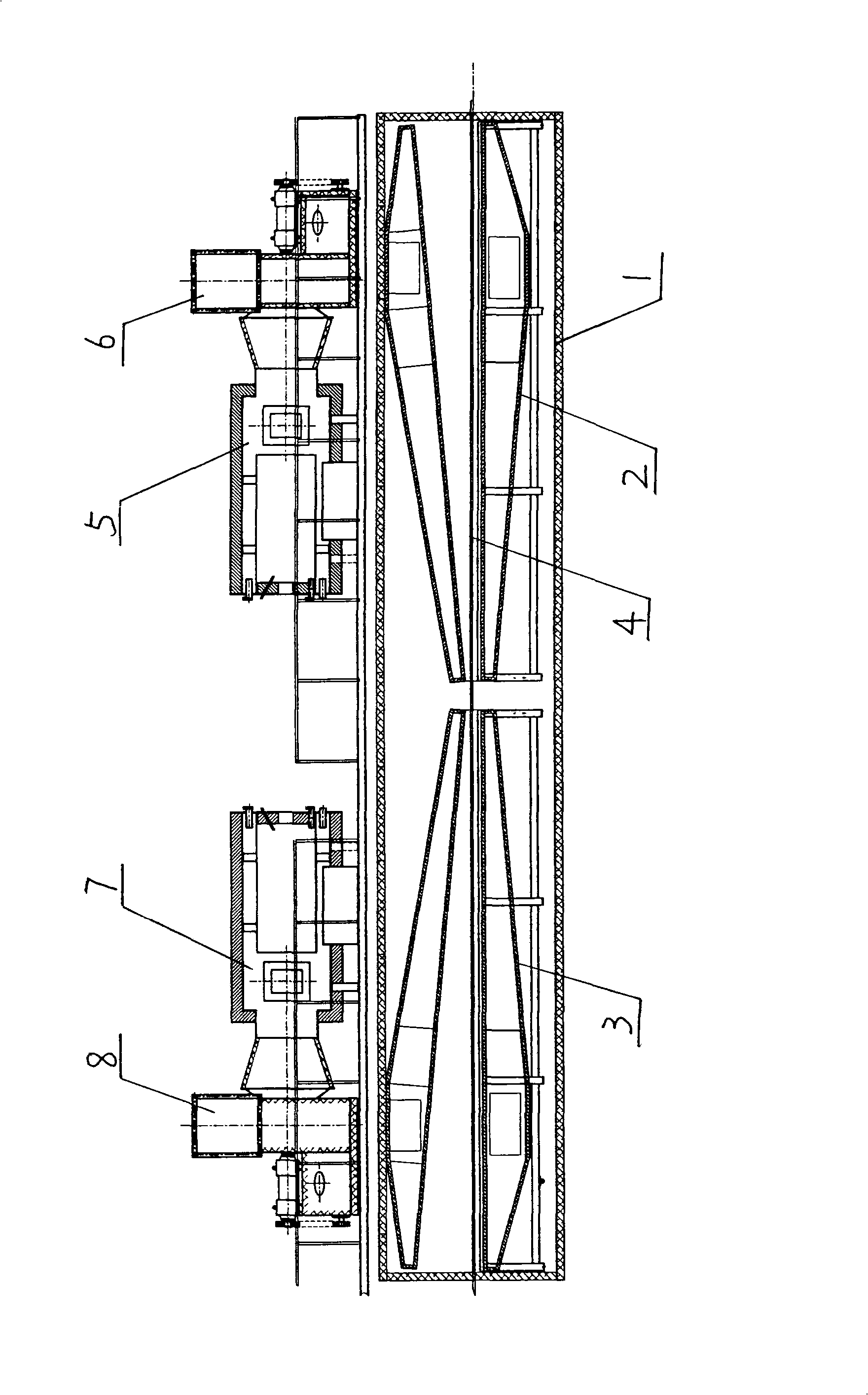

[0008] With reference to accompanying drawing, a kind of cross-linking and foaming heating furnace is provided with cross-linking box 2 and foaming box 3 in insulation box 1, and stainless steel conveyor belt 4 is set in cross-linking box 2 and foaming box 3; A heating device is provided on the heat preservation box 1, and the heating device communicates with the cross-linking box 2 and the foaming box 3 respectively through pipelines. The heating device is composed of two combustion chambers and two fans; the heat outlet of the combustion chamber 5 is closely connected with the air inlet of the fan 6, and the air outlet of the fan 6 is connected with the crosslinking box 2 through a pipeline; the other combustion chamber The heat outlet of the chamber 7 is closely connected with the air inlet of the fan 8, and the air outlet of the fan 8 is communicated with the foam box 3 through a pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com